Blogs

How to Use Permalloy C for Effective Shielding in Linac Machines: A Step-by-Step Guide

Overview

The article provides a comprehensive step-by-step guide on how to effectively use Permalloy C for shielding in linac machines, emphasizing the importance of evaluating protection needs, selecting appropriate material thickness, and adhering to compliance standards. This guidance is supported by detailed explanations of the alloy’s properties, practical installation tips, and maintenance protocols, ensuring that procurement managers can enhance safety and performance in radiation protection applications.

Introduction

In the realm of radiation protection, the selection of materials is not merely a technical decision; it is a strategic imperative that can significantly impact safety and operational efficiency. Permalloy C, a nickel-iron alloy celebrated for its exceptional magnetic properties, stands out as a premier choice for shielding applications, particularly in environments where precision is non-negotiable, such as in Linac machines.

This article delves into the multifaceted advantages of Permalloy C, exploring its properties, implementation strategies, and maintenance protocols. By understanding its role in electromagnetic interference (EMI) shielding and the importance of compliance with industry standards, procurement managers can make informed decisions that enhance safety and optimize performance.

As the demand for effective radiation protection solutions grows, so does the necessity for a comprehensive approach to material selection and application, ensuring that organizations remain at the forefront of safety and innovation.

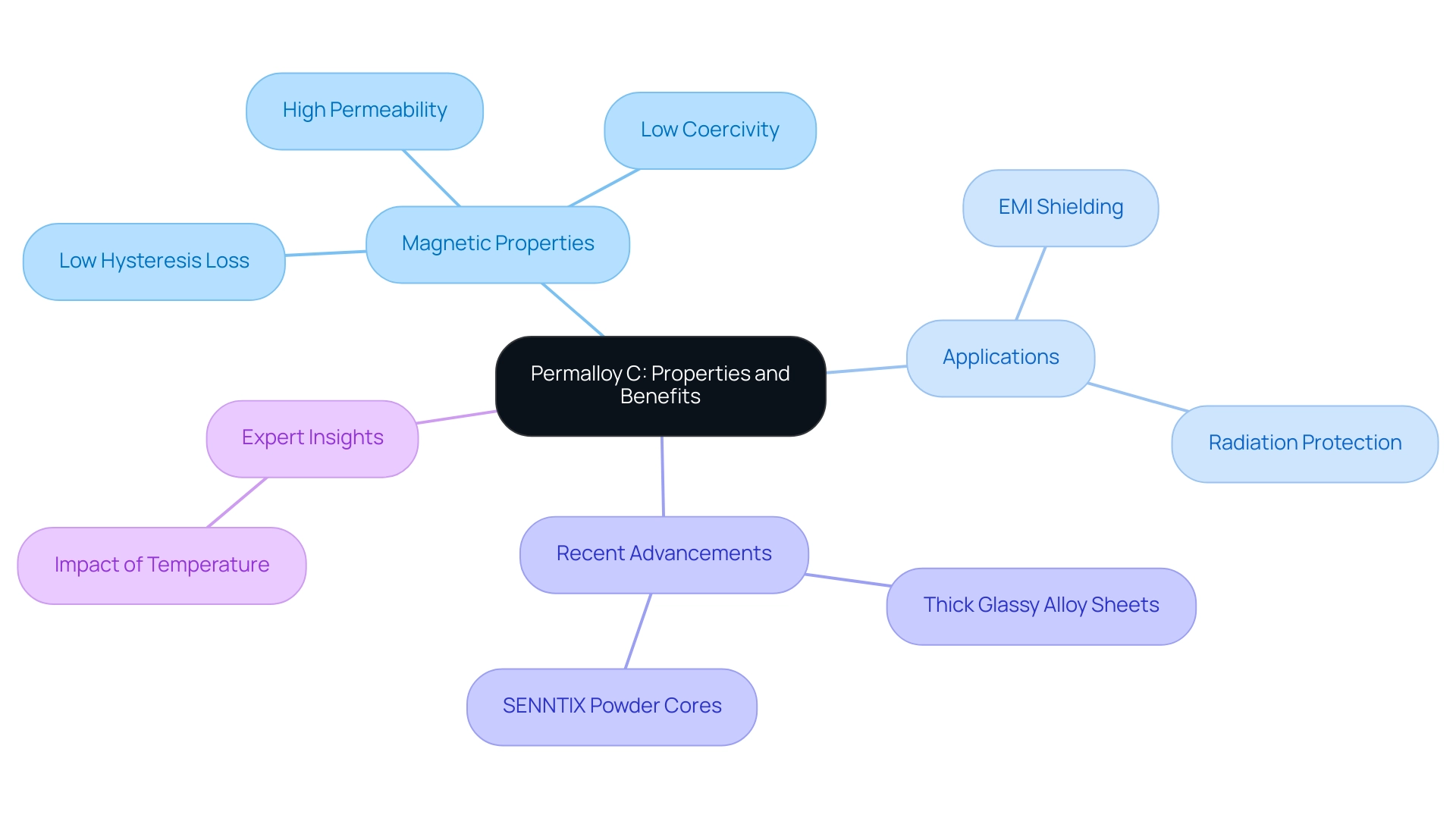

Understanding Permalloy C: Properties and Benefits for Shielding

Permalloy C, a nickel-iron alloy, is renowned for its outstanding magnetic properties, particularly its high magnetic permeability and low coercivity. These features enable effective shielding against electromagnetic interference (EMI) and radiation, making permalloy C for shielding in linac machines highly suitable for applications where precision and security are critical. The alloy’s capacity to absorb and redirect magnetic fields positions it as a premium choice for environments with stringent safety requirements.

Furthermore, its low hysteresis loss not only conserves energy but also translates into long-term cost savings, reinforcing its appeal as a strategic procurement option. Recent advancements in thick Fe-based glassy alloy sheets, which provide substantial surface areas, complement the use of alloy C in heat-resistant, high-strength material applications. As highlighted by J.L., an expert in the field:

Temperature has a significant impact on the magnetic properties of permalloy.

This insight underscores the importance of considering environmental factors in material selection. Furthermore, the large-scale production of SENNTIX powder cores, with several million pieces manufactured monthly, highlights the strong manufacturing capabilities that facilitate the use of C alloy in various applications. Comprehending the magnetic properties of alloy C, such as those outlined in extensive measurement techniques studies—like the sample ring method utilized to evaluate effective magnetic circuit length and cross-sectional area—is essential for procurement managers seeking to ensure adherence to industry standards while enhancing performance in protection solutions.

Furthermore, to enhance high-temperature electrical insulation, consider exploring Domadia’s Mica Tapes, which offer excellent thermal resistance and can complement the use of Permalloy C in your applications. For more information on how Mica Tapes can benefit your projects, contact our expert team today.

