Blogs

Understanding Invar Coefficient of Thermal Expansion: An In-Depth Tutorial

Introduction

In the realm of material science, understanding the Coefficient of Thermal Expansion (CTE) is paramount for ensuring the integrity and performance of engineering components. As temperatures fluctuate, materials respond in varied ways, making the knowledge of their expansion characteristics critical for applications where precision is non-negotiable.

This article delves into the intricacies of CTE, exploring its implications in the selection of materials, particularly in high-stakes environments. From the unique properties of Invar, a nickel-iron alloy celebrated for its low thermal expansion, to the historical significance of low thermal expansion alloys, the discussion highlights innovations and practical considerations that procurement managers must navigate.

The exploration of machining techniques and measurement methods further underscores the importance of meticulous material selection in achieving optimal performance and reliability in engineering designs.

Understanding the Coefficient of Thermal Expansion (CTE)

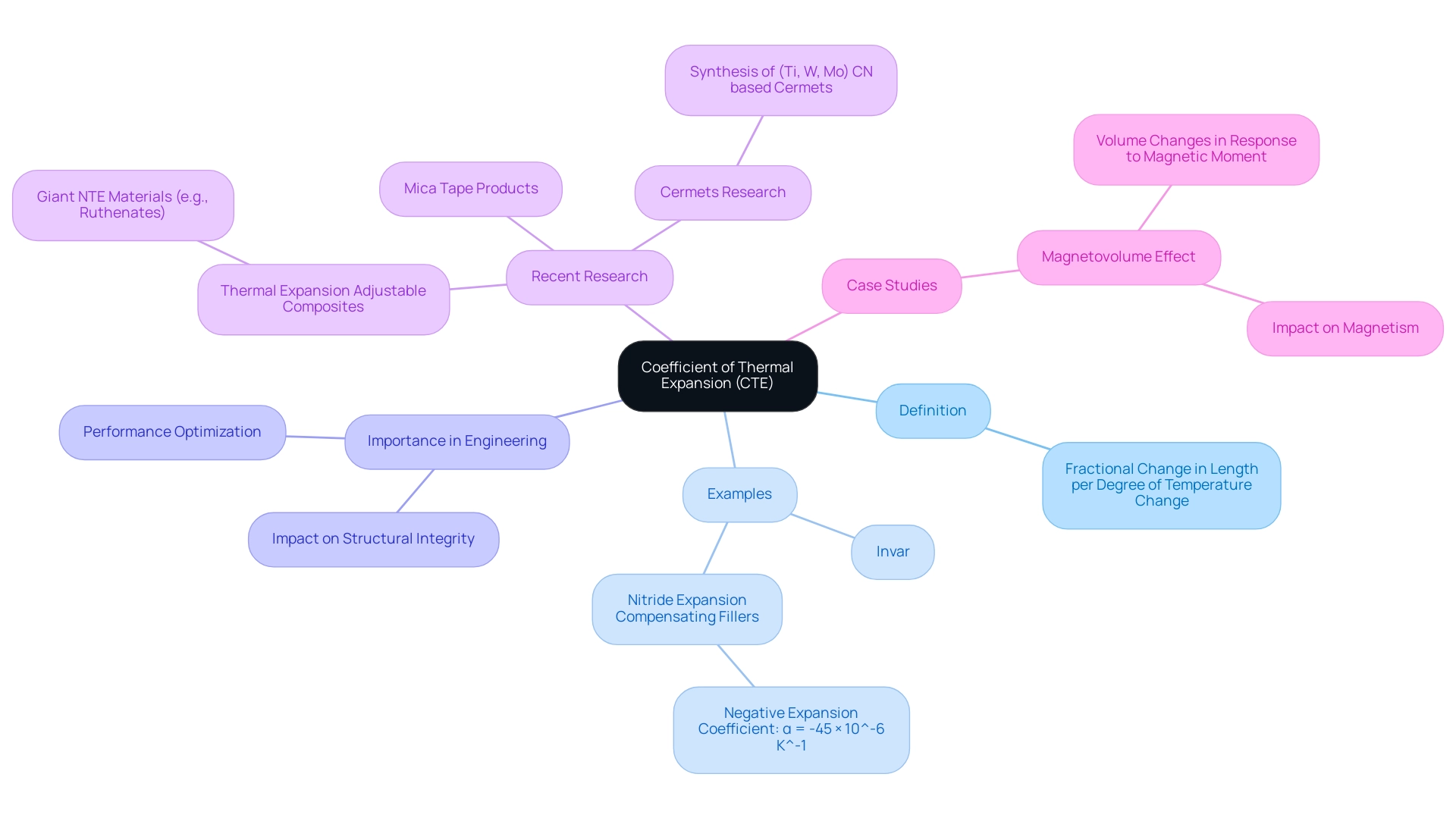

The invar coefficient of thermal expansion serves as a critical parameter in material science, quantifying how much a material expands or contracts in response to temperature fluctuations. Specifically, it is defined as the fractional change in length per degree of temperature change (°C or °F). A solid grasp of the invar coefficient of thermal expansion is essential, particularly in scenarios where temperature variations are commonplace, as it directly influences the integrity and performance of engineering components.

Materials showing high CTE values are prone to warping or even catastrophic structural failure when subjected to temperature stress. For example, recent advancements have demonstrated that nitride expansion compensating fillers possess a remarkable negative expansion (NTE) coefficient of α = -45 × 10^-6 K^-1 between 305–340 K, highlighting their potential benefits in specific applications. Moreover, the creation of new expansion adjustable composites utilizing giant NTE substances, including ruthenates, highlights continuous advancements in the field.

Furthermore, the magnetovolume effect demonstrates how the volume of a substance alters in response to the amplitude of the magnetic moment, highlighting the complex relationship between expansion due to heat and magnetism. As noted by Jiwoong Kim,

The careful selection of resources based on their CTE characteristics is crucial for optimizing performance and ensuring reliability.

This insight highlights the necessity of selecting materials with the invar coefficient of thermal expansion to protect against the adverse effects of temperature fluctuations in engineering designs.

Grasping these heat-related properties is especially important when choosing Mica tape products, as their performance in high-temperature uses can be greatly affected by their expansion characteristics. Furthermore, the recent release on cermets, titled ‘Synthesis of (Ti, W, Mo) CN based cermets with various carbides configurations for challenging uses,’ further emphasizes the significance of ongoing research in expansion effects in engineering contexts.

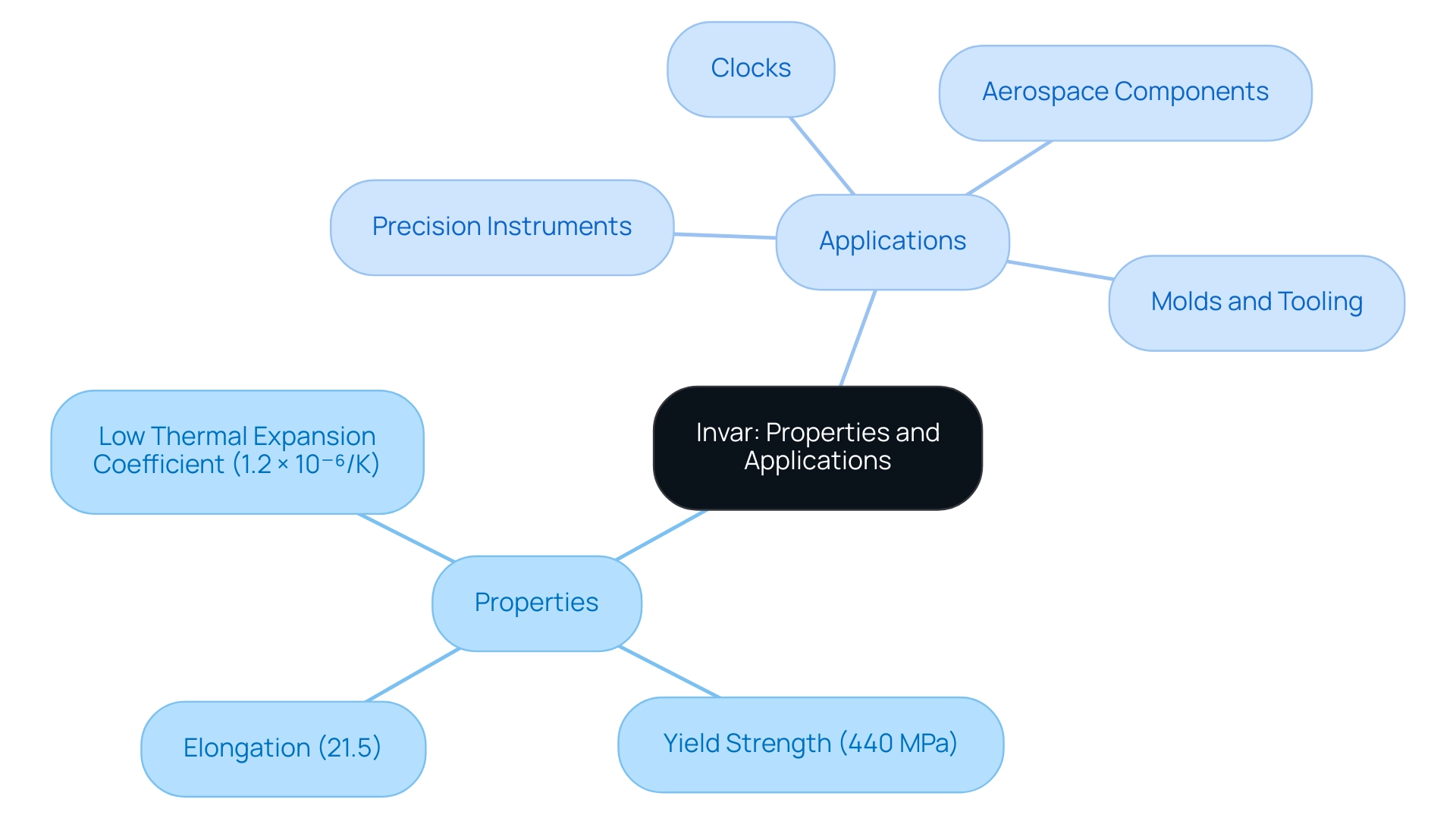

Invar: Properties and Applications of a Low Thermal Expansion Alloy

The nickel-iron alloy is renowned for its remarkably low invar coefficient of thermal expansion, which is approximately 1.2 × 10⁻⁶/K at room temperature. This unique characteristic renders it particularly suitable for applications demanding high dimensional stability, such as:

- Precision instruments

- Clocks

- Aerospace components

- Those that utilize the invar coefficient of thermal expansion

The capacity of this material to maintain its form and dimensions across different temperatures is crucial in vital areas such as metrology and optics, where even slight dimensional alterations can lead to significant measurement inaccuracies.

Furthermore, this material is instrumental in the production of high-quality molds and tooling; its thermal stability ensures enhanced accuracy in the final products. The yield strength (YS) of the alloy samples is reported at 440 MPa, with an elongation (EL) of 21.5%, highlighting its robust mechanical properties. As highlighted by scientist Zi-Kui Liu, ‘Thermal Expansion Anomaly Regulated by Entropy,’ which emphasizes the importance of the alloy in advanced manufacturing and precision engineering.

Additionally, the European market is expected to demonstrate robust growth in the alloy sector, backed by favorable governmental policies and rising R&D investments, making this alloy essential in fields that prioritize precision and reliability.

