Blogs

DOMADIA™ CuNi30Mn1Fe Alloy UNS C71500: Built to Brave the Impossible

The Alloy Designed to Handle the Toughest Challenges

Imagine a material created to survive the harshest oceans, the hottest industrial plants, and the toughest weather conditions. DOMADIA™ CuNi30Mn1Fe is that material — a Copper-Nickel alloy crafted to deliver outstanding performance where others fail. If you need strength, reliability, and endurance, you’re in the right place. Let’s dive into the 4 W’s and discover why this alloy stands apart!

What is DOMADIA™ CuNi30Mn1Fe?

DOMADIA™ CuNi30Mn1Fe is a superhero in the metal world — a Copper-Nickel-Manganese-Iron alloy designed for superior corrosion resistance, durability, and performance. It proudly meets the standards of EN 1652 and ASTM B122 and is tagged under EN CW 354H and UNS C71500. Crafted for those who build the future, this material knows no limits.

🔍 Are copper and nickel the same? No — copper and nickel are two distinct metals. However, when combined, they form powerful alloys like DOMADIA™ CuNi30Mn1Fe, where their complementary strengths create enhanced corrosion resistance and mechanical integrity.

Chemical Composition

| Element | Composition (%) |

| Copper (Cu) | 68.5 – 71.5% |

| Nickel (Ni) | 29.0 – 32.0% |

| Manganese (Mn) | 0.5 – 1.0% |

| Iron (Fe) | 0.4 – 1.0% |

| Others (Total) | 0.5% max |

Why is DOMADIA™ CuNi30Mn1Fe the Alloy of Champions?

Because when the going gets tough, the tough get DOMADIA™ CuNi30Mn1Fe.

- Corrosion? What Corrosion? This alloy laughs at seawater, salt solutions, and even aggressive chemicals.

- Built Tough: It holds its ground under high pressures and extreme temperatures.

- Smart Thermal Behaviour: Temperature swings? No sweat — it maintains its mechanical integrity.

- Lifetime Savings: Invest once, save on repairs, replacements, and downtime.

In an unpredictable world, DOMADIA™ CuNi30Mn1Fe is your steady, strong partner.

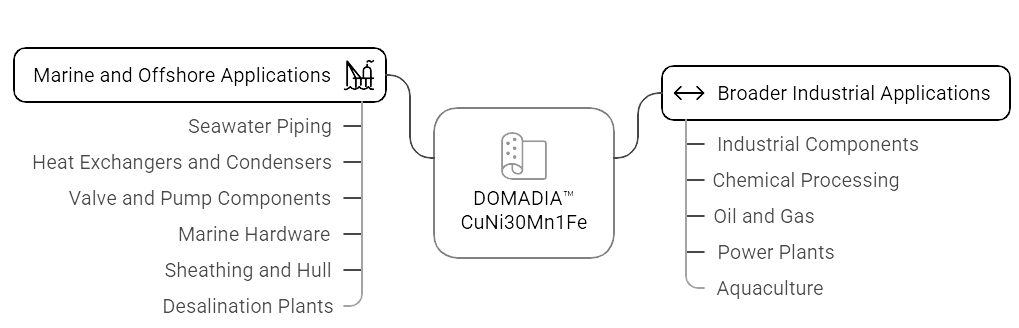

Where Can You Find DOMADIA™ CuNi30Mn1Fe in Action?

Marine and Offshore Applications:

- Seawater Piping: Ideal for piping systems in ships, offshore platforms, and desalination plants due to its exceptional seawater corrosion resistance.

- Heat Exchangers and Condensers: Widely used in marine heat exchangers and condensers, including in power plants and ships.

- Valve and Pump Components: Trusted for marine valves and pumps thanks to its erosion resistance against flowing seawater.

- Marine Hardware: Perfect for fittings, flanges, and other essential hardware exposed to harsh marine environments.

- Sheathing and Hull: Applied for boat sheathing and hulls, especially in premium-quality vessels.

- Desalination Plants: A popular choice for handling desalinated and seawater processes.

Broader Industrial Applications:

- Industrial Components: Utilized in pump impellers, heat exchanger tubes, and evaporator tubes.

- Chemical Processing: Resistant to a wide range of acids and waters, making it ideal for chemical processing equipment.

- Oil and Gas: Perfect for oil and gas systems where strength and corrosion resistance are essential.

- Power Plants: Used for condensers and heat exchangers in high-stress environments.

- Aquaculture: Applied in fish cages and equipment for seawater aquaculture setups.

Key Features Contributing to its Applications:

- Excellent Corrosion Resistance: Outstanding protection against seawater corrosion and impingement attack.

- High Strength: Medium to high mechanical strength for demanding industrial needs.

- Resistance to Erosion: Effectively withstands the erosive effects of flowing seawater.

- Good Fabric ability: Easily fabricated into diverse forms without compromising performance.

- Stress Corrosion Resistance: Excellent resistance to chloride-induced stress corrosion cracking.

If it’s tough, wet, corrosive, or high-stress, DOMADIA™ CuNi30Mn1Fe is already there, working overtime.

Who Needs DOMADIA™ CuNi30Mn1Fe?

- Marine Engineers who need ship components that don’t rust away.

- Designers and Architects craving strength without sacrificing style.

- Industrial Operators demanding materials that handle punishment.

- Project Managers tired of surprise repairs and maintenance.

If you’re serious about performance, you need a material that’s equally serious — DOMADIA™ CuNi30Mn1Fe.

Equivalent Grade Designation

- CuNi 70/30

- Alloy 70/30

- UNS C71500

- EN DIN 2.0882

- EN CuNi30Mn1Fe

- DIN CEN/TS 13388

- EN CW354H

Properties and Technical Specifications

| Property | Value |

| Material Name | CuNi30Mn1Fe |

| Standards | EN 1652 / ASTM B122 |

| Material No. | EN CW 354H / UNS C71500 |

| Density | ~8.95 g/cm³ |

| Melting Range | 1170°C – 1240°C |

| Electrical Conductivity | 4 – 7 % IACS |

| Thermal Conductivity | ~30 W/m.K |

| Tensile Strength | 360-500 MPa |

| Yield Strength | 130-270 MPa |

| Elongation | ≥ 30% |

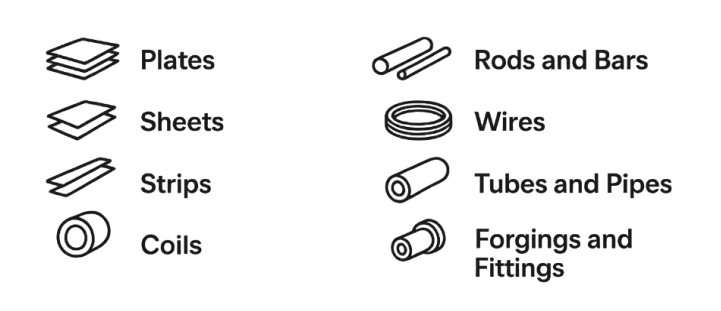

Forms Available

DOMADIA™ offers a tailored form for every mission-critical application.

Conclusion

When ordinary metals surrender, DOMADIA™ CuNi30Mn1Fe doubles down. Built for harsh realities and visionary projects, it’s the ultimate material for industries that simply cannot afford to compromise. Ready to unleash the power?

Choose DOMADIA™ CuNi30Mn1Fe — because “impossible” is just a starting point.

👉 Explore the possibilities with DOMADIA™ CuNi30Mn1Fe today. Have a project in mind or looking for technical consultation?

Visit: https://domadia.net/

Get in touch with our experts and let us help you turn material challenges into performance milestone.

Talk to: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia