Blogs

How to Find Yield Strength from a Stress-Strain Graph: A Step-by-Step Guide

Introduction

The stress-strain curve is a pivotal tool in material science, illustrating the intricate relationship between stress and deformation in materials under load. This graphical representation not only reveals the elastic and plastic behaviors of materials but also serves as a foundation for understanding yield strength—the critical threshold where materials transition from reversible to permanent deformation.

As industries increasingly rely on precise material specifications, comprehending the nuances of the stress-strain curve becomes essential for procurement managers and engineers alike. Recent advancements in analysis techniques, coupled with extensive research, have illuminated the complexities of material behavior, enabling better decision-making in material selection and application.

This article delves into the significance of the stress-strain curve, offering insights into:

- Yield strength calculation methods

- Challenges in data analysis

- The vital role of yield strength in engineering disciplines

Understanding the Stress-Strain Curve: A Foundation for Yield Strength Analysis

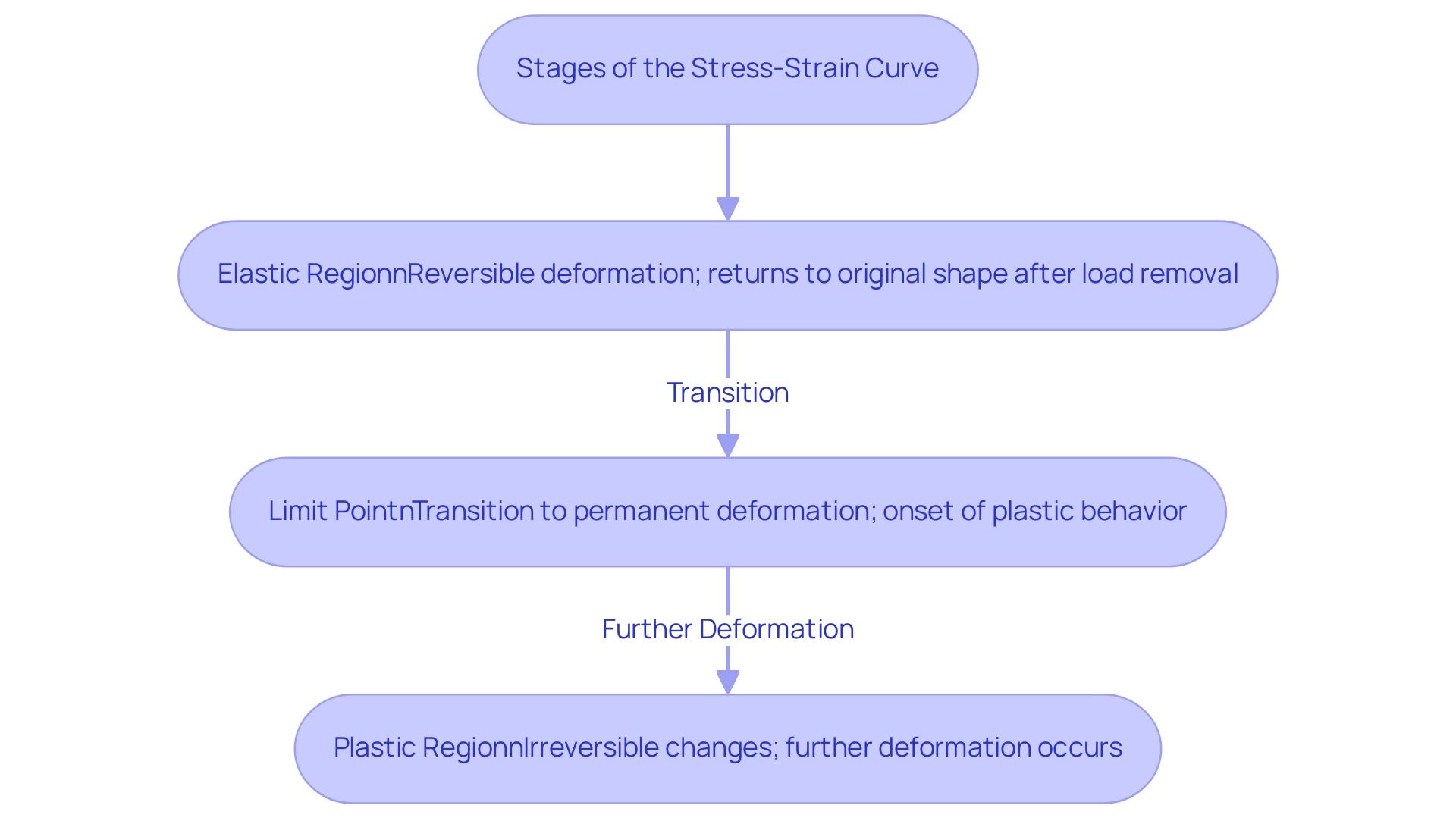

The stress-strain curve functions as an essential graphical depiction of the relationship between stress (force per unit area) and strain (deformation) in substances. This curve consists of several distinct regions, each reflecting different substance behaviors under load. Initially, the elastic region demonstrates reversible deformation; when the load is removed, it returns to its original shape.

At the limit point, the substance transitions into permanent deformation, marking the onset of plastic behavior. Following this, the plastic region illustrates irreversible changes as the substance undergoes further deformation. Comprehending these areas is crucial to find yield strength from the stress-strain graph—the threshold at which a substance begins to deform plastically.

Recent studies emphasize important progress in curve analysis of tension and compression, with researchers like Kumar, Kabra, and Cole creating extensive databases that improve our comprehension of substance behavior. Notably, the behavior curves of high-performance concrete (HPC) exposed to high temperatures are characterized by coefficients such as 0.99, 1.31, and 1.75, among others. As pointed out by Rui Liang in the Journal of Biomechanics, it is vital to find yield strength from the stress-strain graph for predicting performance under various loading conditions.

Furthermore, the Chemical Named-Entity Recognition (CNER) system utilized advanced algorithms to identify chemical entities, which is crucial for effective substance identification and procurement decisions. Getting acquainted with the contour of the curve not only helps in recognizing performance limits but also offers essential understanding of how materials will respond under varying stresses, ultimately guiding improved procurement choices.

Step-by-Step Methods to Calculate Yield Strength from the Stress-Strain Graph

To accurately calculate yield strength from a force-deformation graph, the following systematic approach can be adopted:

