Blogs

Understanding Film Materials: A Comprehensive Tutorial on Types and Applications

Introduction

In the rapidly advancing landscape of technology, thin-film materials have emerged as pivotal components across various industries, from electronics to aerospace. Their unique properties, such as optical transparency and electrical conductivity, enable innovative applications that drive efficiency and performance. As procurement managers navigate the complexities of sourcing these materials, understanding the fundamentals of thin films, their fabrication techniques, and their diverse applications is crucial.

This article delves into the essential aspects of thin-film technology, highlighting the challenges and innovations shaping the field, while also emphasizing the importance of sustainability in future material choices. By exploring these insights, procurement professionals can make informed decisions that align with both industry demands and environmental goals.

Fundamentals of Thin-Film Materials

Thin-film substances are defined by their thickness, which usually varies from a few nanometers to several micrometers. These materials exhibit unique physical and chemical properties due to their reduced dimensions, which can differ significantly from their bulk counterparts. Key properties include:

- Optical transparency

- Electrical conductivity

- Mechanical strength

Understanding these fundamentals is essential, as they dictate how thin films can be utilized in various applications, such as:

- Coatings

- Semiconductors

- Sensors

Among these materials, Indium stands out for its high conductivity and low melting point, making it particularly valuable in electronics and semiconductors, especially for soldiers and thermal interface materials. Moreover, as industries increasingly require dependable solutions for high-temperature resistance and insulation, mica tape products arise as essential components. These tapes provide outstanding thermal and insulation characteristics, rendering them essential in various applications across industries, including:

- Aerospace

- Automotive

Deposition Techniques for Thin-Film Fabrication

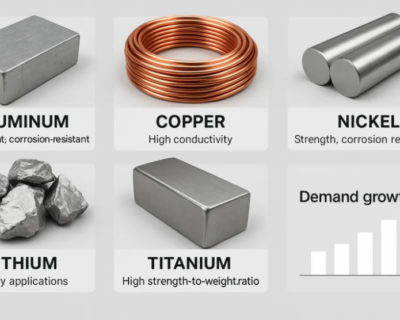

Aluminum Beryllium Alloy Ingots are utilized extensively in aerospace, defense, and telecommunications sectors, valued for their lightweight yet strong properties, thermal stability, and excellent electrical conductivity. Common deposition techniques for these substances include:

- Chemical Vapor Deposition (CVD)

- Physical Vapor Deposition (PVD)

- Atomic Layer Deposition (ALD)

CVD is preferred for producing high-purity films, while PVD is versatile for creating metallic films, including those made from Aluminum Beryllium Alloy Ingots, which are crucial for high-performance components. ALD provides precise control over film thickness and uniformity, making it appropriate for uses requiring exact specifications. Each technique has its unique benefits and drawbacks, affecting resource choice according to particular usage requirements.

Domadia’s Aluminum Beryllium Alloy Ingots stand out due to their superior quality, customization flexibility, and commitment to sustainability, making them ideal for structural components and electronic devices. Moreover, Mica Tape Products serve a crucial function in high-temperature resistance and electrical insulation across different uses, further highlighting the significance of strategic sourcing in procurement. Comprehending these substances and their deposition techniques is crucial for effective sourcing and procurement decisions.

Applications of Thin-Film Materials in Modern Technology

Thin-film substances are extensively utilized in the electronics sector for purposes such as transistors, displays, and photovoltaic cells. In renewable energy, these substances are essential for creating lightweight and flexible solar panels, which can be integrated into various surfaces. Additionally, in the automotive sector, thin films are applied in sensors and coatings that enhance efficiency and durability. Comprehending these uses enables procurement managers to recognize possible suppliers and resources that correspond with sector requirements.

Transitioning to Mica Tape products, these materials are renowned for their high-temperature resistance and excellent insulation properties, making them ideal for diverse applications, from household appliances to industrial machinery. Specifically, Mica Insulation Tape and Mica Sheet Tape offer strong solutions essential for safety and performance in engineering and automotive sectors. Mica Tape products not only offer superior thermal stability but also exceptional dielectric strength, ensuring reliability in environments where electrical insulation is paramount. Providers and producers of these resources play a crucial role in satisfying the increasing needs of sectors that emphasize safety and performance.

