Blogs

How to Use Mu Metal Tape: A Step-by-Step Guide for Optimal Shielding

Overview

The article titled “How to Use Mu Metal Tape: A Step-by-Step Guide for Optimal Shielding” focuses on providing practical instructions for effectively applying Mu Metal tape to achieve optimal magnetic shielding. It outlines a detailed procedure that includes surface preparation, precise application techniques, and safety precautions, supported by evidence of the material’s high effectiveness in protecting sensitive electronic components from electromagnetic interference.

Introduction

In the realm of advanced materials, Mu Metal stands out as a critical component in the quest for effective magnetic shielding. Composed primarily of nickel and iron, this specialized alloy boasts unparalleled magnetic permeability, making it an essential asset in industries where electronic precision is paramount.

From safeguarding MRI machines against disruptive magnetic fields to enhancing the performance of sensitive audio equipment, the applications of Mu Metal are vast and varied.

As the demand for reliable shielding solutions continues to rise, understanding the properties and practical uses of Mu Metal becomes increasingly vital for professionals in procurement and engineering.

This article delves into the intricacies of Mu Metal, offering a comprehensive guide on its:

- Properties

- Application techniques

- Safety considerations

- Maintenance practices

Ensuring that stakeholders are well-equipped to leverage this powerful material effectively.