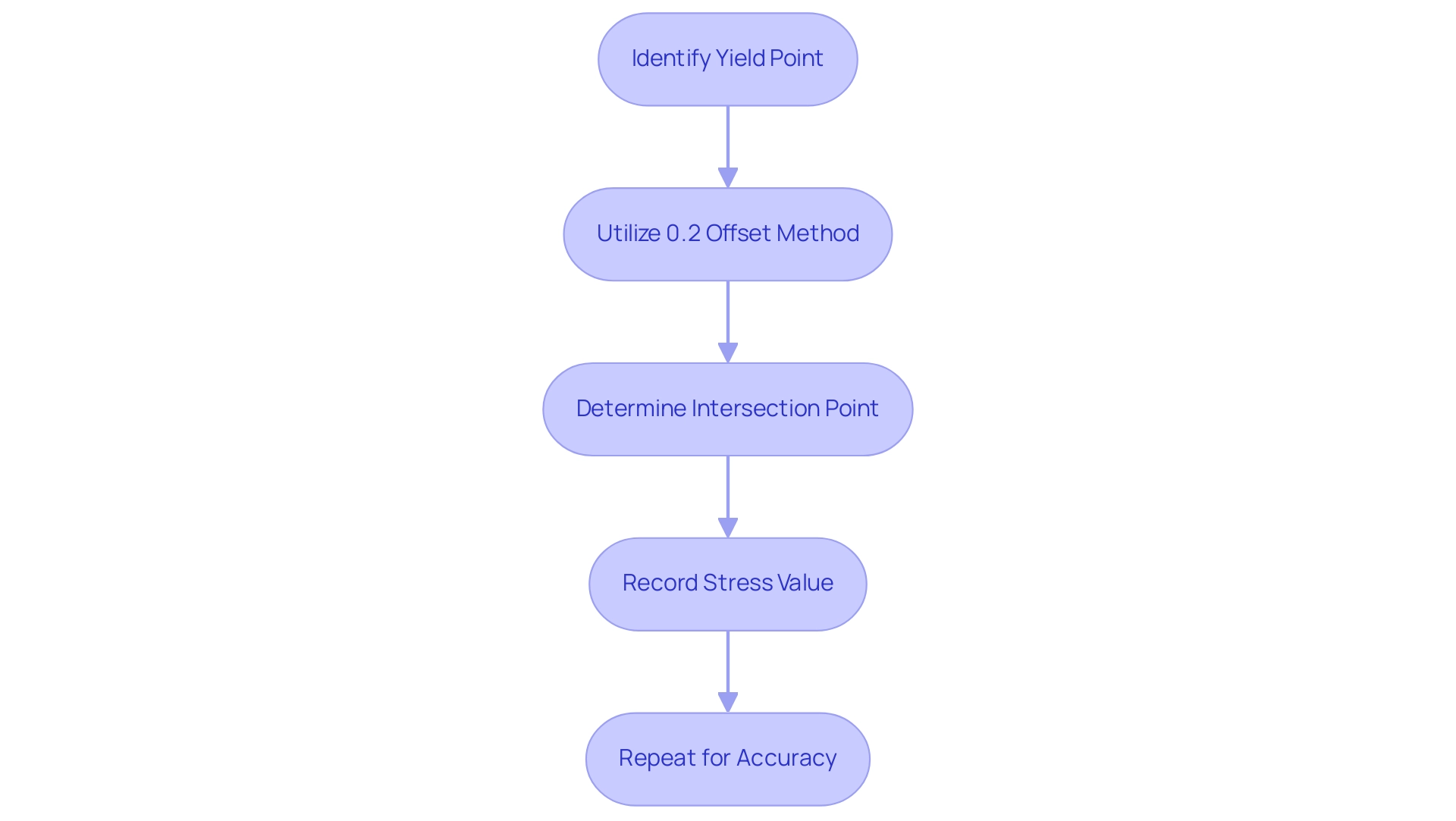

- Identify the Yield Point: Begin by locating the point on the curve of stress versus strain where plastic deformation initiates, which is typically characterized by a noticeable change in slope. This transition is critical as it marks the onset of permanent deformation. As pointed out by Kat de Naoum, this aspect is crucial for manufacturers and engineers to comprehend how a substance will withstand tensile strength.

- Utilize the 0.2% Offset Method: To apply this method, draw a line parallel to the linear elastic portion of the curve, offset by 0.2% strain. This offset accounts for the small amount of elastic deformation that occurs before yielding. The intersection of this line with the stress-strain curve signifies the failure point of the material.

- To find yield strength from stress-strain graph: Once the intersection point is identified, note the corresponding stress value. This stress value is the ultimate capacity, offering insight into how the substance will behave under tensile loads.

- Repeat for Accuracy: For enhanced reliability, it is advisable to perform this calculation using multiple samples. Differences in substance characteristics can produce varied values, so averaging outcomes can offer a more precise depiction of performance capacity.

Comprehending performance capacity is essential for substance selection and engineering uses. For instance, the resistance values differ greatly among various substances:

– Hot rolled A36 steel has a resistance of about 220 MPa,

– Tempered steels can attain up to 1,570 MPa.