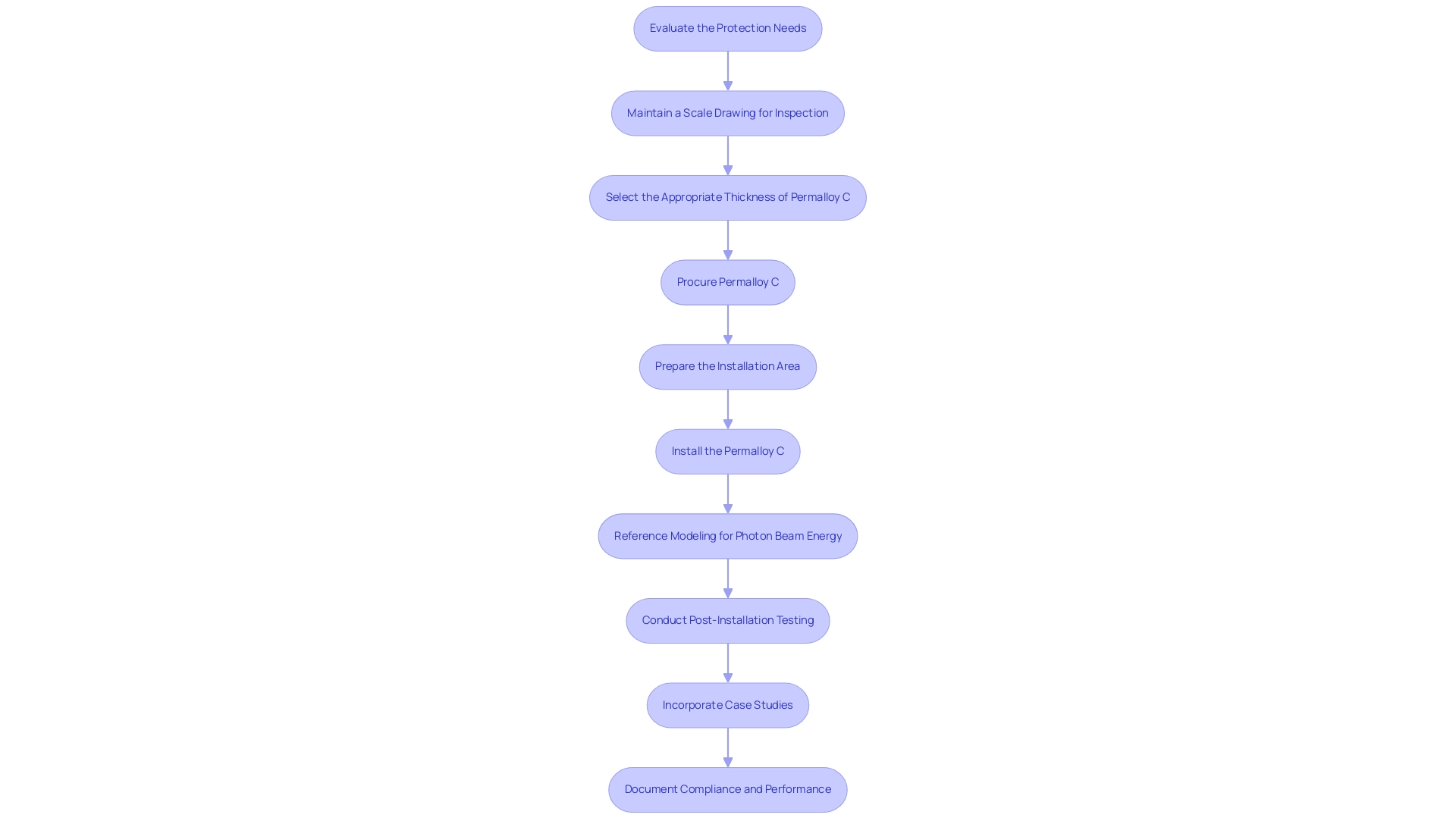

Step-by-Step Guide to Implementing Permalloy C in Linac Shielding

- Evaluate the Protection Needs: Begin with a comprehensive assessment of the Linac machine’s particular barrier requirements. This assessment should encompass the types of radiation emitted and the requisite attenuation levels. Significantly, research shows that on average, 19.4% more positron particles are produced in settings without adequate protection, emphasizing the essential importance of this analysis in ensuring optimal performance of the Linac machine.

- Maintain a Scale Drawing for Inspection: As part of compliance and operational efficiency, it is essential to maintain a scale drawing of the room where the Linac machine is located. This drawing should indicate adjacent area usage and occupancy estimates, facilitating effective inspections and compliance with protocols.

- Select the appropriate thickness of permalloy c for shielding in linac machines: Following the assessment, determine the optimal thickness of permalloy c for shielding in linac machines necessary to achieve effective shielding. It is vital to consult established standards and guidelines to ensure compliance with industry requirements, enhancing both safety and performance.

- Procure permalloy c for shielding in linac machines: Engage with suppliers specializing in high-performance alloys to procure permalloy c for shielding in linac machines, ensuring that the materials meet stringent international quality standards. Negotiate terms that align with your budgetary constraints while safeguarding the quality essential for effective radiation shielding.

- Prepare the Installation Area: Prior to installation, ensure the area is meticulously cleaned and free of contaminants that could degrade the shielding material’s effectiveness. Consider environmental factors such as humidity and temperature, which may affect the integrity of the alloy C over time.

- Install the permalloy c for shielding in linac machines: Scrupulously adhere to the manufacturer’s installation guidelines. It is essential to secure the protection thoroughly and eliminate any gaps that could undermine its attenuation capabilities, thereby ensuring regulatory compliance and optimal safety.

- Reference Modeling for Photon Beam Energy: Utilize modeling tools such as the BEAMnrc code to understand the photon beam energy relevant to the Linac machine. This knowledge assists in identifying the essential protective measures to guard against particular types of rays.

- Conduct Post-Installation Testing: After installation, carry out comprehensive testing to confirm that the protection using permalloy c for shielding in linac machines meets the necessary standards. This may involve utilizing detection equipment to assess the effectiveness of the Permalloy C in reducing exposure, aligning with best practices in the industry.

- Incorporate Case Studies: Consider real-world applications, such as the 3D energy mapping of the Zap-X system, where effective protection practices were assessed. This case study, which involved creating a 3D radiation map using 855 measurement points, illustrates the significance of protective features and enhances understanding of risk profiles.

- Document Compliance and Performance: Maintain meticulous records of the procurement process, installation procedures, and testing outcomes. This documentation is essential for compliance audits and serves as a valuable resource for future maintenance or upgrades. As A.B. emphasized, maintaining thorough documentation enhances the overall safety profile and operational efficiency of protective practices.

