Blogs

How to Leverage Beryllium Copper’s Electrical Properties for Optimal Automotive Connections

Introduction

The automotive industry stands at a pivotal crossroads, driven by innovation and the relentless pursuit of efficiency. Among the materials reshaping this landscape, beryllium copper emerges as a standout contender, renowned for its exceptional strength, electrical conductivity, and corrosion resistance. As vehicles evolve to meet the demands of electrification and lightweight design, the applications of this specialized alloy are becoming increasingly crucial.

This article delves into the myriad advantages of beryllium copper in automotive contexts, exploring its:

- Properties

- Applications in electrical connections

- Best practices for sourcing

- Compliance standards

- Future trends that will define its role in the industry

By understanding these elements, procurement managers can make informed decisions that enhance performance while navigating the complexities of modern automotive manufacturing.

Understanding Beryllium Copper: Properties and Advantages for Automotive Use

Beryllium bronze is a specialized alloy created by merging a specific percentage of a certain element with a metal, resulting in a material noted for its remarkable strength and electrical conductivity. At Domadia, we leverage these key properties, making us a leader in supplying high-performance Beryllium Copper Plates tailored for diverse industrial applications including aerospace, defense, and telecommunications. Our commitment to customization ensures that we can meet the specific needs of our clients, providing tailored solutions that enhance performance in various applications.

