Blogs

Understanding the Invar Effect: A Complete Tutorial for Materials Scientists

Overview:

The Invar effect, characterized by low thermal expansion in specific iron-nickel alloys, is crucial for applications requiring dimensional stability, particularly in precision instruments and aerospace components. The article elaborates on the mechanisms behind this phenomenon, such as atomic vibrations and magnetic interactions, and discusses its historical significance and modern innovations, highlighting ongoing research and sustainability efforts in material production.

Introduction

The Invar effect represents a fascinating intersection of material science and engineering, particularly within iron-nickel alloys known for their minimal thermal expansion. This unique property is not just a scientific curiosity; it plays a pivotal role in industries where precision is paramount, such as aerospace, electronics, and metrology.

As organizations strive for greater accuracy and reliability in their products, understanding the intricacies of the Invar effect becomes essential. Recent advancements in research, including the application of Density Functional Theory and innovative manufacturing techniques, have shed light on the mechanisms behind this phenomenon, paving the way for enhanced applications and material performance.

This article delves into the significance of the Invar effect, exploring its historical context, modern innovations, and future directions, while emphasizing its critical role in shaping procurement strategies for high-tech industries.

Introduction to the Invar Effect: Significance and Overview

The Invar effect describes specific iron-nickel mixtures that show remarkably low thermal expansion over a wide temperature range. This characteristic is especially critical in fields where dimensional stability is essential, such as precision instruments, aerospace components, and a variety of electronic devices. Notably, the lattice parameter of Ni-20Cr compositions is often underestimated by 1% compared to neutron diffraction measurements, emphasizing the importance of accurate assessments in material selection.

Recent studies employing Density Functional Theory (DFT) have examined Fe-Ni alloys, concentrating on essential factors such as enthalpy of mixing and elastic characteristics, which are crucial for comprehending material behavior in temperature-sensitive contexts. Furthermore, Mica Tape products, such as:

- Mica Insulation Tape

- Mica Sheet Tape

- Insulating Mica Tapes

are recognized for their high-temperature resistance and electrical insulation features. These products provide reliable solutions for electrical insulation in transformers and other critical devices, ensuring safety and performance.

Mica Sheet Tape provides strong mechanical strength, while Insulating Mica Tapes demonstrate excellent dielectric strength, making them essential in various uses. As Masao Miyake noted,

The mean crystallite size of the electrodeposited CdTe deposits was within the range of 5–20 nm; the crystallite size for the chloride solutions was larger than those from the sulfate and nitrate solutions.

This reflects the nuances in material properties that can significantly impact functionality.

Additionally, the case study on NILO® 77—a soft, magnetic material containing nickel, iron, copper, and molybdenum—demonstrates the practical uses of the phenomenon, especially in transformers, inductors, and magnetic amplifiers. The yield strengths of these alloys have been normalized by their shear moduli in recent literature to evaluate their influence on solid solution strengthening, providing crucial insights for procurement managers. The consequences of the invar effect extend into 2024, with continuous applications in precision instruments and aerospace, where ensuring stability under fluctuating thermal conditions is essential.

Mica Tape products therefore complement these applications, ensuring safety and performance in environments that demand exceptional thermal and electrical insulation.