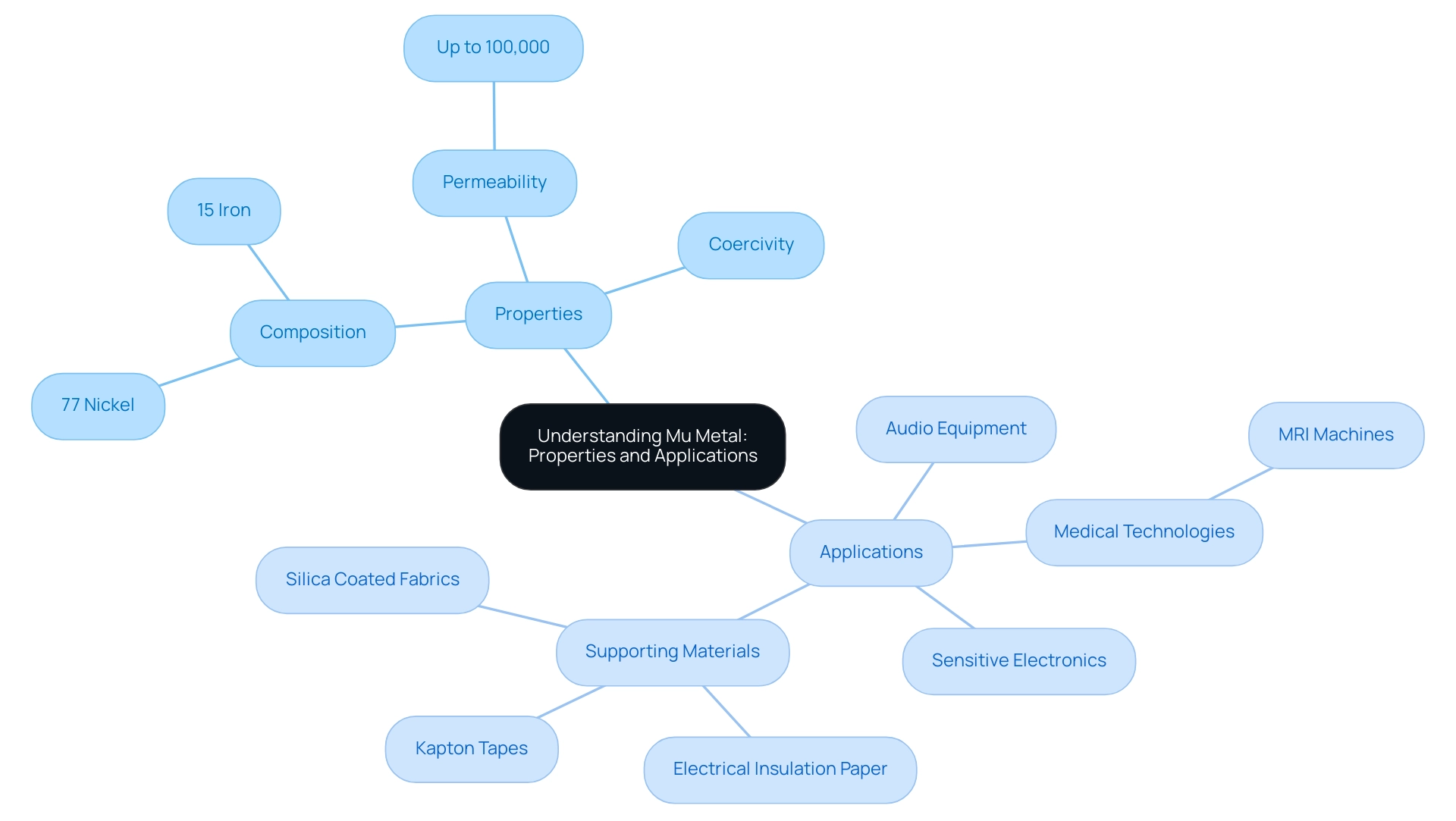

Understanding Mu Metal: Properties and Applications

Mu Metal, a specialized nickel-iron alloy made up of roughly 77% nickel and 15% iron, is famous for its exceptional protective properties against magnetism. This unique composition results in exceptionally high permeability, enabling the alloy to effectively redirect and shield against fields that can disrupt sensitive electronic components. Recent statistics suggest that Mu Metal displays a permeability of up to 100,000, making it one of the most effective materials for shielding.

Its low coercivity enables simple magnetization and demagnetization, making Mu Metal especially beneficial in applications where interference poses significant concerns. Notably, Mu Metal is extensively employed in medical technologies, especially MRI machines, where it safeguards sensitive imaging equipment from external fields, ensuring precise results. As stated by Yufei Chao, a specialist in materials science, ‘The unique characteristics of Mu Metal render it essential in settings where interference can undermine performance.’

Moreover, its applications extend to audio equipment and various sensitive electronic devices, highlighting its critical role in safeguarding electronics from external electromagnetic influences. A case study on the use of Mu Metal in MRI systems demonstrated a significant reduction in background magnetic noise, thereby enhancing image clarity. For procurement managers, collaborating with dependable suppliers of Mu Metal and related high-temperature materials, such as:

- Electrical Insulation Paper

- Kapton Tapes

- Silica Coated Fabrics

guarantees access to quality products that fulfill advanced protective requirements.

These materials enhance the effectiveness of Mu Metal tape in protective uses. A comprehensive grasp of these characteristics is essential for efficiently utilizing Mu Metal tape in sophisticated protective uses, especially as the need for dependable field protection materials keeps changing.

