Blogs

Understanding Types of Rolling: A Complete Tutorial for Manufacturers

Overview

The article titled “Understanding Types of Rolling: A Complete Tutorial for Manufacturers” focuses on the various types of rolling processes used in manufacturing metals, specifically distinguishing between hot, cold, and warm rolling methods. It explains that these processes are essential for optimizing material properties, production efficiency, and cost-effectiveness, supported by insights into the operational advantages and applications of different rolling mills and techniques in the industry.

Introduction

In the realm of manufacturing, the types of rolling in manufacturing play a crucial role in shaping metals. This technique reduces thickness, enhances surface finish, and improves material strength. As industries evolve and markets shift, knowing the differences between hot, cold, and warm rolling becomes essential. Especially for procurement managers, this knowledge supports informed sourcing and process optimization.

New technologies are making rolling more efficient and sustainable. Moreover, the choice of rolling mills can impact both cost and quality. This guide explores rolling processes, mill types, and the benefits they offer in modern production.

Introduction to Rolling in Manufacturing

Rolling involves passing metal through rolls to reduce its thickness and improve finish. It’s widely used to produce sheets, plates, and structural components. Typically, this applies to strips thinner than 6 mm and narrower than 600 mm.

There are two main types of rolling: hot and cold.

Hot rolling happens above the metal’s recrystallization temperature. This allows more deformation and better ductility. It’s ideal for large-scale production.

Cold rolling occurs at room temperature. It improves surface finish and accuracy, making it suitable for applications needing tight tolerances.

Industry data shows a slight drop in steel usage—from 1,779.3 million tons in 2019 to 1,763.0 million tons in 2023. Despite this, demand for quality and precision remains high. As noted in the Machinery Leasing Global Market Report 2025, leasing equipment is also gaining ground, adding flexibility to procurement strategies.

