Blogs

Understanding Permalloy Composition: An In-Depth Tutorial for Material Scientists

Overview

The article focuses on the composition and properties of permalloy, primarily consisting of 80% nickel and 20% iron, which grants it exceptional magnetic characteristics suitable for various applications in electronics and automotive sectors. It supports this by detailing how the alloy’s low coercivity and high permeability make it ideal for components like sensors and transformers, while also discussing advancements in manufacturing processes and the importance of quality control to ensure consistent performance.

Introduction

In the realm of advanced materials, Permalloy stands out as a cornerstone in the development of high-performance magnetic applications. Comprising primarily nickel and iron, this versatile alloy is renowned for its exceptional magnetic permeability and low coercivity, making it an essential component across various industries, from electronics to aerospace.

As technology continues to evolve, so too does the demand for innovative solutions that leverage Permalloy’s unique properties. This article delves into the fundamental aspects of Permalloy, exploring its composition, manufacturing processes, and the rigorous quality evaluations that ensure its reliability in critical applications.

Furthermore, it highlights emerging trends and best practices for procurement managers seeking to optimize their sourcing strategies in a competitive landscape, underscoring the importance of collaboration and adaptability in navigating the future of this vital material.

Fundamentals of Permalloy: Composition and Properties

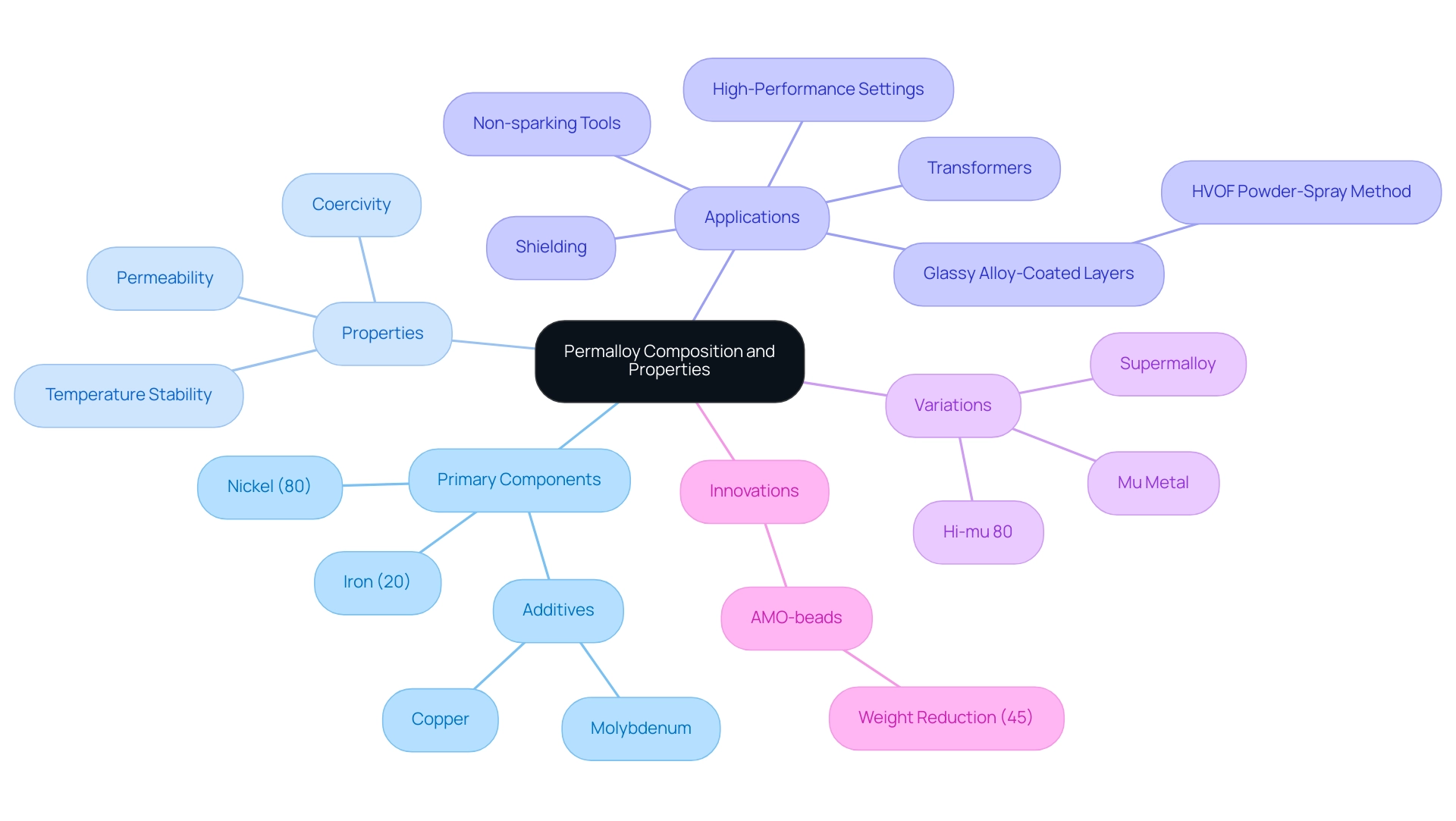

A permalloy composition, which is primarily made up of 80% nickel (Ni) and 20% iron (Fe), offers outstanding permeability and low coercivity, rendering it suitable for numerous uses related to magnetism. To enhance its properties, small quantities of molybdenum (Mo) or copper (Cu) may be added, ensuring superior corrosion resistance and high-temperature stability. A defining trait of this alloy is its capacity to be magnetized effortlessly and to demagnetize with minimal residual magnetism, essential for uses in shielding, transformers, and inductors.

Furthermore, the stability of the magnetic properties across varying temperature conditions solidifies the role of permalloy composition as a preferred substance in high-performance settings. Successful production of permalloys composition using high-purity raw materials without prealloying guarantees consistent performance quality. Variants of this alloy, such as Supermalloy, Mu metal, and Hi-mu 80, showcase its versatility for diverse application needs.

Significantly, this alloy’s properties also render it appropriate for application in non-sparking tools, which are crucial in explosive settings, ensuring safety and dependability. The application of sophisticated substances can also provide considerable benefits, as demonstrated by AMO-beads which can decrease steel gear weight by approximately 45%. Furthermore, advancements in substances such as glassy alloy-coated layers generated through the HVOF powder-spray method offer improved corrosion resistance and hardness, demonstrating suitability for use in solder-melting containers and as heat-resistant substances.