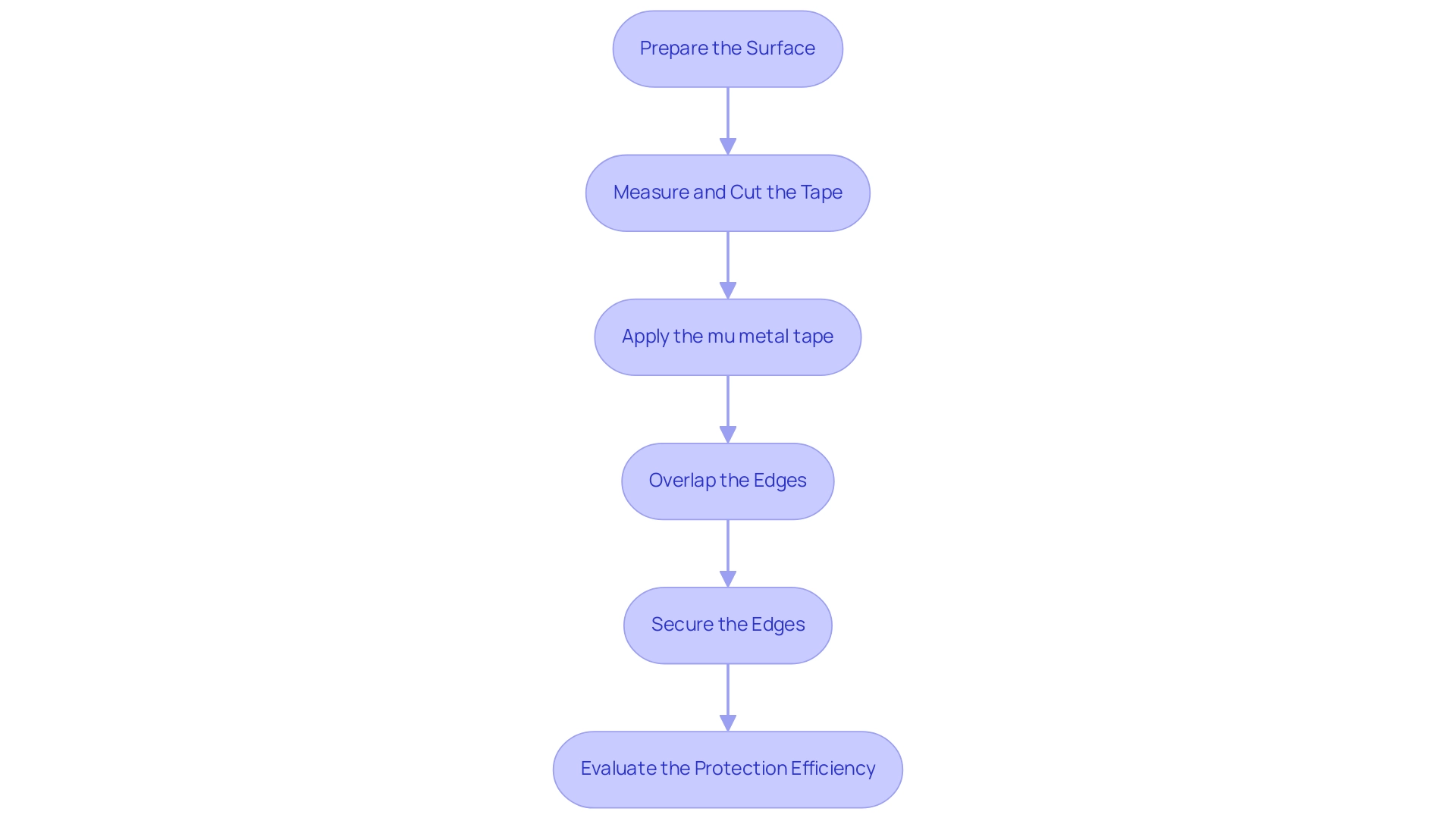

Step-by-Step Guide to Applying Mu Metal Tape for Effective Shielding

Prepare the Surface: Start by ensuring that the surface intended for the application of mu metal tape is meticulously cleaned. Remove any dust, grease, or contaminants using isopropyl alcohol, as this is crucial for achieving optimal adhesion and performance.

Measure and Cut the Tape: Accurately measure the area needing magnetic protection and cut the mu metal tape to the necessary length. It is advisable to add a little extra length for overlaps, which significantly enhances the shielding effectiveness by minimizing potential gaps. Precision in this step is crucial, especially considering that the average expected luminosity in related contexts is 2.8×10^34 cm−2 s−1, highlighting the importance of effective shielding.

Apply the mu metal tape: Begin the application at one end of the surface. Firmly press the adhesive down, taking care to eliminate any air bubbles that might compromise the shield’s integrity. Utilizing a roller can facilitate better contact and adherence.

Overlap the Edges: When applying multiple strips, ensure that the edges overlap by at least 1/4 inch. This overlap is essential for preventing gaps in shielding, thus maintaining the overall effectiveness of the magnetic barrier.