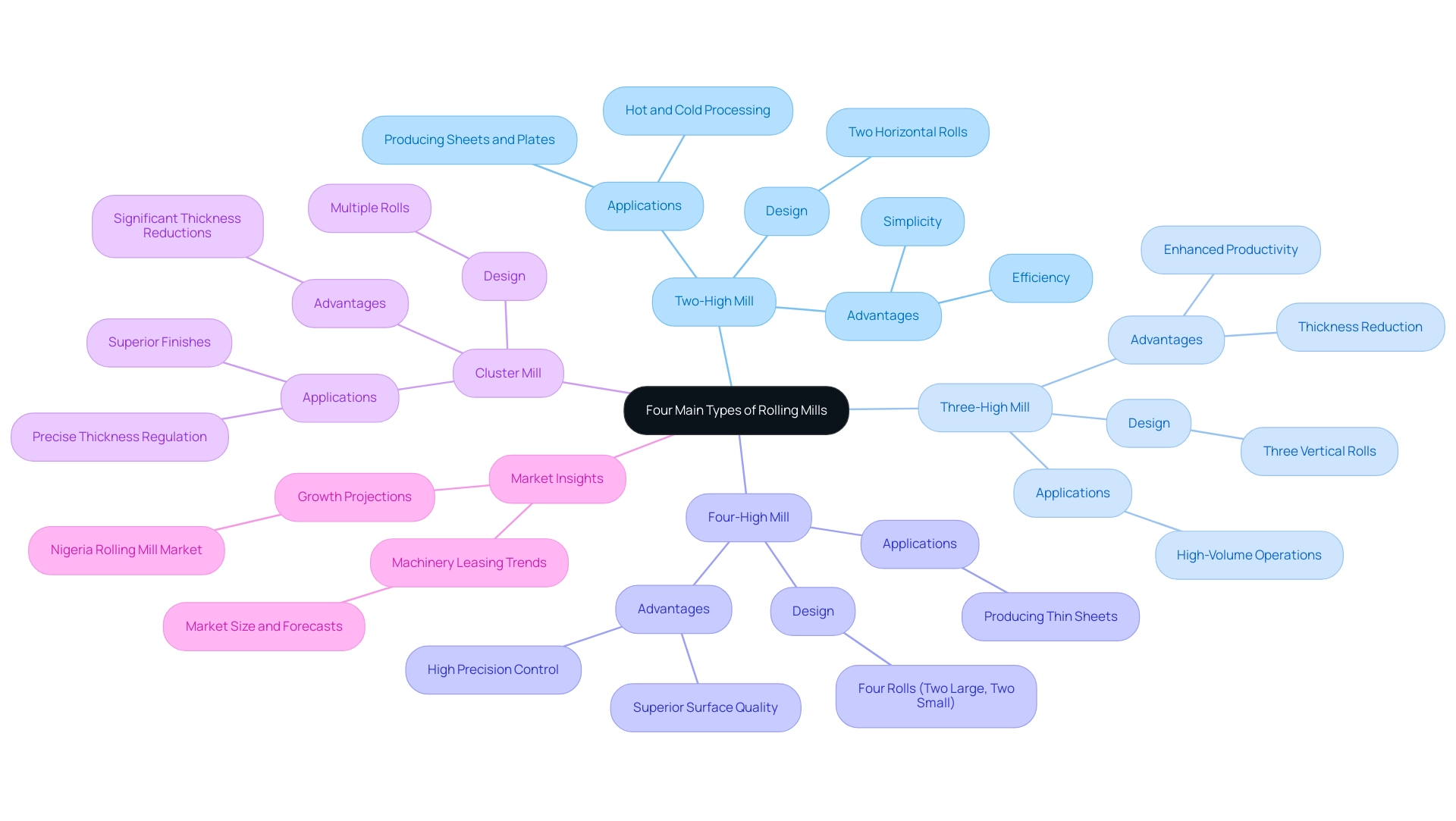

The Four Main Types of Rolling Mills

Metal mills are fundamental in metal processing, and understanding the various types is crucial for procurement managers aiming to optimize production efficiency. The four primary types of mill processes are:

Two-High Mill: Has two horizontal rolls. It’s versatile and used in both hot and cold rolling. Ideal for producing sheets and plates.

Three-High Mill: Stacks three rolls vertically. The design allows multiple passes, improving productivity and reducing thickness quickly.

Four-High Mill: Features two small rolls between two larger ones. It offers better control and produces thin sheets with a smooth finish.

Cluster Mill (Sendzimir): Uses multiple small rolls for precise thickness and excellent surface quality. Best for materials needing tight control.

Chitranshi Jaiswal emphasizes the significance of quality in this field, stating,

NSSMC stands as a formidable entity in the Mill Machine Market, with a reputation established on providing exceptional product quality and technological leadership.

This insight underscores the competitive landscape where efficiency and innovation are paramount.

Moreover, the Nigeria Rolling Mill and Other Metalworking Machinery Market is projected to experience significant growth, with a focus on capacity segmentation and forecasts extending to 2034.

As the machinery leasing market develops, as outlined in the Machinery Leasing Global Market Report 2025, understanding the specifications and uses of these mills becomes increasingly essential for strategic procurement decisions. Recent trends suggest that procurement managers must evaluate the efficiency comparisons between two-high and three-high mills, along with the specific applications that match their operational needs.

