Blogs

Top 7 Applications of Mumetal Rods You Should Know About

Overview

Mumetal rods are utilized in various applications, particularly in medical imaging, electronics, telecommunications, scientific research, aerospace, automotive, and industrial equipment, due to their exceptional soft ferromagnetic properties that provide effective shielding against magnetic interference. The article underscores their significance by detailing how these rods enhance the performance and safety of technologies, such as MRI machines and electronic devices, while also emphasizing their critical role in ensuring operational efficiency and reliability across multiple sectors.

Introduction

Mumetal rods stand at the forefront of advanced materials, celebrated for their remarkable soft magnetic properties that make them indispensable across a variety of critical applications. With their exceptional magnetic permeability and low coercivity, these rods effectively channel magnetic fields while minimizing energy loss, a necessity in sectors ranging from medical imaging to aerospace.

As industries increasingly rely on sophisticated technologies, understanding the unique characteristics of Mumetal becomes paramount for procurement professionals seeking to ensure optimal performance and safety in their projects.

This article delves into the properties, applications, and future innovations surrounding Mumetal rods, highlighting their integral role in enhancing functionality and driving advancements in various fields.

Through expert insights and practical considerations, it aims to equip procurement managers with the knowledge needed to navigate the complexities of sourcing and implementing this vital material.