Applications of Permalloy in Modern Technology

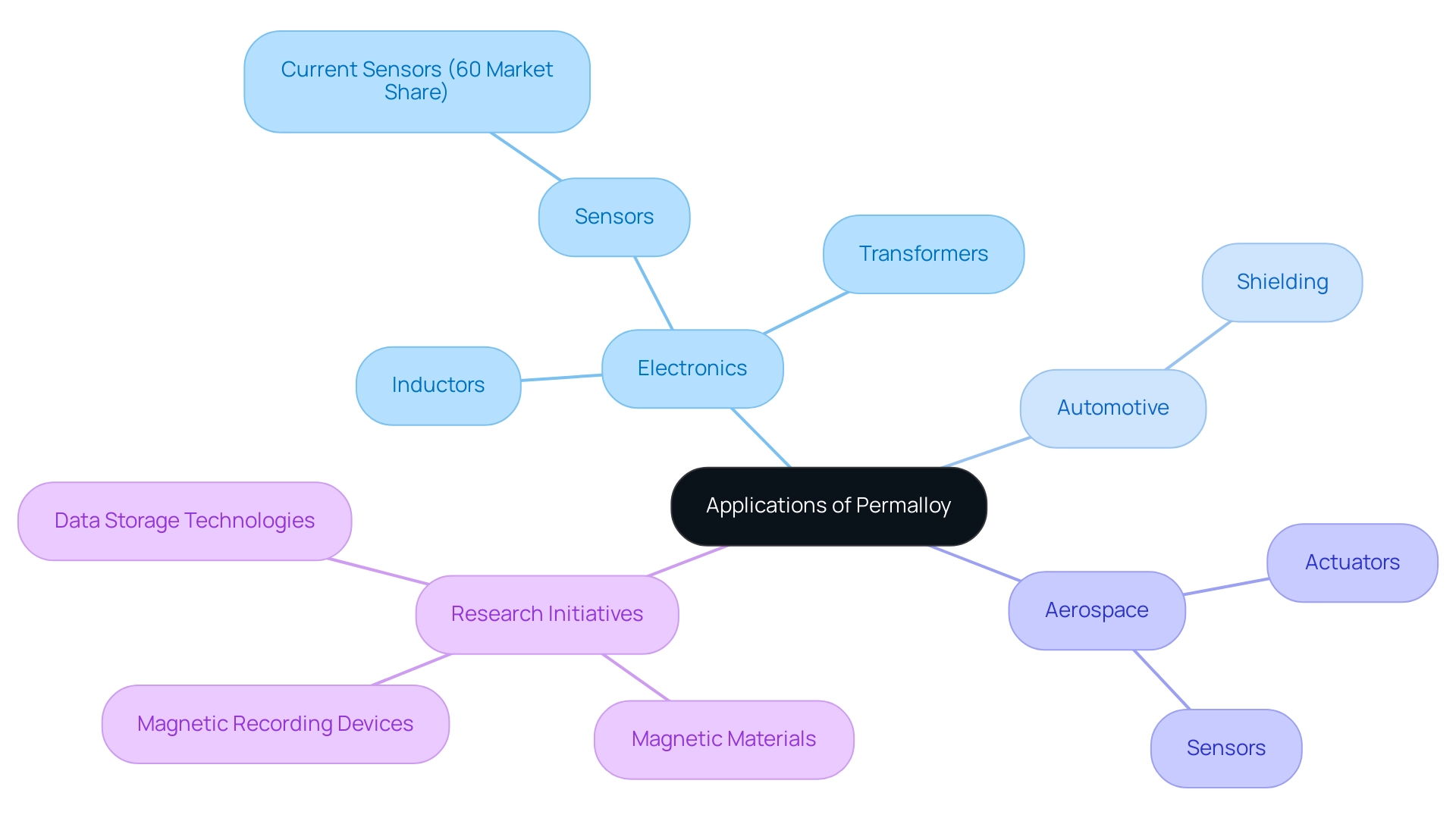

The unique properties of this permalloy composition make it an essential material in multiple sectors, especially in electronics and automotive uses. In the electronics sector, the high permeability of permalloy composition makes it essential for components like:

- Sensors

- Transformers

- Inductors

This facilitates efficient energy transfer and minimizes energy loss. Significantly, the Current Sensors segment leads the market with approximately 60% share, highlighting the importance of permalloy composition in the development of sensor technologies.

The automotive sector utilizes a specific permalloy composition for shielding, which protects delicate electronic parts from external interference, thus improving the reliability of vehicle electronic systems. Additionally, in aerospace technology, a specific permalloy composition is used in specialized sensors and actuators where precision and reliability are crucial. The versatility of the permalloy composition extends to research initiatives focused on magnetic materials, where scientists explore its potential for advancements in data storage technologies and magnetic recording devices.

As highlighted by industry experts, ‘the ongoing research and development in technology hubs contribute significantly to advancements in sensor technologies, creating growth opportunities for manufacturers.’ Given the technological evolution, the significance of this material is assured, leading to sustained research and development efforts that provide abundant opportunities for innovation within the field.