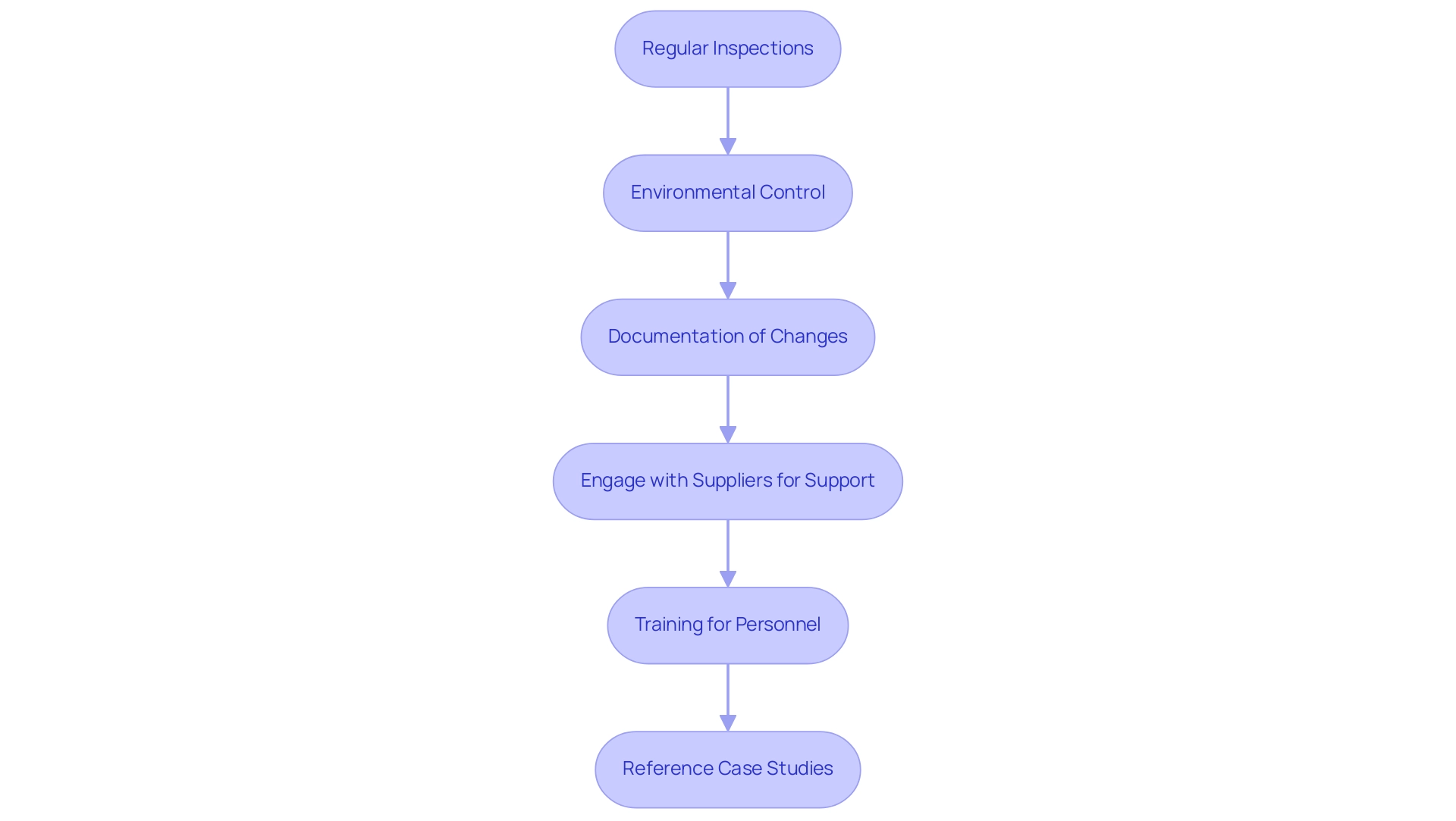

Maintaining Permalloy C Shielding for Long-Term Effectiveness

To ensure the long-term effectiveness of Permalloy C shielding, adhere to the following guidelines:

- Regular Inspections: Establish a routine schedule for inspecting the protective material for signs of wear, corrosion, or damage. Early detection of potential issues can mitigate the risk of more severe problems in the future. Research indicates that proactive maintenance is crucial for preserving protective integrity.