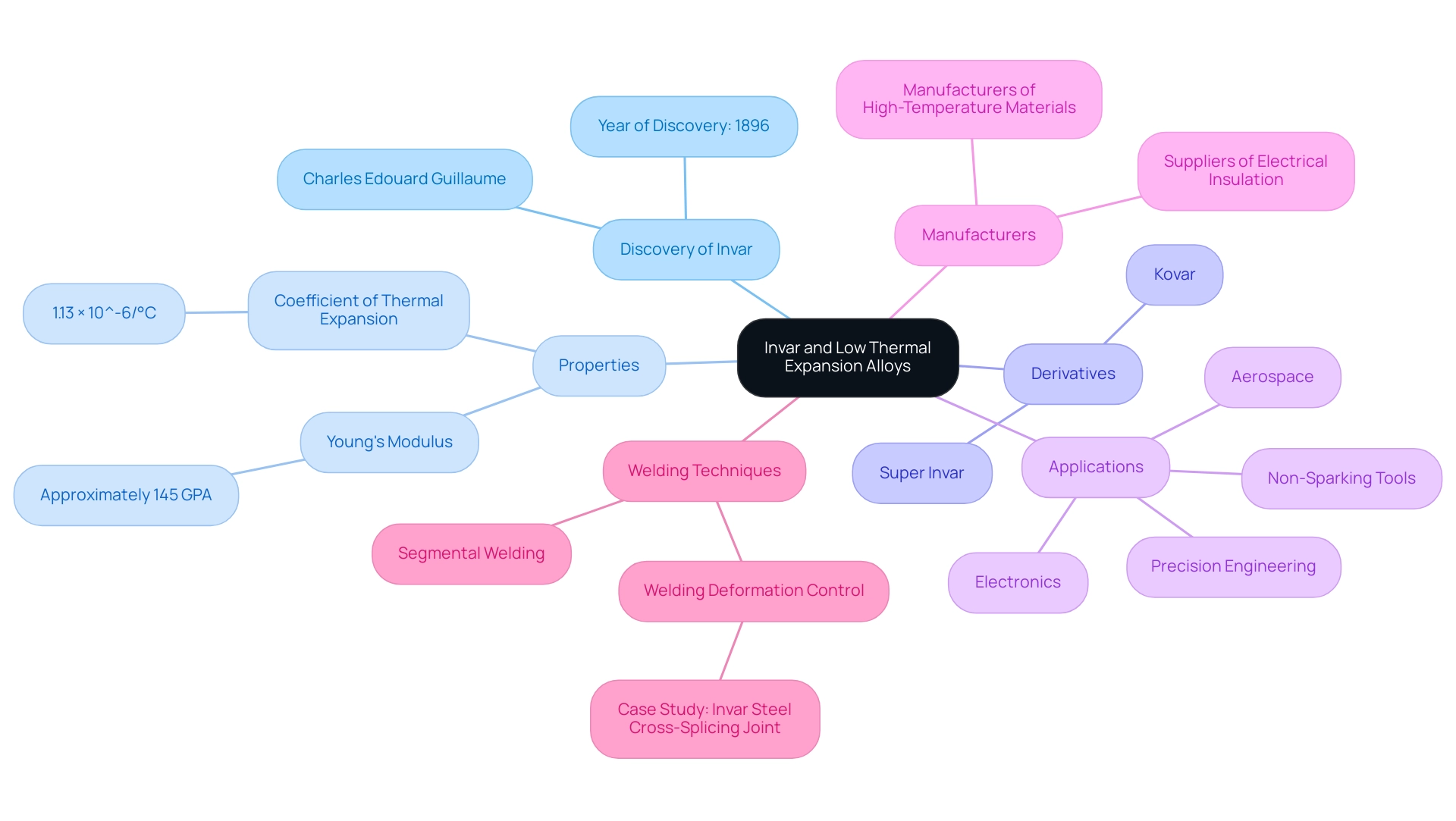

A Brief History of Invar and Low Thermal Expansion Alloys

The alloy, discovered in 1896 by Swiss physicist Charles Edouard Guillaume, signifies a significant milestone in material science because of its exceptional temperature stability, with an invar coefficient of thermal expansion of 1.13 × 10^-6/°C, and a Young’s modulus of approximately 145 GPA. The name ‘Invar,’ which comes from ‘invariable,’ aptly describes its minimal heat expansion characteristics, as indicated by the invar coefficient of thermal expansion. This finding stimulated the investigation and creation of several low expansion alloys, including Kovar and Super Invar, which further improve performance in particular uses.

Over the years, these innovations have found extensive use across critical sectors such as aerospace, electronics, and precision engineering, where maintaining thermal stability is essential for operational integrity. Significantly, suppliers and manufacturers of electrical insulation and high-temperature substances, including papers, fabrics, and metals, play a crucial role in providing the necessary components for these applications. Additionally, the importance of non-sparking tools in explosive environments cannot be overstated, as they provide safe alternatives for handling materials.

