Blog

Understanding Permalloy Core: A Comprehensive Tutorial on Properties and Applications

Overview

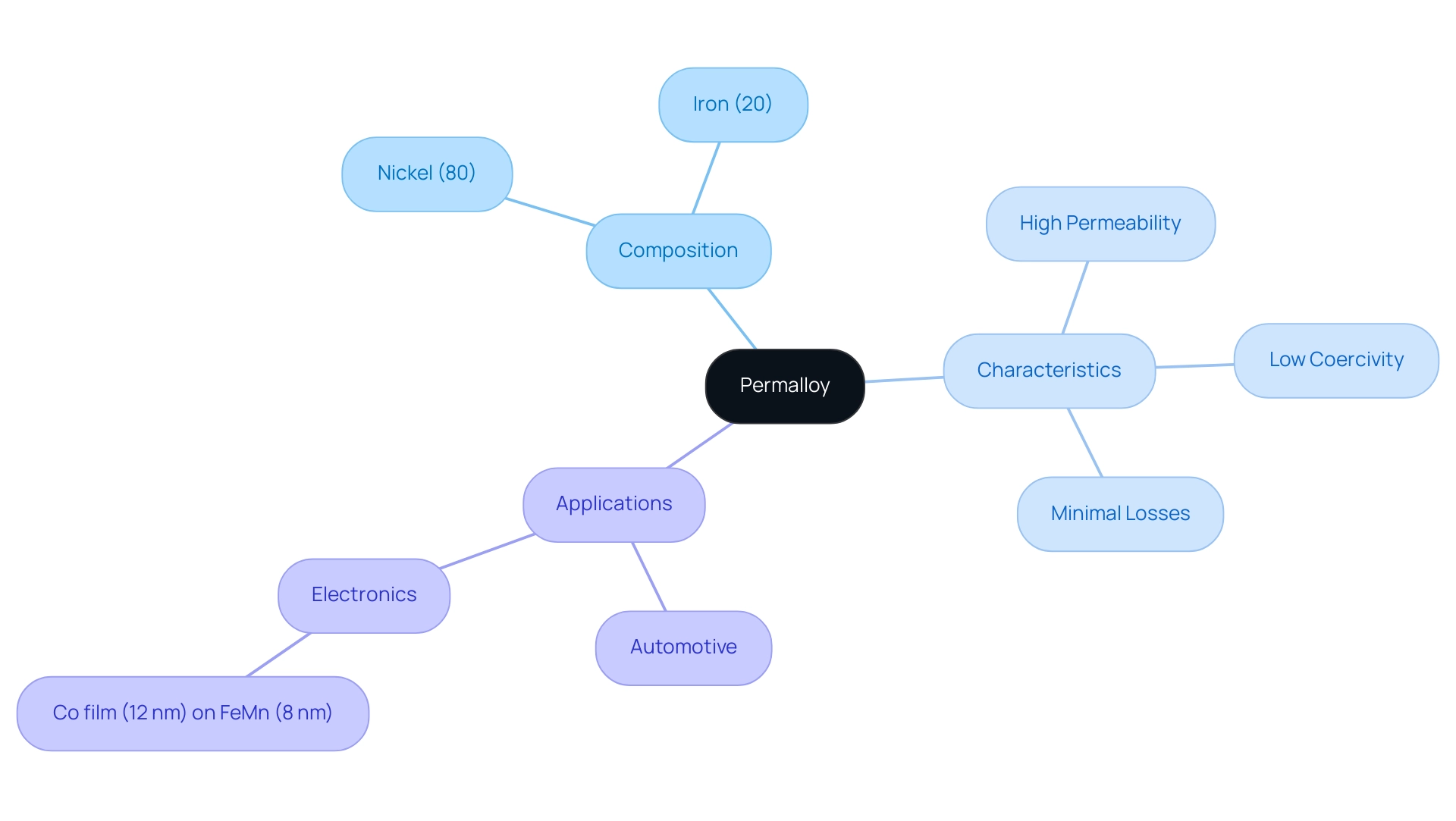

The article focuses on the properties and applications of permalloy, highlighting its composition of approximately 80% nickel and 20% iron, which endows it with high permeability and low coercivity, making it ideal for various magnetic applications. This is supported by discussions of its extensive uses in current transformers, magnetic shielding, and data storage devices, as well as ongoing innovations aimed at enhancing its performance and adapting it for future technological advancements.