Manufacturing Processes for Permalloy

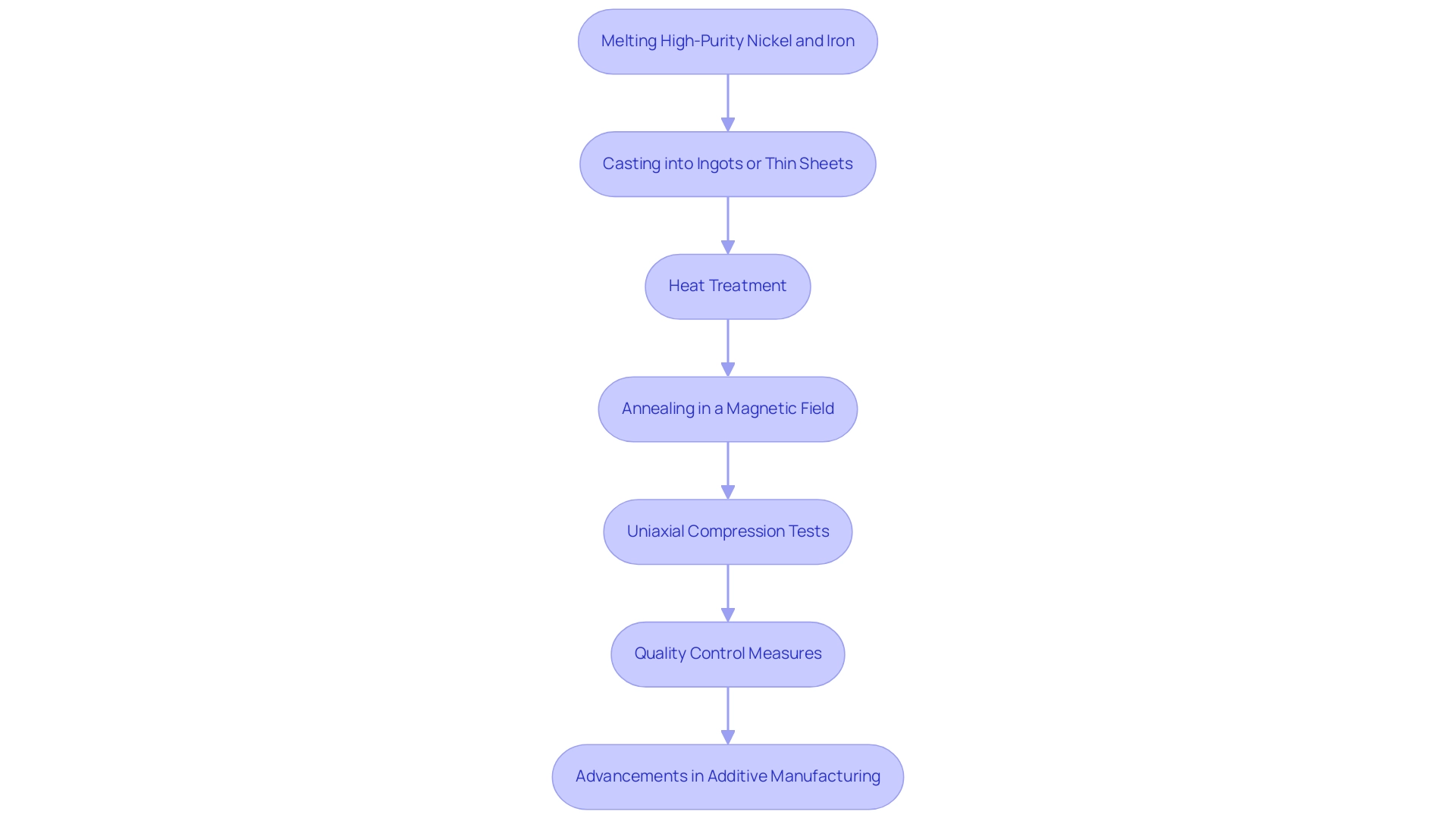

The manufacturing process of permalloy composition encompasses several crucial steps, beginning with the melting of high-purity nickel and iron in a controlled atmosphere to prevent contamination. Once melted, the alloy is cast into either ingots or thin sheets, customized for particular uses. The role of heat treatment is essential in this process; it enhances the properties of the alloy by precisely controlling the microstructure of the permalloy composition.

Techniques such as annealing in a magnetic field can significantly enhance the alignment of the permalloy composition, thereby boosting its performance in diverse applications. Notably, there was no significant change in permeability and magnetization saturation after annealing, affirming the stability of these properties. Additionally, uniaxial compression tests were performed on the permalloy composition to a true strain of 0.9 at temperatures ranging from 900 °C to 1150 °C, providing critical insights into the mechanical behavior of the alloy under stress.

Manufacturers must adhere to rigorous quality control measures, including thorough testing of magnetic properties and compliance with international standards, to ensure the reliability and performance of products made with permalloy composition in the marketplace. As noted by expert F.L. Kong,

Owing to these advantages, the glassy alloy-coating technique has been applied to surface glassy alloy layers inside solder-melting vessels in continuous solder casting machines of 50 cm in diameter and 34–40 cm in height.

This technique is especially pertinent in today’s manufacturing methods, as it underscores the significance of quality control in improving the performance of permalloy composition. Furthermore, recent advancements in additive manufacturing processes, such as directed energy deposition (DED) and laser beam melting (LBM), underscore the ongoing innovations in the production techniques of permalloy composition. A case study on the optimization of selective laser melting (SLM) parameters for pure iron demonstrated that laser power significantly affects the properties, illustrating the advantages of modern manufacturing techniques.