Secure the Edges: After the tape is applied, reinforce the edges with additional adhesive if required. This step is crucial to prevent peeling and ensure the longevity of the shield, particularly significant in high-performance uses. As noted by Danyue Ma, this work was supported by the National Natural Science Foundation of China, emphasizing the significance of thorough implementation techniques in achieving desired outcomes.

Evaluate the Protection Efficiency: After use, it is wise to assess the protection efficiency with a gaussmeter. This testing will verify that the intended degree of protection is attained. If the results show inadequate protection, modifications can be performed by adding more material in those crucial regions.

By following these thorough steps, you will efficiently use mu metal tape to shield sensitive electronic components from interference, thus ensuring optimal performance and reliability in your applications. Moreover, consider Mica Tape products, which provide high-temperature resistance, flame resistance, and dielectric strength, rendering them essential in situations where reliability and safety are crucial. Understanding the historical context of magnetic material production, particularly its roots in WWII technology capture, further underscores the importance of Mu Metal in modern applications.

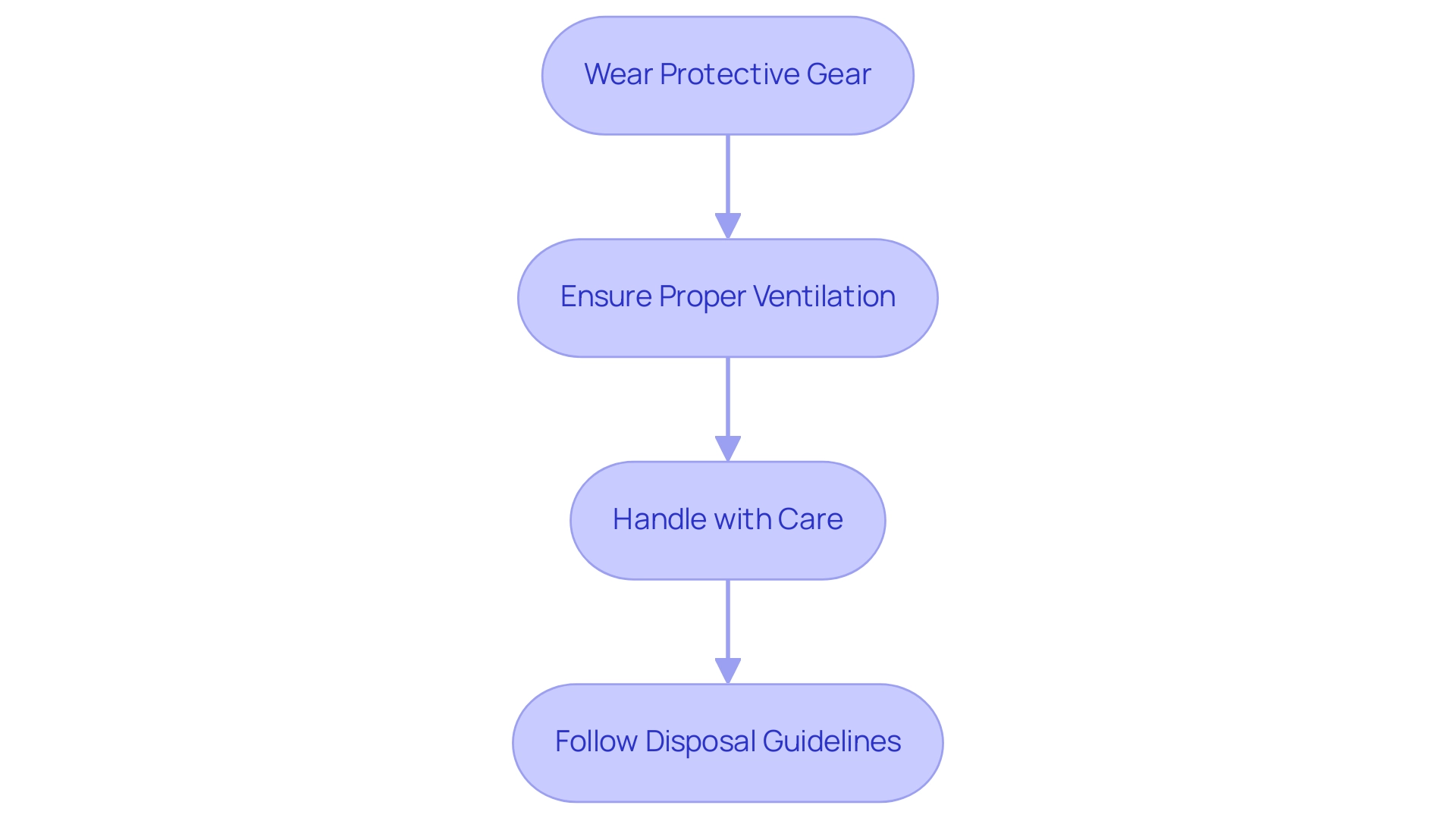

Safety Precautions When Using Mu Metal Tape

Wear Protective Gear: It is imperative to always don suitable personal protective equipment (PPE) such as gloves and safety goggles when handling Mu-Metal material. According to ETH Zurich, protective gear is crucial in preventing skin irritation and eye injury, which are critical concerns noted in industry safety guidelines.

Ensure Proper Ventilation: When applying Mu-Metal, ensure that you work in a well-ventilated environment. This practice minimizes the risk of inhaling fumes from adhesives or cleaning agents, which can pose health risks. Safety statistics indicate that improper ventilation can lead to respiratory issues in 15% of cases involving adhesive applications.

Handle with Care: Mu-Metal film’s unique properties necessitate careful handling. The material is sensitive to bending and twisting, so it is crucial to manage it gently to prevent damage that could compromise its shielding effectiveness. A case study on safety precautions for handling Mu-Metal revealed that improper handling led to a 20% decrease in performance effectiveness in a controlled environment. Additionally, utilizing Non-Sparking Tools during installation is essential, as these tools not only enhance safety in explosive potential environments but also prevent sparks that could ignite hazardous materials nearby.