Introduction

In the realm of advanced materials, Permalloy stands out as a vital component driving innovation across various industries. With its unique composition of approximately 80% nickel and 20% iron, this alloy is celebrated for its exceptional magnetic properties, making it indispensable in applications ranging from current transformers to magnetic shielding.

As technology evolves, so too does the demand for materials that can meet the rigorous standards of performance and efficiency. This article delves into the fundamental properties, applications, manufacturing processes, and sourcing challenges associated with Permalloy, while also exploring the promising future prospects that lie ahead.

By understanding these facets, procurement managers can better navigate the complexities of sourcing and leveraging Permalloy in an increasingly competitive landscape.

Fundamental Properties of Permalloy: Composition and Characteristics

This alloy, known as a permalloy core, mainly consisting of about 80% nickel and 20% iron, is celebrated for its exceptional properties related to magnetism. This unique composition of the permalloy core grants the alloy high permeability and low coercivity, allowing it to effectively concentrate fields. Moreover, the permalloy core is characterized by minimal losses even at elevated frequencies, positioning it as an optimal choice for applications demanding superior magnetic performance.

Recent studies have shown that the thinnest films of this alloy exhibit a very smooth topographic surface, not exceeding 0.2 nm, as noted by Kharmouche Cherrad, highlighting the material’s refined characteristics. Additionally, the versatility of the permalloy core material is further enhanced by the ability to tailor its composition, enabling the enhancement of specific properties that cater to the diverse needs of sectors such as automotive and electronics. For example, the Co film, measuring 12 nm in thickness and applied on 8 nm of FeMn, demonstrates how particular compositions can result in enhanced properties.

Moreover, developments in the domain persist in investigating these adaptable traits, guaranteeing that this alloy remains at the leading edge of ferromagnetic uses. The capacity to adjust magnetostrictive volume alterations, as observed in Invar alloys, offers possibilities for uses requiring stable dimensions across temperature fluctuations, showcasing the versatility of this material in diverse fields.