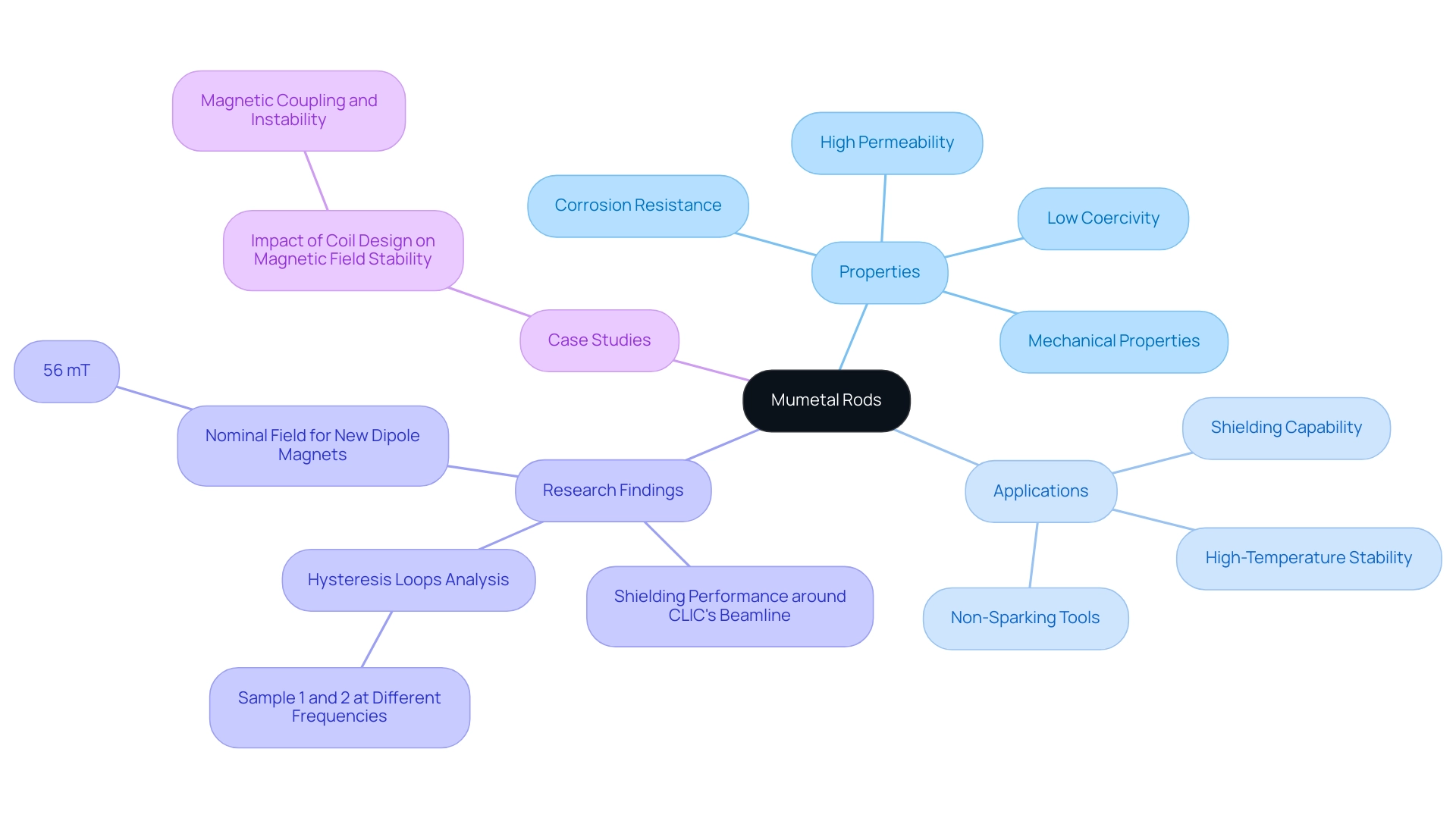

Understanding the Unique Properties of Mumetal Rods

These rods, known as mumetal rods, are highly esteemed for their outstanding soft ferromagnetic characteristics, defined by high permeability and low coercivity. These attributes enable a mumetal rod to effectively channel fields while minimizing energy loss, making it an optimal choice for a variety of applications. The alloy is mainly made up of nickel, iron, and molybdenum, improving its functionality across various environments, especially because of its superior corrosion resistance and excellent mechanical properties.

Recent research suggests that the shielding capability of a mumetal rod with a 1-mm layer around Clic’s beamline has been significantly observed, demonstrating its effectiveness in reducing interference in sensitive applications. As emphasized by Mariano Pentella,

Measured hysteresis loops for sample 1 (top) and 2 (bottom) at different frequency values

demonstrate the subtle behavior of the material in varying operational conditions. Additionally, the nominal field for the new dipole magnets is only 56 mT, emphasizing the importance of the mumetal rod’s properties in effectively managing fields.

This performance is complemented by its high-temperature stability and precision manufacturing, essential for applications in aggressive environments. Furthermore, in explosive environments, Non-Sparking Tools are critical as they provide a safe alternative, preventing potential ignition sources. The case study titled ‘Impact of Coil Design on Field Stability‘ further illustrates how the design of the coil in relation to the innermost shield affects stability, highlighting the coupling as a potential source of instability.

Moreover, the shielding capabilities of a mumetal rod render it indispensable in environments where magnetic interference could undermine functionality. The tensile properties characterized for functional and mechanical performance also play a crucial role in ensuring reliability. For procurement professionals, a deep understanding of these properties, along with the importance of Non-Sparking Tools, is crucial to leveraging the material’s advantages effectively in their projects.

Exploring Key Applications of Mumetal Rods in Various Industries

Alloy rods are essential in numerous important sectors because of their outstanding shielding characteristics. Here are some of the key applications:

Medical Imaging: In MRI machines, specialized rods are essential for protecting sensitive components from external fields, ensuring precise imaging and patient safety. Recent studies have shown that the shielding effectiveness of this material significantly enhances the quality of medical diagnostics, with shielding coefficients averaging 819.22 in the radial direction and 383.6 in the axial direction, representing increases of 16.5% and 91.3% over conventional ferrite magnetic shielding. Moreover, the combination of DOMADIA Oxygen Free Copper (OFE/OHFC) with a specific alloy in medical components guarantees optimal functionality in critical applications.

Electronics: Within transformers and inductors, a specialized alloy is utilized to improve operational efficiency by effectively reducing energy losses. This not only boosts performance but also contributes to overall energy conservation in electronic devices.