Evaluating the Quality of Permalloy

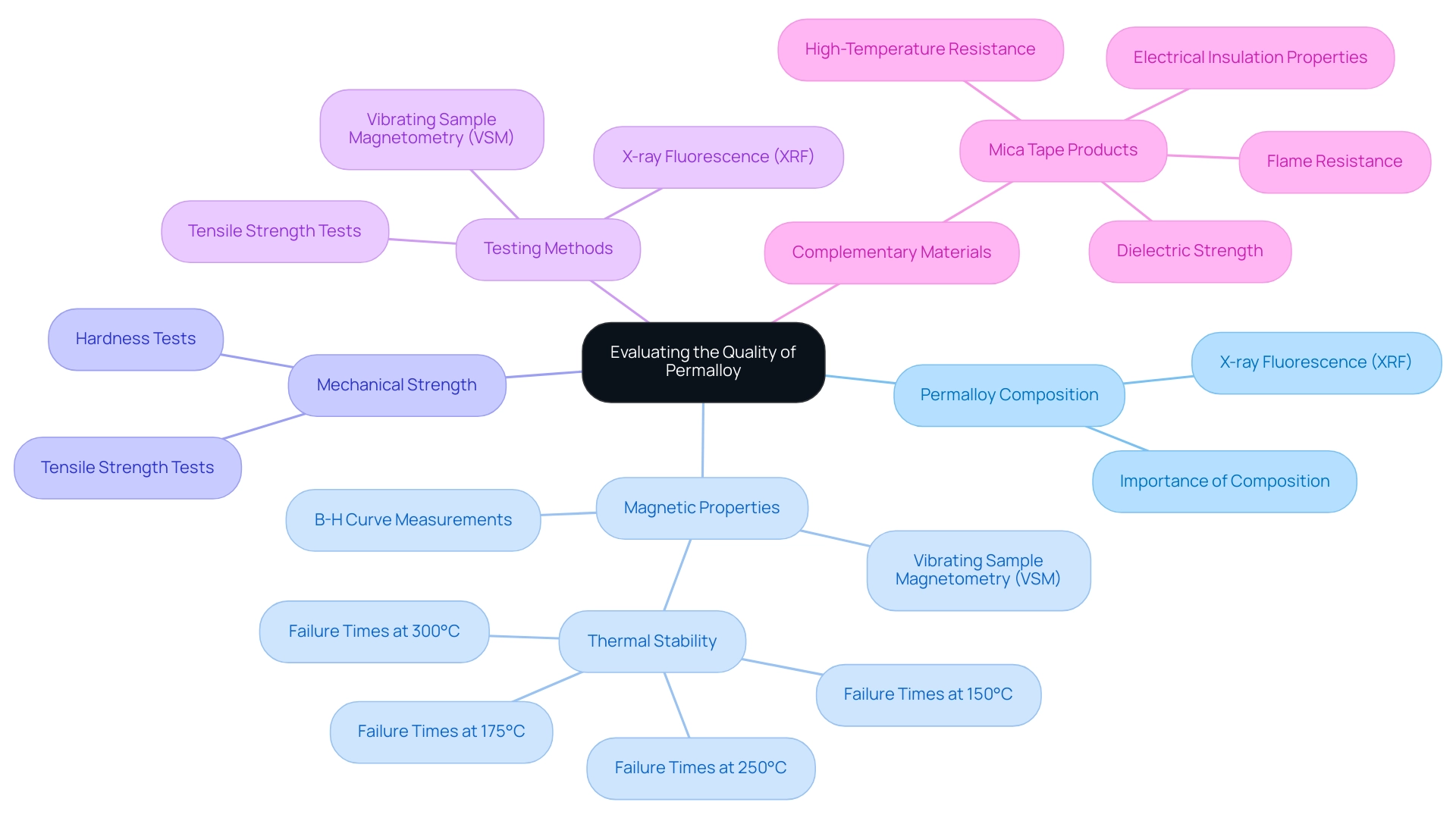

Assessing the quality of this alloy involves a multifaceted approach, considering key elements such as permalloy composition, attraction properties, and mechanical strength. Material scientists employ a variety of testing methods to ensure the integrity of the alloy. For instance, X-ray fluorescence (XRF) is a widely utilized technique for verifying the permalloy composition, which is crucial for consistency and performance.

To assess the magnetic properties of materials, including permalloy composition, techniques like vibrating sample magnetometry (VSM) and B-H curve measurements are employed, providing critical insights into their permeability and coercivity. Furthermore, mechanical properties are validated through rigorous tensile strength and hardness tests, confirming that the alloy can endure the physical demands of its intended uses. Notably, studies have shown that the permalloy composition exhibits varying failure times at temperatures of 150, 175, 250, and 300 degrees C, emphasizing the significance of thermal stability in its applications.

