Blogs

Understanding Mumetal Shielding for Telegraph Cables: A Complete Tutorial

Overview

Mumetal shielding is crucial for telegraph cables as it effectively reduces electromagnetic interference (EMI) due to its high permeability and low coercivity, ensuring clear signal transmission over long distances. The article supports this by detailing Mumetal’s composition and properties, along with its applications in various industries, highlighting its importance in maintaining the integrity of sensitive electronic communications.

Introduction

Mumetal, an alloy celebrated for its exceptional magnetic shielding properties, has become indispensable across various industries, from telecommunications to advanced medical equipment. Comprising primarily nickel, along with iron, copper, and molybdenum, this unique composition equips Mumetal with high permeability and low coercivity, making it a formidable barrier against electromagnetic interference (EMI).

As the demand for reliable shielding solutions grows, understanding Mumetal’s fundamental characteristics, its diverse applications, and the challenges associated with its use is crucial for procurement managers seeking to enhance product performance and reliability.

This article delves into the key attributes of Mumetal, its historical evolution, and best practices for sourcing and installation, providing valuable insights for those navigating the complexities of electromagnetic shielding in today’s technology-driven landscape.

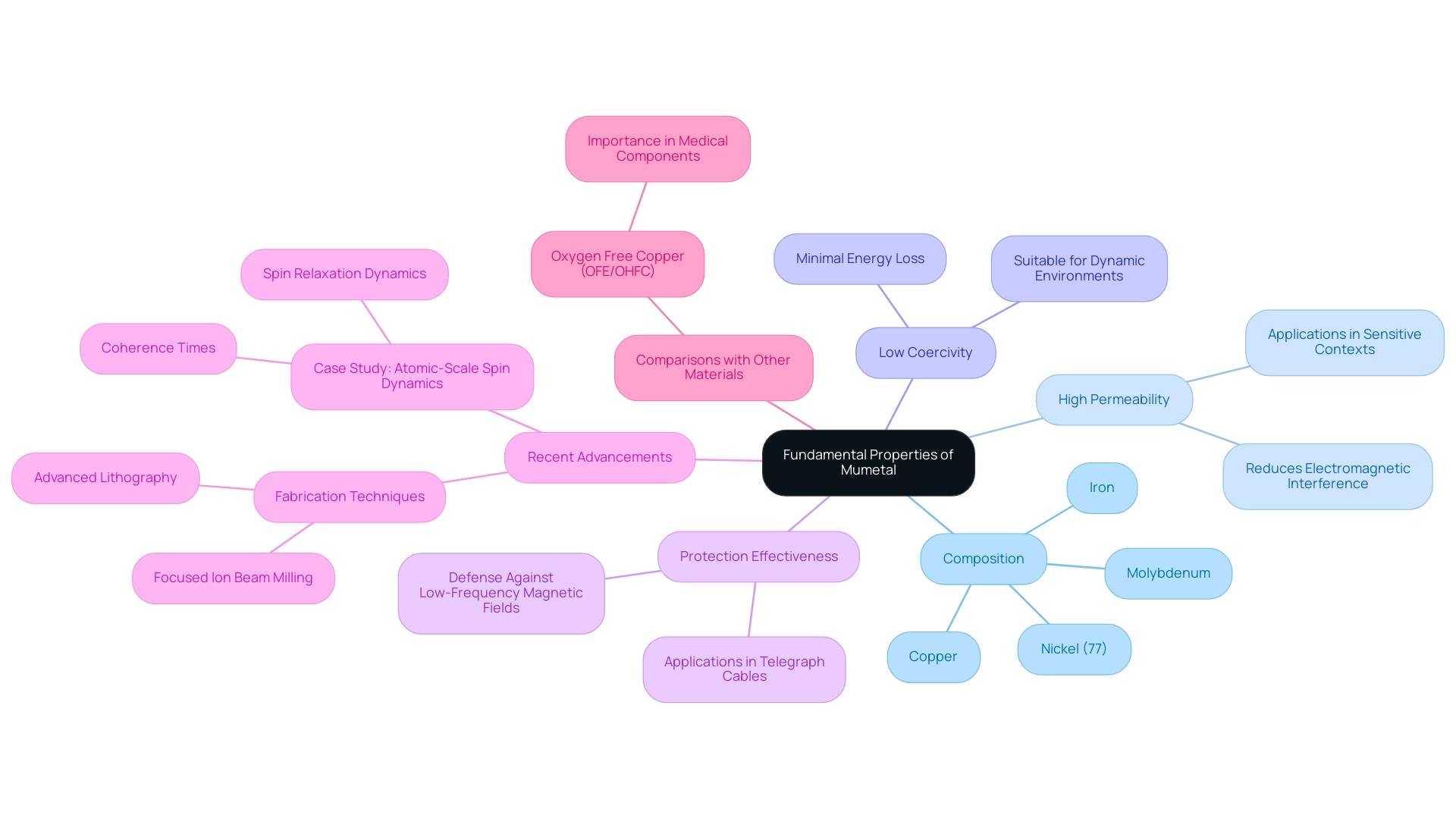

Fundamental Properties of Mumetal: Key Characteristics for Shielding

This specialized alloy is primarily composed of approximately 77% nickel, supplemented with iron, copper, and molybdenum. This unique composition imparts several essential characteristics that make it highly effective for magnetic protection uses:

- High Permeability: This feature enables the alloy to adeptly redirect magnetic fields, significantly reducing electromagnetic interference, which is crucial in sensitive contexts.