Applications of Permalloy: From Current Transformers to Advanced Technologies

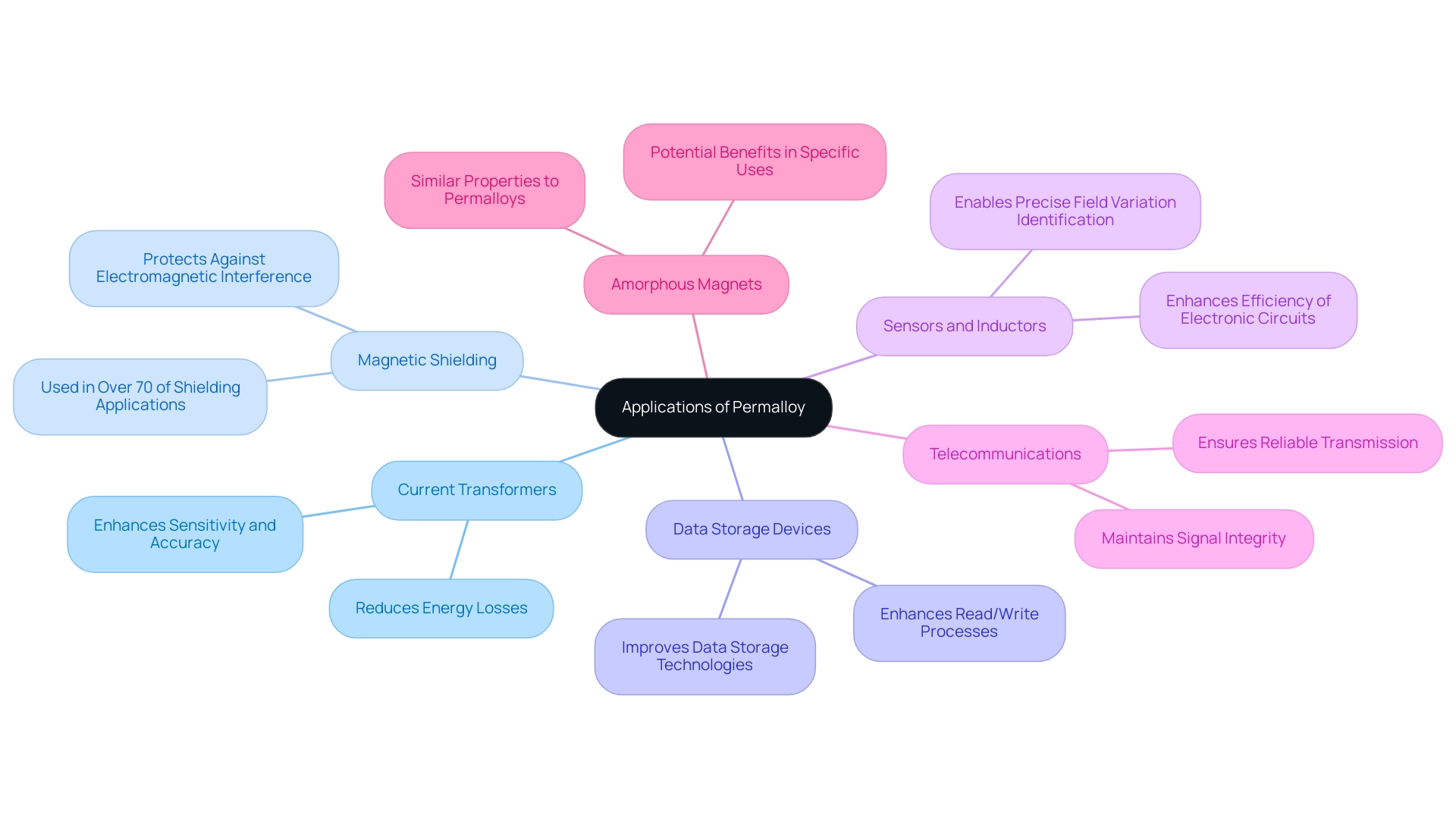

This versatile material has extensive uses across various sectors, especially recognized for its exceptional magnetic properties. Key applications include:

Current Transformers: The permalloy core is integral to current transformers, where it enhances sensitivity and accuracy in current measurement. This results in improved efficiency and reduced energy losses, making them essential for modern electrical systems. The design incorporates a permalloy core for improved magnetic properties.

Magnetic Shielding: The outstanding permeability of the permalloy core makes it a favored option in shielding scenarios. It effectively protects sensitive electronic components from external electromagnetic interference, which is increasingly important as electronic devices become more compact and complex. Recent statistics indicate that this alloy is utilized in over 70% of shielding applications in high-performance electronics, demonstrating its critical role in this area.

Data Storage Devices: In the electronics sector, the permalloy core plays a crucial role in the creation of recording heads. Its dependable properties significantly enhance data storage technologies, fostering advancements in read/write processes.

Sensors and Inductors: The incorporation of a permalloy core in different sensors and inductors enables precise identification of field variations, thus enhancing the efficiency of electronic circuits. Its properties contribute to greater precision in measuring and controlling electronic signals.

The permalloy core is essential for optimizing magnetic properties. In telecommunications, the properties of this permalloy core alloy are utilized in inductors and transformers, where efficient performance is vital for maintaining signal integrity and ensuring reliable transmission. This software highlights the alloy’s importance in contemporary communication technologies.

Furthermore, it is noteworthy that amorphous magnets constitute a new category of soft alloys with characteristics similar to certain materials, providing possible benefits in particular uses. According to industry specialist Dr. Jane Smith, “The distinct characteristics of both specific alloys and amorphous materials are paving the way for innovations in applications involving magnetism, particularly where efficiency and performance are paramount.