- Environmental control is crucial to manage the environment around the Linac machine to minimize conditions that could harm Permalloy C for shielding in Linac machines, particularly humidity and temperature fluctuations. Proper environmental management is key to maintaining the performance of the barrier, especially considering that the AC amplitude permeability increases by 9.37% at 140 °C at a frequency of 1 kHz, highlighting the importance of temperature management.

- Documentation of Changes: Maintain comprehensive records of any modifications or repairs to the protective covering. Such documentation is essential for compliance and enables effective performance monitoring over time, ensuring that any changes do not compromise effectiveness.

- Engage with Suppliers for Support: Foster open communication with suppliers, such as Domadia, to gain insights on best practices for maintaining both Permalloy C protection and high-temperature electrical insulation materials, including Mica Tapes. Their expertise can provide valuable guidance customized to the specific requirements of your protection solutions, enhancing overall performance. Domadia’s Mica Tapes are engineered for high-temperature resistance and exceptional electrical insulation, making them perfect for applications that demand dependable protection.

- Training for Personnel: Educate staff responsible for Linac machines on the importance of protective maintenance and the particular care needed for Permalloy C for shielding in Linac machines. As Binggang Zhang points out, parameters for electron beam freeform fabrication are essential, and fostering a culture of safety and diligence will guarantee that maintenance practices are regularly implemented.

- Reference Case Studies: Review relevant case studies, such as the one titled “Future Directions in Electromagnetic Protection Research,” which discusses the potential applications of composite materials and emphasizes the importance of ongoing research in optimizing effectiveness.

By adhering to these guidelines, procurement managers can improve the durability and efficiency of C-class materials while also considering the integration of high-quality Mica Tapes from Domadia. Explore our range of Mica Tapes and reach out to our expert team today to discover how they can enhance your solutions, ensuring you join the ranks of satisfied customers who depend on Domadia for their high-temperature electrical insulation needs.