- Low Coercivity: The material exhibits a remarkable ability to be magnetized and demagnetized with minimal energy loss, rendering it exceptionally suited for dynamic environments where performance consistency is vital.

- Excellent Protection Effectiveness: The alloy’s distinctive properties provide superior defense against low-frequency magnetic fields, which is crucial for mumetal shielding for telegraph cables that are particularly vulnerable to interference.

Recent advancements in fabrication techniques, including those mentioned by Dennis V Christensen, allow for the development of more complex and compact sensing devices, further enhancing the applicability of this material in high-tech environments. For example, the case study on Atomic-Scale Spin Dynamics emphasizes the capacity to resolve spin behavior at atomic scales, which may utilize the unique properties of the material to examine spin relaxation dynamics and coherence times.

Furthermore, recent fold tests suggest that the ChRM was obtained before any tilting, reinforcing the dependability of directional analysis in contexts involving the material. These features render this material a highly favored option for protective uses across various industries, particularly where accuracy and dependability are essential. Its continuous improvements in characteristics further expand its usage range, preserving its position as a top choice in electromagnetic protection solutions.

In relation to other specialized substances, like Oxygen Free Copper (OFE/OHFC), which is vital for crucial medical components, this alloy provides unique benefits in magnetic protection that are important for delicate electronic uses. Integrating this magnetic alloy with other high-temperature insulation materials can further enhance performance in demanding environments, showcasing its versatility and importance in the market.

