Blog

How to Choose and Use Monel Threaded Rods: A Step-by-Step Guide

Overview

To choose and use Monel threaded rods effectively, one must consider factors such as size, alloy grade, application environment, and load requirements, followed by a detailed installation and maintenance process. The article emphasizes that understanding these elements ensures optimal performance and durability in various industries, supported by specific guidelines for installation and maintenance practices to enhance the longevity of these fasteners.

Introduction

In the world of industrial applications, the selection of materials can significantly impact the performance and longevity of projects. Among the most reliable options available are Monel threaded rods, crafted from a unique nickel-copper alloy that offers exceptional resistance to corrosion and remarkable strength under extreme conditions.

This article delves into the composition, benefits, and applications of Monel threaded rods, providing critical insights for procurement managers navigating the complexities of material selection.

From understanding the nuances of different grades to the meticulous installation and maintenance practices essential for optimal performance, this comprehensive guide equips professionals with the knowledge needed to leverage Monel’s advantages across various demanding environments.

With a focus on practical solutions, it aims to enhance decision-making processes, ensuring that projects not only meet but exceed expectations.

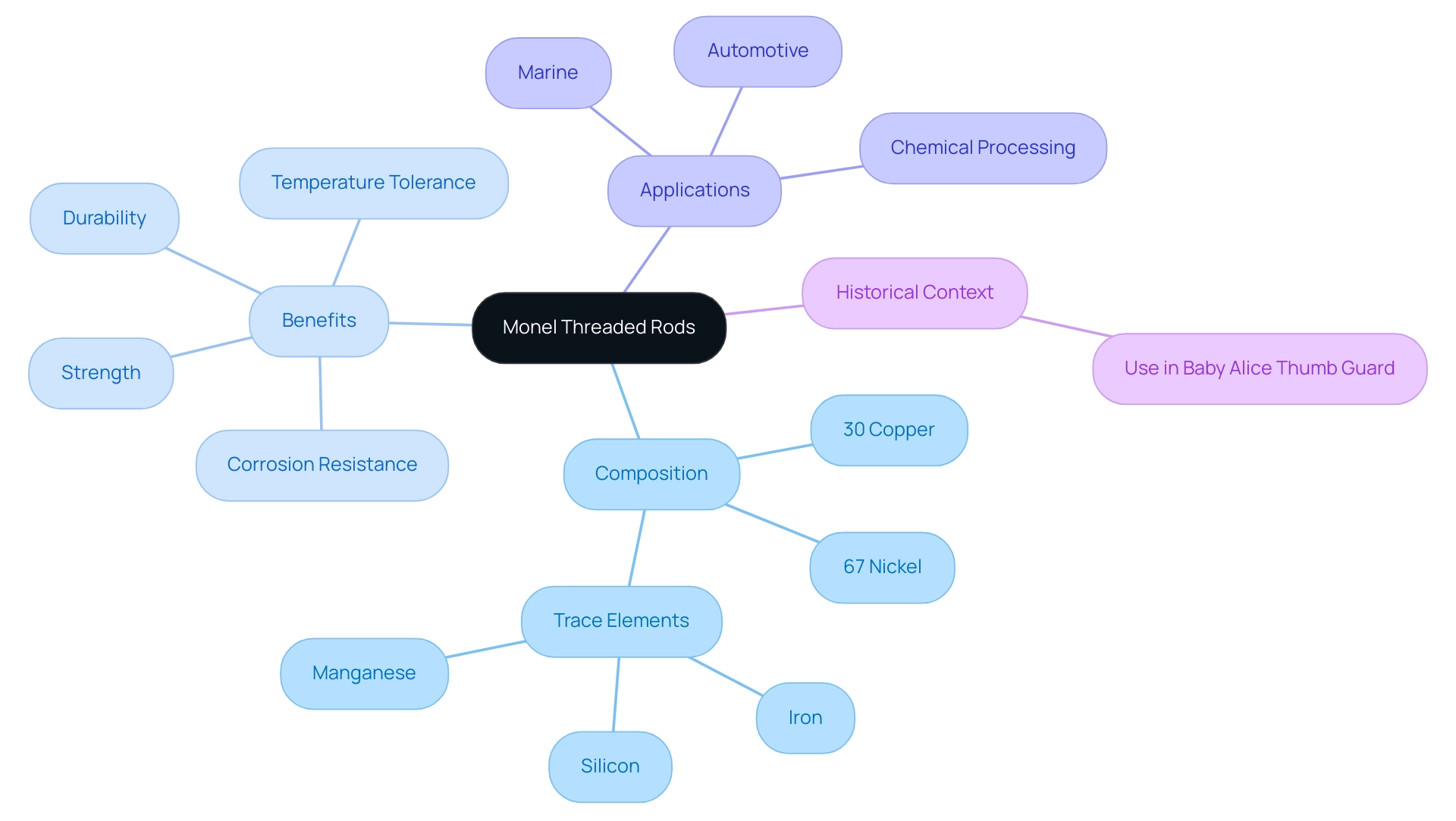

Understanding Monel Threaded Rods: Composition and Benefits

Monel threaded rods, which are made from a nickel-copper alloy, demonstrate remarkable resistance to corrosion, exceptional strength, and the ability to withstand extreme temperatures. Typically, the alloy composition comprises approximately 67% nickel and 30% copper, augmented by trace amounts of iron, manganese, and silicon. These intrinsic properties make the monel threaded rod particularly suitable for marine applications, chemical processing, and other challenging environments.

A historical example of the material’s utility is its use in the Baby Alice Thumb Guard, a 1930s-era anti-thumb-sucking device, showcasing its long-standing reliability. The benefits of using durable fasteners like monel threaded rod are considerable; they show great durability, excellent resistance to pitting and stress corrosion cracking, and the capacity to uphold structural integrity under high-pressure conditions. At Domadia, we offer a diverse range of copper nickel alloys, including Monel® (Alloy 400, Alloy 500) and Alloy C22, along with monel threaded rod, specifically designed for various applications across the marine, automotive, and electrical industries.

For procurement managers, a thorough understanding of these characteristics is vital when selecting the appropriate material to meet project specifications, especially in scenarios where longevity and reliability are paramount. We invite you to explore our extensive product catalog to find the perfect solution for your project needs.