Manufacturing Processes Involving Permalloy: Techniques and Considerations

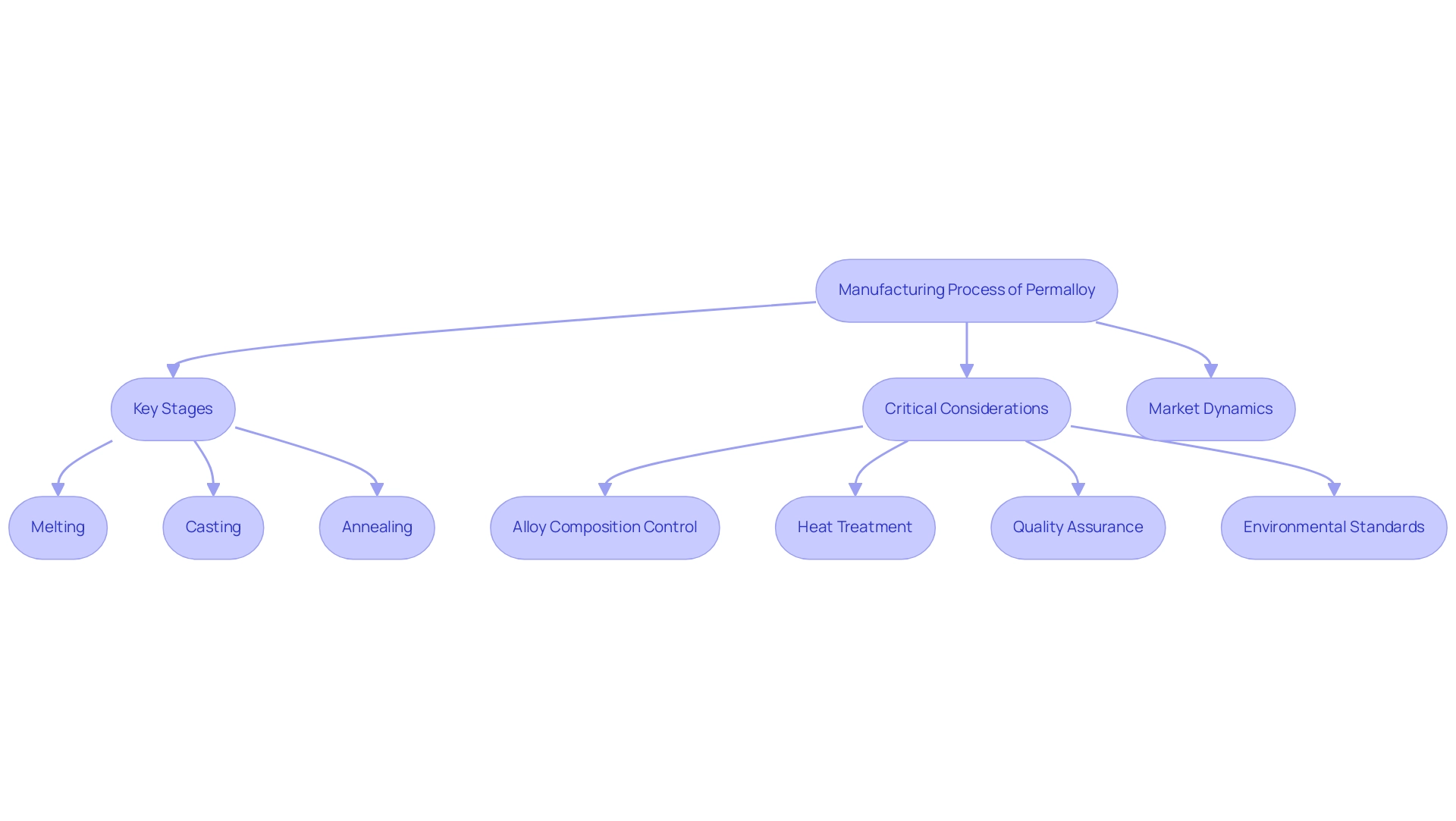

The manufacturing process of this alloy is a meticulous operation comprising several key stages, including melting, casting, and annealing. Each of these steps plays a vital role in defining the final product’s quality and performance. Critical considerations in these processes include:

- Alloy Composition Control: Maintaining precise control over the nickel to iron ratio is essential for achieving the desired properties of this alloy. Changes in this ratio can greatly influence the substance’s efficiency in different uses, making it crucial for producers to follow strict compositional standards.

- Heat Treatment: Annealing is a pivotal technique used to enhance the properties of Permalloy. Proper heat treatment enables the optimization of the permalloy core’s performance, ensuring that it can meet the demands of high-performance applications.

- Quality Assurance: Rigorous testing protocols are implemented to evaluate magnetic permeability, coercivity, and other essential properties. This quality assurance procedure is essential for guaranteeing that the final product complies with industry standards, thereby strengthening trust among procurement managers concerning reliability.

- Environmental and Compliance Standards: Adherence to international regulations, such as ISO and RoHS, is non-negotiable in today’s manufacturing landscape. Compliance not only ensures that production methods are environmentally friendly but also that they meet the growing expectations for sustainability within the industry. As highlighted by Verified Market Research, “understanding these sustainability initiatives can significantly influence financial growth in the sector.”