Mechanisms of the Invar Effect in Iron-Nickel Alloys

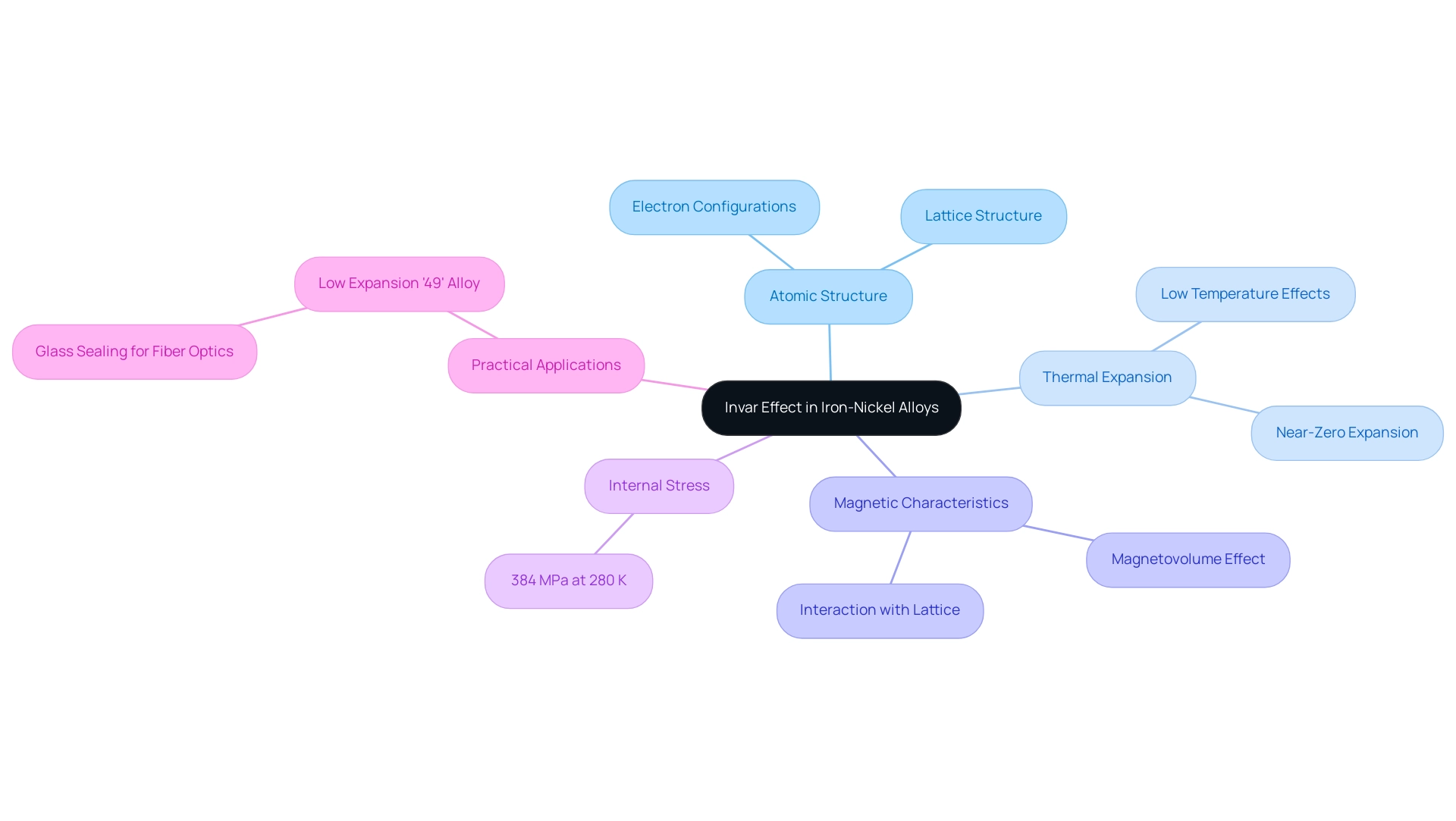

The distinct atomic structure and electron configurations of iron-nickel mixtures are fundamentally rooted in the Invar effect. At lower temperatures, the reduction in atomic vibrations effectively cancels out thermal expansion, resulting in the remarkable near-zero thermal expansion features characteristic of these materials. A crucial element of this phenomenon is the interaction between the material’s magnetic characteristics and its lattice structure, reflecting the invar effect.

Recent advancements in research, particularly those employing first-principles theories, have deepened our understanding of these complex interactions. Notably, Song et al. highlighted the significance of these mechanisms, stating,

A strategy to reduce thermal expansion and achieve higher mechanical characteristics in iron mixtures.

Furthermore, the internal stress in the metal mixture is estimated to be 384 MPa at 280 K, offering quantitative backing for the discussion on the temperature effect. The Low Expansion ’49’ metal, with the highest nickel content, is especially significant for its use in glass sealing for fiber optics, demonstrating practical benefits relevant to procurement managers. Furthermore, experimental studies have corroborated these theoretical frameworks, shedding light on how the intrinsic mechanisms—such as the compensatory action of the magnetovolume effect and the invar effect, which evolves with changes in magnetism—contribute to the overall effect.

This collaboration of theoretical and experimental insights is vital for progressing our understanding of material behavior under diverse conditions, ultimately improving uses across various sectors.

