Blogs

DOMADIA™ Beryllium Copper C17200 – High Strength, High Conductivity, Exceptional Performance

Introduction

In the world of advanced engineering and manufacturing, material selection often determines the difference between success and failure. Beryllium Copper C17200 – Alloy 25 is a prime choice when designing aerospace components, automotive systems, microelectronic devices, or high-performance tooling. Engineers face relentless demands for strength, reliability, and precision.

That’s why DOMADIA™ is trusted worldwide. We provide specialty alloys that are meticulously engineered for peak performance in even the most demanding environments.

One of our most reliable and high-performing materials is DOMADIA™ Beryllium Copper C17200, also known as CuBe2 or Alloy 25. This remarkable alloy stands out due to its exceptional mechanical strength, superior thermal and electrical conductivity, and excellent fatigue and corrosion resistance — all packed into one versatile material.

Moreover, its unique combination of properties makes it the preferred choice for industries that operate under extreme conditions and cannot afford compromise.

C17200 doesn’t just meet expectations; it redefines them. With a tensile strength reaching up to 1400 MPa, this alloy rivals the performance of certain steels while still retaining the workability and conductivity of copper. As a result, it powers innovation in everything from aerospace landing gear bushings to semiconductor test sockets.

What is Beryllium Copper C17200 (CuBe2)?

DOMADIA™ Beryllium Copper C17200 is a precipitation-hardenable copper alloy containing 1.8–2.0% beryllium. It is known for having the highest strength among all copper alloys, reaching up to 1400 MPa (200 ksi), while still maintaining excellent electrical and thermal conductivity.

This combination makes it ideal for precision parts, demanding environments, and long-lasting performance under stress.

Key Properties

- High Strength: Up to 1400 MPa after heat treatment

- Excellent Conductivity: ~20% IACS electrical conductivity

- Non-magnetic

- Superior Fatigue Resistance

- Outstanding Corrosion and Wear Resistance

Chemical Composition (% by Weight)

| Element | Content (%) |

| Copper (Cu) | Balance |

| Beryllium (Be) | 1.80 – 2.00 |

| Cobalt (Co) | ≤ 0.60 |

| Nickel (Ni) | ≤ 0.25 |

| Lead (Pb) | ≤ 0.02 |

| Iron (Fe) | ≤ 0.20 |

| Other Impurities | ≤ 0.50 (total) |

Properties & Benefits of DOMADIA™ Beryllium Copper C17200

DOMADIA™ C17200 (CuBe2, Alloy 25) is known for its exceptional blend of strength, conductivity, durability, and formability. These qualities make it one of the most versatile and high-performance copper alloys in the world today.

1. High Strength – Up to 1400 MPa

- Achieves tensile strength up to 1400 MPa (200 ksi) after age-hardening.

- Benefit: Comparable to alloy steels, it handles heavy mechanical loads without deformation — ideal for aerospace, defense, and tooling applications.

2. Excellent Electrical Conductivity (~20% IACS)

- Delivers ~20% IACS conductivity, even in its hardened state.

- Benefit: Ensures efficient current flow in electrical connectors, switches, and semiconductor test equipment.

3. Superior Thermal Conductivity (~105 W/m·K)

- Supports fast, consistent heat dissipation.

- Benefit: Perfect for thermal connectors, heat sinks, and components exposed to high temperature variations.

4. Non-Magnetic

- Completely non-magnetic, unlike many high-strength steels.

- Benefit: Ideal for use in sensitive instrumentation, aerospace equipment, and magnetically shielded environments.

5. Outstanding Fatigue Resistance

- Resists cyclic loading, mechanical stress, and fatigue failure.

- Benefit: Extends the life of springs, bushings, relays, and other components under continuous motion.

6. Exceptional Corrosion & Wear Resistance

- Withstands oxidation, corrosion, and surface wear, even in aggressive environments.

- Benefit: Reduces maintenance and extends lifespan in marine, oil & gas, and chemical processing industries.

7. Excellent Formability & Machinability

- Easy to work with in both soft and hardened states.

- Benefit: Supports precision manufacturing, lowers production costs, and ensures tight dimensional tolerances.

Technical Specifications

| Property | Value |

| Alloy Designation | CuBe2 (Alloy 25) |

| UNS Number | C17200 |

| Density | 8.26 g/cm³ |

| Hardness (after aging) | Up to 42 HRC |

| Electrical Conductivity | ~20% IACS |

| Thermal Conductivity | ~105 W/m·K |

| Tensile Strength | 1100–1400 MPa (160–200 ksi) |

| Elongation | 1–10% depending on temper |

| Melting Point | 866°C – 980°C |

Applications of DOMADIA™ Beryllium Copper C17200

Aerospace & Defense

- Precision springs, bushings, bearings

- Landing gear components

- High-fatigue structural parts

Electronics

- High-reliability connectors and switches

- Semiconductor test sockets

- Micro-relays

Automotive

- ECU connectors and sensors

- Ignition components

- Vibration-resistant parts

Oil & Gas

- Non-sparking tools

- Corrosion-resistant fittings

- Downhole drilling components

Tooling & Molds

- Injection mold components

- Die-casting inserts

- Welding electrodes

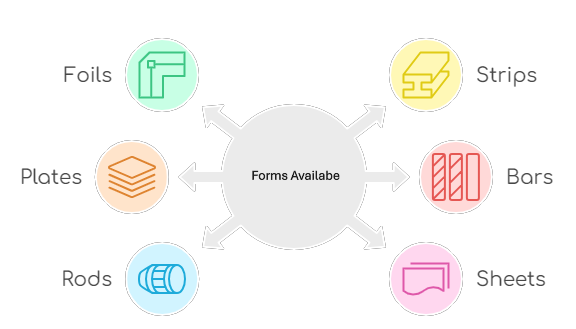

Forms & Shapes Available

We offer DOMADIA™ Beryllium Copper C17200 in:

Custom sizes, tempers, and heat treatments available on request.

Standards & Designations

- UNS: C17200

- ASTM: B194, B196, B197

- AMS: 4533, 4534

- EN/DIN: CW101C

- ISO Designation: CuBe2

- Trade Name: Alloy 25

Why Choose DOMADIA™ C17200?

- Consistent Quality

- Meets Global Standards

- Custom Processing & Heat Treatment

- Fast Delivery with Technical Support

Whether you need high reliability in mission-critical aerospace systems or precision in microelectronics, DOMADIA™ C17200 delivers outstanding, long-term performance.

Conclusion

DOMADIA™ Beryllium Copper C17200 is the ideal choice when your application demands high strength, excellent conductivity, and durability in tough environments.

From aerospace to electronics, this alloy offers the perfect balance of performance and reliability.

🔗 Discover more on our website https://domadia.net/

Talk to us: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia. For inquiries about Beryllium Copper C17200, often referred to as Alloy 25, these professionals are your point of contact.