– Additionally, austenitic stainless steel starts around 250 MPa,

– Precipitation-hardened stainless steel can go up to 1,000 MPa,

– Aluminum alloys range from 24 MPa for 1100 grade aluminum to 483 MPa for 7075 aluminum.

Moreover, carbon-fiber reinforced polyamide displays a tensile capacity of 300 MPa. As emphasized in the case study named ‘Examples of Yield Values’, these differences demonstrate the significance of precisely identifying resistance for various substances. Utilizing modern methods in yield capacity assessment improves precision and guarantees that engineers can make knowledgeable choices in resource selection.

The Importance of Yield Strength in Material Science and Engineering

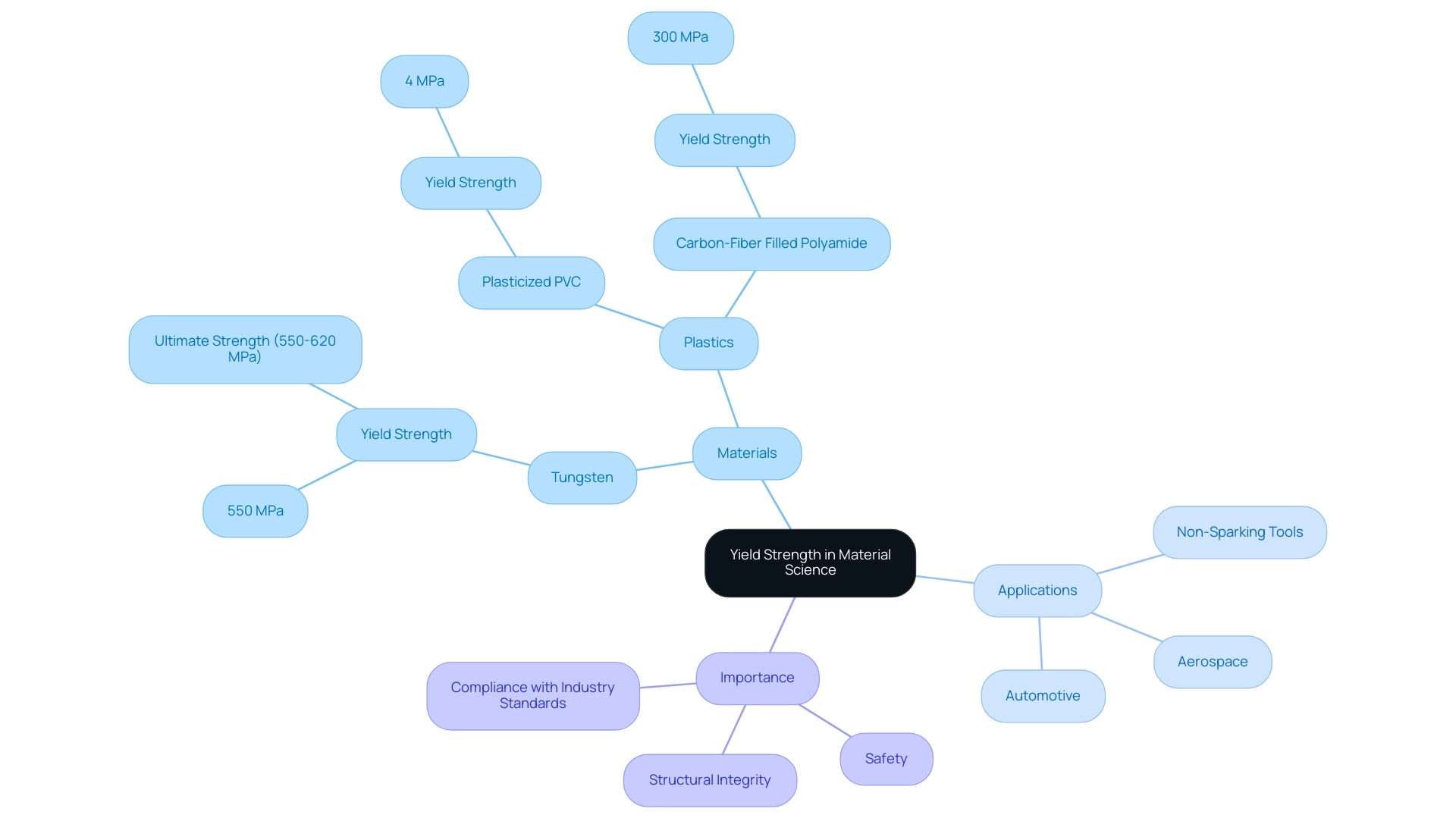

In substance science, a fundamental factor is yield resistance, which is essential to find yield strength from the stress-strain graph, delineating the maximum stress that a substance can endure without incurring permanent deformation. This property is particularly significant in engineering fields, especially when choosing substances for Non-Sparking Tools that are utilized in explosive environments. For example, Non-Sparking Tools must have particular resistance qualities to ensure safety and performance in hazardous applications.

Tungsten (annealed), with a tensile capacity of 550 MPa and a maximum resistance varying from 550 to 620 MPa, exemplifies a durable substance appropriate for such tools. In contrast, plastics display a broad spectrum of yield capacities, from 4 MPa for plasticized PVC to 300 MPa for carbon-fiber filled polyamide, emphasizing the variability of yield capacity across substances. David Stamper, a Graduate Materials Engineer at Parker Meggitt, emphasizes that to find yield strength from the stress-strain graph, one must recognize that yield capacity is a property that measures the maximum stress a substance can endure before it permanently deforms or fractures.

It is crucial in predicting failure, determining load-bearing capacity, ensuring quality control, choosing resources for specific applications, and designing cost-effective structures and products. Comprehending material resistance enables engineers to predict how substances will perform under stress, which is vital to find yield strength from the stress-strain graph, making it a crucial element in material choice and structural integrity evaluations. Furthermore, it plays an integral role in adhering to industry standards and regulations, thereby ensuring that products meet both safety and performance requirements.

Recent studies have emphasized that various sectors, especially aerospace and automotive, have particular resistance criteria to maintain structural integrity and safety under different stress conditions. In the context of Non-Sparking Tools, it is critical to evaluate tensile strength at yield requirements to enhance safety in critical applications, as these tools must withstand the rigors of explosive environments while preventing spark generation.

Common Challenges in Analyzing Stress-Strain Data for Yield Strength

Analyzing stress-strain data presents several challenges that require careful consideration and strategic approaches:

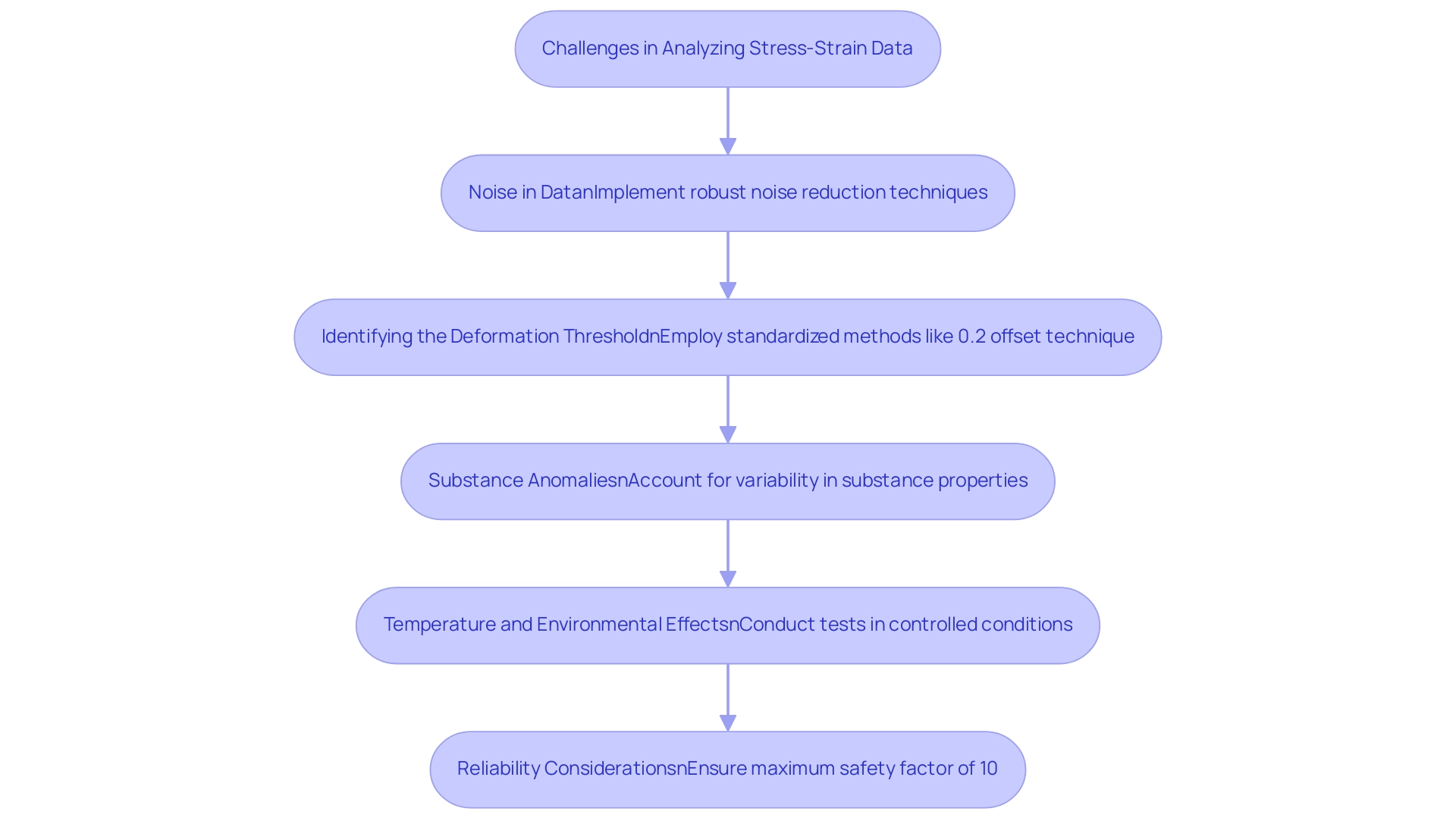

Noise in Data: Experimental data often suffers from noise introduced by measurement errors or limitations of the testing equipment. Implementing robust noise reduction techniques, such as incorporating fuzzy c-means, is essential to enhance data accuracy and reliability, ensuring that the analysis reflects true substance behavior.

Identifying the Deformation Threshold: The assessment of the deformation threshold can be subjective, particularly in substances exhibiting gradual transitions between elastic and plastic changes. To achieve consistency, employing standardized methods such as the 0.2% offset technique is crucial to find yield strength from stress-strain graph for clarity in reporting.

Substance Anomalies: Variability in substance properties, stemming from factors like processing conditions or historical treatments, can significantly impact results. It is vital to account for these anomalies by thoroughly understanding the context and ensuring that all relevant data is considered in the analysis.

Temperature and Environmental Effects: Yield resistance is susceptible to variations caused by temperature and other environmental factors. Conducting tests in controlled conditions minimizes these influences, thereby reducing variability and ensuring more reliable outcomes.

Reliability Considerations: The framework protecting the test fixture may possess a maximum safety factor of 10, highlighting the significance of reliability in the testing arrangement.