As mentioned by Tomar et al., ‘Due to the aforementioned optimal process parameters, the deposited components in this study are free from common defects such as macroscopic deformation, delamination, and cracking,’ emphasizing the significance of precise welding techniques in employing this material. A pertinent case study named ‘Welding Deformation Control in Steel Cross-Splicing Joint‘ demonstrates how segmental welding effectively manages deformation, highlighting the practical uses of this material in contemporary engineering. This historical development highlights the significance of Invar’s derivatives in promoting technological uses, creating a basis for continuous research and advancement in substances with an invar coefficient of thermal expansion.

Furthermore, related products such as Beryllium Copper and Mu-Metal are essential for various applications, emphasizing the interconnectedness of these materials in the procurement process.

Machinability and Heat Treatment of Invar Alloys

Alloys exhibit good machinability, yet achieving optimal results necessitates specific tools and techniques tailored to their unique properties. Utilizing carbide tools is highly recommended, as they can withstand the demands of machining this alloy; however, operators should employ slower cutting speeds to mitigate the risk of work hardening. Heat treatment plays a pivotal role in enhancing the mechanical properties of this alloy, notably its strength and ductility.

The standard heat treatment process involves:

- Solution annealing

- Rapid cooling

This method preserves the alloy’s characteristic low invar coefficient of thermal expansion, while simultaneously enhancing its performance in different uses. As noted by Charles-Edouard Guillaume, ‘This alloy has been so important to scientific advancement that it earned the Nobel Prize in 1920 for its inventor.’ This historical significance highlights the importance of these alloys in precision instruments and components.

Moreover, these alloys have a long history of uses in:

- Electronics

- Aerospace

- Cryogenic transport

showcasing their versatility. It is essential for professionals to comply with substance specifications and guidelines to ensure best practices are followed during both machining and heat treating of alloys. With a typical hardness range of 84 to 88 on the Rockwell B scale for ½ hard material, these considerations are essential in optimizing the use of Invar, particularly regarding the invar coefficient of thermal expansion in high-performance uses, such as selecting TRB for high-speed spindles.