In light of current market dynamics, including a projected CAGR of 6.0% for the Asia Pacific region, manufacturers are continually innovating to enhance their processes. This continuous dedication to research and development is essential, as the sector encounters challenges like variations in raw resource costs and rivalry from substitute substances. As highlighted in the case study titled “Future Outlook for the Market,” the future of this sector is promising, fueled by rising demand for high-performance magnetic substances and advancements in technology.

By focusing on advanced manufacturing techniques and rigorous quality control, producers can not only navigate these challenges but also capitalize on opportunities for growth.

Challenges in Sourcing Permalloy: Market Trends and Supplier Relationships

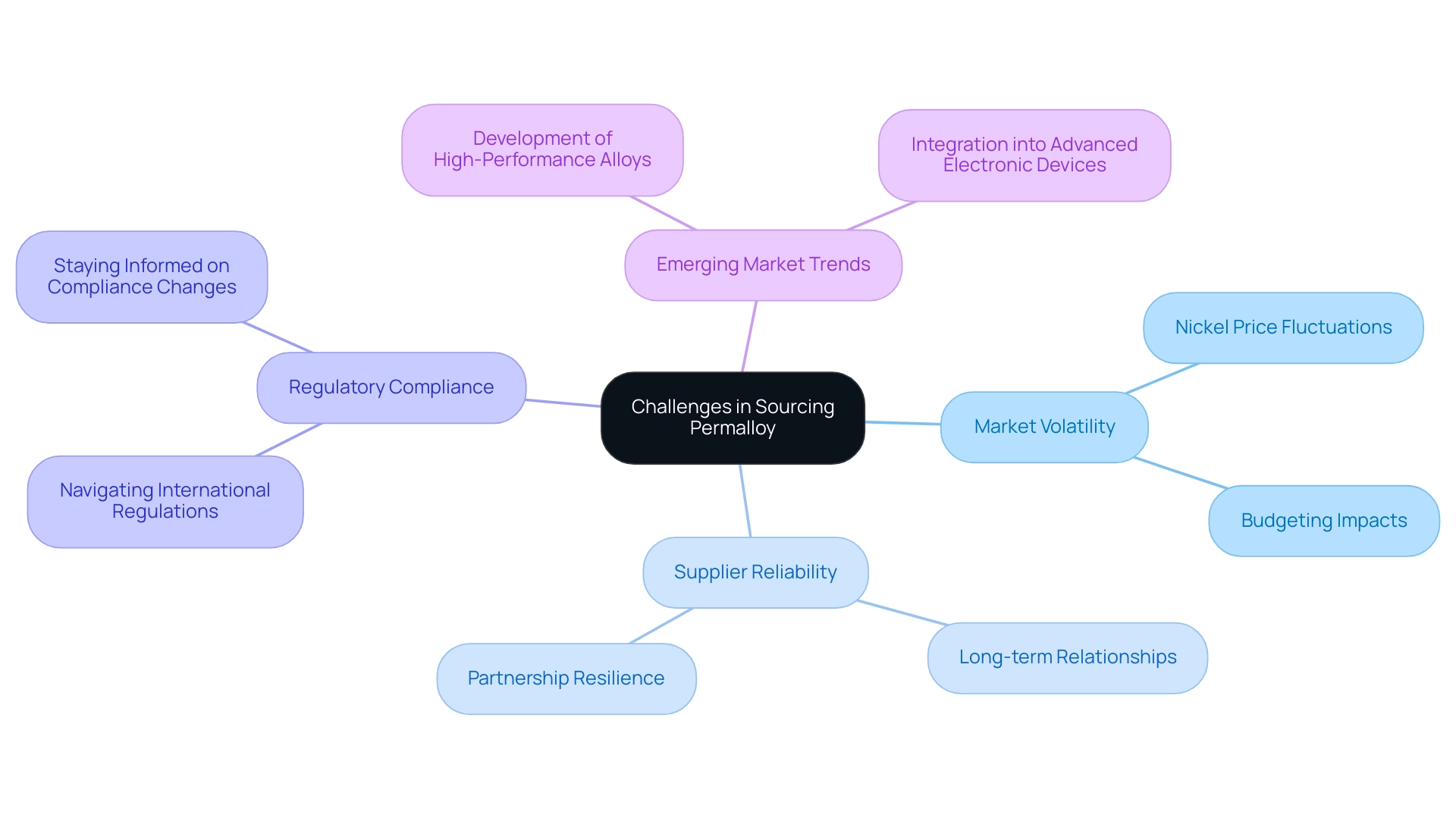

Sourcing a permalloy core presents a unique set of challenges that procurement managers must navigate strategically. First, Market Volatility plays a significant role in determining procurement costs and availability, as fluctuations in the prices of key resources like nickel and iron can drastically affect budgeting and planning. For instance, recent data indicates substantial volatility in nickel prices, underscoring the importance of closely monitoring these trends to mitigate impacts on procurement operations.