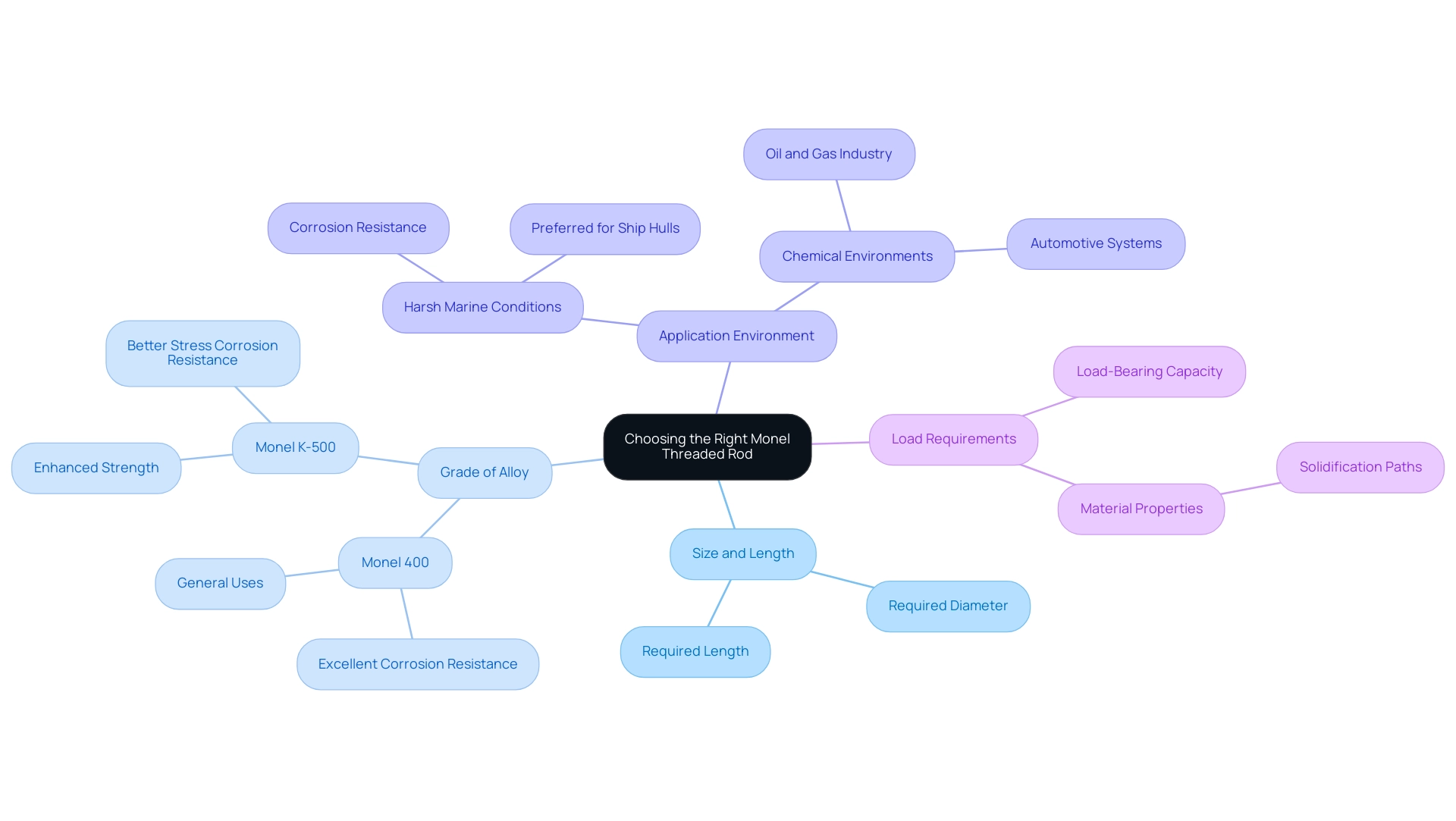

Choosing the Right Monel Threaded Rod: Key Considerations

When selecting Monel threaded rods, several critical factors must be taken into account to ensure optimal performance for your specific application:

Size and Length: It is essential to determine the required diameter and length based on your project specifications. Alloy rods are available in various sizes; therefore, selecting the appropriate dimensions is crucial for functionality and compatibility with existing components.

Grade of Alloy: Different grades exhibit distinct properties. For instance, the Monel threaded rod made from Monel 400 is well-suited for general uses due to its excellent corrosion resistance, while the Monel threaded rod made from Monel K-500 provides enhanced strength and better resistance to stress corrosion cracking. Understanding these differences can significantly impact the effectiveness of your application.

Application Environment: Evaluate the environmental conditions in which the rods will be utilized. Certain alloys are particularly effective in harsh marine and chemical environments, thanks to their superior resistance to corrosion. Similarly, copper nickel alloys are preferred in marine engineering for components such as ship hulls and seawater piping systems, due to their exceptional performance against corrosion compared to stainless steel. Their outstanding corrosion resistance and durability make them a favored choice in industries like oil and gas, where reliability is paramount. Additionally, copper nickel alloys are utilized in automotive systems, electronics, heat exchangers, and even coinage, showcasing their versatility across various sectors. As mentioned in a case study titled ‘Metals in Modern Uses,’ this alloy is utilized in various contexts, including kitchen sinks and oilfield drill collars, emphasizing its versatility despite a decrease in usage relative to newer materials.

Load Requirements: Analyze the load-bearing capacity required for your project. While these metal bars are recognized for their strength, it is essential to comprehend the load specifications to guarantee safety and performance under operational conditions. A crucial comprehension of solidification paths, as mentioned by Prof. John Dupont, highlights the significance of material properties in load-bearing contexts.

By carefully evaluating these factors, you can guarantee the choice of high-quality metal fasteners that not only meet but surpass your project’s needs, improving durability and performance. Additionally, considering the advantages of copper nickel alloys in specific applications can provide a strategic edge in material selection for demanding environments.