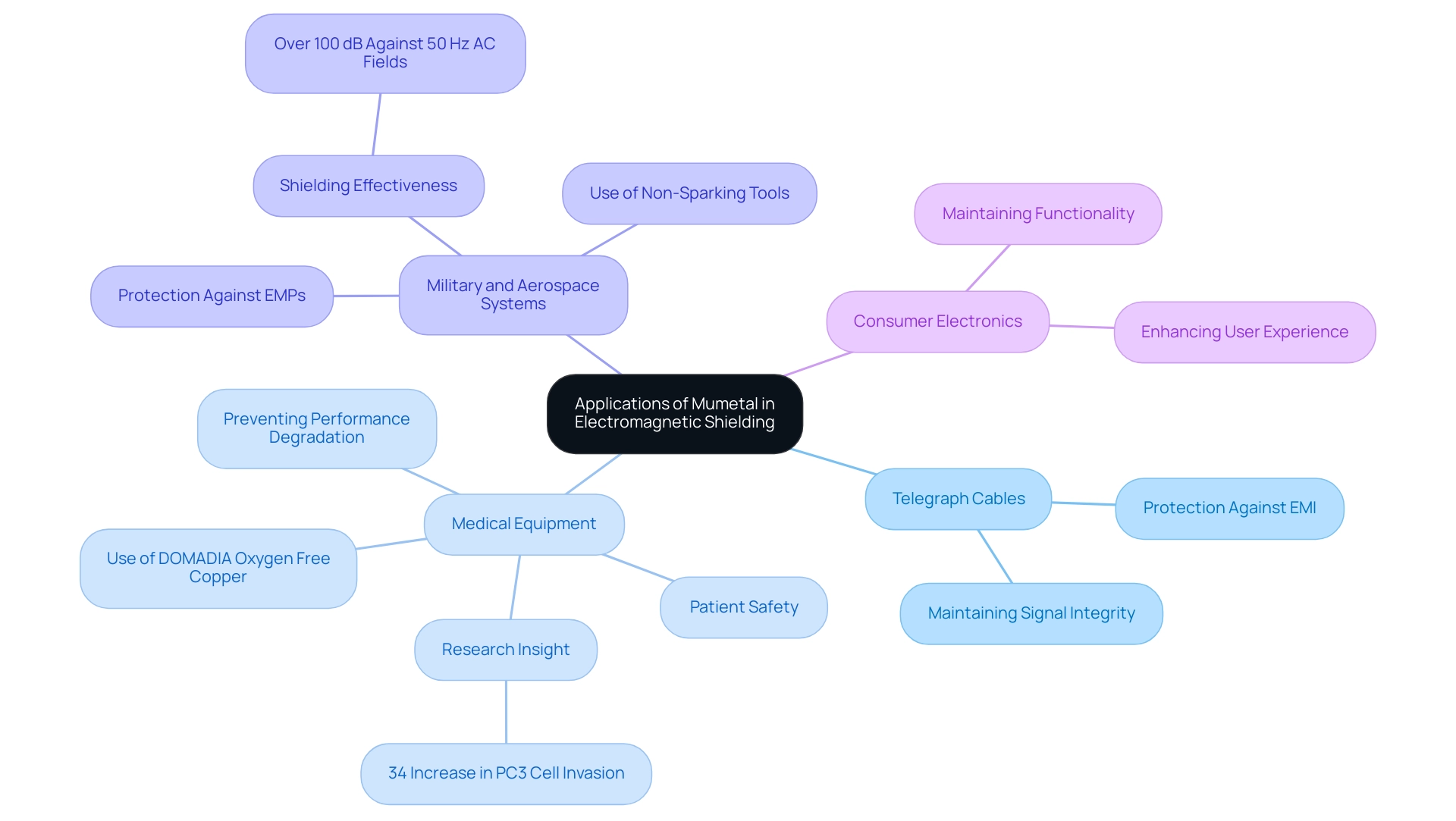

Applications of Mumetal in Electromagnetic Shielding: From Telegraph Cables to Advanced Technologies

The material has positioned itself as a top option for electromagnetic protection across various uses, including:

Telegraph Cables: The substance effectively guards against electromagnetic interference (EMI), ensuring the integrity and clarity of signals transmitted over long distances. This is crucial for maintaining communication fidelity in telecommunication networks.

Medical Equipment: The protective properties of Mumetal are vital for sensitive medical devices. By protecting these devices from external magnetic fields, manufacturers can prevent performance degradation, thereby safeguarding patient safety and ensuring accurate diagnostics. Significantly, research indicates that effective barriers are essential, as demonstrated by a 34% rise in the invasion of PC3 cells following LMF exposure, emphasizing the necessity for strong protection in delicate contexts. Additionally, DOMADIA Oxygen Free Copper (OFE/OHFC) is often utilized alongside a specialized alloy for critical medical components, enhancing the overall reliability and performance of these devices.

Military and Aerospace Systems: In these high-stakes environments, this alloy provides robust protection against electromagnetic pulses (EMPs) and other potential interference sources. Its unmatched protective effectiveness—exceeding 100 dB against 50 Hz AC magnetic fields, as highlighted by expert Qingzhi Meng—is crucial for the reliability of critical systems in defense and aerospace sectors. Furthermore, the use of Non-Sparking Tools in these environments is crucial, as they prevent accidental sparks that could lead to catastrophic failures during maintenance or operation.