Measuring the Coefficient of Thermal Expansion: Techniques and Considerations

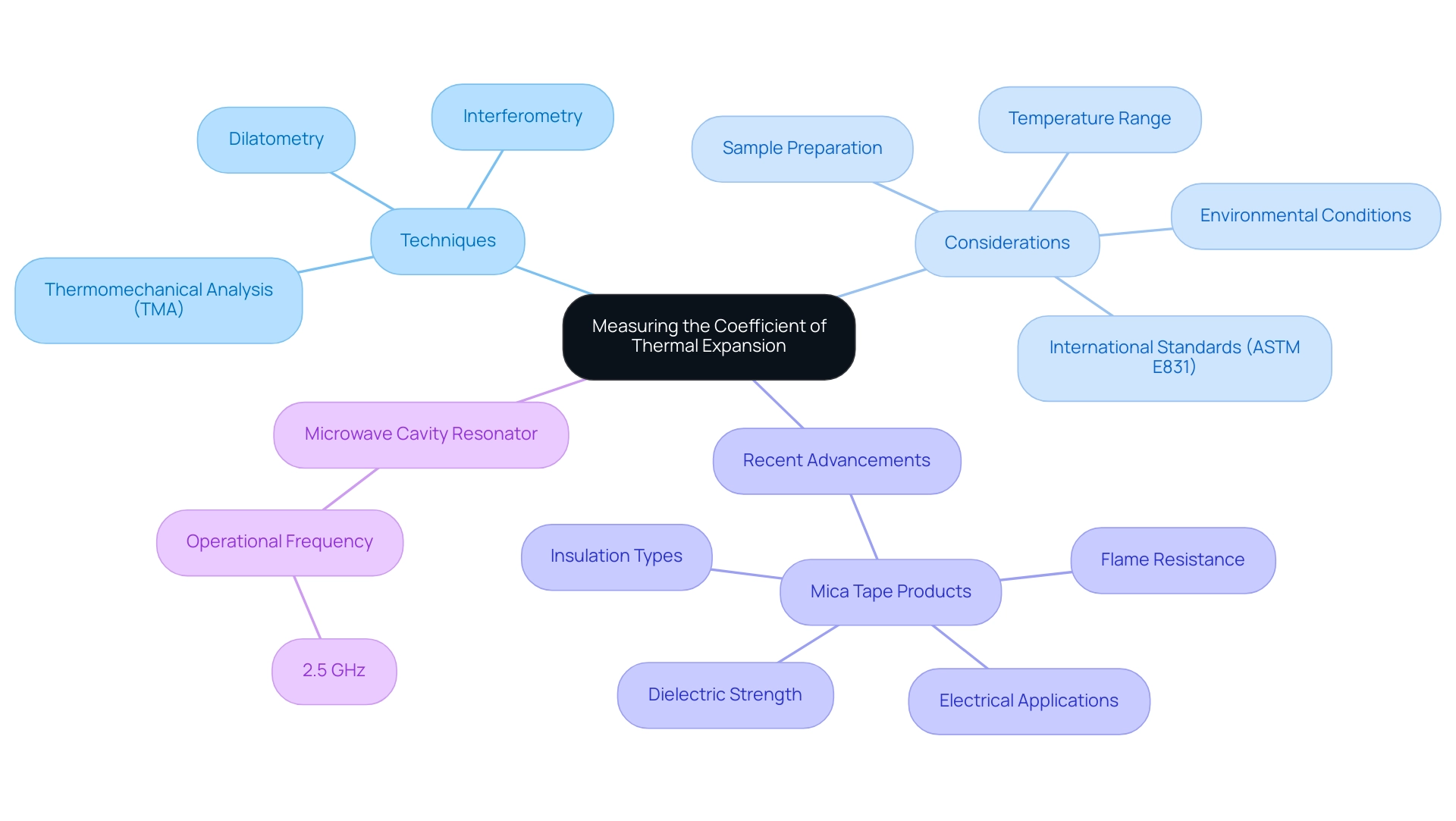

Several techniques are employed to measure the invar coefficient of thermal expansion, with dilatometry, interferometry, and thermomechanical analysis (TMA) being the most prominent. Dilatometry, in particular, remains the most widely used method for measuring the invar coefficient of thermal expansion by accurately assessing a sample’s length change as it undergoes temperature variations. The accuracy of this technique hinges on meticulous sample preparation, the temperature range utilized, and the environmental conditions during measurement.

As noted by researcher Xiulu Hao, “The black shading tube makes the dark environment for interfering the optical path to avoid the interference of external light,” which underscores the significance of controlling external influences. Moreover, adherence to international standards, such as ASTM E831, is critical for validating results and ensuring consistency across different testing environments. Recent advancements in techniques for measuring the invar coefficient of thermal expansion have enhanced reliability and usage across various sectors, paralleling the evolution of Mica Tape products, which are essential for high-temperature resistance and electrical insulation in diverse uses—from household appliances to critical electrical systems.

This includes specialized Mica Tape for electrical applications that exhibit excellent flame resistance and dielectric strength, as well as Mica Sheet Tape for insulating large flat surfaces and Insulating Mica Tapes designed for high-grade insulation in coils and capacitors. Additionally, it is noteworthy that the microwave cavity resonator operates at a frequency of 2.5 GHz, illustrating the precision required in these measurements.

Conclusion

Understanding the Coefficient of Thermal Expansion (CTE) is crucial for ensuring the reliability and performance of engineering components in a variety of applications. This article has explored the significance of CTE, particularly highlighting how materials respond to temperature fluctuations. The unique properties of Invar, a low thermal expansion alloy, have been discussed in detail, emphasizing its critical role in precision engineering and manufacturing.

The historical context of Invar and its derivatives illustrates the advancements in low thermal expansion materials that have emerged over time, driven by the need for enhanced dimensional stability in high-stakes environments. Furthermore, the discussion on machining techniques and heat treatment underlines the necessity of adopting tailored approaches to optimize the performance of Invar alloys, ensuring they meet the demands of modern engineering applications.

Ultimately, the careful selection of materials based on their thermal expansion characteristics is not merely a technical consideration; it is a strategic imperative for procurement managers. By prioritizing materials with favorable CTE properties, organizations can safeguard against potential failures and enhance the integrity of their engineering designs. As the landscape of material science continues to evolve, staying informed about these critical parameters will empower professionals to make informed decisions that drive innovation and excellence in their respective fields.