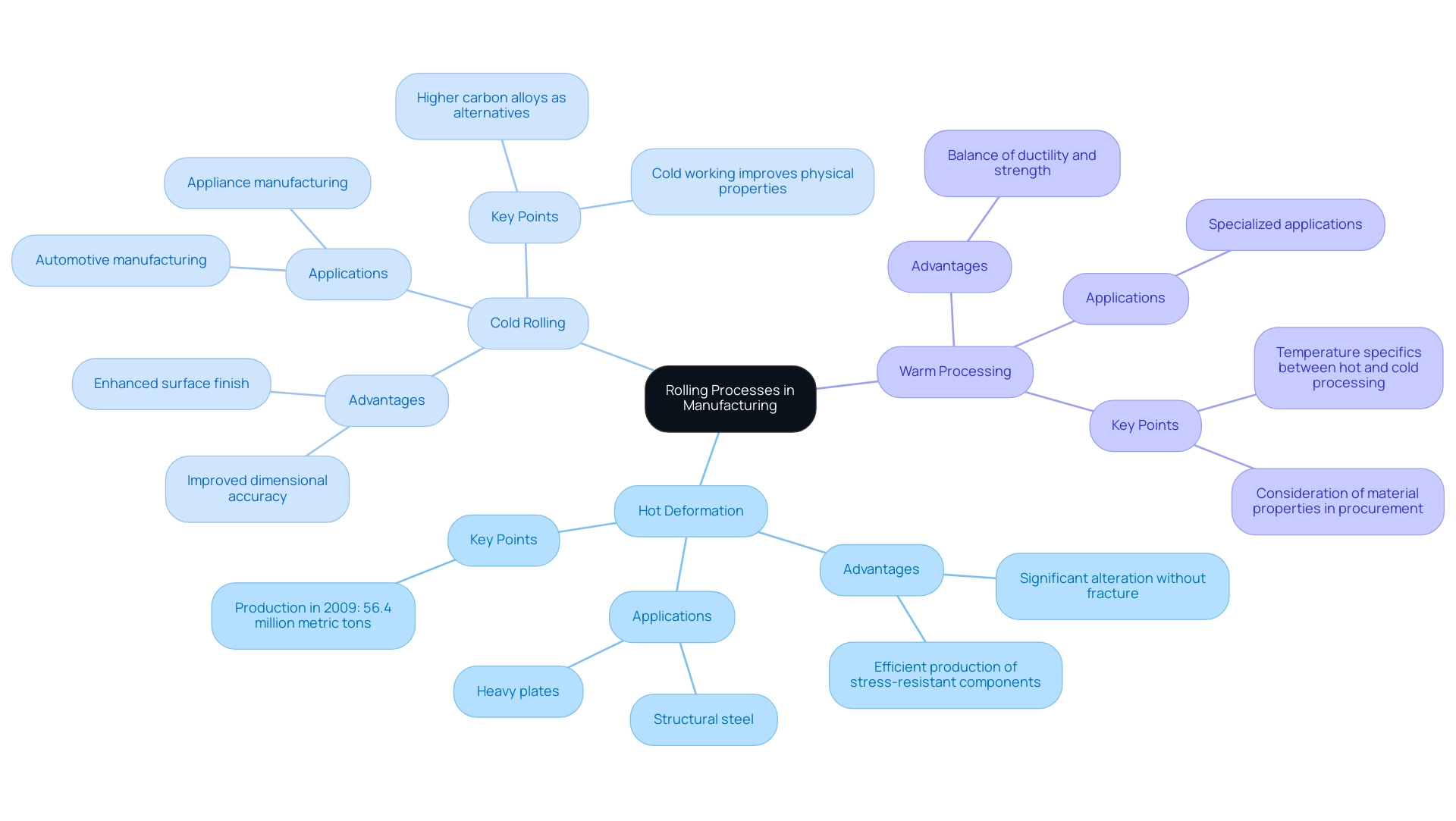

Understanding Different Rolling Processes in Manufacturing

Manufacturing utilizes different deformation techniques, each with unique advantages and applications:

- Hot Deformation: This method involves shaping at elevated temperatures, allowing significant alteration without the risk of fracture. Commonly utilized for structural steel and heavy plates, it allows for the efficient production of components that can withstand significant stresses. In fact, the production of hot rolled steel products in the U.S. reached 56.4 million metric tons in 2009, reflecting its critical role in the industry.

- Cold Rolling: Executed at room temperature, cold rolling enhances both surface finish and dimensional accuracy. The process is particularly valuable in automotive and appliance manufacturing, where precise specifications are crucial. Recent discussions in the industry highlight that cold working can significantly enhance the physical properties of substances, making them more suitable for demanding applications. This improvement is critical for procurement managers when selecting materials that must meet stringent performance standards. If cold rolled steel is not available, considering higher carbon alloys can be an effective alternative to maintain desired physical properties in finished products.