Consumer Electronics: Soft magnetic alloys are increasingly utilized in devices such as smartphones and computers, where they help maintain functionality amidst environmental noise, thus enhancing user experience and product reliability.

By harnessing the exceptional protective capabilities of soft magnetic alloys alongside the safety features of Non-Sparking Tools and the conductivity of DOMADIA Oxygen Free Copper, manufacturers can significantly improve the performance and reliability of their products, particularly as they navigate the challenges posed by increasingly complex electromagnetic environments. Moreover, the utilization of substitute substances such as carbon fiber for EMI protection in aerospace sectors illustrates the changing environment of protection solutions.

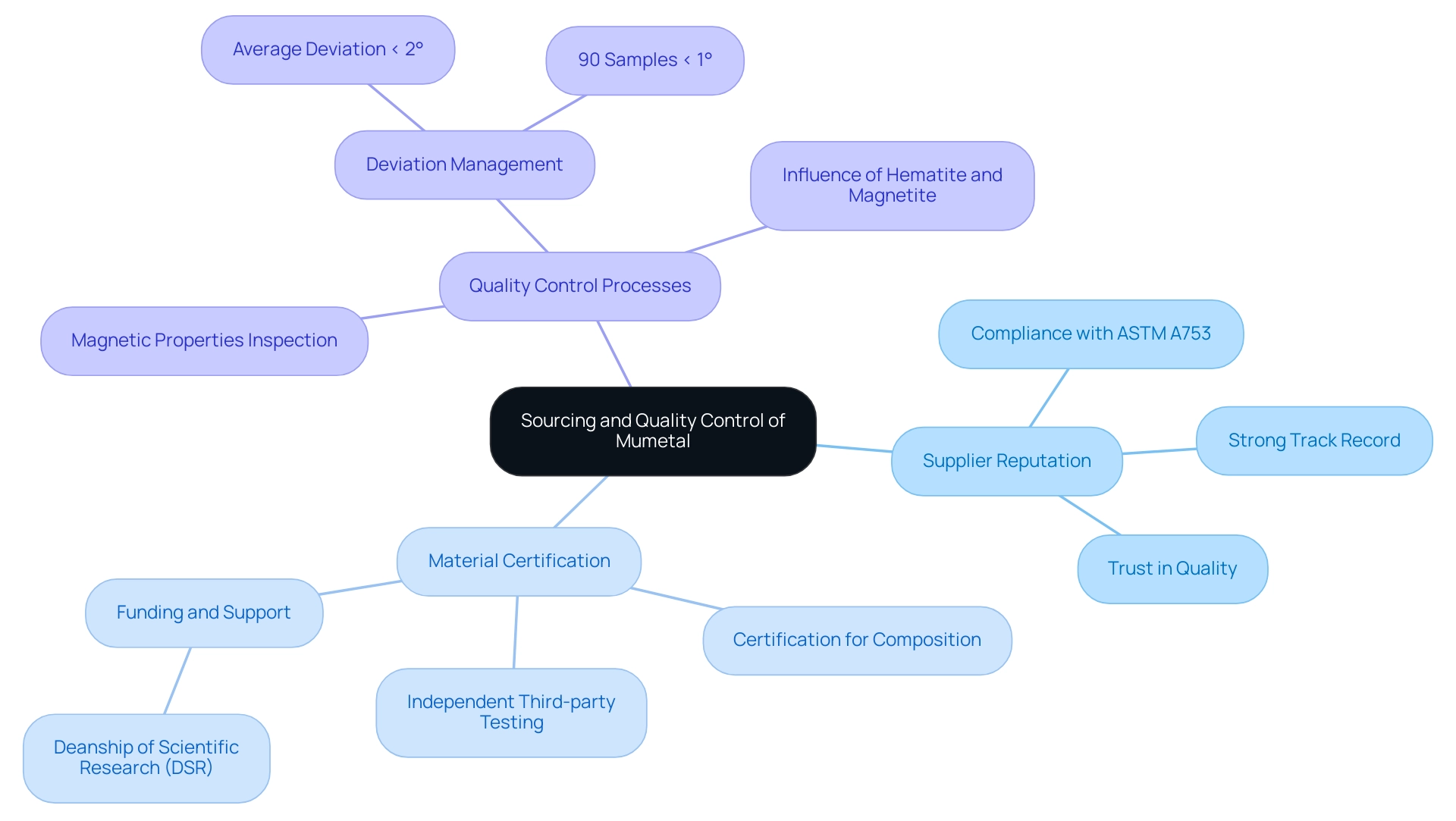

Sourcing and Quality Control of Mumetal: Ensuring Effective Shielding Solutions

When sourcing Mumetal, several critical factors must be prioritized to ensure optimal performance in shielding applications:

- Supplier Reputation: It is essential to select suppliers with a strong track record for delivering high-quality Metal that adheres to international standards, such as ASTM A753. Selecting Domadia as your supplier not only ensures compliance but also cultivates trust in the quality of resources provided, as we are dedicated to supporting your business’s growth through dependable and genuine service.

- Material Certification: Confirm that the alloy is certified for its composition and protection effectiveness. This certification ought to be confirmed through independent third-party testing, reinforcing trust in the product’s reliability. As noted by A.R., “This project was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under grant No. (G: 481-829-1442),” highlighting the importance of rigorous funding and support in ensuring quality standards.

- Quality Control Processes: Implementing rigorous quality control measures during production is vital. This includes thorough inspections and testing of magnetic properties, ensuring that any deviations are addressed promptly. Notably, the average deviation in sample cup positioning remains less than 2° for all samples, with 90% falling below 1°, underscoring the effectiveness of strict quality checks. Additionally, the inversion of principal axis directions may be influenced by the relative contributions of hematite and magnetite to AARM and AMS, which should be considered during the sourcing process.

By implementing strong sourcing and quality control protocols, procurement managers can significantly improve the reliability and effectiveness of the material used in mumetal shielding for telegraph cables. This proactive approach not only aligns with the latest trends in sourcing high-quality resources but also reflects a commitment to maintaining industry standards. Furthermore, the case study titled ‘Testing the Universality of Free Fall with Atom Interferometry’ illustrates the practical applications of the material in advanced scientific contexts, emphasizing its importance in precision measurements.

In addition, Domadia offers a range of related products, including Beryllium Copper, Kovar, and various high-temperature materials, which can enhance your requirements. By joining our network, you not only gain access to these exceptional products but also a committed partner dedicated to your business success.