The research funded by the German Research Foundation under grant KA 1163/37-2 exemplifies this approach, focusing on structural design informed by multiscale modeling and polymorphic uncertainty. It is acknowledged that the funding by the German Research Foundation (DFG) under grant KA 1163/37-2 is gratefully acknowledged.

By tackling these challenges with a methodical and knowledgeable approach, procurement managers can greatly enhance the reliability of data analysis related to deformation and learn how to find yield strength from stress-strain graph in their evaluations.

Further Resources for Mastering Stress-Strain Analysis and Yield Strength Calculation

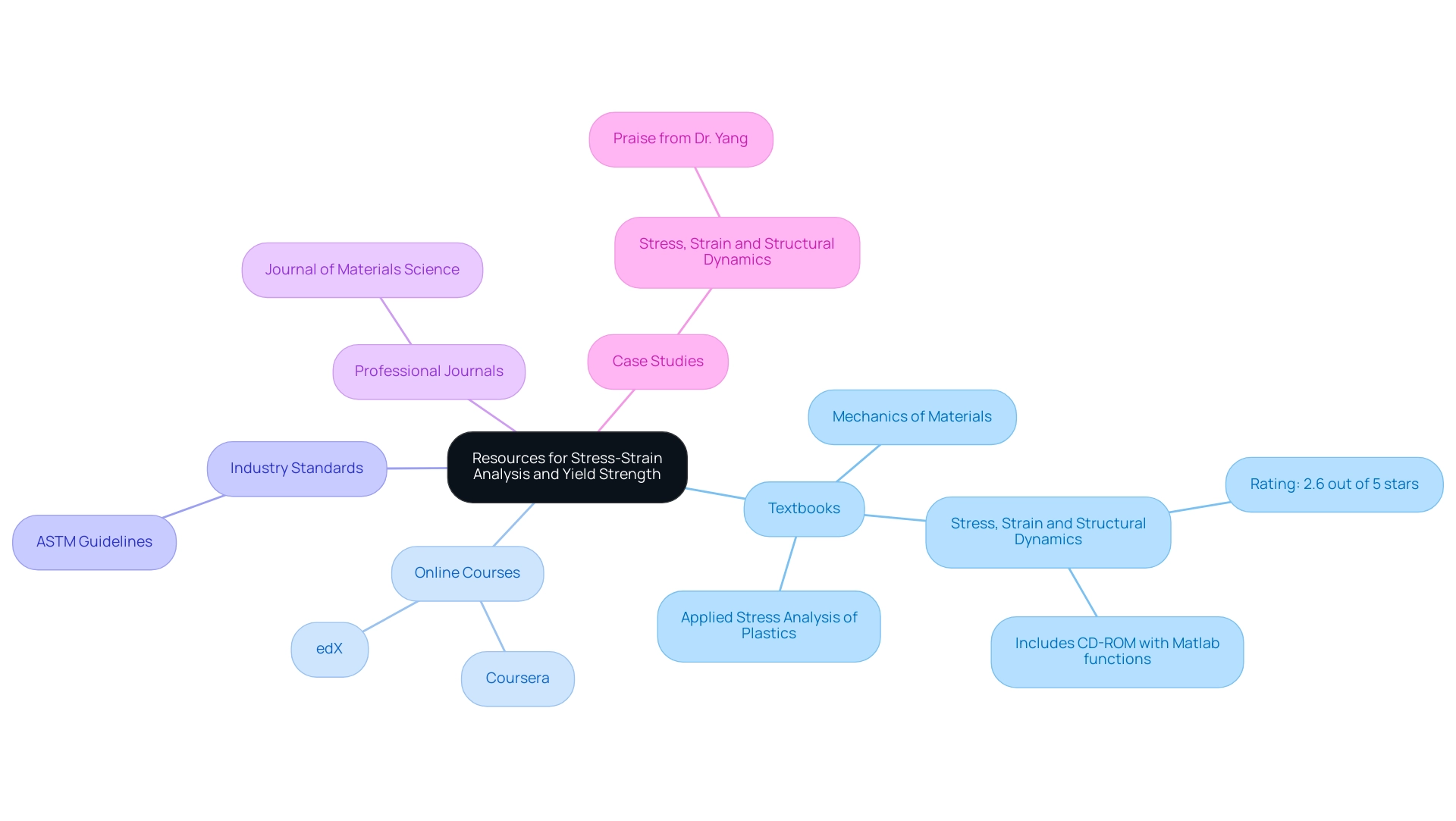

To deepen your expertise in deformation analysis and yield strength calculation, it is essential to explore the following resources:

- Textbooks: A highly recommended science textbook is ‘Mechanics of Materials’ by Beer and Johnston, which thoroughly addresses stress-strain relationships. Additionally, the book ‘Applied Stress Analysis of Plastics: A Mechanical Engineering Approach’ by S I Krishnamachari and L J Broutman is noteworthy for its exploration of the long-term behavior of plastics, supported by computational stress analysis concepts and practical case studies. This book is especially valuable for understanding how these substances behave under various conditions.

- Online Courses: Engage with platforms like Coursera and edX, which provide comprehensive courses in science and engineering. These courses frequently include modules specifically focused on tensile properties and stress-strain analysis, enabling students to find yield strength from stress-strain graph while offering practical insights and applications.

- Industry Standards: Becoming acquainted with ASTM guidelines is essential, as they detail the procedures for substance testing and yield capacity assessment. Adhering to these standards ensures that you can accurately find yield strength from stress-strain graph, providing reliability in your analyses.

- Professional Journals: Subscribing to journals like the Journal of Materials Science can keep you informed about the latest research and case studies that concentrate on properties and the innovative techniques used in their analysis. These journals serve as valuable resources for staying informed about advancements in the field.