- Warm Processing: Positioned between hot and cold processing, this method occurs at temperatures lower than those used in hot processing but higher than room temperature. It offers a favorable balance of ductility and strength, making it ideal for specialized applications, as various types of rolling techniques have distinct implications for the mechanical properties of the finished products. For instance, the limitations of hot rolled 1215 steel highlight the need for careful consideration of properties in procurement decisions, especially given that this steel may not respond effectively to heat treatment due to its low carbon content. Grasping these procedures is vital for making informed choices regarding material specifications and suitability for various manufacturing applications.

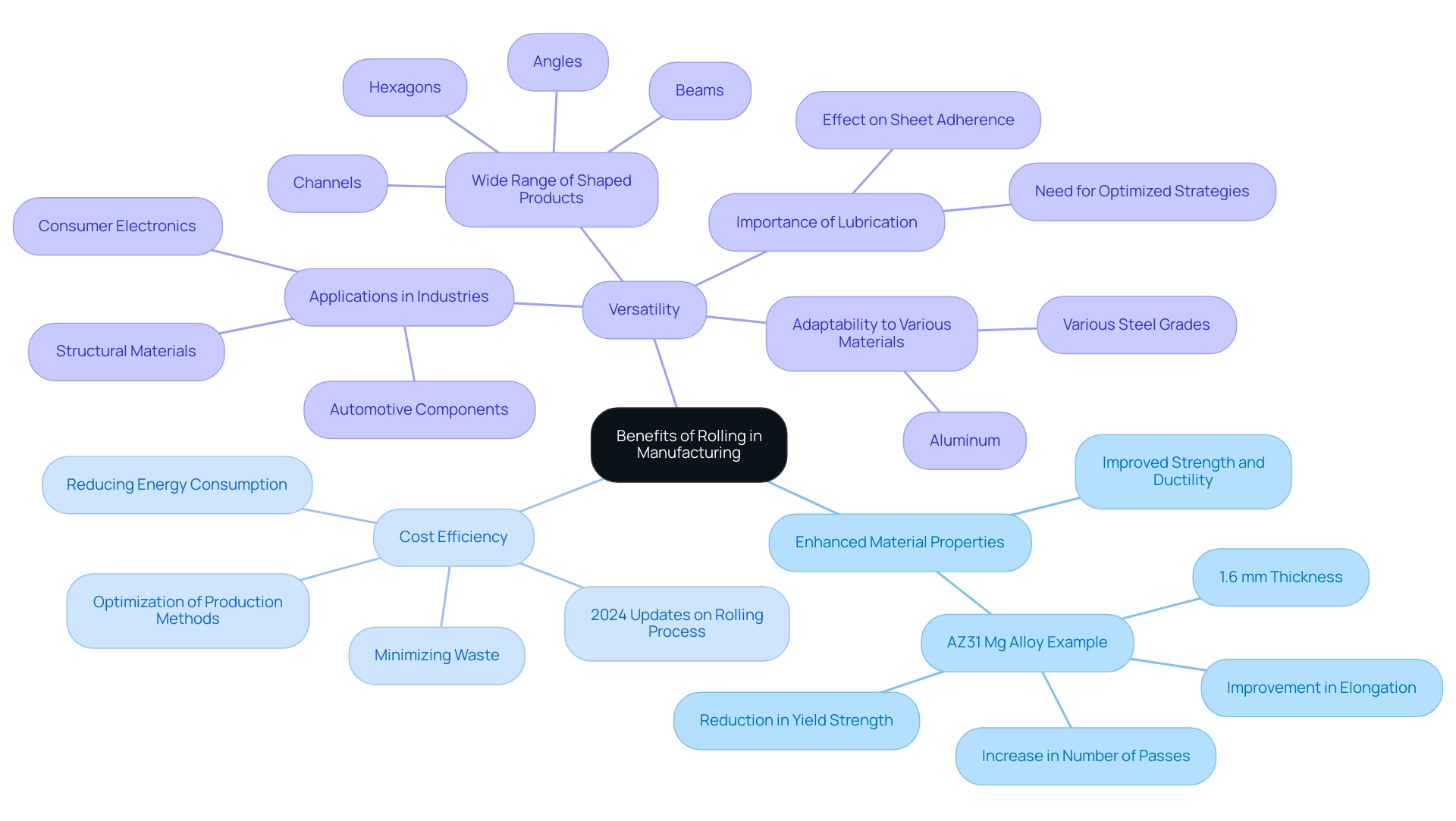

The Benefits and Applications of Rolling in Manufacturing

The process of deformation offers numerous benefits within the manufacturing sector, including:

- Enhanced Material Properties: This technique effectively improves the mechanical characteristics of metals, such as strength and ductility. For instance, research has shown that the AZ31 Mg alloy with a thickness of 1.6 mm exhibited a reduction in yield strength while demonstrating improved elongation with an increase in the number of passes. This demonstrates how controlled deformation, which combines heat treating and regulated shaping, can optimize material performance and enhance mechanical properties.

- Cost Efficiency: The procedure greatly aids in cost savings by optimizing production methods. By minimizing waste and reducing energy consumption, manufacturers can achieve lower operational costs. Recent updates in 2024 highlight that optimization strategies within the types of rolling process have resulted in heightened cost efficiency, reflecting the industry’s ongoing commitment to financial prudence.

- Versatility: The types of rolling are adaptable to a wide variety of substances, ranging from aluminum to various steel grades, thus providing a flexible manufacturing solution. It produces a variety of shaped products, including angles, channels, beams, and hexagons, which are essential in many industries. Its widespread applications include automotive components, structural materials, and consumer electronics, where quality and performance are critical. The significance of lubrication during hot processing further highlights the necessity for optimized strategies, as improper lubrication can lead to sheet adherence, negatively impacting product quality. A case study emphasizes that inadequate lubrication at elevated temperatures can elevate the chances of sheet adherence, highlighting the crucial importance of control in achieving successful outcomes while maximizing formability.