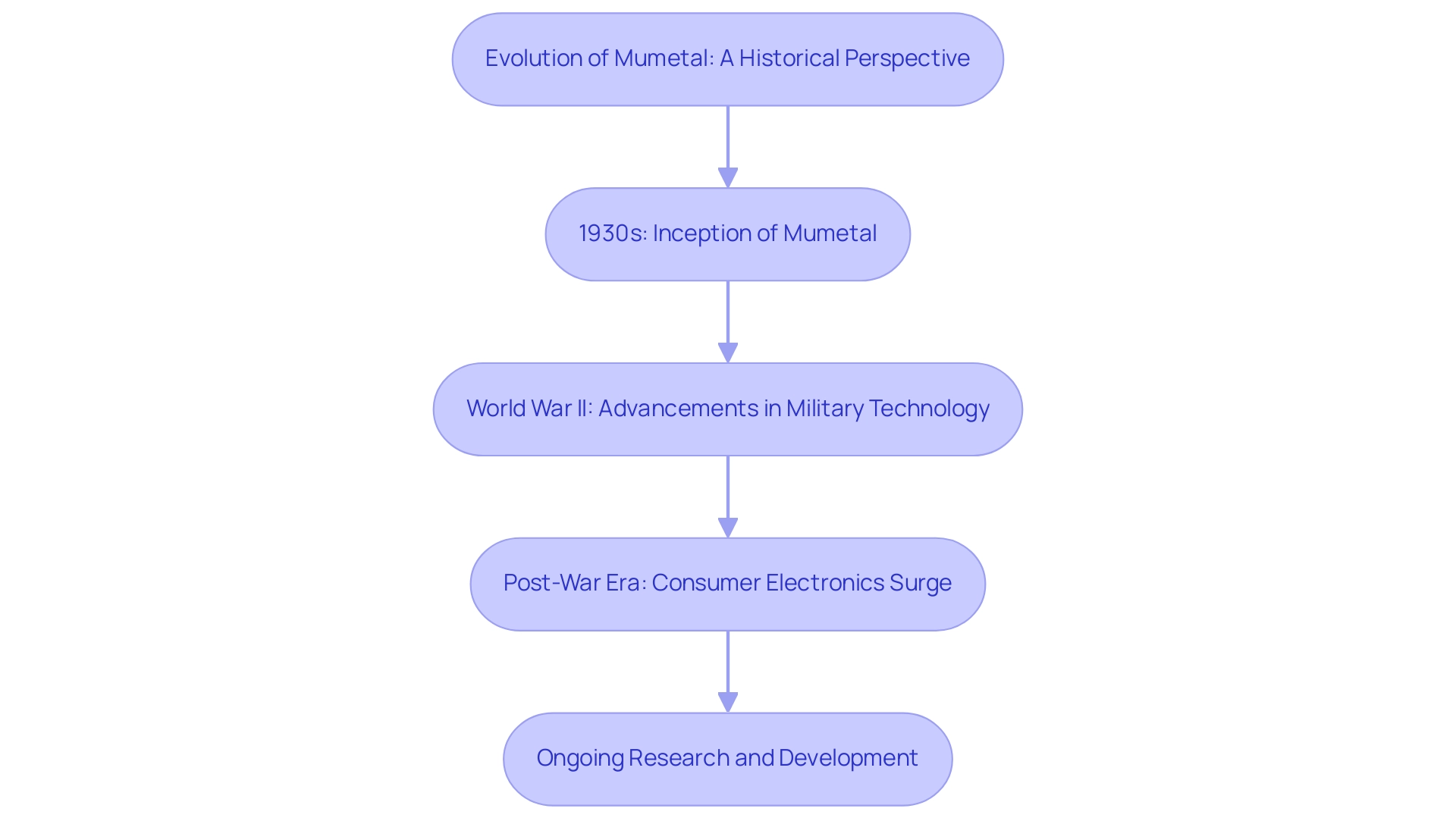

The Evolution of Mumetal: A Historical Perspective on Magnetic Shielding

The alloy was initially created in the 1930s by a company to meet a growing need for mumetal shielding for telegraph cables and efficient magnetic protection in various sectors. The introduction of this high-permeability alloy marked a significant advancement in mumetal shielding for telegraph cables. Key milestones in its development include:

- 1930s: The inception of this material as a premier choice for magnetic protection due to its unparalleled permeability.

- World War II: The urgent need for advanced magnetic protection in military technology spurred rapid advancements in production techniques, enabling enhanced performance in various uses. Significantly, studies during this period revealed a success rate of 3/30 for near-zero affected phenotypes at 2–5 µT, highlighting the efficacy of mumetal shielding for telegraph cables in essential protective scenarios.