In this context, complementary materials such as Mica Tape products become essential, offering high-temperature resistance and excellent electrical insulation properties, including flame resistance and dielectric strength. These features make Mica Tape essential in uses ranging from the manufacture of fire-resistant cables to critical electrical insulation systems, ensuring safety and reliability in electrical systems. The case study titled ‘Two-dimensional Vector Magnetic Properties in Transformer Models’ demonstrates the use of finite element method (FEM) to examine the characteristics of a specific alloy in practical transformer models.

It is paramount for procurement managers to collaborate with suppliers who provide thorough documentation of these evaluations. Ensuring that resources meet industry standards and align with specific project requirements enhances the reliability and efficacy of the final products.

Future Trends in Permalloy Research

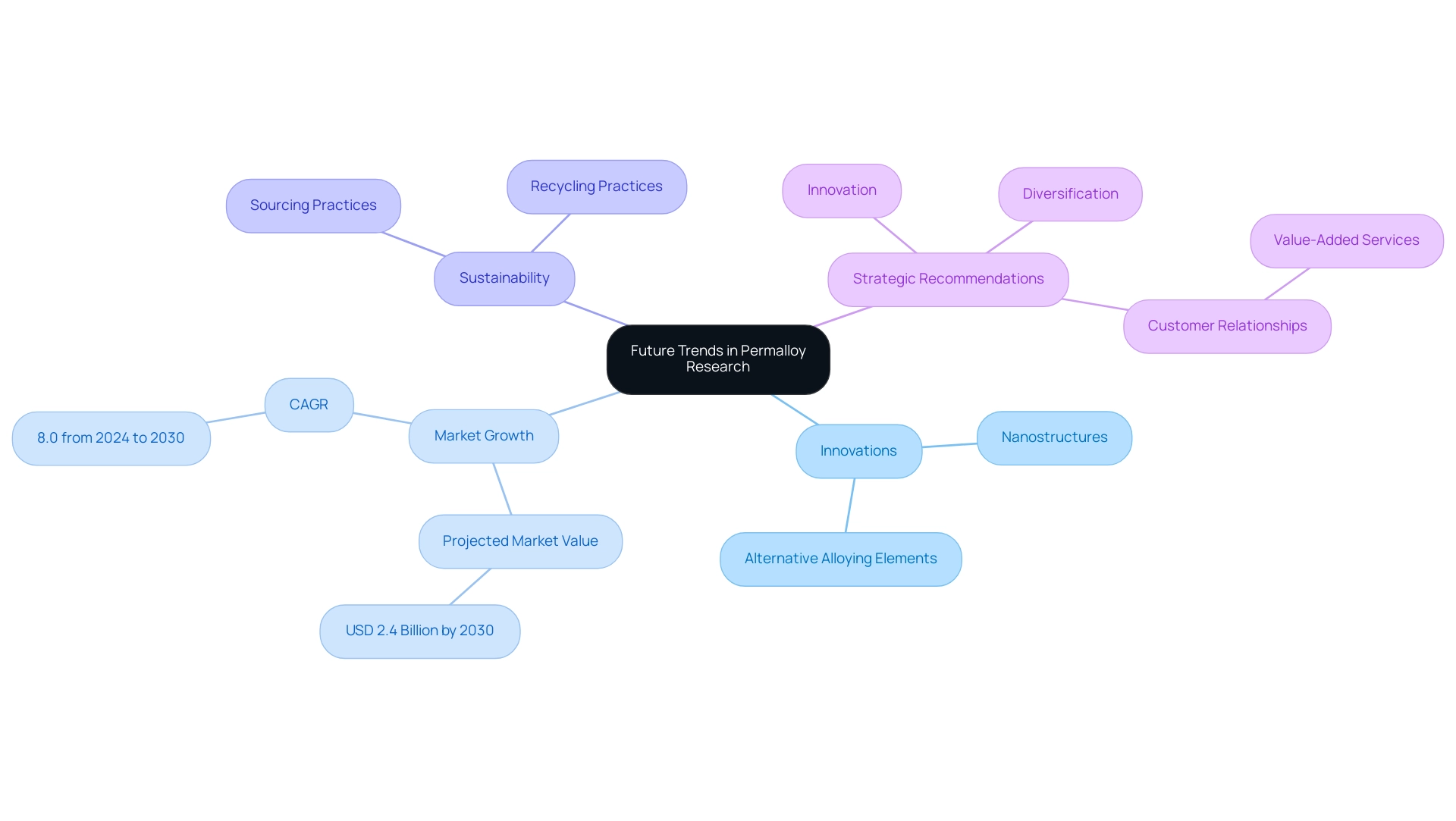

Studies on the permalloy composition are experiencing notable progress, especially in improving its attraction characteristics and expanding its uses. Recent studies are increasingly focused on integrating nanostructures and exploring alternative alloying elements in permalloy composition to optimize performance in high-frequency domains, such as telecommunications and advanced electronics. With the global market projected to reach USD 2.4 billion by 2030, growing at a CAGR of 8.0% from 2024 to 2030, the importance of these innovations cannot be overstated.

Furthermore, there is a significant shift towards sustainable sourcing and recycling practices for this alloy, driven by environmental concerns and the industry’s need for energy-efficient substances. However, the market also encounters obstacles, including rivalry from alternative magnetic substances that could affect the demand for permalloy composition. As sustainability becomes a priority across sectors, scientists and procurement managers must remain vigilant regarding these trends to align their sourcing strategies with future market demands.

Collaborative efforts between academia and industry will be crucial in propelling innovations, thereby shaping the future landscape of these applications.

As noted by a Global Consulting Firm, “Our company has been working with for some years now and we are very happy with the quality of the reports provided by the company.” This sentiment highlights the significance of dependable partnerships in navigating the complexities of resource sourcing in a rapidly evolving market. Additionally, companies in the commercial alloys market can strategize for success by focusing on:

- Innovation

- Diversifying product offerings

- Strengthening customer relationships through value-added services

These strategies are crucial for achieving competitive advantage and long-term growth.