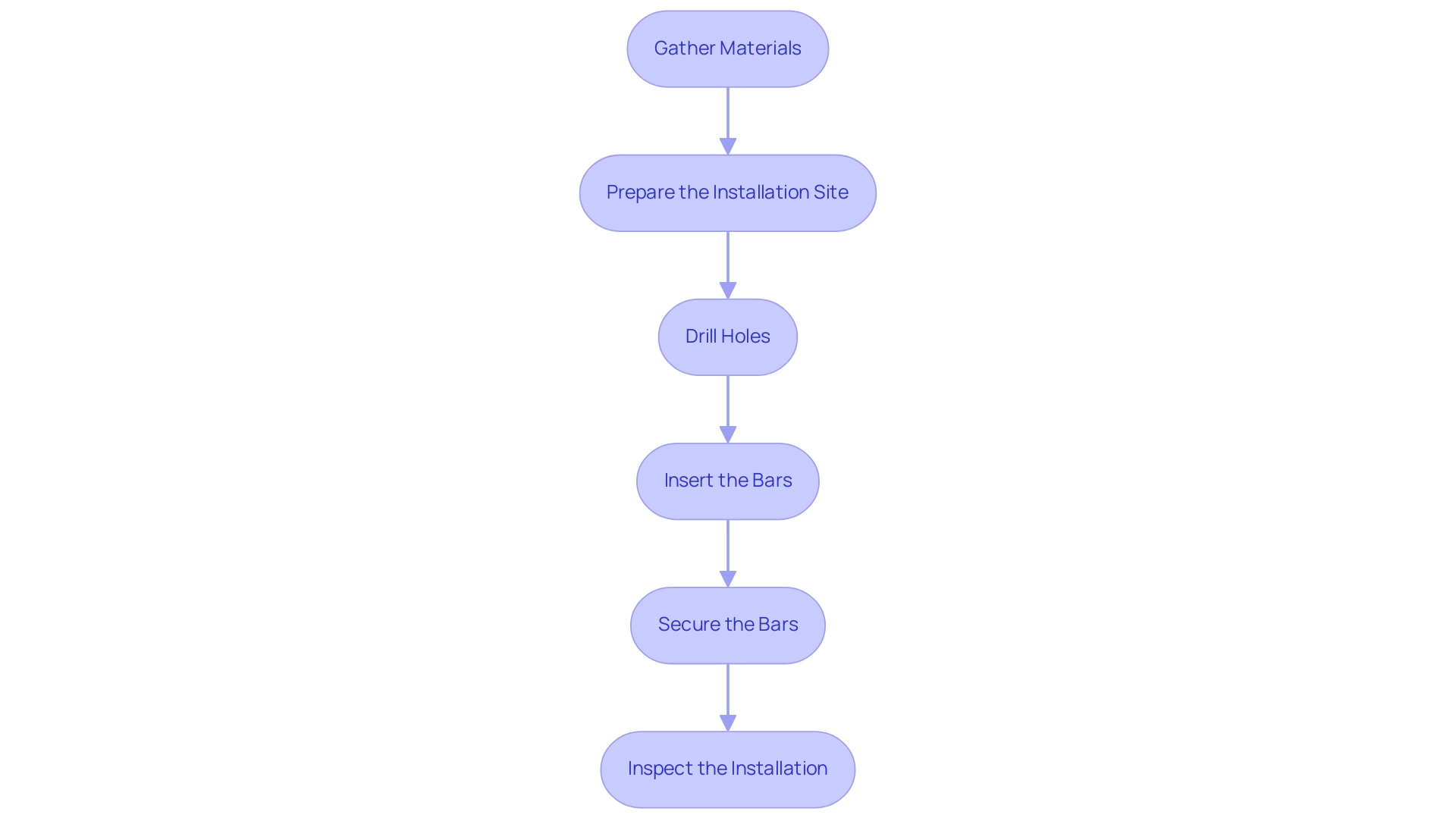

Step-by-Step Guide to Installing Monel Threaded Rods

Installing specialized metal fasteners requires meticulous attention to detail and the appropriate tools. Follow this comprehensive guide to ensure a successful installation:

- Gather Materials: Begin by collecting essential tools, including a high-quality wrench, a power drill, and suitable fasteners such as nuts and washers that match the rod specifications.

Consider using wedge anchors, rod hangers, monel threaded rod, or back plates for added security in concrete applications.

Prepare the Installation Site: Thoroughly clean the installation area to remove debris, dust, or any contaminants that could compromise the integrity of the installation.

Drill Holes: Utilize the power drill to create holes in the material where the supports will be anchored.

It is essential that the holes are drilled to the correct diameter to fit the monel threaded rod effectively.

Insert the Bars: Carefully thread the Monel bars into the pre-drilled holes, ensuring they are properly aligned to maintain structural integrity during use.

Secure the Bars: Utilize nuts and washers to firmly fasten the bars in position. Use the wrench to tighten them adequately, but exercise caution to avoid over tightening, which could damage the material or the rod itself.