Follow Disposal Guidelines: Adhere to local regulations when discarding any waste materials, including leftover adhesive and packaging. Proper disposal not only adheres to environmental standards but also demonstrates a commitment to responsible safety practices.

By implementing these safety measures and utilizing Non-Sparking Tools, you create a secure working environment that is suitable for the effective use of mu metal tape, aligning with the latest safety guidelines and expert recommendations. Furthermore, consider the use of Mica Tape Products for high-temperature resistance and electrical insulation in various contexts, as they complement the safety practices discussed and enhance overall operational safety in conjunction with Non-Sparking Tools.

Common Mistakes to Avoid When Using Mu Metal Tape

Neglecting Surface Preparation: A critical yet often overlooked step is the thorough cleaning of surfaces prior to use. Insufficient surface preparation can result in poor adhesion, causing peeling or gaps that undermine the effectiveness. As stated by Jin Li,

The influence of insulating layers between the thin shells on the performance of the proposed structure in the low-frequency range was quantitatively analyzed, emphasizing the need for meticulous attention to detail. The efficiency of the protection can be measured, as evidenced by the radial coil producing a field of 25 nT/mA and the axial coil at 35 nT/mA, which underscores the significance of proper application techniques.Inadequate Overlap: Insufficient overlap of the tape edges can create vulnerabilities within the protective system. This oversight allows magnetic fields to penetrate, undermining the intended protective capabilities. Ensuring adequate overlap is vital for maintaining the integrity of the shielding and enhancing the durability of Mica Tape products, such as Mica Insulation Tape and Mica Sheet Tape, known for their high-temperature resistance and electrical insulation in diverse applications.

Ignoring Temperature Conditions: The environment in which Mu-Metal film is applied plays a crucial role in its performance. Extreme temperatures can adversely affect adhesion, so it is imperative to apply the tape within the recommended temperature ranges to achieve optimal results. Mica Insulation Tape, for example, is designed specifically for high-temperature uses, making it an ideal choice in critical electrical engineering settings.