Telecommunications: Devices requiring high-frequency magnetic shielding often utilize a specialized alloy, which is essential for maintaining signal integrity and minimizing interference.

Scientific Research: In experimental setups, particularly those involving biomagnetism measurements, this specialized material provides the necessary isolated environment to eliminate biological and environmental interferences. This capability greatly enhances the accuracy of research findings, as it may benefit other biomagnetism measurements by isolating signals from external noise.

Aerospace: Components in aerospace applications often require high-performance shielding against electromagnetic interference. The characteristics of this alloy make it an ideal choice for such demanding environments, ensuring the reliability and safety of aerospace technologies.

Automotive: The rise of electric vehicles has spurred the use of specialized alloys in power management systems, where efficient energy control is paramount for optimal vehicle performance.

Industrial Equipment: In machinery that necessitates enhanced magnetic control, this special alloy plays a crucial role, ensuring operational efficiency and longevity of equipment.

Additionally, in explosive environments, the application of Non-Sparking Tools becomes critical. These tools, when utilized with soft magnetic components, help reduce risks linked to sparks that could ignite combustible substances, thereby improving safety in various industrial environments.

The versatility of the rods across these sectors not only highlights their significance but also demonstrates their integral role in advancing technology and enhancing product performance across multiple fields. As Margot J. Taylor aptly states, ‘It’s all about time: Optimizing infrastructure for functional brain imaging in children,’ reflecting the critical need for advanced materials like the mumetal rod in medical imaging applications.