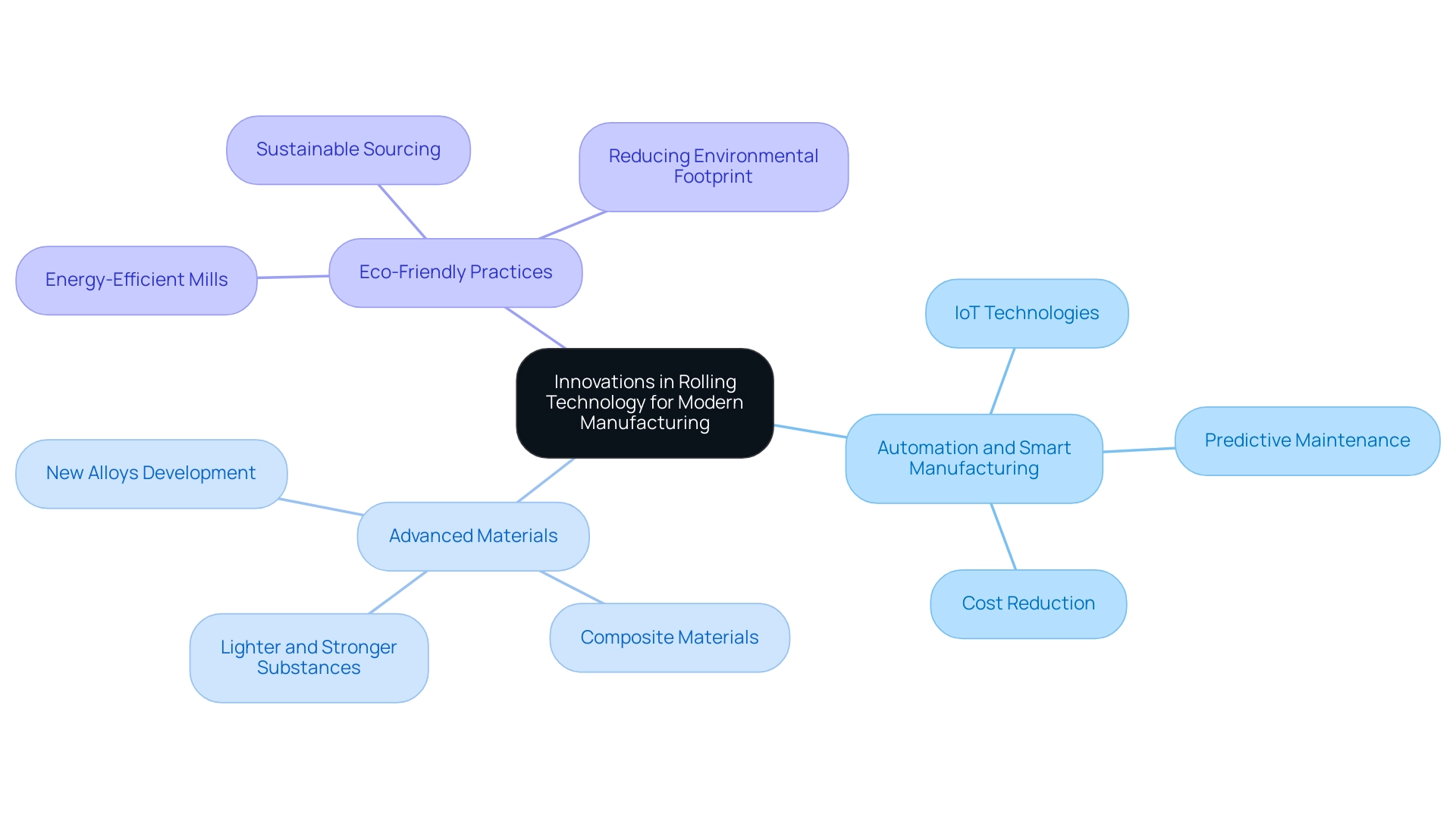

Innovations in Rolling Technology for Modern Manufacturing

Recent advancements in information technology are transforming the landscape of the manufacturing sector, particularly within the cold mill market, which is crucial for the global steel industry. Key innovations include:

- Automation and Smart Manufacturing: The integration of IoT technologies has revolutionized operations by enabling real-time monitoring and data analytics. This facilitates predictive maintenance, significantly enhancing operational efficiency. Erin Thompson, an industry expert, emphasizes this shift, stating, “Learn how automated solutions can enhance efficiency, reduce costs, and improve accuracy in warehouse operations.” By adopting these technologies, manufacturers streamline processes and mitigate the risk of costly downtime.

- Advanced Materials: Ongoing development of new alloys and composites is pushing the boundaries of forming capabilities. These advancements result in the development of lighter and stronger substances suitable for a variety of applications, meeting the demands of modern manufacturing.

- Eco-Friendly Practices: With the construction sector accountable for a staggering 37% of global emissions, innovations aimed at reducing the environmental footprint of processing methods are gaining momentum. Energy-efficient mills and sustainable sourcing of materials are becoming pivotal practices for manufacturers committed to eco-friendly operations. The cold rolling mill market is actively innovating with different types of rolling to meet these environmental challenges, reflecting a broader industry trend towards sustainability.

Furthermore, insights from the case study titled “Recent Trends in the Cold Rolling Mill Market” reveal that the market is dynamically adapting to these innovations, highlighting ongoing efforts to innovate and effectively meet the evolving demands of the steel industry.

Staying abreast of these developments is essential for manufacturers seeking to optimize their processes and maintain a competitive edge in a rapidly evolving market.

Conclusion

The types of rolling in manufacturing are more than basic techniques—they’re strategic tools that shape success. Understanding hot, cold, and warm rolling allows procurement managers to choose the right method for the right job. Each has distinct benefits, from cost savings to material precision.

The selection of rolling mills—two-high, three-high, four-high, or cluster—also impacts output and efficiency. Staying informed on new technologies, materials, and eco-friendly practices will help manufacturers stay competitive.

Ultimately, types of rolling in manufacturing remain a foundation of industrial production. Embracing innovation while mastering the fundamentals will ensure long-term success.