Applications of Invar: From Historical Uses to Modern Innovations

This material has a storied history as a crucial component in the development of precision measuring instruments, notably in the pendulums of clocks and various scientific devices, where even the slightest temperature-induced dimensional changes could result in significant inaccuracies. As the need for accuracy has advanced, so too have the uses of specific materials. Today, they are integral to aerospace components, electronic devices, and optical instruments, where their exceptional stability across varying temperature ranges is indispensable.

The Low Expansion ’45’ alloy, for instance, boasts a relatively constant rate of thermal expansion up to about 450°C (842°F), underscoring its dimensional stability in high-precision applications. The need for lightweight materials with superior dimensional stability has spurred innovations in Invar-based solutions, which exemplify the invar effect and establish it as a preferred choice in high-tech industries, including telecommunications and space exploration. Recent advancements in wire arc additive manufacturing (WAAM) technology for an alloy have focused on symmetrical phenomena, enhancing process quality and material utilization.

Furthermore, the findings from neutron-diffraction investigations carried out by Dubinin et al. confirmed the coexistence of paramagnetic and antiferromagnetic phases in the alloy, adding to its material properties credibility. Furthermore, the case study on negative thermal expansion in stainless steel type materials demonstrated improved performance in astronomical telescopes, highlighting the importance of these materials in high-precision environments.

The Low Expansion ’39’ alloy is now prominently used in thermostat bimetal products, while Carpenter Technology’s Glass Sealing 42 alloy has found its niche in hermetic sealing uses for glass and semiconductor packages. These contemporary programs highlight the invar effect, demonstrating Invar’s adaptability and enduring significance in high-precision environments.