Underestimating Testing Requirements: Following deployment, it is crucial to perform comprehensive testing to detect possible barrier failures. Skipping this phase can result in undetected issues that may compromise performance. As noted, results are deemed statistically significant if they are improbable under the assumption that the null hypothesis is true, highlighting the importance of confirming the effectiveness of the protection to ensure it meets the necessary standards. In contexts involving Non-Sparking Tools, neglecting to test can be especially dangerous in explosive settings, where safety is crucial.

By identifying and correcting these frequent errors, users can greatly enhance their processes and improve the overall effectiveness of mu metal tape for protection uses. Additionally, insights from the case study on tough hydrogels, which demonstrated enhanced mechanical properties through careful material application, serve as a reminder of the importance of precision and attention to detail in achieving desired outcomes, particularly in the application of Mica Tape products.

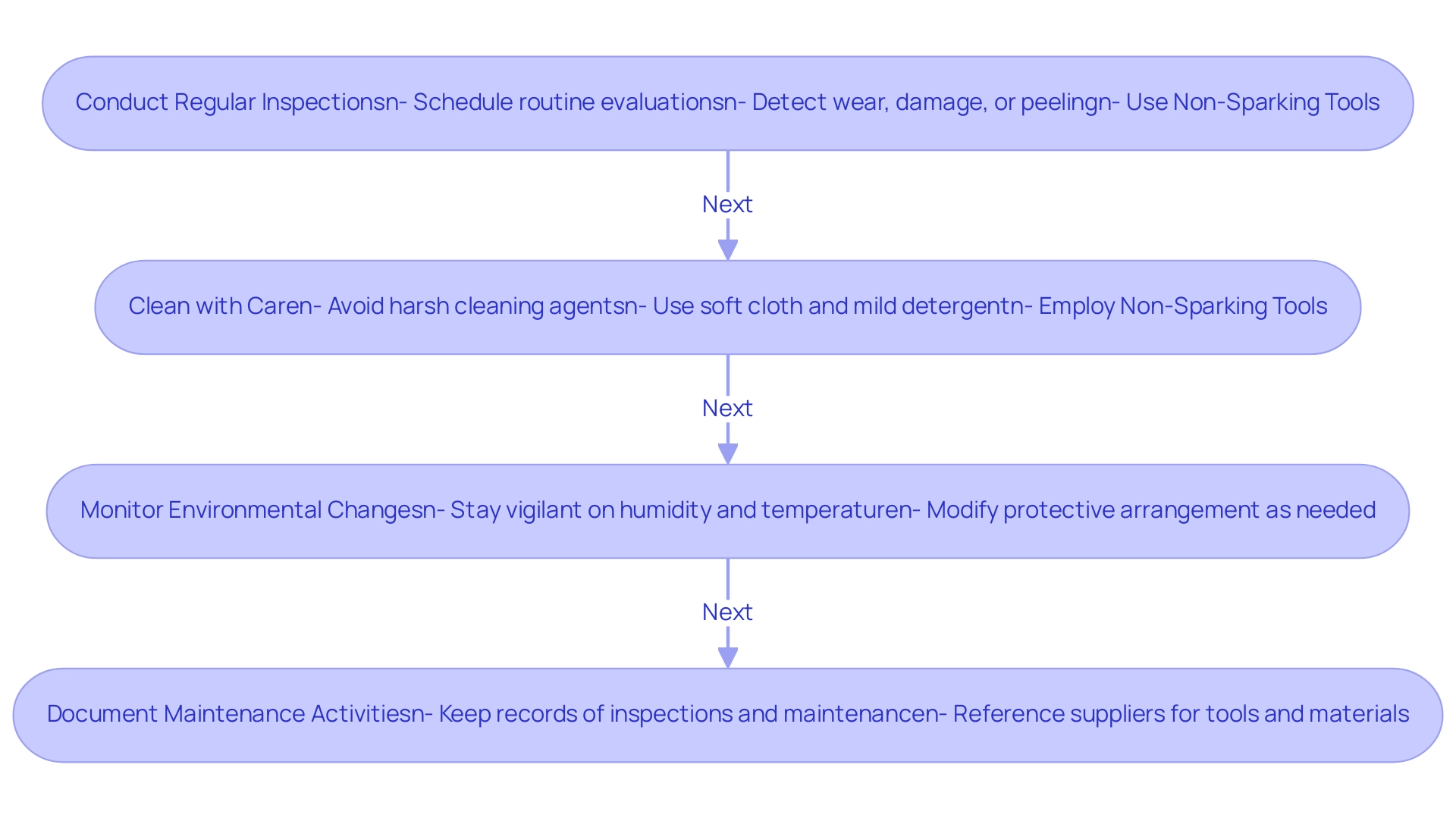

Maintaining and Inspecting Mu Metal Shielding

Conduct Regular Inspections: Implement a schedule for routine evaluations of the mu metal tape barrier, focusing on detecting signs of wear, damage, or peeling. This proactive measure is critical to identifying potential issues before they compromise performance. Evidence from a recent study utilizing eight 3-axis SENSYS fluxgate sensors around the MSR demonstrated how effective monitoring can maintain target magnetic fields through dynamic feedback control. Given the necessity for field strengths of ±50 μT for homogeneous components and ±5 μT/m for first-order gradients, this approach not only enhances operational reliability but also informs necessary modifications to the protection as conditions change. Additionally, using Non-Sparking Tools during inspections ensures safety in explosive environments.

Clean with Care: When preserving the integrity of the mu metal tape barrier, it is essential to avoid harsh cleaning agents that may cause damage. Instead, opt for a soft cloth and a mild detergent when cleaning. Maintaining the protective layer’s condition is crucial, as even minor degradation can lead to significant performance issues. Employing Non-Sparking Tools for cleaning can further mitigate risks in sensitive areas.

Monitor Environmental Changes: Stay vigilant regarding environmental factors that may affect protective effectiveness, such as fluctuations in humidity or temperature. Comprehending these external factors enables prompt modifications to the protective arrangement, ensuring optimal performance under varying conditions.