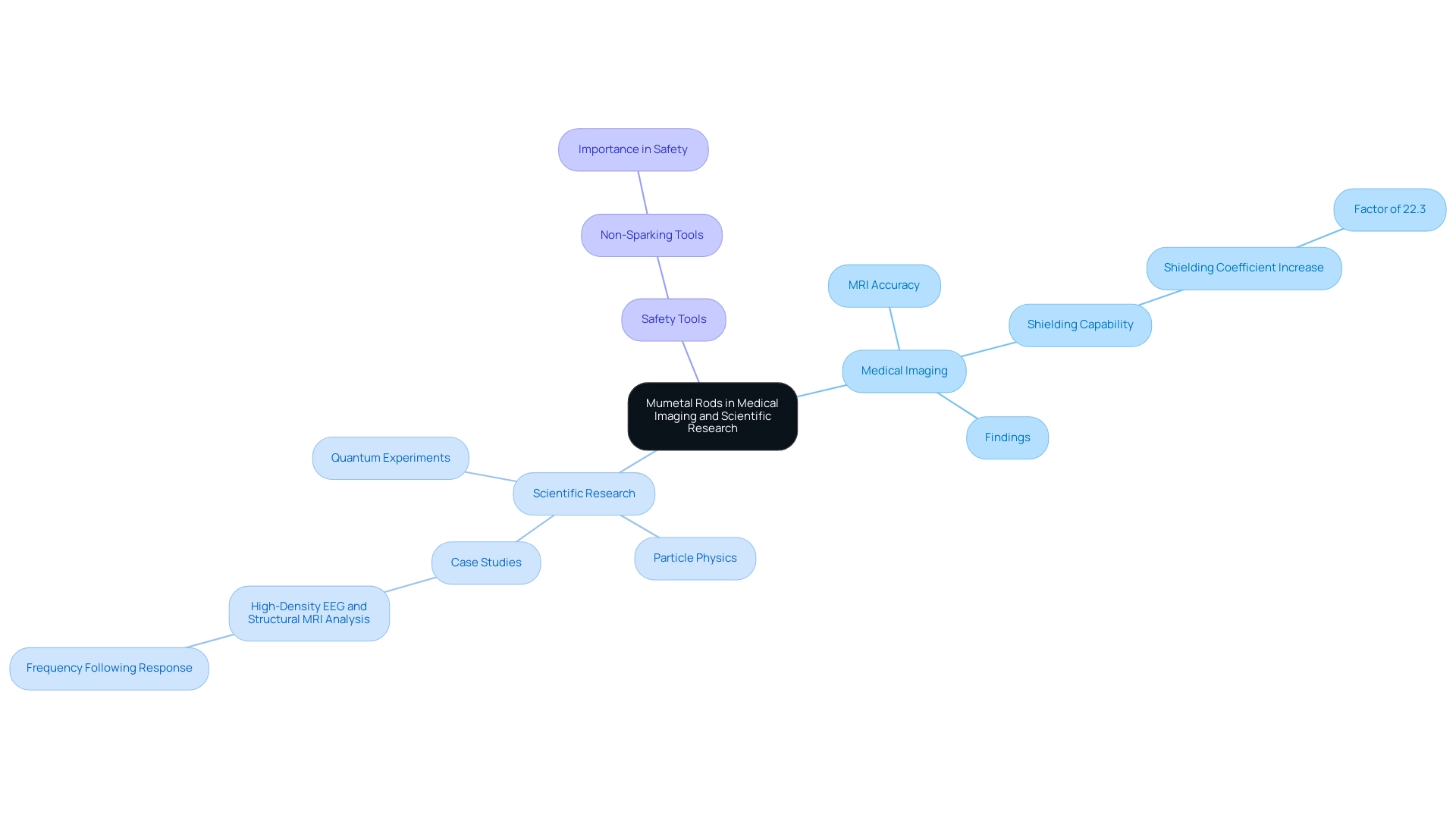

Mumetal Rods in Medical Imaging and Scientific Research

In the realm of medical imaging, mumetal rods are indispensable for ensuring both the accuracy and safety of MRI machines. Their exceptional permeability facilitates effective shielding, which is crucial in preventing external fields from distorting the imaging process. This capability is underscored by recent findings showing that the shielding coefficient significantly increases by a factor of 22.3 when the gap width is maintained at 0.5 mm and the film thickness at 0.1 mm.

Additionally, Mu-metal is crucial in scientific research, especially in quantum experiments where a controlled field environment is essential. For instance, in particle physics laboratories, mumetal rods are utilized to establish shielding that safeguards sensitive equipment from field fluctuations, thereby ensuring the reliability of experimental results. Alisha Duetschler notes, ‘The comparable dosimetric effects irrespective of magnetic field strength indicate that the effects of motion for future MR-guided proton therapy may not be worse than for conventional PBS proton therapy,’ highlighting the importance of Mu-metal in optimizing MRI technology.

Additionally, the case study titled ‘High-Density EEG and Structural MRI Analysis of Frequency Following Response’ provides evidence of Mu-metal’s impact on research outcomes, confirming that low frequencies dominate cortical contributions while higher frequencies also emerge, showcasing the complex nature of the frequency following response. The versatility and efficacy of Mu-metal in these sectors not only illustrate its essential role in advancing healthcare but also in propelling scientific discovery, making it a critical component for procurement considerations. Moreover, in environments where explosive potential exists, the use of Non-Sparking Tools becomes paramount.

While Mu-metal functions to protect delicate equipment, Non-Sparking Tools guarantee safety by stopping sparks that could ignite combustible substances. Grasping the characteristics and uses of both Mu-metal and Non-Sparking Tools is crucial for procurement managers responsible for sourcing resources that emphasize safety and functionality. It is also worth noting that the authors of related studies often declare various financial interests and funding sources, which adds depth to the credibility of the research findings associated with Mu-metal.