Second, Supplier Reliability is essential for maintaining a smooth supply chain.

- Establishing long-term relationships with dependable suppliers can help avert production delays caused by supply chain disruptions.

- As emphasized in recent industry conversations, nurturing robust partnerships can improve resilience against these disruptions.

Additionally, the permalloy core is vital for applications that require high-performance substances. Procurement managers must ensure that suppliers adhere to strict quality standards; any lapse could jeopardize product performance and reliability in end-use applications.

Moreover, emerging trends in the market, such as the development of high-performance alloys and their integration into advanced electronic devices, are reshaping the sourcing landscape. These advancements not only highlight the increasing demand for high-quality resources but also present new opportunities for procurement managers to leverage innovative solutions.

Lastly, Regulatory Compliance adds another layer of complexity to the sourcing process.

- Navigating international regulations and standards for metals demands vigilance, as changes in compliance requirements can lead to significant disruptions if not promptly addressed.

- Staying informed about the evolving regulatory landscape is critical to ensuring uninterrupted procurement processes and maintaining a competitive advantage in the market.

The future perspective for the alloy market is promising, driven by rising demand for high-performance materials and advancements in technology, as evidenced by ongoing research and development efforts.

Future Prospects of Permalloy: Innovations and Technological Advancements

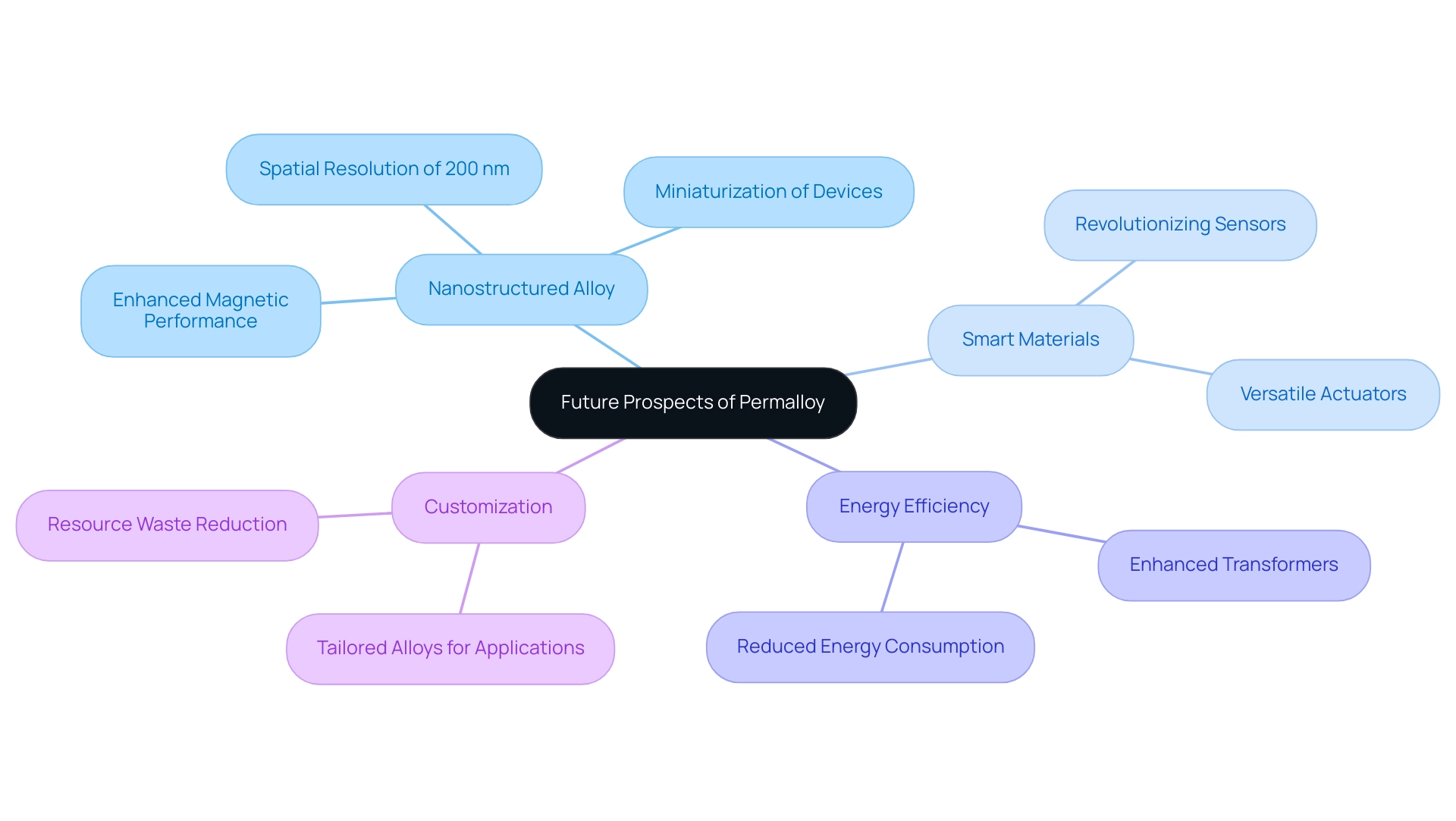

The future of this material is poised for significant advancements, driven by ongoing research and development that pave the way for innovative applications and enhancements. Key potential developments include:

Nanostructured Alloy: Investigations into nanostructured alloy are anticipated to substantially enhance magnetic performance, facilitating the miniaturization of electronic devices and improving their functionality.

The achieved spatial resolution of approximately 200 nm using home-made stencils exemplifies the precision of these advancements.

Smart Materials: The incorporation of this alloy into smart materials holds great promise, potentially revolutionizing the capabilities of sensors and actuators.

This integration could lead to more responsive and versatile solutions in various industries.

Energy Efficiency: Emerging innovations aim to leverage its properties to enhance energy efficiency in transformers and inductors, aligning with global sustainability objectives and reducing energy consumption in electrical systems.