Recent Advances in Research on the Invar Effect

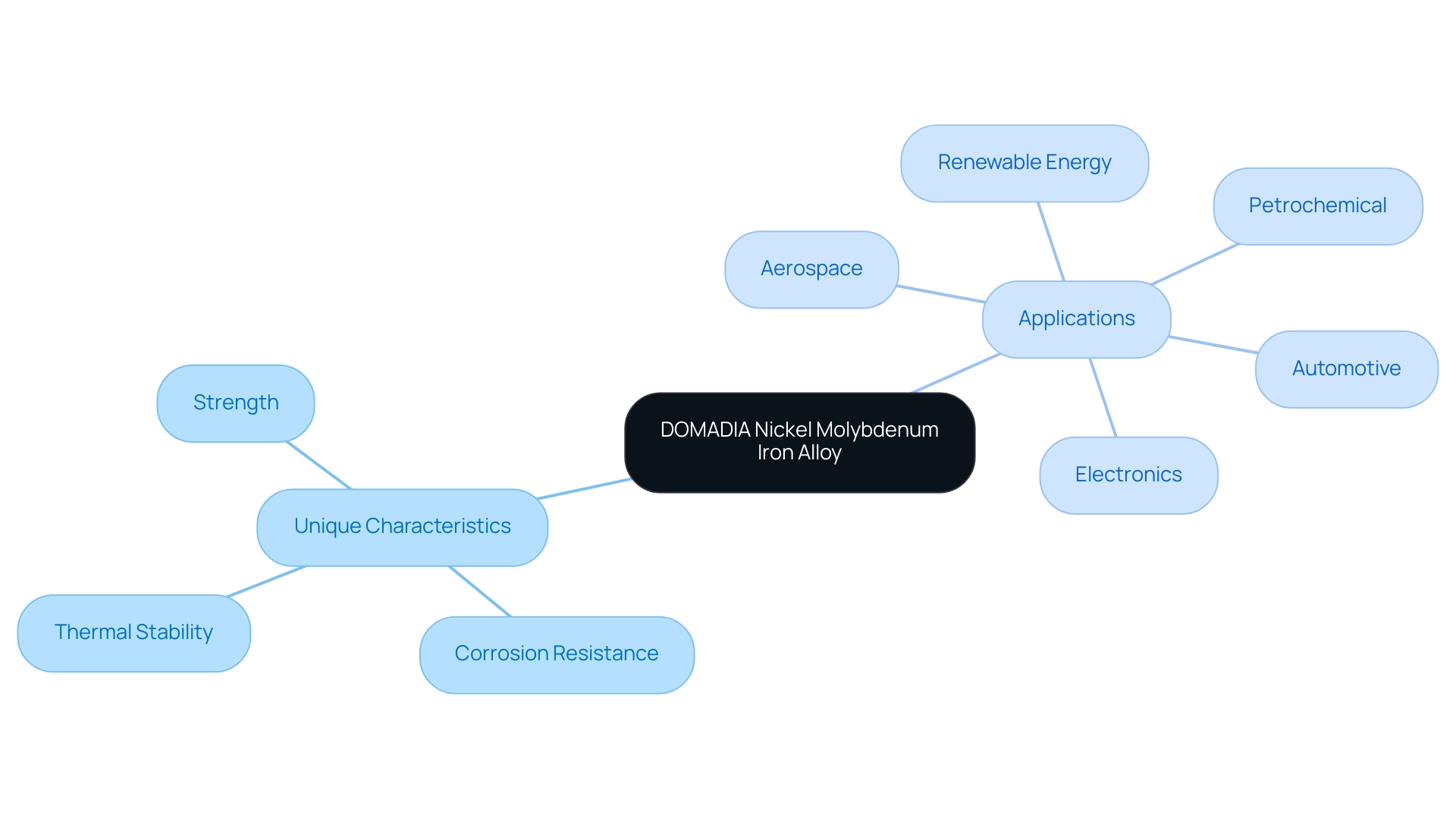

Q1. What makes DOMADIA Nickel Molybdenum Iron Alloy unique?

DOMADIA Nickel Molybdenum Iron Alloy distinguishes itself with its remarkable strength, corrosion resistance, and thermal stability, making it a strategic option for crucial uses.

Its distinct characteristics are especially advantageous in sectors like:

- Aerospace

- Automotive

- Petrochemical

- Electronics

- Renewable energy

For instance, in the aerospace sector, its strength and thermal stability enhance performance in high-stress environments, while in the automotive industry, its corrosion resistance contributes to longer-lasting components. These attributes not only improve product reliability but also drive market growth in sectors requiring advanced materials.