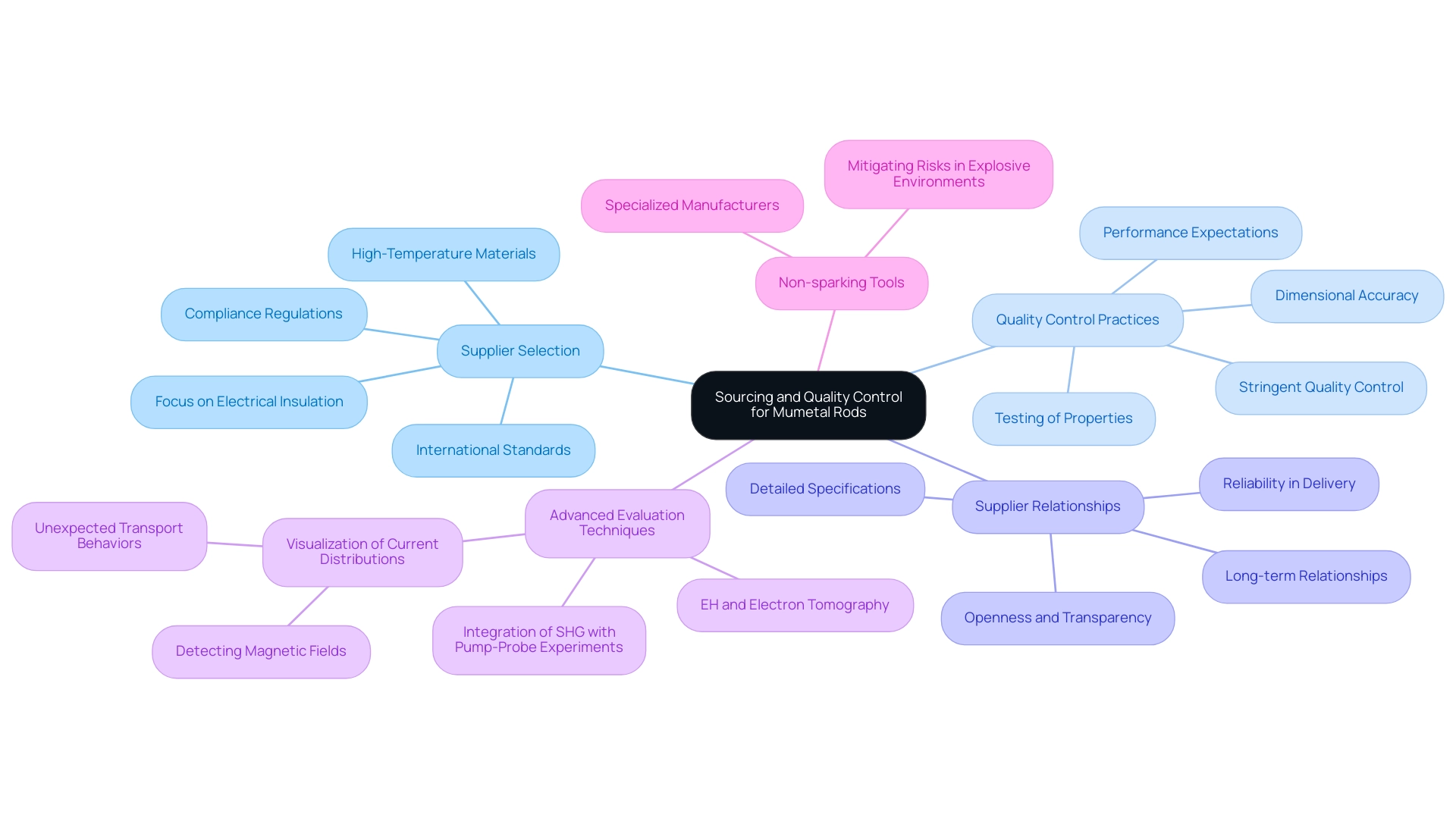

Sourcing and Quality Control for Mumetal Rods

Sourcing mumetal rods necessitates a meticulous approach to supplier selection, particularly focusing on adherence to international standards and compliance regulations. It’s essential to collaborate with providers who focus on electrical insulation and high-temperature materials, ensuring they exhibit stringent quality control practices that include thorough testing of properties and dimensional accuracy. This guarantees that the rods meet performance expectations, especially considering that the shielding factor for regions where rubidium atoms are prepared and manipulated must exceed 10⁴.