- Post-War Era: The consumer electronics surge further stimulated advancements in the alloy, cementing its status as a crucial substance for magnetic protection solutions. Today, ongoing research persists in expanding the limits of this material’s capabilities, concentrating on enhancing its characteristics and widening its uses in increasingly advanced technologies. As Dillan Schulte pointed out, ‘A luminosity of 4.3×10^34 cm−2 s−1 can be obtained with an ideal collider, which is nearly three times the nominal luminosity goal of 1.5×10^34 cm−2 s−1,’ emphasizing the progress in magnetic shielding and its significance for high-performance uses. Additionally, practical applications of metal are illustrated in the case study titled ‘Modifications for Hypomagnetic Fields,’ which describes the necessity of mumetal shielding for telegraph cables in experiments testing near-zero magnetic field exposure. This setup allows for accurate testing of hypomagnetic conditions while ensuring that control conditions are maintained within the MagShield apparatus. For those interested in exploring similar resources, we provide access to a network of suppliers specializing in electrical insulation and high-temperature substances, including Beryllium Copper, Kovar, Nickel, and various types of electrical insulation papers and fabrics. This ensures that procurement managers have the support they need for their inquiries. Our suppliers are well-equipped to assist with specific requirements and provide insights into the latest advancements in the field. Recent studies, including those found in the figshare data repository, continue to investigate the development of magnetic protection substances, highlighting their significance across different fields, including electronics and scientific inquiry.