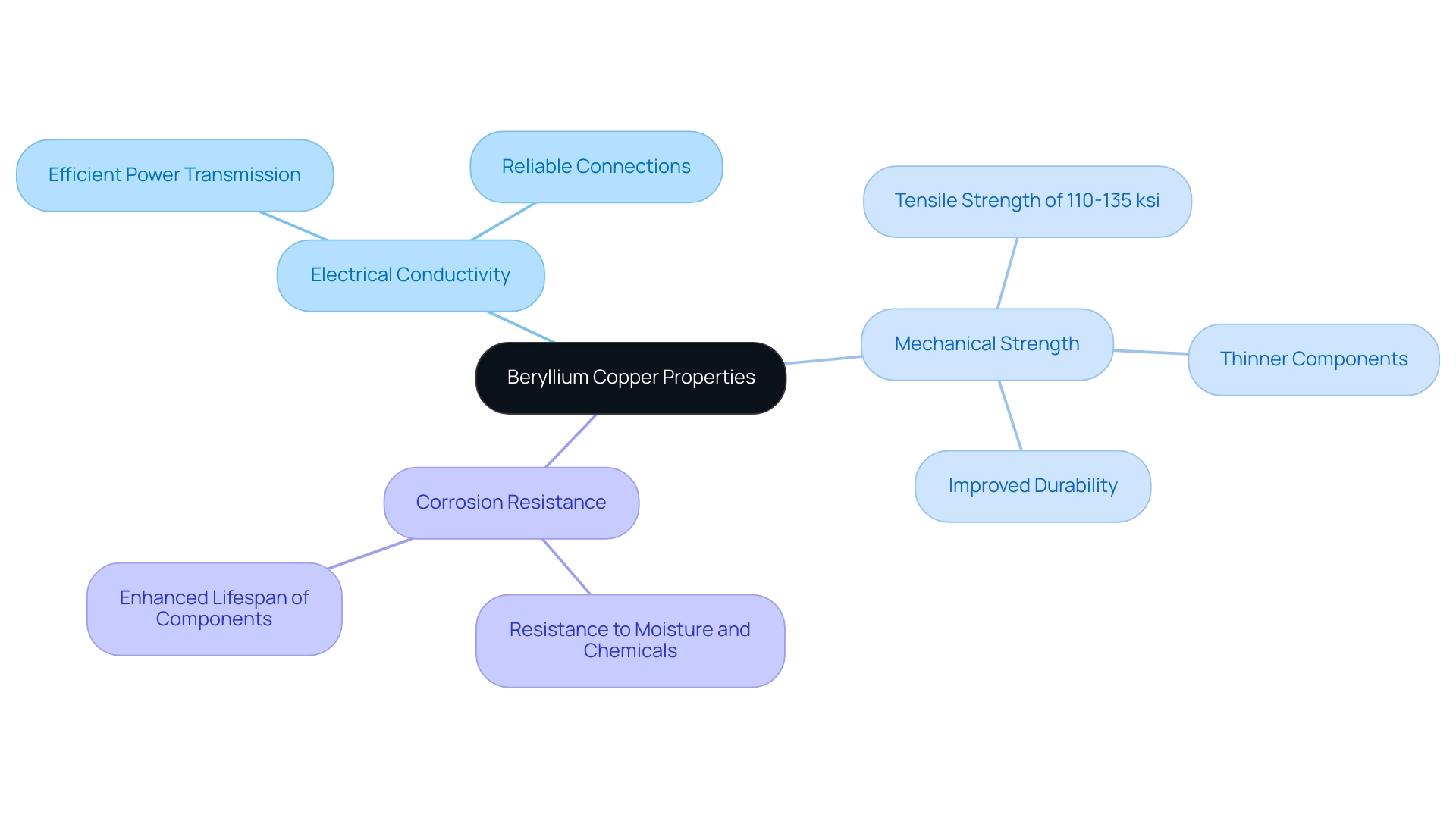

The advantages of this alloy are particularly pronounced in automotive applications:

Electrical Conductivity: Beryllium copper is renowned for its outstanding electrical conductivity, which is critical for efficient power transmission in vehicle electrical systems. This property ensures reliable connections that are essential for optimal vehicle performance, underscoring Domadia’s commitment to providing reliable solutions.

Mechanical Strength: With a tensile strength ranging from 110 to 135 ksi, this alloy exceeds pure metal in mechanical performance. This strength allows the design of thinner components that can withstand significant mechanical stress, thereby improving the overall durability of vehicle systems without compromising functionality. For example, the creation of Because Seals’ for direct injection injector seals demonstrates how the metal’s strength is utilized in real-world uses, improving reliability in vehicle systems.

Corrosion Resistance: This alloy demonstrates remarkable resistance to corrosion, making it suitable for vehicle environments that frequently encounter moisture and various chemicals. Such resistance is vital for maintaining the integrity of electrical connections over time, which is especially true when considering beryllium copper’s electrical properties for automotive connections, thereby reducing maintenance needs and enhancing the lifespan of components.

In a related study on the wear behavior of Cu-Cr-Zr alloy, it was found that aging heat treatment significantly increased the hardness of substances, providing insights into how certain alloys’ properties can lead to improved performance under stress. These characteristics together establish beryllium copper’s electrical properties for automotive connections as a favored choice in vehicle applications, greatly enhancing both the performance and longevity of electrical connections, all while showcasing Domadia’s proficiency in providing quality and tailored support. Additionally, we provide pricing and inventory details for our Beryllium Copper Strips and highlight our Beryllium Copper Non-Sparking Wrench, which offers safety features essential for various applications.

Applications of Beryllium Copper in Automotive Electrical Connections

Beryllium copper’s electrical properties for automotive connections are crucial in a variety of vehicle electrical connections, showcasing its unique attributes that drive performance and reliability. At Domadia, we are committed to providing high-quality, customized Beryllium Copper plates and solutions that elevate project success, backed by our expert support. Our extensive product range includes foils, sheets, rods, and wires, ensuring that we can meet your specific requirements.

Notable applications of Beryllium Copper include:

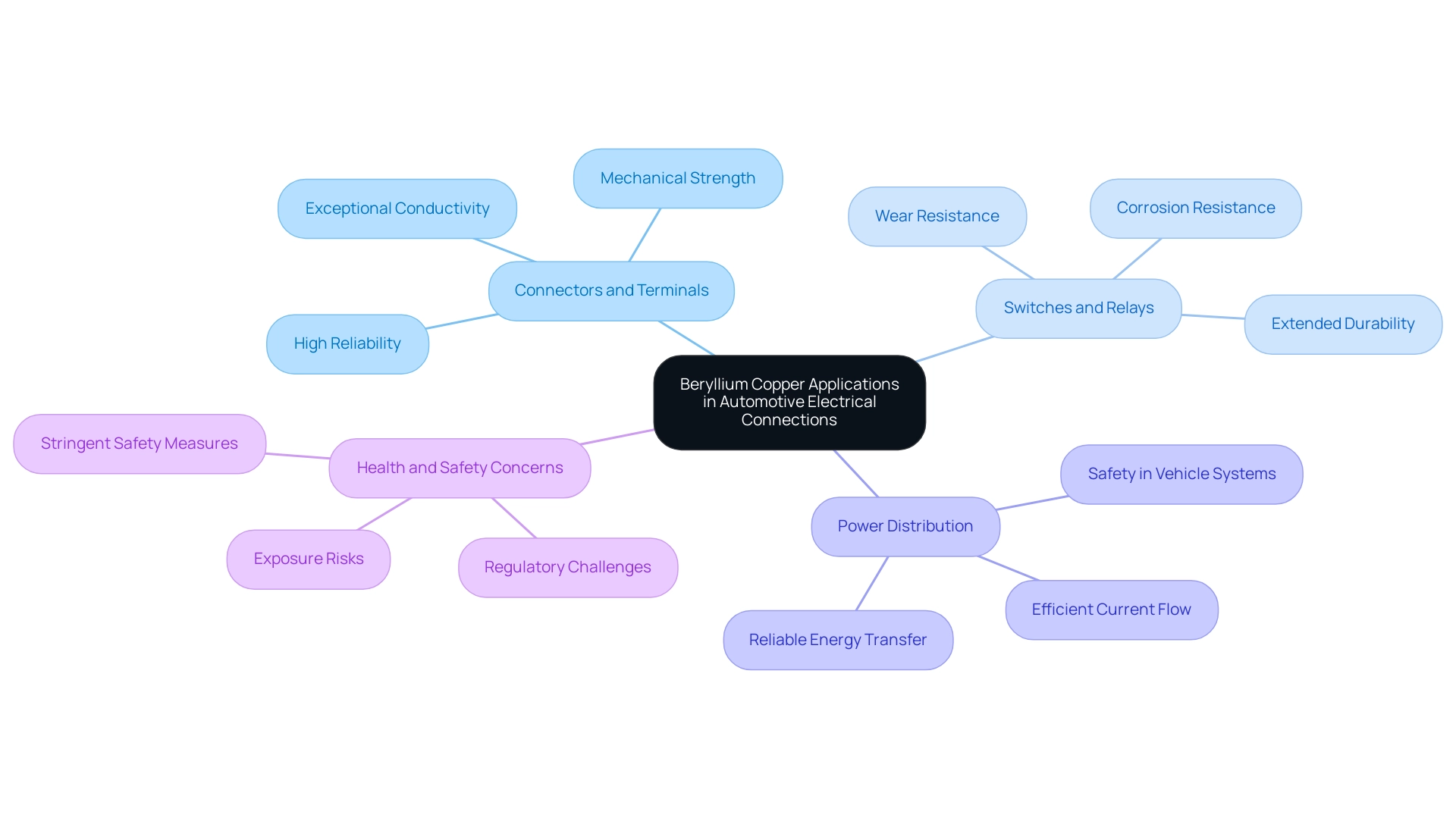

- Connectors and Terminals: Renowned for its exceptional conductivity and mechanical strength, Beryllium Copper is the preferred option for manufacturing connectors and terminals that demand high reliability. The incorporation of this alloy in vehicle connectors ensures that they can withstand the rigors of daily use while maintaining optimal performance.

- Switches and Relays: The material’s impressive resistance to wear and corrosion guarantees that switches and relays operate effectively over extended periods, even in challenging environments. This durability is essential for maintaining the functionality of critical vehicle components.

- Power Distribution: Beryllium Copper is frequently utilized in bus bars and power distribution systems, where efficient current flow is paramount for vehicle operation. Its properties facilitate the reliable transfer of electrical energy, which is vital for the overall performance and safety of vehicle systems.