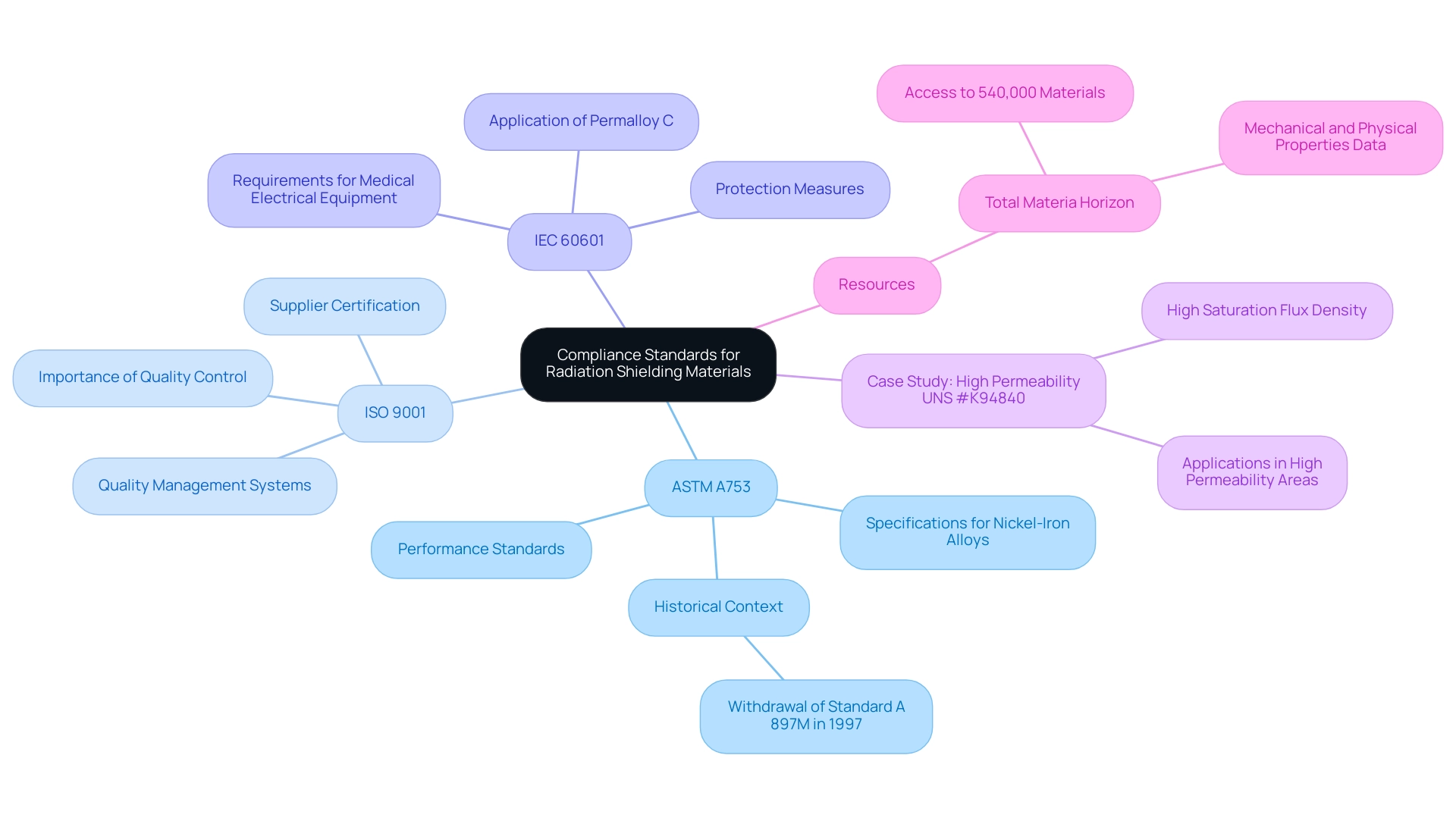

Understanding Compliance Standards for Radiation Shielding Materials

When choosing and applying protective materials such as Permalloy C, adherence to established compliance standards is paramount for ensuring both safety and efficiency. Key standards that procurement managers must consider include:

- ASTM A753: This standard delineates the specifications for nickel-iron alloys utilized in magnetic applications, particularly in protective contexts. Its significance is in guaranteeing that the materials satisfy the essential performance standards needed for effective protection against harmful exposure. Notably, the historical context of compliance is underscored by the withdrawal of Standard A 897M in 1997, emphasizing the need to adhere to current standards.

- ISO 9001: Focusing on quality management systems, this standard mandates that suppliers maintain consistent quality across their products. Certification to ISO 9001 indicates that a supplier follows stringent quality controls, which is vital for the dependability of protective materials.

- IEC 60601: This international standard is crucial for the security and efficacy of medical electrical equipment, outlining requirements for protection measures. Adherence to IEC 60601 guarantees that the protective solutions not only conform to legal standards but also incorporate Permalloy C for shielding in linac machines, offering strong protective measures.

In practical applications, the high permeability UNS #K94840 nickel-iron alloy illustrates the advantages of utilizing advanced materials in defense against harmful emissions. Known for its high saturation flux density of about 16000 gauss (1.6 tesla), it enhances the efficiency and effectiveness of equipment requiring extremely high permeability at low magnetizing forces.

Additionally, resources such as Total Materia Horizon offer access to over 540,000 materials and comprehensive data on mechanical and physical properties, which can aid procurement managers in making informed decisions. By comprehensively understanding and applying these standards, procurement managers can ensure that their chosen shielding solutions will not only comply with legal requirements but also deliver the necessary safety and performance levels essential for effective operation in radiation environments.