Challenges in Using Mumetal for Shielding: Considerations and Best Practices

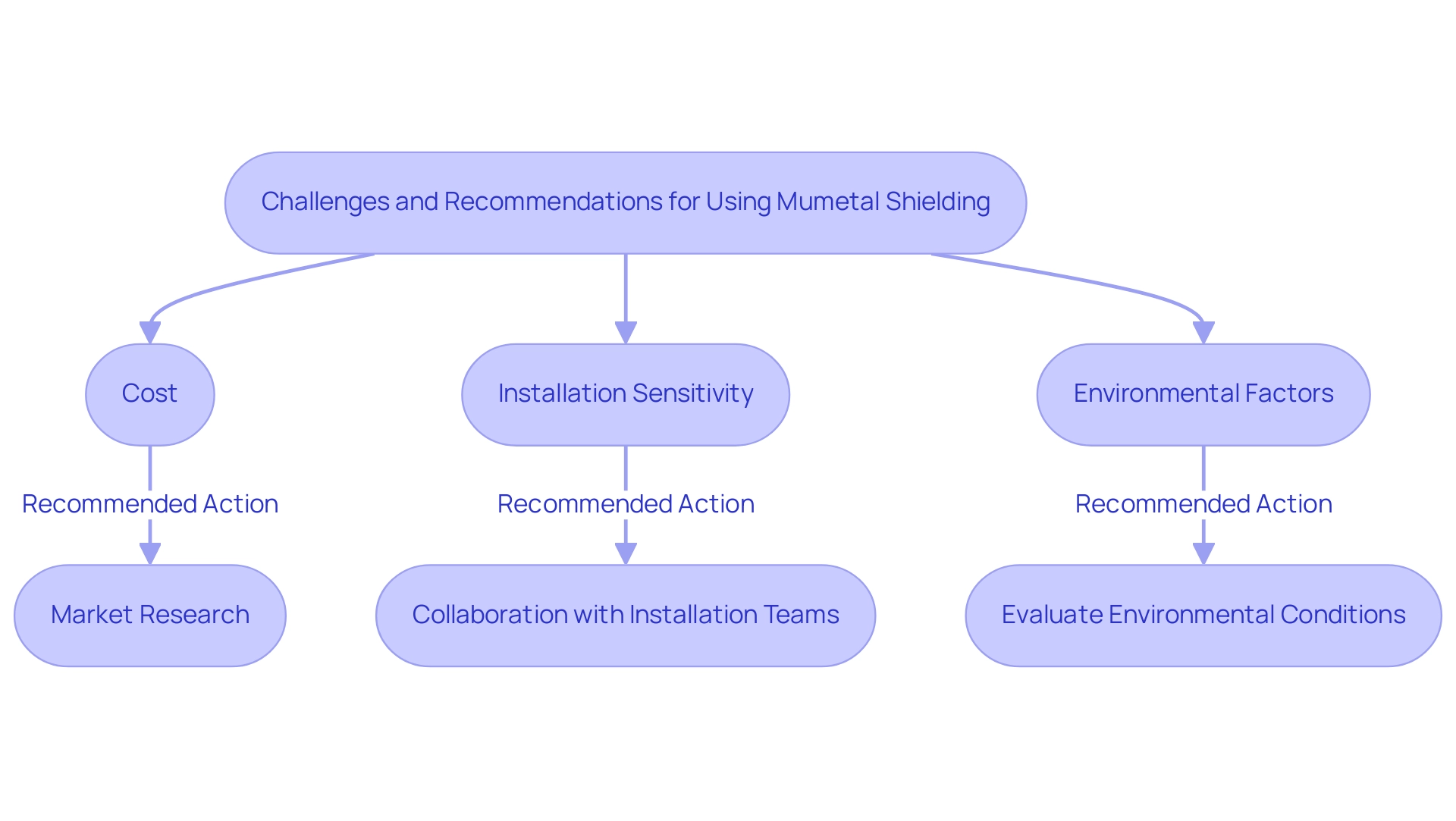

Mumetal is renowned for its outstanding shielding capabilities; however, several challenges warrant careful consideration:

- Cost: The expense associated with Mumetal often exceeds that of alternative shielding materials, necessitating a rigorous cost-benefit analysis to ensure that the investment aligns with project requirements. Recent studies highlight the need for procurement managers to weigh these costs against the potential performance benefits. Notably, annealing can result in a boost in the magnetic permeability of more than an order of magnitude, enhancing the material’s effectiveness in specific applications.

- Installation Sensitivity: The effectiveness of Mumetal protection is heavily contingent upon proper installation techniques. Inadequate handling can significantly impair performance, underscoring the importance of adhering to best practices throughout the installation process. As Christopher J. von Klemperer observes, “Conversely, fiber reinforced polymeric (FRP) composite substances are generally lightweight and can be less expensive to manufacture, but usually lack the inherent EMI protection capabilities that may be necessary.” This highlights the necessity for thorough evaluation when choosing protective substances.

- Environmental Factors: Mumetal’s susceptibility to corrosion and degradation in specific environments can pose challenges. Therefore, implementing protective coatings or specialized handling procedures is essential to maintain its integrity and performance.

To navigate these challenges effectively, procurement managers should:

- Engage in comprehensive market research to identify cost-effective sourcing options that balance quality and budget. With a variety of suppliers and manufacturers available for electrical insulation and high-temperature materials—including Electrical Insulation Paper, Kapton Tapes, PTFE Coated Yarn, Beryllium Copper, Kovar, and Nickel—procurement managers can explore options that meet both performance and budgetary needs. For example, a case study named “Use of Iron Scale for Electromagnetic Interference Protection” examined the application of iron scale, a byproduct from industrial processes, as a budget-friendly protective solution, achieving notable attenuation levels while being eco-friendly.