These applications exemplify how leveraging beryllium copper’s electrical properties for automotive connections not only enhances performance in vehicle electrical systems but also significantly contributes to reliability and safety. As engineers highlight, the integration of beryllium copper’s electrical properties for automotive connections leads to improved efficiency and longevity in electrical systems, underscoring its importance in contemporary vehicle design. Furthermore, it is essential to acknowledge the health and safety concerns related to exposure to this substance, which have led to a reevaluation of its applications in some contexts.

Current statistics indicate that while Beryllium Copper remains a preferred choice, manufacturers must implement stringent safety measures to mitigate exposure risks. At Domadia, we ensure that our clients receive the highest quality Beryllium Copper products, customized to their specifications, with the support they need for project success. Contact us today to learn more about how our tailored solutions can elevate your projects.

Best Practices for Sourcing Beryllium Copper for Automotive Applications

When sourcing beryllium copper for vehicle applications, procurement managers should adhere to the following best practices:

Supplier Evaluation: A rigorous evaluation of potential suppliers is essential. This process should focus on their adherence to international standards and certifications specific to automotive substances. By assessing their adherence to these benchmarks, you can mitigate risks related to quality and reliability. As the Asia-Pacific region is projected to capture a 25% market share, understanding regional suppliers, especially those who provide electrical insulation and high-temperature substances, can be advantageous.

Quality Assurance: Implementing robust quality control measures is critical. Ensure that the alloy provided meets stringent specifications through thorough substance testing and validation processes. This proactive approach helps to maintain the integrity of your supply chain, particularly by utilizing beryllium copper’s electrical properties for automotive connections. As our company has risen in the standard of processing metal, prioritizing quality in sourcing is vital for sustained success, especially when dealing with materials like Kovar and Mu-Metal that share similar applications.

Negotiation and Relationships: Cultivating strong, long-term relationships with suppliers can yield significant advantages. Employ effective negotiation strategies to secure favorable pricing and ensure consistent quality, which is vital for maintaining production schedules and cost efficiency. Comprehending the elements affecting alloy scrap pricing—such as market demand, purity, and current metal prices—can improve your negotiation power. At Domadia, we are dedicated to equitable and clear pricing for all scrap transactions involving alloy, ensuring that our rates stay competitive and appealing.

Market Research: Keeping up with market trends and price variations will enable you to make well-informed buying choices. This knowledge allows you to align your sourcing strategies with current budgetary constraints while still prioritizing quality. The case study on market segmentation of the alloy illustrates how targeted marketing strategies can enhance understanding of market needs, which is crucial for effective sourcing. Furthermore, think about investigating our network of suppliers for related products, such as high-temperature fabrics and electrical insulation substances, to expand your sourcing choices.

By applying these best practices, procurement managers can effectively manage the complexities of sourcing alloys, particularly focusing on beryllium copper’s electrical properties for automotive connections to ensure that the resources fulfill the rigorous standards of the vehicle industry.

Compliance and Standards for Beryllium Copper in Automotive Manufacturing

In the vehicle industry, following compliance standards is extremely vital when using alloys and non-sparking instruments such as specific wrenches and other specialized gear. Key regulations to consider include:

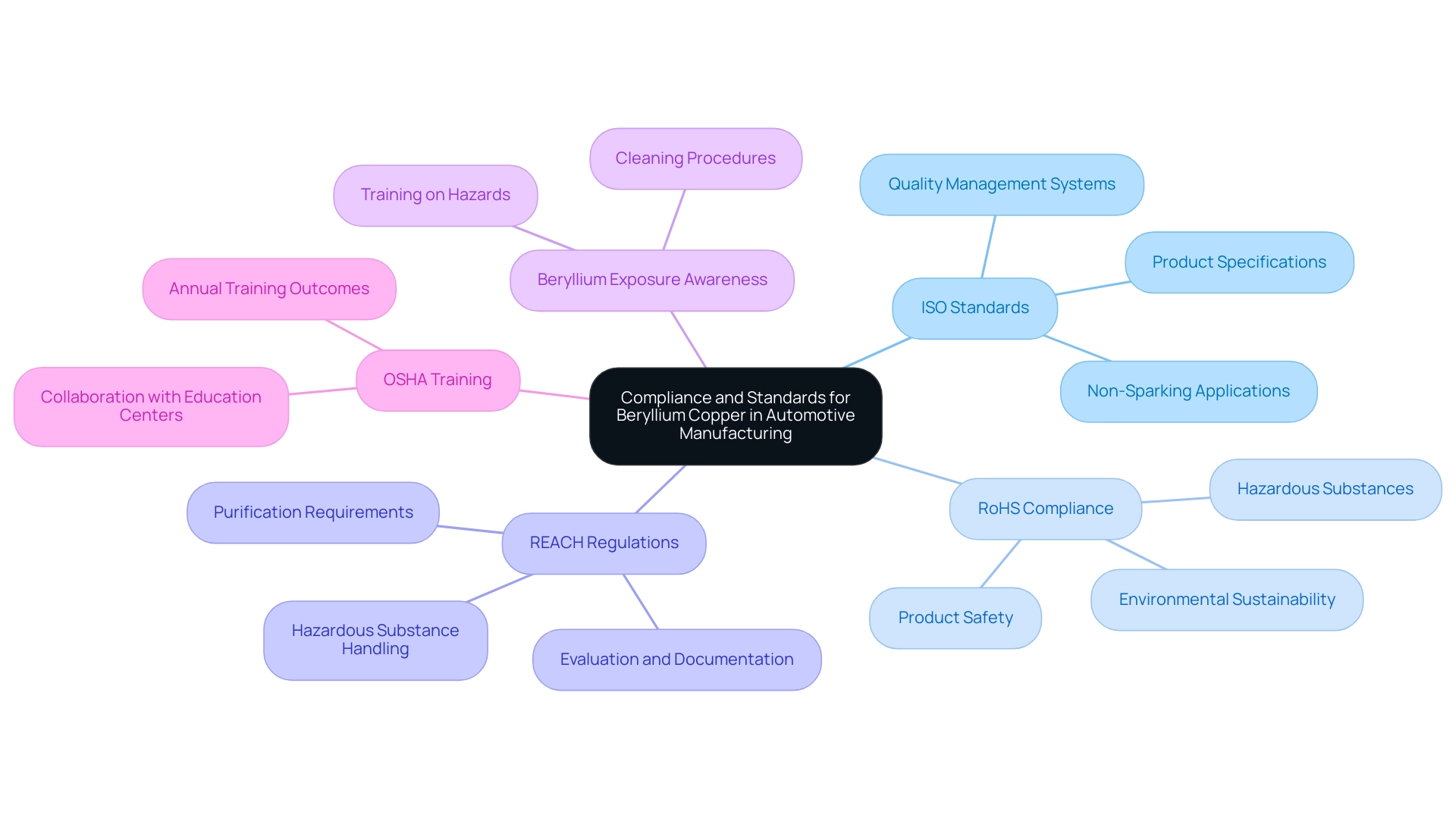

ISO Standards: It is crucial for suppliers to comply with ISO standards, which dictate quality management systems and product specifications tailored for automotive materials, including non-sparking applications in explosive potential environments. These standards guarantee that products fulfill strict quality and performance criteria.

RoHS Compliance: Verifying that non-sparking tools and products made from beryllium alloys conform to the Restriction of Hazardous Substances (RoHS) directive is vital. This regulation limits the use of certain hazardous substances in electrical and electronic equipment, thereby improving product safety and environmental sustainability, especially in sensitive applications.

REACH Regulations: Understanding the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulations is essential, especially for sourcing copper alloy in Europe. These regulations necessitate comprehensive evaluation and adherence, guaranteeing that hazardous substances are appropriately handled and documented, which is particularly crucial for materials utilized in explosive settings.

Furthermore, substances containing at least 0.1 percent of the specified element by weight must be purified to be as free as practicable of that element, emphasizing the significance of rigorous cleaning procedures in adherence. It is also essential to inform those who launder or clean beryllium-contaminated PPE about the hazards associated with beryllium exposure, ensuring safety is prioritized in compliance discussions.