Challenges and Innovations in Thin-Film Technology

Challenges in thin-film technology include:

- Substance stability

- Performance degradation over time

- Scalability of production processes

Innovations such as the development of robust materials and advanced deposition techniques are addressing these challenges. For example, ongoing research into protective layers and enhanced semiconductor interfaces aims to improve the longevity and efficiency of thin films.

Procurement managers should stay informed about these advancements to make strategic sourcing decisions that enhance product performance. Additionally, suppliers like Domadia excel in providing high-quality Mica Tape Products designed for high-temperature resistance and electrical insulation, suitable for a variety of applications, including electrical engineering and fire-resistant cable manufacturing.

Domadia’s ultra-thin metal foils are also important in sectors such as aerospace, electronics, and medical devices, where their exceptional performance characteristics foster innovations. What distinguishes Domadia is its dedication to quality, tailored solutions, and outstanding customer service, establishing it as a valuable ally in sourcing resources that meet rigorous industry standards.

Future Trends in Thin-Film Materials and Sustainability

The future of thin-film substances is increasingly focused on sustainability, particularly with the development of biodegradable options. Innovations like inkjet-printed graphene/PEDOT: PSS temperature sensors demonstrate a significant reduction in substance waste through advanced fabrication processes. These developments are paving the way for more environmentally friendly applications across various fields.

For example, the performance of a molecule-based transistor, with a steady-state drain current measured at -4 × 10^-5 C/s under a source-drain potential of 0.2 V, highlights the efficiency of innovative substances that align with sustainability goals. This statistic not only emphasizes the potential of these substances but also their compatibility with eco-friendly initiatives.

Moreover, case studies such as the Passive Perspiration Biofuel Cell reveal the promise of sustainable energy applications. This biofuel cell has shown a high energy return on investment, highlighting the practical benefits of adopting biodegradable substances.

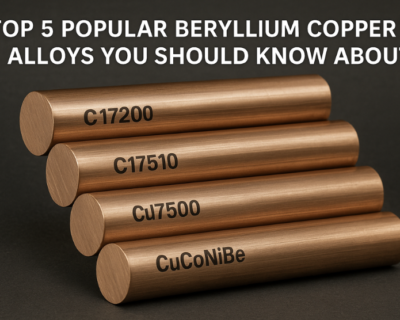

In parallel, companies like Domadia exemplify a commitment to sustainability through their high-quality beryllium copper products and competitive recycling solutions. By purchasing and recycling beryllium copper scrap, Domadia contributes to a greener future while providing reliable services to suppliers. This commitment to sustainability is further underscored by expert insights, such as those from Wei Gao, which highlight the crucial role of wearable sensor technologies in advancing personalized medicine through continuous health monitoring.

As these trends evolve, procurement managers should prioritize sourcing sustainable materials, like those offered by Domadia, that align with corporate social responsibility (CSR) objectives and regulatory standards. By choosing Domadia’s beryllium copper products, procurement managers not only enhance performance but also contribute positively to environmental sustainability.

Conclusion

Thin-film materials represent a cornerstone of modern technology, with their unique properties enabling a wide array of applications ranging from electronics to aerospace. Understanding the fundamentals of these materials, including their fabrication techniques and diverse uses, is essential for procurement managers aiming to make informed sourcing decisions. The article has highlighted the critical role of materials like Indium and Aluminum Beryllium Alloy Ingots, showcasing their significance in enhancing product performance and meeting industry demands.

The challenges faced in thin-film technology, such as material stability and scalability, are being addressed through ongoing innovations and advanced deposition techniques. Staying abreast of these developments allows procurement professionals to strategically source materials that not only meet technical specifications but also align with the evolving landscape of sustainability. The emphasis on biodegradable materials and eco-friendly practices, exemplified by companies like Domadia, underscores the growing importance of incorporating sustainable options into procurement strategies.

As industries increasingly prioritize both performance and environmental responsibility, the integration of sustainable thin-film materials will be paramount. By focusing on quality, innovation, and sustainability, procurement managers can position their organizations at the forefront of technological advancements while also contributing to a greener future. The commitment to sourcing high-quality materials that support corporate social responsibility objectives will ultimately lead to enhanced efficiencies and long-term success in a rapidly changing market.