Blogs

Understanding Invar Thermal Expansion Coefficient: An In-Depth Tutorial for Engineers

Introduction

In the realm of precision engineering, the selection of materials can significantly influence the success of a project. Among the various options available, Invar—a unique iron-nickel alloy—stands out for its exceptional low thermal expansion coefficient, typically around 1.2 x 10^-6/K. This property not only ensures dimensional stability under fluctuating temperatures but also meets the stringent demands of industries ranging from aerospace to automotive.

As procurement managers navigate the complexities of material selection, understanding the fundamental properties of Invar, its applications, and the comparative advantages over other alloys becomes crucial. This article delves into the science behind Invar’s thermal expansion characteristics, its manufacturing considerations, and the strategic implications for engineering applications, providing valuable insights for those seeking reliable solutions in high-precision environments.

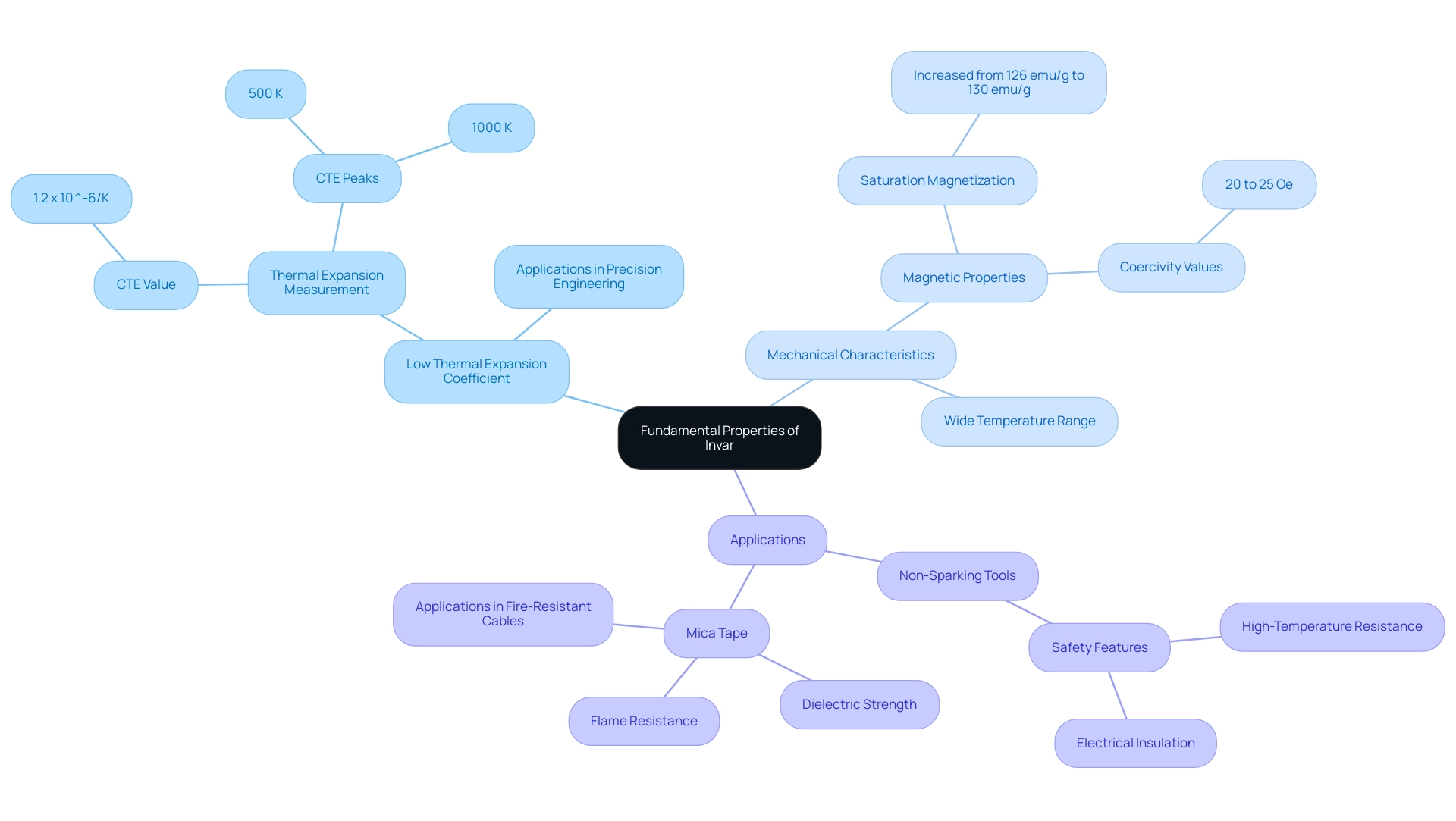

Fundamental Properties of Invar: Understanding Its Low Thermal Expansion

This unique iron-nickel blend is renowned for its invar thermal expansion coefficient, which is exceptionally low and usually measures about 1.2 x 10^-6/K. This property makes this alloy exceptionally suitable for applications requiring dimensional stability amidst temperature fluctuations, aligning with the needs of procurement managers seeking dependable resources for precision engineering. The alloy’s low heat expansion is a result of its unique atomic structure, which minimizes lattice vibrations responsible for heat expansion.

Furthermore, this alloy showcases remarkable mechanical characteristics over a wide temperature range, strengthening its position as a favored option in critical engineering applications. Recent studies indicate that CTE peaks are observed around 500 K and 1000 K, further underscoring the material’s behavior under varying thermal conditions. As noted by Markus Merkel, ‘Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Invar 36,’ the stability of the invar thermal expansion coefficient is crucial for precision applications.

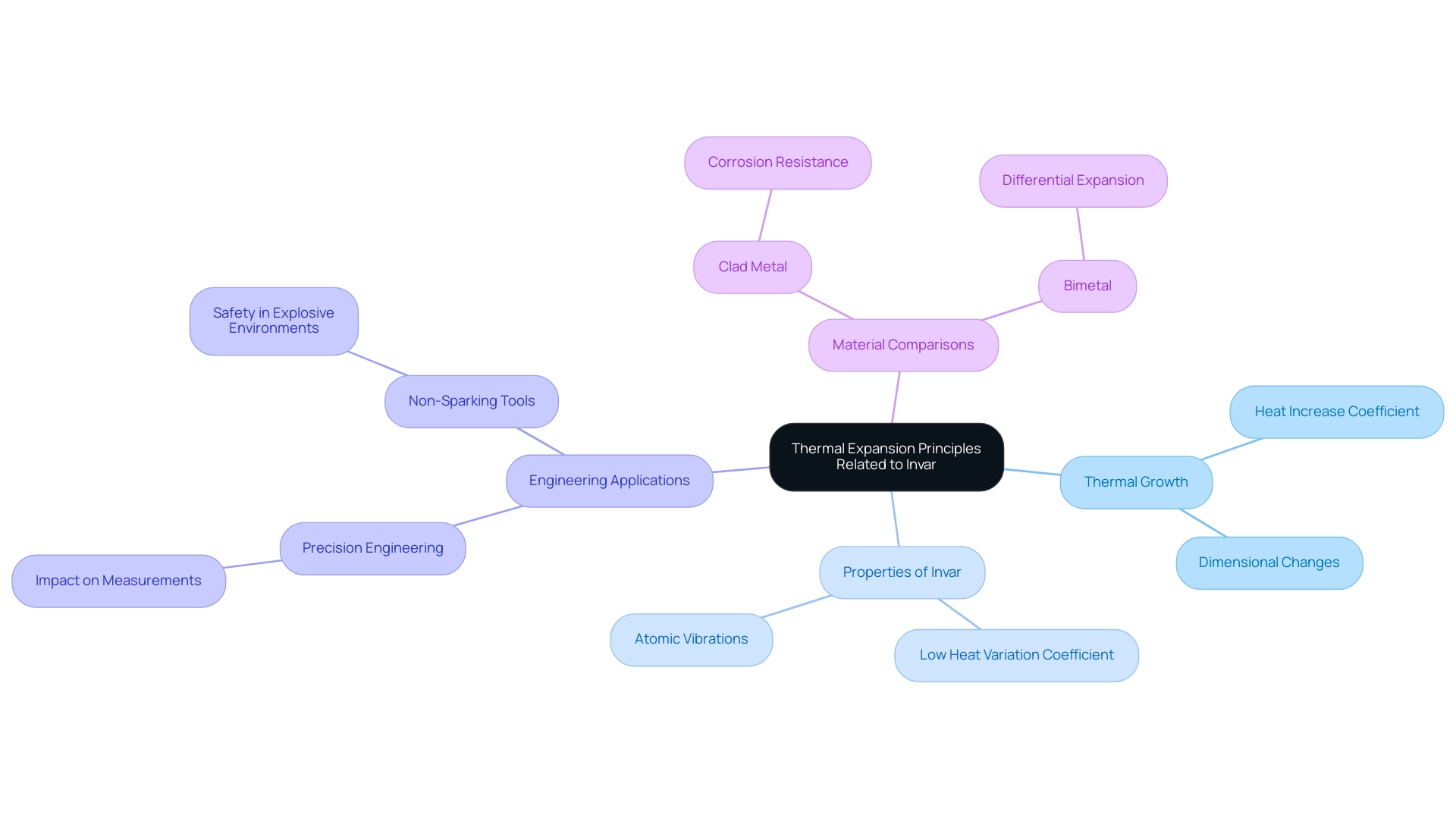

Furthermore, in environments with explosive potential, the use of Non-Sparking Tools is paramount, providing a safe alternative that complements the high-temperature resistance and electrical insulation offered by products like Mica Tape. These specialized tapes not only feature excellent flame resistance and dielectric strength but are also essential for applications in the manufacture of fire-resistant cables and other critical electrical insulation systems. Procurement managers can depend on the combination of the performance characteristics and the safety features of non-sparking tools to meet the rigorous demands of their projects, ensuring reliability and safety in challenging environments.

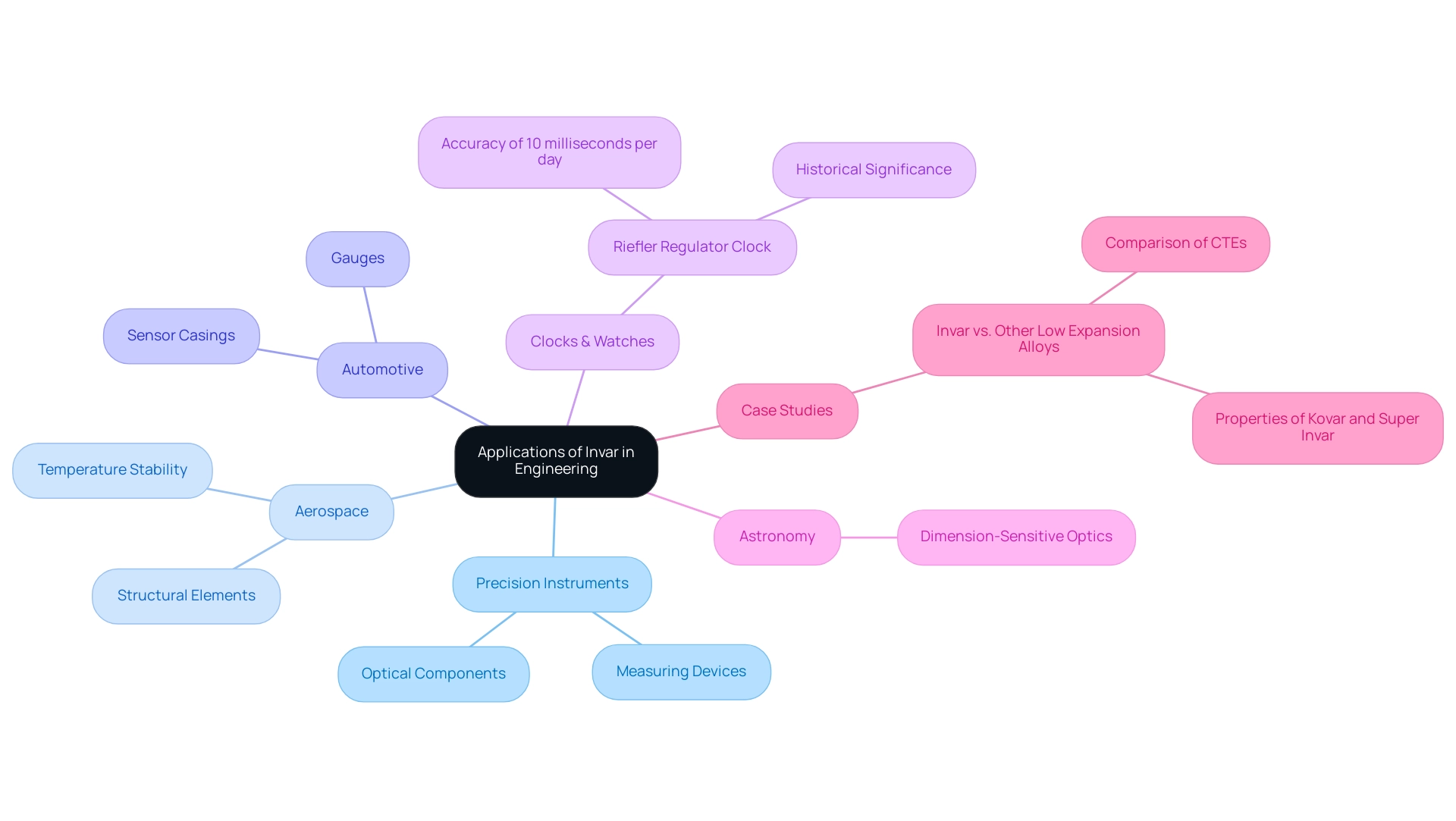

Applications of Invar in Engineering: Where Low Thermal Expansion Matters

The alloy is integral to numerous engineering applications, particularly within precision instruments such as measuring devices, optical components, and aerospace components. In high-precision optical systems, a specific alloy plays a crucial role in the manufacturing of frames and mounts, ensuring that even the slightest temperature variations do not compromise alignment. This trait is especially significant in the aerospace sector, where its low heat variation is crucial for preserving the integrity of structural elements in diverse environmental conditions.

In the automotive field, it is employed in components requiring strict tolerances, such as gauges and sensor casings, where dimensional stability is fundamental for optimal performance. Moreover, its applications extend to the production of clocks and watches, where thermal expansion can significantly affect timekeeping accuracy. Clemens Riefler’s creation of the Riefler regulator clock in 1898, which included a special pendulum, exemplifies this: it achieved an impressive accuracy of 10 milliseconds per day and set a standard in naval observatories and national time services until the 1930s.

As Riefler stated, ‘The use of a special alloy in the pendulum was revolutionary, allowing for unprecedented precision in timekeeping.’ Recent studies indicate that gas atomized alloy powder commonly has particle sizes ranging from 10 to 150 microns, which enhances its application in producing precise components. As we look towards 2024, the current uses of this material in precision engineering continue to evolve, driving advancements in aerospace and optical systems.

A case study comparing a certain alloy with other low expansion materials highlights that Alloy 36 and Alloy 38 exhibit the lowest invar thermal expansion coefficients among common materials, reaffirming their importance in engineering solutions where precision is non-negotiable.

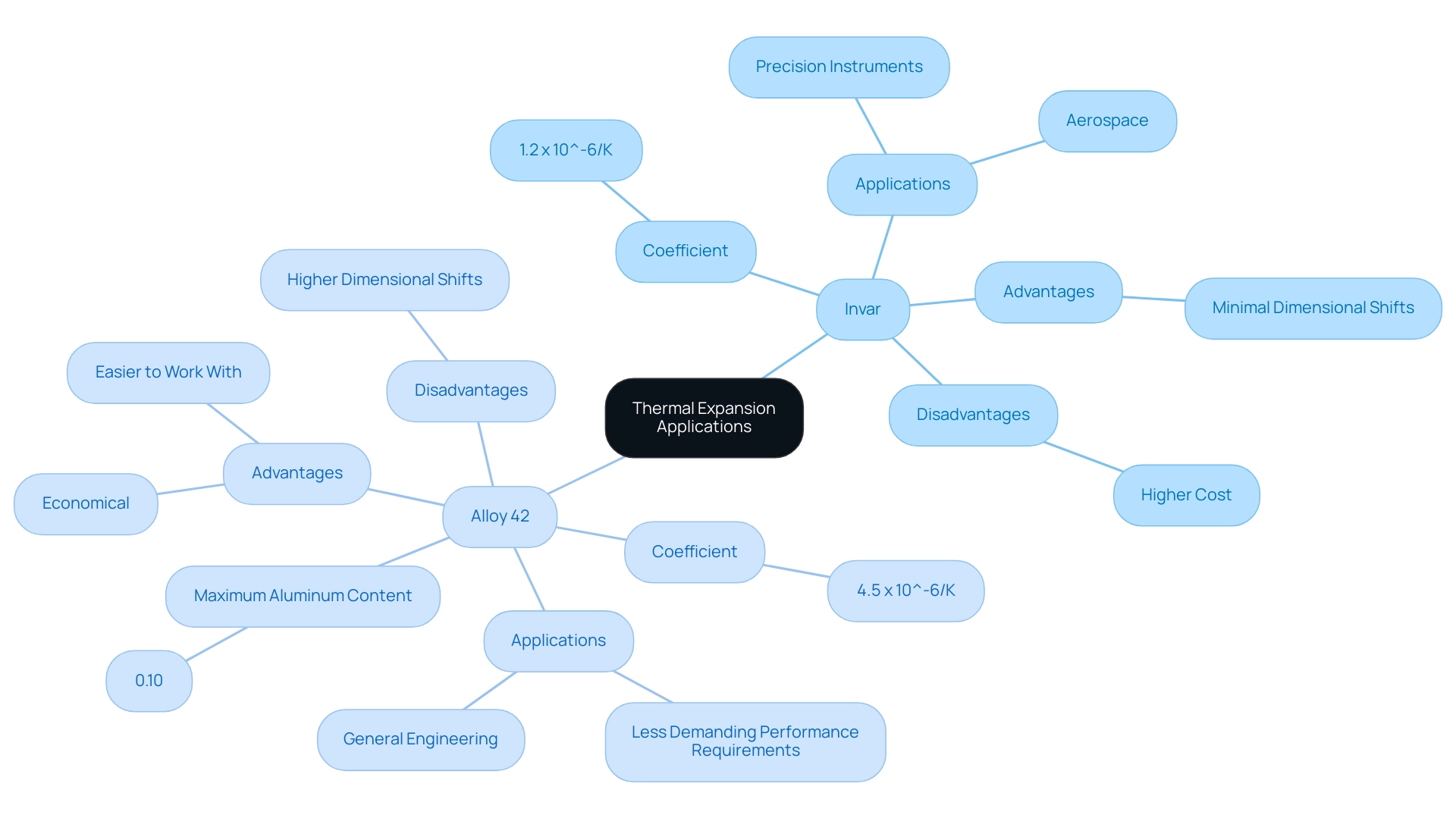

Comparative Analysis: Invar vs. Alloy 42 in Thermal Expansion Applications

When assessing the heat growth characteristics of a specific metal and Alloy 42, significant distinctions in their coefficients become clear. This alloy displays an exceptionally low invar thermal expansion coefficient of roughly 1.2 x 10^-6/K, rendering it an optimal selection for uses requiring minimal dimensional shifts, like precision instruments and aerospace parts. In contrast, Alloy 42, primarily composed of iron and nickel, exhibits an invar thermal expansion coefficient of approximately 4.5 x 10^-6/K, along with a maximum aluminum content of 0.10, which can affect its heat performance.

This significant disparity highlights the advantages of the invar thermal expansion coefficient in maintaining stability under varying temperature conditions. However, Alloy 42 offers its own advantages; it is frequently more economical and simpler to work with, attracting engineers overseeing projects with less demanding performance requirements.

In comparing Clad Metal and Bimetal, it’s important to note that:

- Clad Metal refers to a composite material made by bonding different metals, which can offer enhanced properties such as corrosion resistance and strength.

- Bimetal depends on the differential temperature growth of two metals to operate effectively in applications like switches and thermostats.

Clad Metal’s characteristics focus more on the combination of metals rather than their separate temperature responses.

The mechanism of bimetal, consisting of two metals joined together that expand at different rates when heated, is particularly relevant in applications like switches and thermostats. This mechanism depends on the differential heat growth characteristics to operate efficiently. As mentioned by Zi-Kui Liu in the paper ‘Thermal Expansion Anomaly Regulated by Entropy,’ comprehending the intricacies of heat dilation is essential for substance selection.

Consequently, the choice among these alloys should be strategically influenced by the particular heat performance requirements and budgetary limitations, ensuring that the selected substance aligns with project objectives and operational efficiency. Moreover, insights from the case study on heat growth anomalies provide valuable context for comparing the thermodynamic properties of these materials.

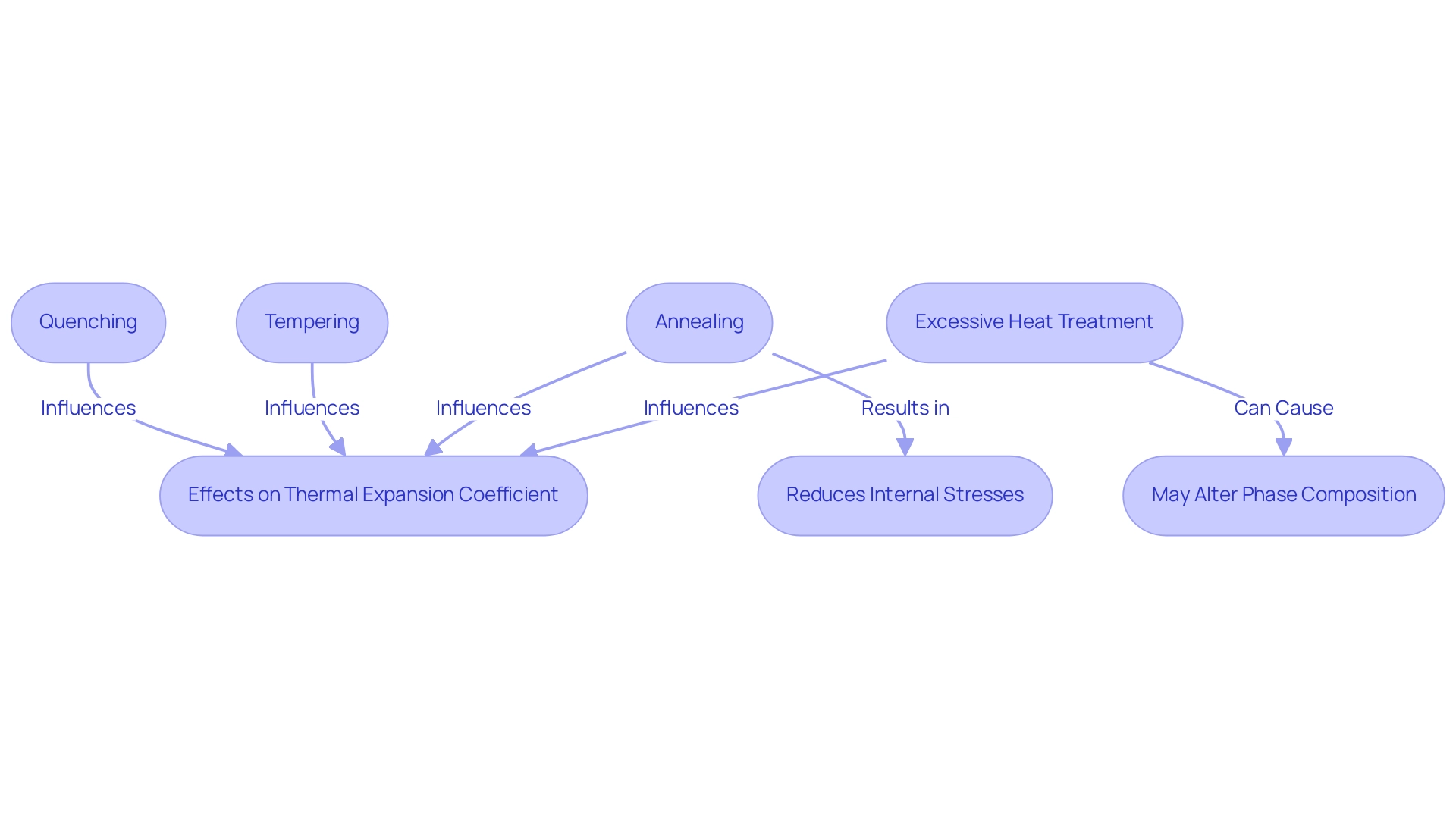

Manufacturing and Treatment Effects on Invar’s Thermal Expansion Coefficient

The production methods and after-manufacturing treatments, including quenching, tempering, and annealing, significantly affect the invar thermal expansion coefficient. These processes can modify the alloy’s microstructure, which directly influences the invar thermal expansion coefficient and its other heat-related characteristics. For instance, annealing is especially important as it reduces internal stresses, resulting in enhanced dimensional stability and a decrease in the invar thermal expansion coefficient.

A recent examination of the linear growth curve of SLM alloy over a temperature range of 30–300 °C indicated a decrease in the invar thermal expansion coefficient, emphasizing the temperature’s influence on these characteristics. However, excessive heat treatment may induce alterations in the alloy’s phase composition, potentially increasing heat increase instead. Case studies, such as the ultrasonic and expansion analysis, have demonstrated this relationship, revealing Young’s modulus values and the invar thermal expansion coefficient measurements for alloy components, which underscore the significance of manufacturing processes and heat treatments.

Significantly, as the volumetric energy density rises, the inhomogeneity of grain morphology diminishes, which further influences the invar thermal expansion coefficient and heat behavior. It is crucial for engineers to work closely with suppliers to gain a thorough understanding of how specific treatments affect the performance of alloys in various applications. Additionally, the research received financial support from the Nuclear Power Institute of China and the Sichuan University Joint Innovation Fund, with gratitude expressed to AVIC Chengdu Aircraft Industrial (Group) Co., Ltd. for their implementation of the research in the aviation industry.

As noted by Qiu et al.,

This behavior is not in agreement with Qiu et al. who reported very similar CTE values for as-deposited and heat-treated substances, underscoring the need for thorough investigation into the effects of manufacturing processes on the invar thermal expansion coefficient and Invar’s heat-related characteristics.

The Science of Thermal Expansion: Principles Relevant to Invar

Thermal growth is the phenomenon whereby substances change their size or volume in response to temperature variations. This behavior is measured by the heat increase coefficient, a crucial factor that varies significantly among different substances. In the instance of this material, its notably low heat variation coefficient suggests that it shows slight dimensional alterations even with considerable temperature changes.

This unique characteristic is fundamentally linked to atomic vibrations; as temperature increases, the atoms within a substance begin to vibrate more intensely, resulting in increased spacing between them. However, Invar’s distinctive arrangement of iron and nickel atoms effectively dampens these vibrations, thereby minimizing the invar thermal expansion coefficient. This understanding is pivotal for engineers, particularly in precision engineering contexts, where even minor shifts can adversely affect the positioning of samples in sensitive instruments like scanning electron microscopes.

Additionally, in explosive environments, the use of Non-Sparking Tools is crucial to prevent ignition risks. These tools, crafted from substances that do not generate sparks, are essential for safety in such settings. Furthermore, understanding the differences between Clad Metal and Bimetal is important in engineering applications.

- Clad Metal, a composite substance created by bonding different metals, offers unique properties such as enhanced corrosion resistance.

- Bimetal consists of two metals joined together that expand at different rates.

This differential thermal growth can significantly impact the performance of temperature-sensitive devices. Consequently, by thoroughly understanding these principles, engineers can more accurately anticipate the invar thermal expansion coefficient and Invar’s performance in various environments, ultimately enhancing design precision and selection.

As highlighted in the book ‘Phase Equilibria, Phase Diagrams and Phase Transformations,’ the estimation of area expansion is valid under similar conditions as linear expansion. Recent discussions among experts, including Yi Wang and colleagues, emphasize that ‘Zi-Kui Liu, Shun-Li Shang and Yi Wang discussed the results and commented on the manuscript equally,’ underscoring the importance of these principles in advancing materials science and engineering applications.

Conclusion

Invar’s unique properties make it an invaluable asset in precision engineering, particularly due to its remarkably low thermal expansion coefficient. This characteristic not only ensures dimensional stability under varying temperatures but also positions Invar as a preferred material in critical applications across aerospace, automotive, and optical sectors. Understanding the science behind Invar’s thermal behavior, alongside its manufacturing considerations, is essential for procurement managers aiming to make informed decisions that align with project requirements.

The comparative analysis with other alloys, such as Alloy 42, highlights Invar’s superior performance in temperature-sensitive applications, reinforcing its role in maintaining structural integrity across diverse environments. While Alloy 42 may offer cost benefits and ease of machining, the stringent demands of high-precision projects often necessitate the exceptional stability that Invar provides. Furthermore, the influence of manufacturing processes on Invar’s thermal expansion properties underscores the importance of collaboration between engineers and material suppliers to achieve optimal performance.

Ultimately, the strategic selection of materials like Invar can significantly impact project outcomes in high-stakes engineering situations. By leveraging Invar’s unique characteristics and understanding its applications, procurement managers can ensure reliability and precision in their engineering solutions, ultimately driving success in their projects. The insights shared in this article serve as a guide for navigating the complexities of material selection, empowering professionals to make strategic choices that meet both performance and safety standards in their operations.