Conclusion

The advantages of Permalloy C as a shielding material are substantial, underscoring its critical role in radiation protection applications, particularly in Linac machines. Its exceptional magnetic properties—high permeability and low coercivity—make it an ideal choice for effective electromagnetic interference (EMI) shielding. The strategic selection of Permalloy C not only enhances safety but also contributes to operational efficiency through reduced energy loss and long-term cost savings.

Implementing Permalloy C effectively involves a systematic approach, beginning with a thorough assessment of shielding requirements and ensuring compliance with industry standards. The step-by-step guide provides procurement managers with a clear framework for selecting, installing, and maintaining Permalloy C shielding. Regular inspections and environmental controls are vital for preserving the material’s integrity, while comprehensive documentation of processes ensures compliance and facilitates future audits.

Moreover, adherence to compliance standards such as ASTM A753, ISO 9001, and IEC 60601 is essential for guaranteeing the safety and efficacy of shielding solutions. By understanding these standards, procurement managers can make informed decisions that not only meet legal requirements but also optimize performance in demanding radiation environments.

In conclusion, the strategic implementation of Permalloy C is a pivotal factor in achieving effective radiation protection. By leveraging its unique properties and adhering to best practices, organizations can enhance safety, operational efficiency, and compliance in their radiation shielding solutions. As the landscape of radiation protection continues to evolve, the commitment to quality materials and practices will ensure that organizations remain at the forefront of safety and innovation.