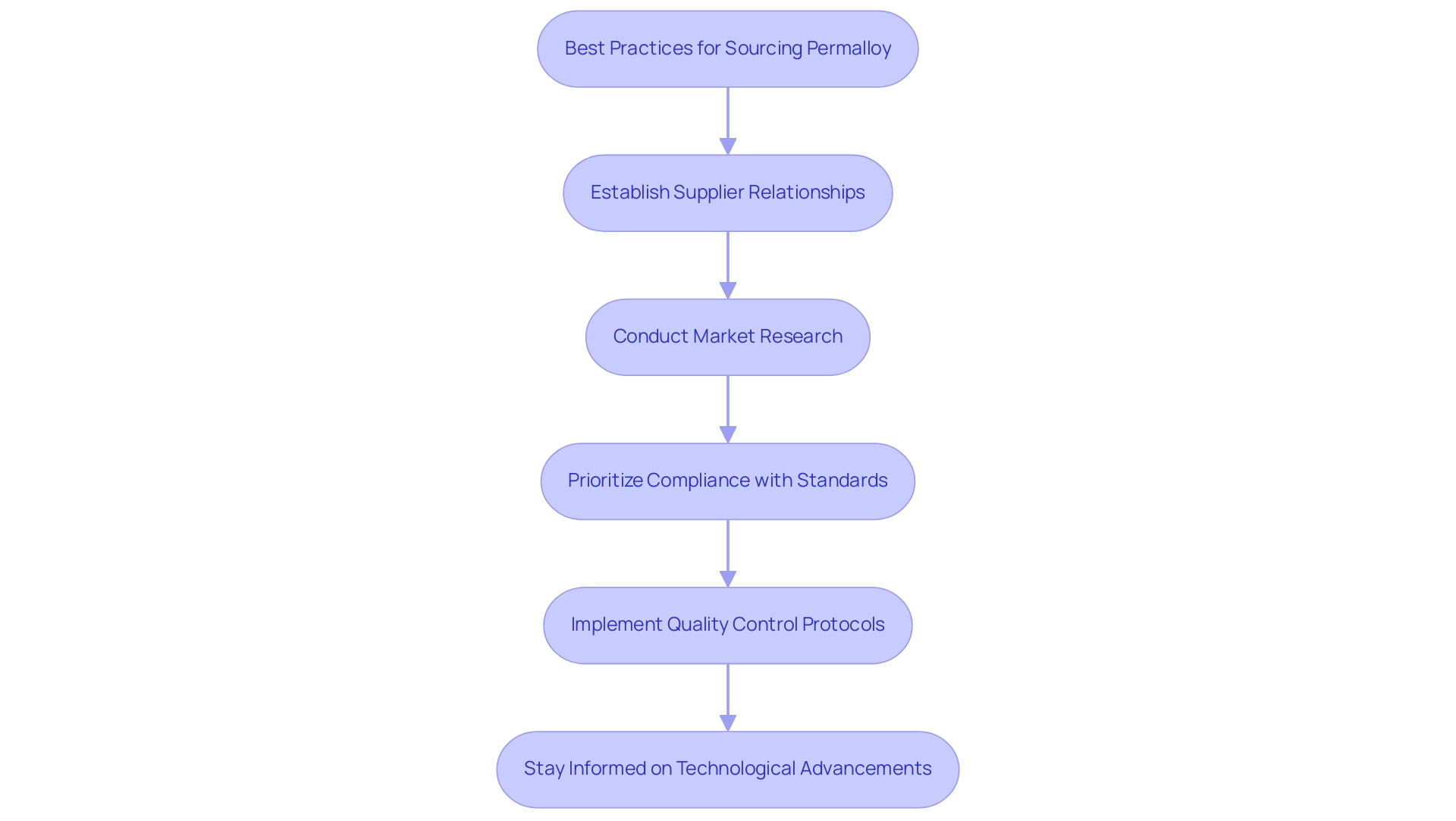

Best Practices for Sourcing Permalloy

To enhance their supply chain strategy when sourcing materials, procurement managers should consider the permalloy composition and follow several key best practices. Establishing strong relationships with reputable suppliers, such as those specializing in Mica Tape products, is paramount, as it ensures the delivery of consistent quality and reliable lead times for high-temperature resistance and electrical insulation applications. Domadia is committed to quality and customer-centric solutions, which enhances the credibility of their offerings.

Conducting in-depth market research will enable managers to grasp pricing trends, allowing for the negotiation of contracts that yield favorable terms for both parties involved. It is crucial to prioritize suppliers who comply with international standards and can provide necessary certifications for their products, enhancing transparency and trust in the procurement process. Implementing a rigorous quality control protocol, which includes sample testing prior to full-scale orders, guarantees that the components meet specific project requirements.

Furthermore, staying informed about technological advancements in the industry can reveal new supplier opportunities and innovative products, such as Mica Tape, that may deliver superior performance or cost efficiencies. For example, Mica Tape exhibits excellent flame resistance and dielectric strength, making it ideal for applications in fire-resistant cables. As Fausto Fiorillo observes,

In this report we present a summary of the characteristics of soft and hard substances of current and potential use in electrotechnical devices.