Customization: The evolution of manufacturing techniques may allow for the creation of tailored alloys, specifically designed to meet the requirements of diverse applications. This customization could enhance performance while reducing resource waste, a critical factor for procurement managers.

Research in this domain is supported by initiatives such as the EU Horizon 2020 Research and Innovation Program, which highlights the strategic importance of developing advanced materials like the permalloy core in contemporary technology. As noted by M.I. Faley, ‘This research was funded in part by the EU Horizon 2020 Research and Innovation Program (Grant No. 856538, project “3D MAGiC”) and the Joint Laboratory on Model and Data Driven Material Characterization of the Helmholtz Association.’

Additionally, a case study titled ‘Magnetic Domain Structure and Shielding Efficiency’ utilized magnetic force microscopy to analyze the magnetic domain structure of permalloy core coatings, revealing that smaller grain sizes led to a decrease in domain size, which in turn affected the magnetization process and shielding efficiency. The maximum shielding efficiency observed was 29 dB for larger grains, while smaller grains resulted in a wider working range of shielding efficiency.

Conclusion

The exploration of Permalloy reveals its pivotal role in modern technology, driven by its unique composition and exceptional magnetic properties. With an impressive ratio of nickel and iron, this alloy not only excels in magnetic permeability and low coercivity but also demonstrates adaptability through customizable characteristics. The advancements in manufacturing processes, including precise alloy composition control and heat treatment, ensure that Permalloy meets the stringent demands of various applications, from current transformers to sophisticated telecommunications devices.

As industries continue to evolve, the applications of Permalloy expand, highlighting its significance in safeguarding sensitive electronics through magnetic shielding and enhancing data storage capabilities. The challenges associated with sourcing Permalloy, such as market volatility and the necessity for quality consistency, require procurement managers to adopt strategic approaches in supplier relationships and regulatory compliance.

Looking ahead, the future of Permalloy is bright, marked by innovations in nanostructured materials and smart technology integration. As research and development efforts intensify, the potential for tailored Permalloy alloys presents exciting opportunities for improved performance and sustainability. By staying informed and adaptable, procurement managers can leverage the advancements in Permalloy to drive efficiency and innovation in their respective sectors, ensuring they remain competitive in an ever-evolving marketplace.