Remember that matching the nuts to the rod pitch is vital for ensuring performance and longevity, as highlighted in the case study on rod pitch.

Inspect the Installation: Once the installation is complete, conduct a thorough inspection for any loose fittings or misalignments. This stage is essential for guaranteeing the efficiency and durability of the alloy fasteners.

Statistics indicate that these fasteners are extensively utilized across numerous sectors, such as general construction, electrical installation, and automotive assembly. By following these guidelines, you will improve the reliability of your installations, making them suitable for various applications in industries such as automotive, aviation, and construction.

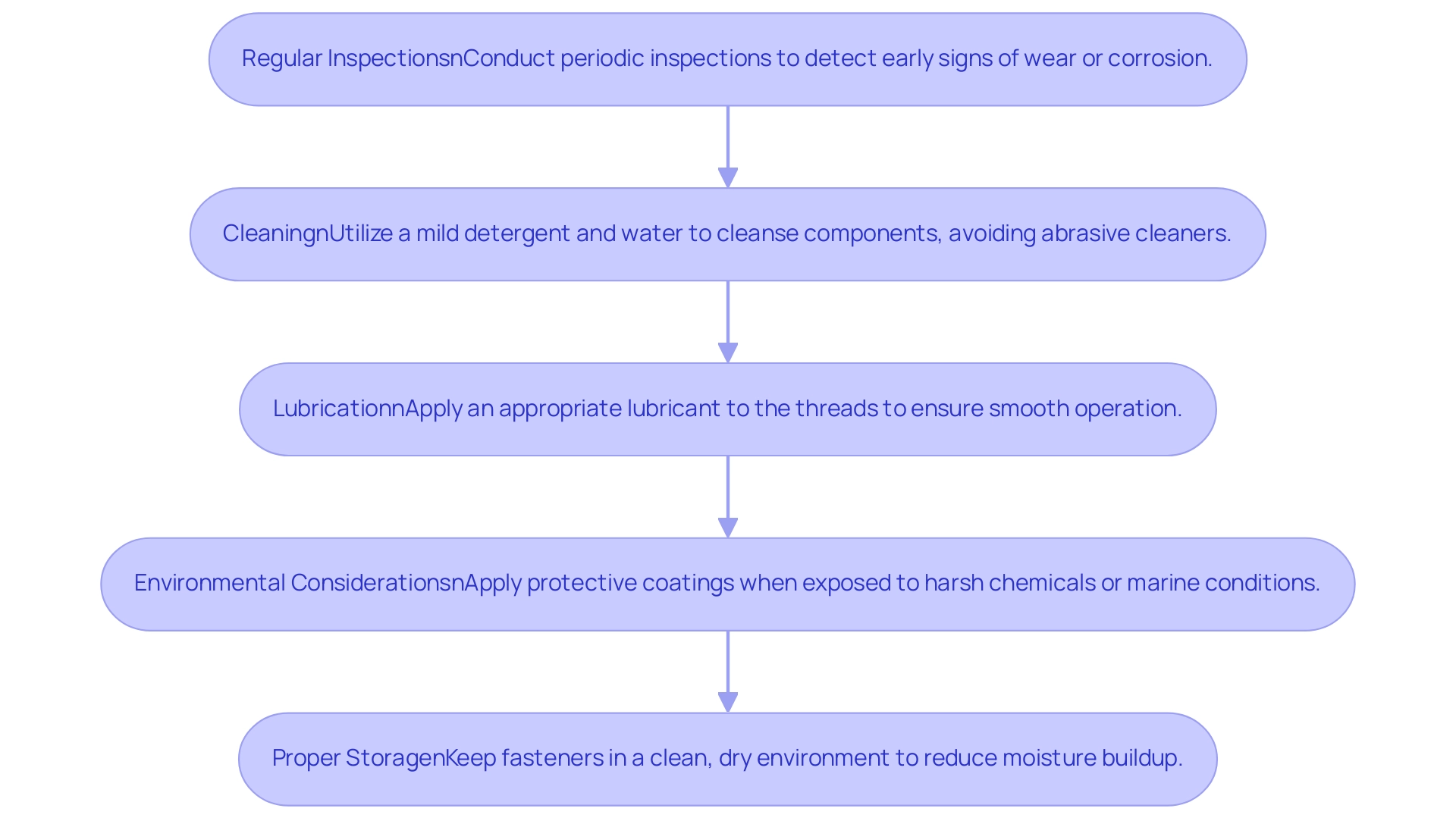

Maintaining Your Monel Threaded Rods for Optimal Performance

To guarantee the best performance and durability of these fasteners, it is crucial to adopt a thorough maintenance plan. Here are key practices to follow:

Regular Inspections: Conduct periodic inspections to detect any early signs of wear or corrosion.