This statistic underscores the critical importance of quality in sourcing. As Daniel Wolf, a researcher, states,

Combining EH and electron tomography enables the reconstruction of magnetic vector fields in 3D.

This emphasizes the advanced techniques, such as the integration of SHG with pump-probe experiments, that can be utilized to evaluate quality and improve understanding of ultrafast magnetization processes.

Furthermore, establishing long-term relationships with suppliers not only fosters better pricing but also enhances reliability in delivery. Providers who offer detailed specifications and certifications show a dedication to openness, which is crucial for sectors that rely on high-performance resources. In the context of explosive environments, utilizing non-sparking tools, such as those provided by specialized manufacturers, can mitigate risks, further emphasizing the importance of selecting qualified suppliers.

For example, the case study titled ‘Visualizing Current Distributions’ demonstrates how SSM can visualize current distributions in substances by detecting the magnetic fields generated by electric currents, revealing unexpected transport behaviors. By highlighting quality procurement standards and cultivating collaborations with dependable suppliers, including those of non-sparking tools and high-temperature substances, organizations can greatly enhance the effectiveness of their applications utilizing mumetal rods, ultimately gaining from recent advancements in sourcing strategies and supplier compliance regulations for 2024.

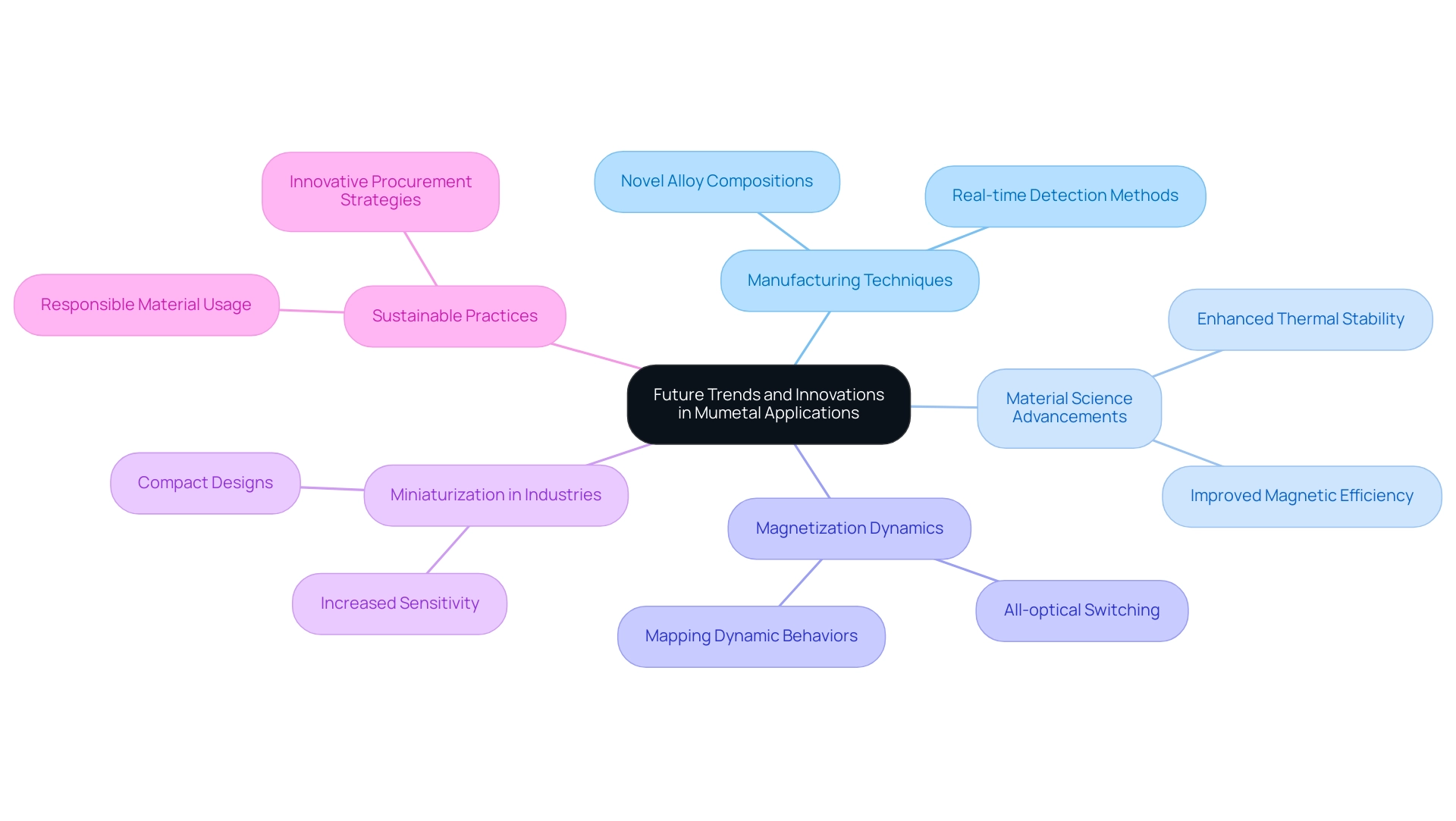

Future Trends and Innovations in Mumetal Applications

The future of these rods is on the brink of transformative innovation, driven by significant advancements in manufacturing techniques and material science. Ongoing research into novel alloy compositions is expected to yield superior performance attributes, including enhanced thermal stability and improved magnetic efficiency. A key area of interest for future studies in magnetization dynamics is all-optical switching of magnetization states, which could further enhance the capabilities of soft magnetic alloy applications.

As industries increasingly prioritize miniaturization in electronics and medical devices, there is a pressing need for smaller, more efficient metal components. This shift is underscored by recent findings from V.G. Lucivero, who stated, “Using pulsed pumping, a free decay scheme and a baseline of 0.2 cm, I achieved an OPM gradiometer with a common-mode rejection ratio of higher than 10 and nearly quantum-noise-limited sensitivity in earth-scale fields.”