- Case Studies: Consider the book ‘Stress, Strain and Structural Dynamics‘ by Dr. Yang, which is praised for its comprehensive coverage of engineering topics, including strength of materials and structural dynamics. It includes a CD-ROM containing nearly 300 self-written Matlab functions, making it an excellent resource for both engineering students and professionals.

Incorporating insights from experts, such as H Wieringa, who emphasizes the importance of comprehensive resources in experimental stress analysis, can further guide your learning journey. His assertion that

This book offers a comprehensive introduction to the field of experimental stress analysis, equipping readers with the necessary tools to design and manufacture structures of different types in a cost-effective and secure manner

underlines the practical benefits of these resources. Notably, the book ‘Stress, Strain, and Structural Dynamics’ has a rating of 2.6 out of 5 stars based on 7 ratings, providing a quantitative assessment that may help you evaluate its usefulness in your studies.

Conclusion

Understanding the stress-strain curve and its implications is essential for effective material selection and engineering applications. This article has highlighted the various aspects of yield strength, including:

- Methods for calculating it

- The challenges faced in data analysis

- Its critical role in ensuring structural integrity across industries

Familiarity with the stress-strain curve not only aids in identifying yield strength but also enhances comprehension of material behavior under different loading conditions.

The methodologies for calculating yield strength, such as the 0.2% offset method, provide procurement managers and engineers with reliable techniques to ascertain material performance. Recognizing the importance of yield strength in specialized applications, such as Non-Sparking Tools, reinforces the necessity of precise material specifications to ensure safety and efficacy in hazardous environments.

Furthermore, addressing common challenges in analyzing stress-strain data, such as noise and material anomalies, is crucial for improving the reliability of results. By adopting systematic approaches and leveraging modern resources, professionals can navigate these complexities, leading to informed decisions in material procurement and application.

In conclusion, a thorough understanding of the stress-strain curve and yield strength is not merely an academic exercise; it is a strategic necessity that underpins successful engineering practices. As industries continue to evolve, the ability to accurately assess and apply these principles will be paramount in achieving both safety and performance in material applications.