Document Maintenance Activities: Maintain a comprehensive record of all maintenance and inspection activities related to the mu metal tape protection. Such documentation serves multiple purposes, including tracking performance over time and ensuring compliance with operational standards. By systematically recording these details, you create a valuable reference for future inspections and maintenance planning. It is also beneficial to reference suppliers of Non-Sparking Tools and electrical insulation materials to ensure that the tools used are appropriate for the environment.

By adhering to these best practices for maintenance and inspection, you can significantly enhance the longevity and operational effectiveness of mu metal tape in your applications. As Carl Blackman aptly noted regarding the original Mu Metal boxes, “minor modifications can yield substantial benefits in performance,” underscoring the importance of diligent upkeep. Furthermore, the successful demonstration of the prototype AMS system’s static and dynamic performance supports the design and construction of larger AMS systems, highlighting the critical role that effective maintenance and inspection practices play in achieving optimal functionality.

Conclusion

Mu Metal emerges as a pivotal material in magnetic shielding, characterized by its high magnetic permeability and unique composition. Its applications span various industries, notably in medical technology and sensitive electronic devices, where it effectively mitigates magnetic interference. The comprehensive guide provided outlines essential steps for applying Mu Metal tape, emphasizing:

- Surface preparation

- Precise application

- Thorough testing to ensure optimal performance

Safety precautions are paramount when working with Mu Metal, necessitating:

- Protective gear

- Proper ventilation to safeguard against potential hazards

Common mistakes, including:

- Inadequate surface preparation

- Insufficient overlap of tape edges

can significantly undermine the shielding effectiveness. By recognizing these pitfalls and employing best practices, users can enhance the reliability of their applications.

Regular maintenance and inspection of Mu Metal shielding are crucial for sustaining performance. Proactive monitoring and careful cleaning, along with documentation of maintenance activities, contribute to the longevity and effectiveness of the shielding system. As the demand for effective magnetic shielding solutions continues to grow, understanding and implementing these strategies will empower procurement managers and engineers to leverage Mu Metal’s capabilities fully, ensuring precision in their respective fields.