A relevant case study is provided by the OSHA Training Institute, which collaborates with various education centers to deliver training on OSHA standards and occupational safety topics. This training enhances workplace safety knowledge and compliance with regulations, illustrating the importance of adherence to standards in the vehicle sector and the critical role of non-sparking tools for safety in explosive environments.

Maintaining compliance with these standards not only bolsters product safety but also reinforces your organization’s commitment to industry best practices. This fosters trust among customers and stakeholders, positioning your organization as a reliable partner in the supply chain and in the safe use of non-sparking tools. Furthermore, related products such as electrical insulation papers and high-temperature fabrics should also meet these compliance standards to ensure comprehensive safety and performance in explosive environments.

Future Trends in Beryllium Copper Usage in Automotive Applications

The car manufacturing sector is experiencing substantial change, impacted by various important trends that will define the use of a specific alloy:

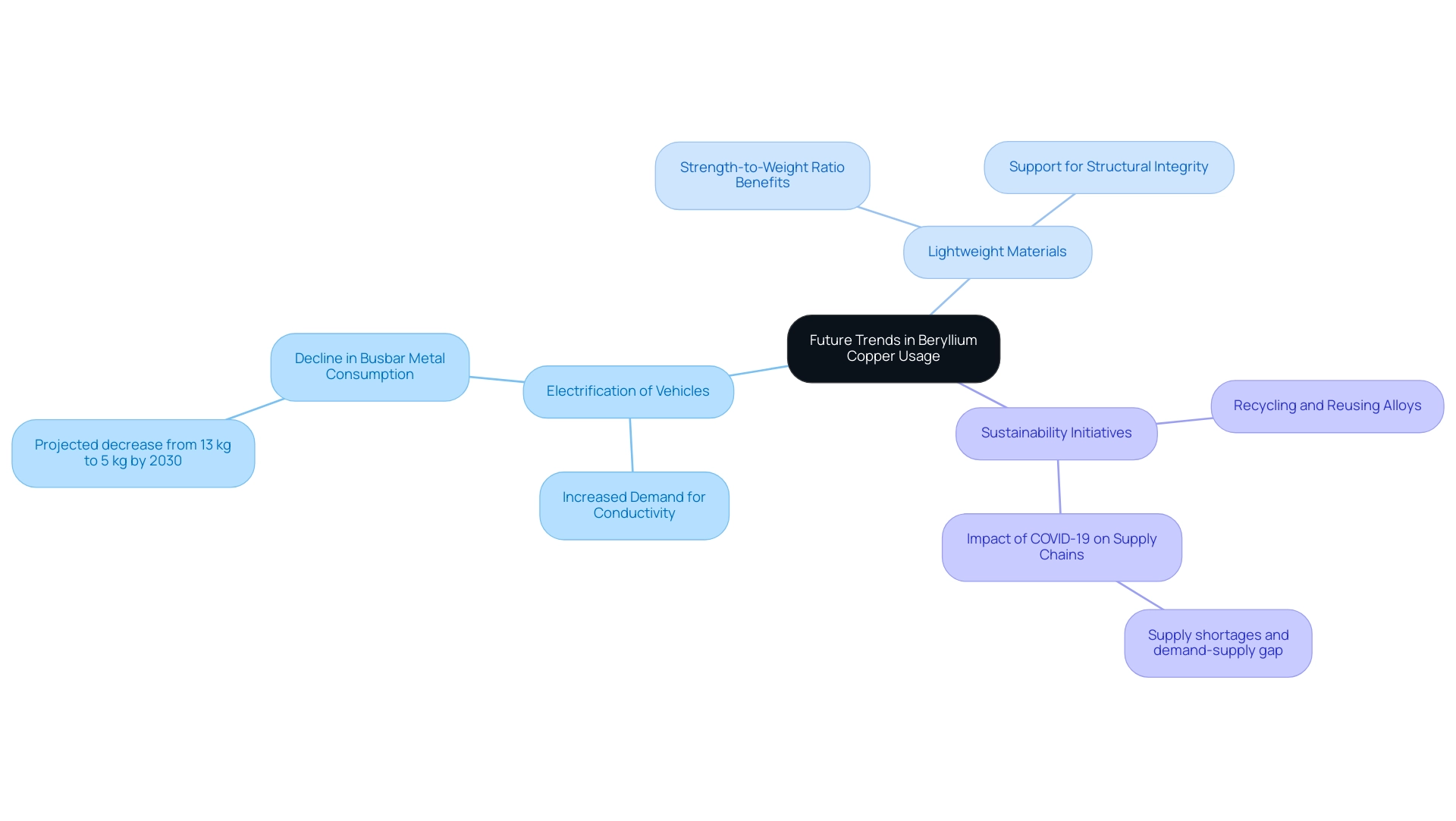

Electrification of Vehicles: The increase in electric vehicles (EVs) is anticipated to boost a greater need for materials that provide outstanding electrical conductivity. Beryllium copper’s electrical properties for automotive connections, along with its remarkable characteristics, are set to play a vital role in the production of EV components, thus becoming an essential resource for vehicle manufacturers. Significantly, as busbar metal consumption is predicted to decline from 13 kg to slightly more than 5 kg by 2030, the need for substitutes such as alternative alloys is expected to grow considerably in relation to electrification.

Lightweight Materials: As producers progressively focus on minimizing vehicle weight to improve fuel efficiency, the exceptional strength-to-weight ratio of these alternative alloys becomes more beneficial. This substance’s capacity to uphold structural integrity while aiding in weight reduction makes it an appealing option in contemporary vehicle design. The latest trends suggest a movement towards lightweight substances that can satisfy the dual requirements of performance and efficiency in vehicle applications.

Sustainability Initiatives: The increasing focus on sustainable practices is expected to encourage creative strategies for recycling and reusing alloys. As vehicle producers pursue eco-friendly substances, the possibility for a specific alloy to be reintegrated into the manufacturing process boosts its appeal as a sustainable choice. Furthermore, the impact of COVID-19 has emphasized the significance of resilient supply chains, as production and supply activities across major industries were impacted, resulting in shortages and an expanding demand-supply gap.