- Foster collaboration with installation teams to ensure adherence to best practices during the installation phase.

- Evaluate environmental conditions thoroughly and adopt necessary protective measures during transport and installation to safeguard the material’s performance and longevity. By addressing these factors proactively, procurement managers can enhance the efficacy of mumetal shielding for telegraph cables in electromagnetic shielding.

Conclusion

Mumetal’s unique properties and historical significance position it as a vital material for effective electromagnetic shielding. Its high permeability and low coercivity make it exceptionally suited for a wide range of applications, including:

- Telecommunications

- Medical equipment

- Military systems

- Consumer electronics

The alloy’s ability to significantly reduce electromagnetic interference ensures the integrity of sensitive devices and enhances their reliability, making it indispensable in today’s technology-driven environment.

As the demand for advanced shielding solutions grows, procurement managers must navigate the complexities of sourcing and installation. Prioritizing the following will ensure the reliability of Mumetal in various applications:

- Supplier reputation

- Material certification

- Rigorous quality control processes

Furthermore, understanding the challenges associated with cost, installation sensitivity, and environmental factors is essential for maximizing Mumetal’s performance and longevity.

Ultimately, by leveraging the exceptional characteristics of Mumetal and implementing best practices in sourcing and installation, organizations can enhance product performance and maintain a competitive edge in the market. The continued evolution of Mumetal, supported by ongoing research and advancements, underscores its importance in meeting the challenges posed by increasingly complex electromagnetic environments. Embracing these insights will empower procurement managers to make informed decisions and drive success in their projects.