This illustrates the potential for improved sensitivity in compact designs. Additionally, the development of a new feedback method for real-time detection of field gradients underscores the innovative spirit within this sector, eliminating traditional least squares methods. Additionally, the study named ‘Mapping Dynamic Behaviors’ emphasizes how coherent x-ray magnetic imaging is creating new opportunities for examining dynamic behaviors in substances, offering insights into the dynamics of magnetic substances and their applications in technology.

For procurement managers, staying informed about these evolving trends is crucial for effectively leveraging the distinctive properties of the mumetal rod. Embracing these innovations not only enhances product performance but also aligns with sustainable practices in material usage, fostering a more responsible approach to procurement.

Conclusion

Mumetal rods are essential components across various industries, revered for their unparalleled soft magnetic properties that facilitate optimal performance in critical applications. Their high magnetic permeability and low coercivity enable effective magnetic field management while significantly reducing energy loss. This article has explored the unique properties of Mumetal, emphasizing its role in:

- Medical imaging

- Electronics

- Telecommunications

- Scientific research

- Aerospace

- Automotive applications

The ability of Mumetal to shield sensitive equipment from magnetic interference is crucial in maintaining accuracy and safety, particularly in MRI technology and experimental setups.

In addition to its diverse applications, the importance of quality sourcing and supplier relationships has been underscored. Procurement professionals must prioritize suppliers who adhere to international standards and demonstrate rigorous quality control. This diligence ensures that Mumetal rods meet the demanding performance expectations required in sensitive environments, particularly those susceptible to magnetic fluctuations.

Looking ahead, the future of Mumetal is poised for innovation, with ongoing research promising enhancements in thermal stability, magnetic efficiency, and miniaturization of components. As industries continue to evolve, staying informed about these trends will empower procurement managers to harness Mumetal’s capabilities effectively. By embracing advancements in material science and manufacturing techniques, organizations can optimize performance while also aligning with sustainable practices, ultimately driving progress in their respective fields.