Proactive identification of issues can prevent costly repairs and ensure uninterrupted operations. For example, a case study on maintenance methods for Monel threaded rod revealed that routine inspections resulted in a 30% decrease in unforeseen failures.Cleaning: Utilize a mild detergent and water to cleanse the components, carefully removing contaminants that may contribute to deterioration.

It is crucial to avoid abrasive cleaners, as they can scratch the surface and compromise the material’s integrity.Lubrication: Where applicable, apply an appropriate lubricant to the threads.

This step is vital for ensuring smooth operation and preventing seizing, which can be detrimental to functionality. As mentioned by materials specialists, proper lubrication practices can significantly extend the service life of threaded components.Environmental Considerations: When alloy bars are exposed to harsh chemicals or marine conditions, consider applying additional protective coatings to enhance their corrosion resistance.

The corrosion rates of this alloy in various environments can vary dramatically; for example, its performance in marine environments is notably different from that in chemical processing settings.Proper Storage: Keep metal fasteners in a clean, dry environment to reduce moisture buildup, a key contributor to corrosion formation.

By following these maintenance practices, you can greatly prolong the service life and dependability of the Monel threaded rod fasteners, ensuring they operate efficiently in challenging environments.

According to materials experts, regular maintenance not only enhances performance but also reduces the likelihood of unexpected failures.

As one specialist mentioned, “Establishing a systematic maintenance schedule is essential to enhancing the longevity of these alloys in industrial settings.