Future Directions in Invar Effect Research and Applications

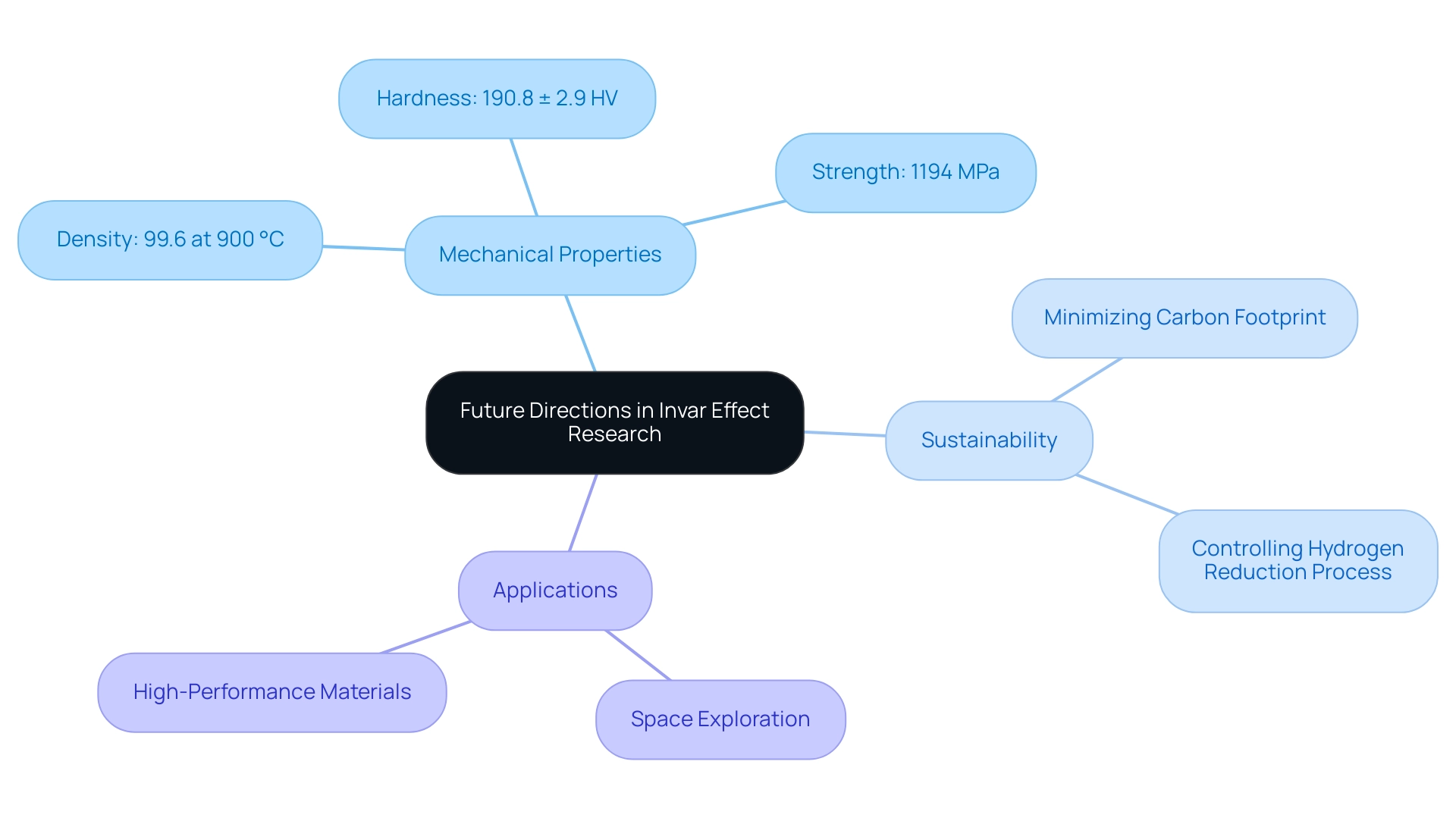

Future studies on the invar effect are set to explore further into nanomaterials and composites, utilizing the distinctive characteristics of this alloy to unveil groundbreaking applications. As highlighted by expert Kotaro Ona, unlocking the potential of non-ferromagnetic Invar-type substances in space exploration showcases the invar effect and emphasizes the versatility of these materials. These materials demonstrate a density of 99.6% at 900 °C and 1194 MPa, with a hardness of 190.8 ± 2.9 HV, highlighting their strong mechanical characteristics.

Concurrently, there is a growing focus on sustainability within the production of Invar materials. Researchers are actively seeking methods to minimize the carbon footprint associated with mining and refining processes. The presence of oxides has been shown to negatively affect mechanical characteristics, making it crucial to control the hydrogen reduction process to minimize these oxides.

This shift towards eco-friendly materials is not merely a trend; it reflects a broader industry commitment to sustainability that is reshaping procurement strategies. For instance, a study on the magnetic properties of Cr-based Invar-type alloys confirmed the invar effect of their non-ferromagnetic nature, making them suitable for applications requiring magnetic neutrality and dimensional stability. As demands for high-performance materials evolve, materials scientists and procurement managers must remain vigilant and adapt their approaches to align with these advancements and market expectations.

The successful integration of sustainable practices in Invar production will be critical in meeting both performance and environmental goals.

Conclusion

The exploration of the Invar effect reveals its critical importance in high-tech industries where dimensional stability is essential. From its historical applications in precision measuring instruments to modern innovations in aerospace and electronics, Invar alloys have proven indispensable. The unique properties of these iron-nickel alloys, characterized by minimal thermal expansion, are rooted in complex atomic structures and magnetic interactions, which are further elucidated by recent research employing advanced theoretical frameworks.

As industries continue to demand greater accuracy and reliability, the significance of the Invar effect cannot be overstated. The ongoing advancements in manufacturing techniques, such as wire arc additive manufacturing, enhance the performance of Invar-based materials, ensuring they meet the rigorous standards required in precision applications. The integration of Mica Tape products further complements these efforts, providing essential thermal and electrical insulation in critical environments.

Looking ahead, the future of Invar research promises exciting developments, particularly in the realm of nanomaterials and sustainability. As the industry shifts towards eco-friendly practices, procurement strategies must adapt to incorporate these innovations, ensuring that high-performance materials remain aligned with environmental goals. The Invar effect stands as a testament to the intersection of material science and engineering, shaping the future of precision applications across diverse sectors.