Alongside these trends, it’s crucial to consider specific product applications such as non-sparking wrenches made from a certain alloy, which are vital for safety in environments where sparks could ignite flammable materials. These wrenches provide durability and reliability, making them ideal for use in the vehicle industry. Moreover, detailed pricing information for metal strips, typically priced at 1,050.00, is essential for procurement managers to make informed decisions.

By proactively addressing these trends and integrating specific product details, procurement managers can strategically position their organizations to capitalize on the unique advantages of beryllium copper’s electrical properties for automotive connections in the rapidly evolving landscape of automotive development.

Conclusion

The exploration of beryllium copper’s role in the automotive industry underscores its significance as a high-performance material that meets the evolving demands of modern vehicle design. With exceptional electrical conductivity, mechanical strength, and corrosion resistance, beryllium copper stands out as a critical component in automotive electrical systems, from connectors and terminals to power distribution systems. Its ability to enhance reliability and performance is further complemented by its adaptability to the rigorous standards required in automotive manufacturing.

As procurement managers navigate the complexities of sourcing beryllium copper, adhering to best practices such as:

- Supplier evaluation

- Quality assurance

- Compliance with industry standards

is essential. Understanding the regulatory landscape, including ISO, RoHS, and REACH, not only ensures product safety but also cultivates trust among stakeholders. The commitment to quality and safety in sourcing beryllium copper reinforces an organization’s reputation as a reliable partner in the automotive supply chain.

Looking ahead, the trends of electrification, the push for lightweight materials, and sustainability initiatives will shape the future applications of beryllium copper. As the automotive sector embraces these changes, the demand for beryllium copper will likely increase, positioning it as a key player in the development of innovative and efficient vehicle technologies. By recognizing and leveraging the advantages of beryllium copper, procurement managers can drive forward-thinking strategies that align with industry advancements, ultimately contributing to the success and sustainability of their organizations in the rapidly changing automotive landscape.