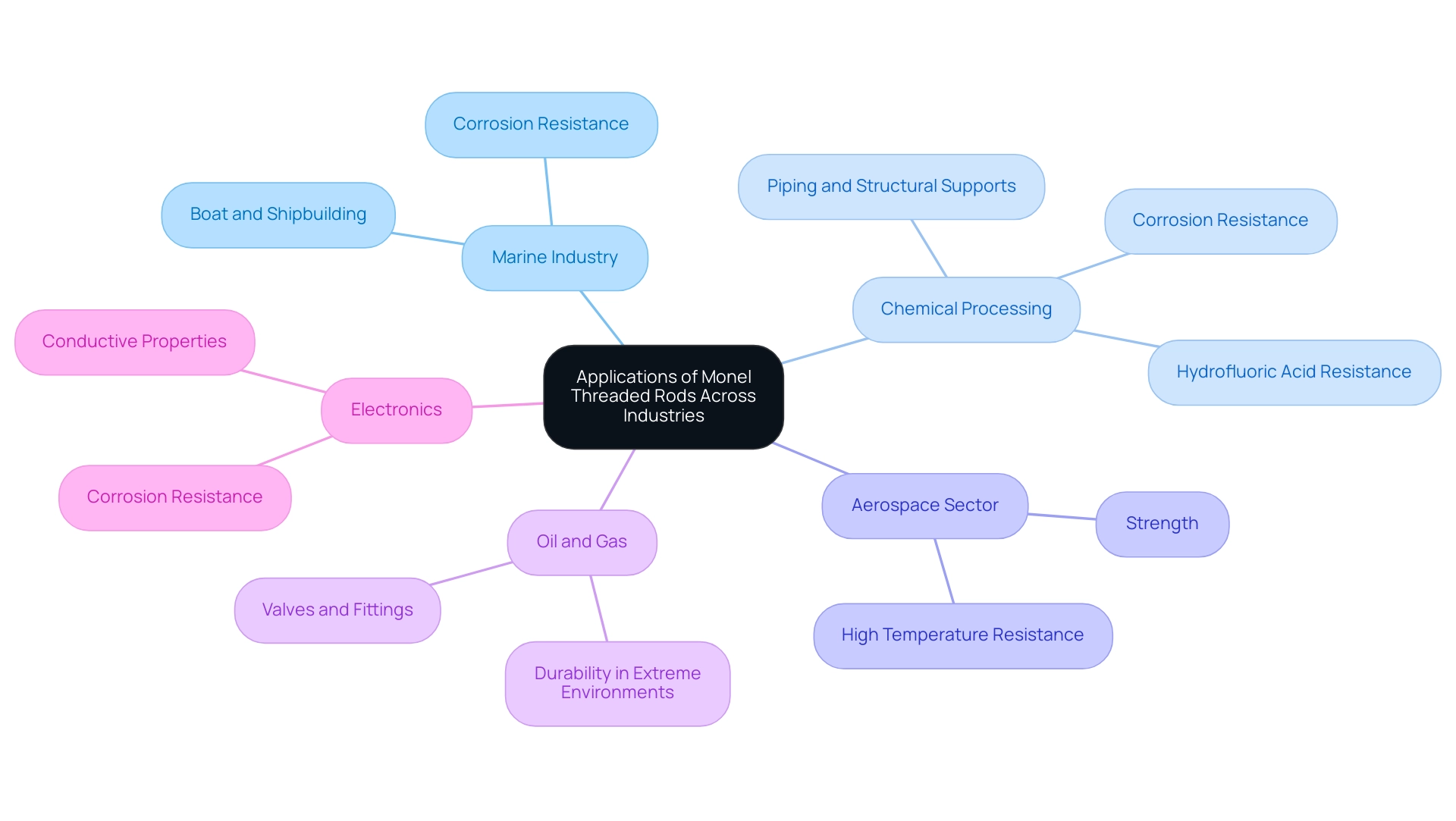

Applications of Monel Threaded Rods Across Industries

Monel threaded rod, which consists of nickel and copper, is highly sought after across various industries due to its exceptional properties, making it a preferred choice for numerous applications. Key areas of usage include:

Marine Industry: This exceptional alloy’s outstanding corrosion resistance positions it as an ideal material for boat and shipbuilding, particularly in components that are routinely exposed to seawater.

Chemical Processing: In chemical plants, these rods serve critical roles in piping and structural supports, where they consistently withstand harsh corrosive substances. Notably, this alloy socket head cap screws demonstrate remarkable resistance to hydrofluoric acid in all concentrations up to the boiling point, underscoring their value in demanding chemical environments. For instance, the alloy’s resistance to hydrofluoric acid positions it as one of the most durable specialty metals for uses involving this hazardous chemical.

Aerospace Sector: The aerospace sector benefits from monel threaded rods made of a specific alloy due to their strength and capacity to withstand high temperatures, making them appropriate for a range of uses.

Oil and Gas: The durability of this material in extreme environments makes it indispensable in the oil and gas industry, particularly for valves and fittings that require reliable performance under pressure.

Electronics: The conductive properties and corrosion resistance of this material also find applications in electronic components, enhancing the performance and longevity of devices.

Additionally, monel threaded rod of this type typically come in a nominal size diameter of 2.0000 with a thread pitch of 0.500, which procurement managers should consider when selecting materials. The MP35N specifications, including AMS 5844, AMS 5845, AMS7468, ASTM F562, and NACE MR0175, further confirm Monel’s compliance with industry standards.

By understanding these diverse applications and specifications, procurement managers can strategically select the right materials to meet the specific requirements of their projects.

Conclusion

Monel threaded rods stand out as a premier choice for various industrial applications due to their unique composition and exceptional properties. The nickel-copper alloy not only provides remarkable resistance to corrosion but also ensures strength and durability under extreme conditions. Understanding the nuances of different grades and the specific environmental factors at play is crucial for procurement managers in making informed material selections that align with project specifications.

In addition to selecting the appropriate grade and size, meticulous installation practices are essential for maximizing the performance of Monel threaded rods. Following a step-by-step installation guide and implementing a robust maintenance strategy can significantly enhance the longevity and reliability of these materials. Regular inspections, proper cleaning, and appropriate lubrication all contribute to maintaining optimal performance, preventing costly repairs, and ensuring uninterrupted operations.

The versatility of Monel threaded rods across industries such as marine, chemical processing, aerospace, and oil and gas underscores their value in demanding environments. By leveraging the advantages of Monel and adhering to best practices in selection, installation, and maintenance, procurement managers can effectively meet the challenges of their projects, ensuring that they not only fulfill but exceed expectations. Investing in Monel threaded rods is a strategic decision that promises durability and performance, ultimately leading to successful project outcomes.