Blogs

Understanding the Curie Temperature of Permalloy: An In-Depth Tutorial

Overview

The article focuses on understanding the Curie temperature of permalloy, emphasizing its significance in determining the magnetic properties and applications of this nickel-iron alloy. It explains that the Curie temperature is crucial for assessing permalloy’s performance in technology, as variations in composition and structural factors can significantly influence its magnetic characteristics, which are essential for reliable functioning in electromagnetic devices.

Introduction

In the realm of magnetic materials, the Curie temperature stands as a fundamental parameter that dictates the behavior and performance of ferromagnetic substances. This critical threshold marks the transition from a state of permanent magnetism to paramagnetism, a shift that can significantly impact the functionality of various technologies. Among these materials, permalloy—a nickel-iron alloy celebrated for its remarkable magnetic properties—illustrates the profound implications of Curie temperature on performance across diverse applications.

As the demand for high-performance magnetic materials escalates, understanding the factors that influence the Curie temperature becomes essential for procurement professionals seeking to optimize material selection and application. Through a comprehensive exploration of measurement techniques, compositional influences, and the strategic role of Curie temperature in magnetic applications, this article delves into the intricacies of permalloy and its critical importance in modern technology.

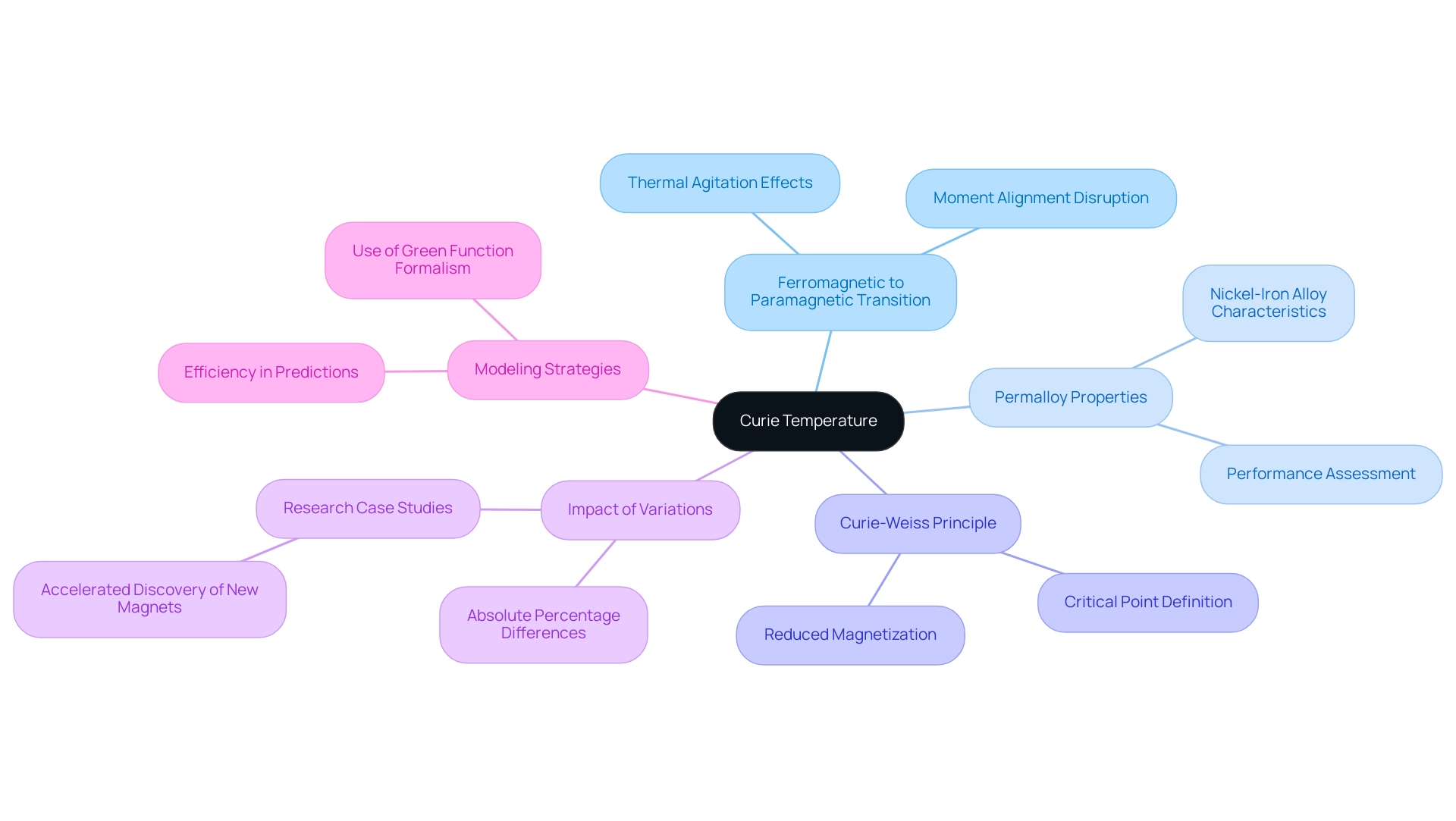

Defining Curie Temperature: The Key to Magnetic Properties

This critical point signifies a crucial limit, characterized as the degree at which a ferromagnetic substance shifts into a paramagnetic condition. Above this critical heat level, thermal agitation causes the disruption of moment alignment, leading to the loss of permanent properties. For permalloy, a nickel-iron alloy known for its remarkable properties, understanding the permalloy curie temperature is essential in assessing its overall performance.

According to the Curie-Weiss principle, the critical point occurs when reduced magnetization drops to zero. This transition plays a vital role in helping researchers understand how substances behave under varying conditions. Recent studies emphasize that substantial absolute percentage variations—surpassing 20% for specific chemical compounds—can impact the critical point, thus affecting the substance’s properties. This is especially pertinent in light of recent research, such as the case study titled ‘Accelerated Discovery of New Magnets in the Heusler Alloy Family,’ which outlines a systematic approach to designing novel substances.

Comprehending the critical point is vital for uses in electromagnetic devices, where reliable functioning is crucial across different operational conditions. As noted by Son Gyo Jung from the Cavendish Laboratory at the University of Cambridge:

The efficiency of our modeling strategy enabled us to surpass the performance of other studies by employing a significantly lower number of input features, and notably, without resorting to the use of regularization techniques during model optimization.

<p>This highlights the significance of advanced modeling in predicting the properties related to the permalloy Curie temperature, ultimately improving the design and use of materials.

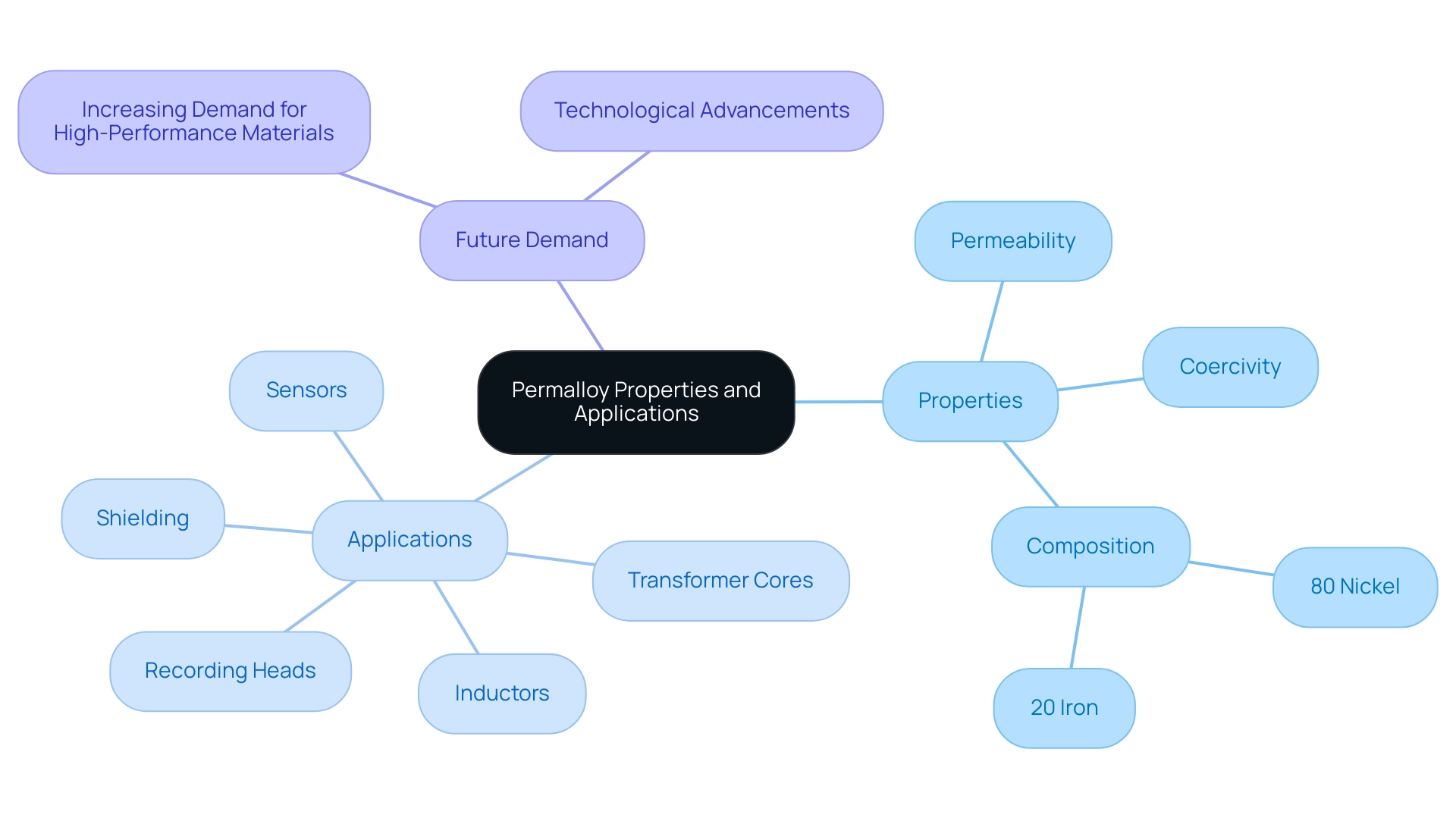

Exploring Permalloy: Properties and Applications in Technology

Permalloy offers remarkable magnetic permeability, typically around 100,000 µ, and exhibits low coercivity—usually under 10 Oe. These traits make it ideal for shielding applications and transformer cores, where magnetic performance and reliability are essential. Typically made up of around 80% nickel and 20% iron, this alloy displays exceptional properties that significantly improve the performance of various devices, including inductors, sensors, and recording heads used in hard drives.A recent case study titled Future Outlook projects a significant rise in the demand for magnetically reactive materials like Permalloy. Advancing technologies across sectors continue to fuel this upward trend.

<p>Moreover, the permalloy curie temperature contributes to Permalloy’s capability to provide consistent performance across a wide temperature range, further solidifying its position as a preferred choice in advanced technological applications. As mentioned by Dr. Jane Smith, a scientist specializing in substances, “Permalloy’s distinctive characteristics enable enhanced efficiency in applications involving magnetism, rendering it an essential asset in contemporary technology.” As the demand for high-performance materials continues to rise, the strategic advantages of utilizing Permalloy in these sectors become increasingly clear.

Measuring Curie Temperature: Techniques and Methodologies

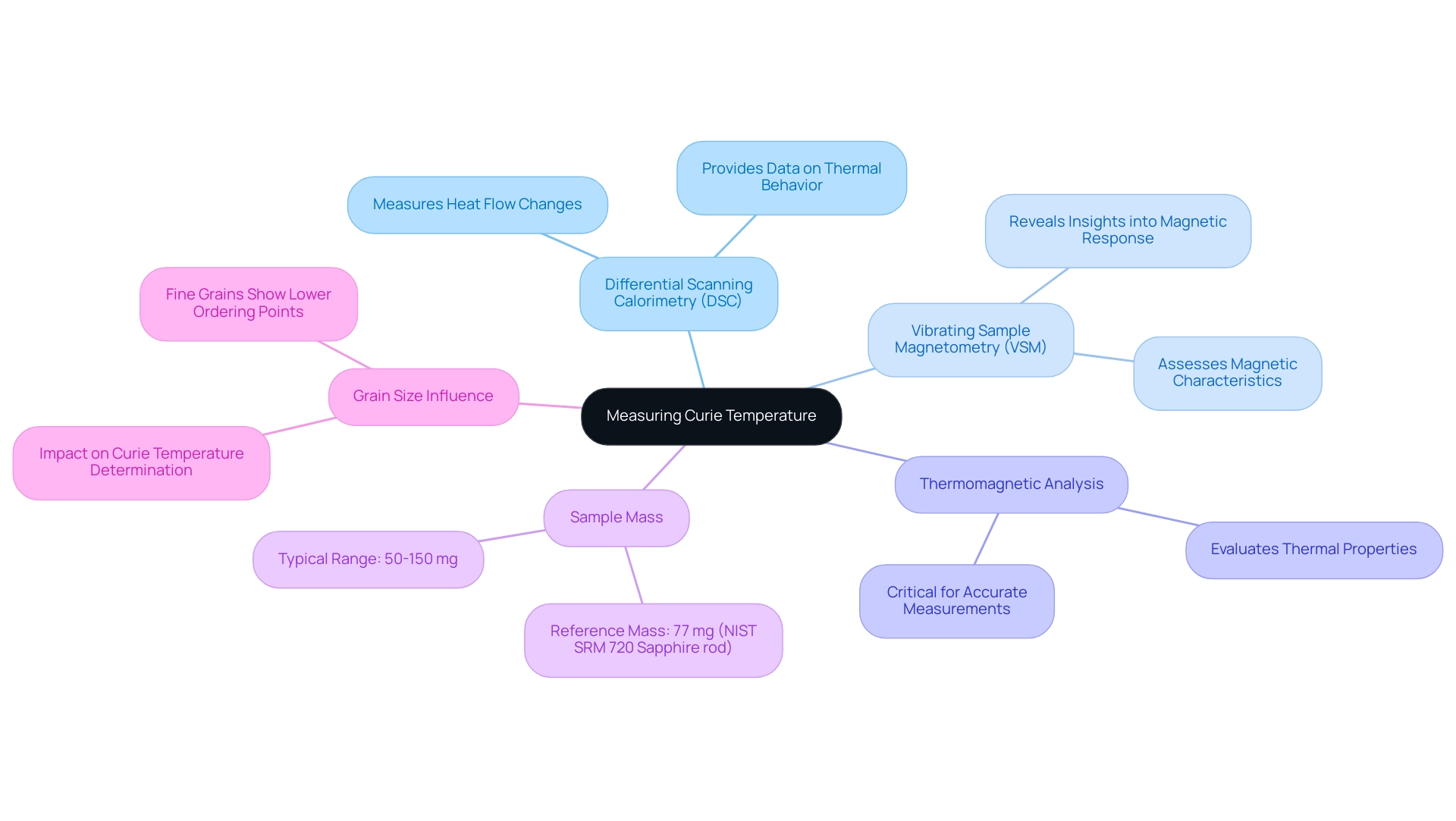

To precisely ascertain the permalloy curie temperature, several established methods are employed, notably:

- Differential scanning calorimetry (DSC)

- Vibrating sample magnetometry (VSM)

- Thermomagnetic analysis

<p>DSC plays a pivotal role by measuring the heat flow changes that occur during phase transitions, providing valuable data on thermal behavior. In contrast, VSM assesses the magnetic characteristics of permalloy as a variable of heat, revealing crucial insights into its permalloy curie temperature and overall magnetic response. <p>The effectiveness of these methodologies is highlighted by research, including an important study by Grommé et al., which stresses the need for precise measurement techniques to ascertain the critical points accurately.

They observe, “The critical points were identified by drawing straight lines roughly aligning with the J–T-curve respectively above and below the estimated point, and projecting their intersection to the thermal axis.” Furthermore, the sample mass used in these measurements typically ranges from 50 to 150 mg, with a reference mass of 77 mg for the NIST SRM 720 Sapphire rod, which is critical for ensuring accurate results.

<p>Furthermore, case studies, including one examining the impact of grain size on the permalloy curie temperature determination, emphasize how differences in grain structure can significantly influence ordering levels. This requires thorough evaluation when analyzing measurement outcomes, as very fine grains can show notably reduced ordering points in comparison to bulk substances. This thorough comprehension of measurement methods is crucial for researchers and engineers evaluating the appropriateness of permalloy based on its curie temperature in different applications, ensuring that they can utilize its properties effectively.

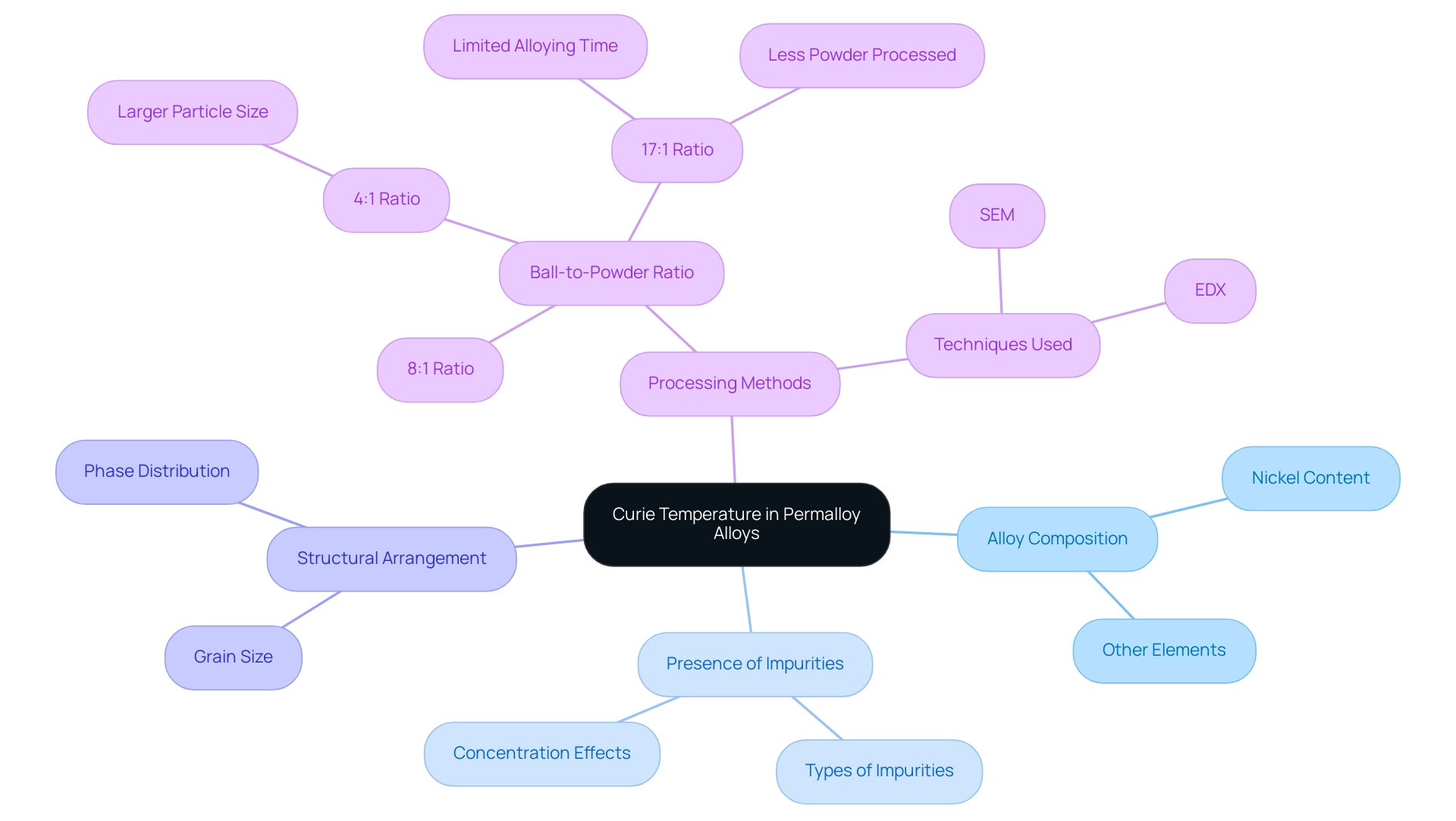

Factors Affecting Curie Temperature in Permalloy Alloys

<p>The critical point in permalloy alloys is significantly influenced by several key factors, including the alloy’s specific composition, the presence of impurities, and the material’s structural arrangement. Significantly, raising the nickel content is recognized to boost the permalloy curie temperature, which enhances the properties of the alloy. However, the introduction of additional elements can lead to variations in these properties. <p>Recent findings underscore this complexity, indicating that careful manipulation of alloy composition can result in tailored performance characteristics vital for advanced applications in technology-driven sectors. As J.S., a recognized authority in the field, states,

According to the measurement and analysis results, the permalloy Curie temperature has a significant impact on the properties of permalloy.

This underscores the critical need for procurement specialists to understand these dynamics, allowing for the customization of permalloy formulations to meet specific operational demands.

Moreover, case studies exploring the influence of factors such as ball-to-powder ratio during alloy production reveal that variations in processing methods can further affect the resultant properties of permal

loy. For instance, a ball-to-powder ratio (BPR) of 17:1 can limit the alloying time to 4 hours but processes less powder, illustrating the trade-offs involved in selecting processing parameters. Additionally, various techniques, including SEM and EDX, were employed to investigate the properties of the compacts, providing critical insights into the resulting characteristics.

Such insights enable manufacturers to optimize their resources for performance, ensuring they align with the rigorous requirements of modern technological applicati

ons.

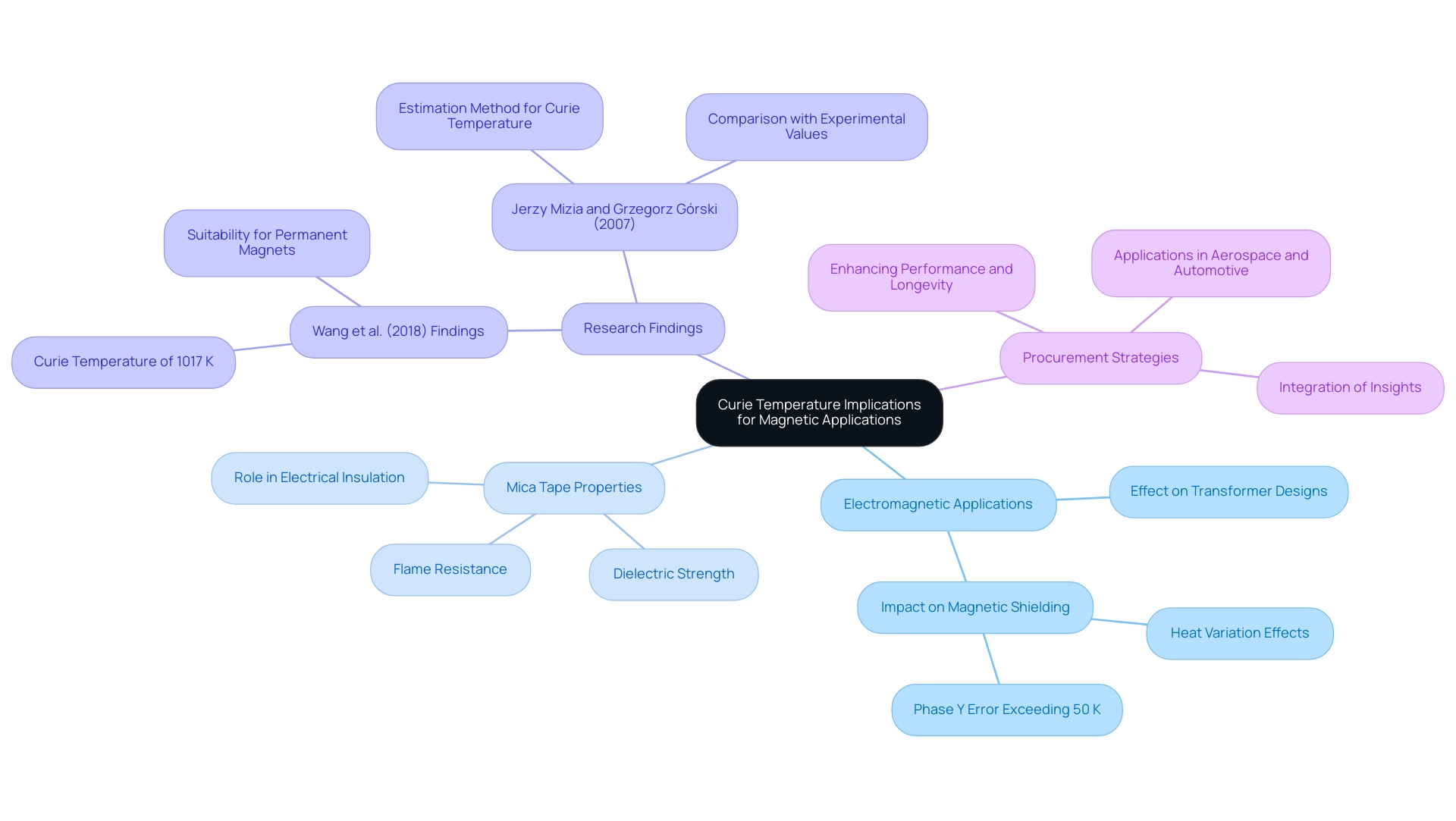

Implications of Curie Temperature for Magnetic Applications

The performance and reliability of electromagnetic applications, especially in transformer designs that utilize mica tape products for electrical insulation, are significantly influenced by the permalloy curie temperat

ure. Mica insulation tapes, recognized for their flame resistance and dielectric strength, are essential in preserving the integrity of shielding substances, ensuring they maintain their characteristics during variations in heat. Recent advancements underscore the importance of stability in these materials; for instance, research has shown that variations in heat can significantly impact the effectiveness of magnetic shielding, with only one phase, Y, displaying errors exceeding 50 K.

Furthermore, studies, such as Wang et al. (2018), reported a critical point of 1017 K for arc-melted polycrystalline Fe B samples, highlighting its suitability for permanent magnet applications. In sensor technologies, comprehending the critical point is vital for ensuring consistent performance across various conditions, thereby preserving sensitivity. As observed by Jerzy Mizia and Grzegorz Gorski in their 2007 research, precise estimates of the transition point can result in improved selection of substances and enhanced device performance.

By integrating insights on the permalloy curie temperature and the role of mica tape products into procurement strategies, professionals can significantly enhance the performance and longevity of magnetic devices in critical applicati

ons. For example, mica tape is widely used in the aerospace and automotive industries for insulating components that operate under extreme conditions. This strategic approach not only improves operational efficiency but also ensures that investments in electrical insulation materials yield optimal results in real-world scenarios.

Conclusion

Understanding the Curie temperature is vital for optimizing the performance of permalloy and other ferromagnetic materials. As highlighted, this critical threshold determines the transition from permanent magnetism to paramagnetism, impacting a wide range of applications in modern technology. The intricacies of measuring Curie temperature through established techniques such as DSC and VSM reveal the importance of precision in obtaining accurate data. Additionally, the composition and processing of permalloy alloys play a crucial role in tailoring their magnetic properties, emphasizing the need for informed decision-making in material selection.

The implications of Curie temperature extend beyond theoretical considerations; they are essential for the practical functionality of devices in various sectors, including aerospace, automotive, and electron

ics. By recognizing the factors that influence Curie temperature and applying this knowledge strategically, procurement professionals can enhance the reliability and efficiency of magnetic applications. This proactive approach not only optimizes material performance but also aligns with the growing demand for high-performance magnetic solutions in an evolving technological landscape.

In summary, a comprehensive understanding of the Curie temperature and its effects on permalloy is indispensable for advancing magnetic technology. As industries continue to innovate, leveraging insights into this fundamental property will be key to achieving optimal performance and ensuring the longevity of magnetic devices across diverse applications.