This insight emphasizes the ongoing evolution within the substance landscape, underscoring the significance of adaptability in procurement strategies. Notably, magnetic losses in soft magnetic substances are primarily due to eddy currents generated by time-varying magnetic flux, which is a critical consideration in the sourcing process. Additionally, the polarization extinction ratio for the reflected light in silicon waveguides is 15.8 dB, with a reflectivity of 93.1%.

This technical detail illustrates the performance characteristics that may influence the selection of materials and suppliers in the procurement of materials based on permalloy composition.

Conclusion

The exploration of Permalloy reveals its fundamental importance in modern technological applications, characterized by its unique composition and magnetic properties. With a primary makeup of nickel and iron, Permalloy’s exceptional magnetic permeability and low coercivity make it indispensable across various sectors, including electronics, automotive, and aerospace. The manufacturing processes employed ensure that the alloy maintains high standards of quality, with rigorous evaluations guaranteeing its reliability in critical applications.

As the demand for innovative solutions continues to grow, the future of Permalloy is bright, driven by advancements in research that focus on enhancing its magnetic characteristics and expanding its applications. The shift towards sustainable practices and the integration of new technologies will play a pivotal role in shaping the landscape of Permalloy usage. Procurement managers must remain attuned to these trends, leveraging best practices in sourcing to secure high-quality materials that meet evolving industry standards.

Ultimately, collaboration with reliable suppliers and adherence to rigorous quality control measures will be vital in navigating the complexities of sourcing Permalloy. By strategically aligning procurement strategies with emerging market demands, organizations can ensure that they not only meet current needs but also position themselves for future growth in an increasingly competitive environment.