Blogs

Understanding C-269 Spring: A Complete Tutorial on Specifications and Uses

Introduction

In the realm of industrial applications, C-269 springs have emerged as a pivotal component, demonstrating remarkable durability and performance across various sectors. Engineered from a high-performance copper nickel alloy, these springs are not only known for their impressive mechanical properties but also for their adaptability in challenging environments, ranging from automotive systems to aerospace technologies.

With specifications that highlight their tensile strength, fatigue resistance, and temperature resilience, C-269 springs are increasingly recognized as a strategic choice for procurement managers seeking reliable solutions.

This article delves into the intricacies of C-269 springs, exploring their specifications, applications, benefits, and real-world case studies that underscore their value in modern engineering. As industries continue to evolve, understanding the role of these springs becomes essential for making informed procurement decisions that align with both performance standards and operational requirements.

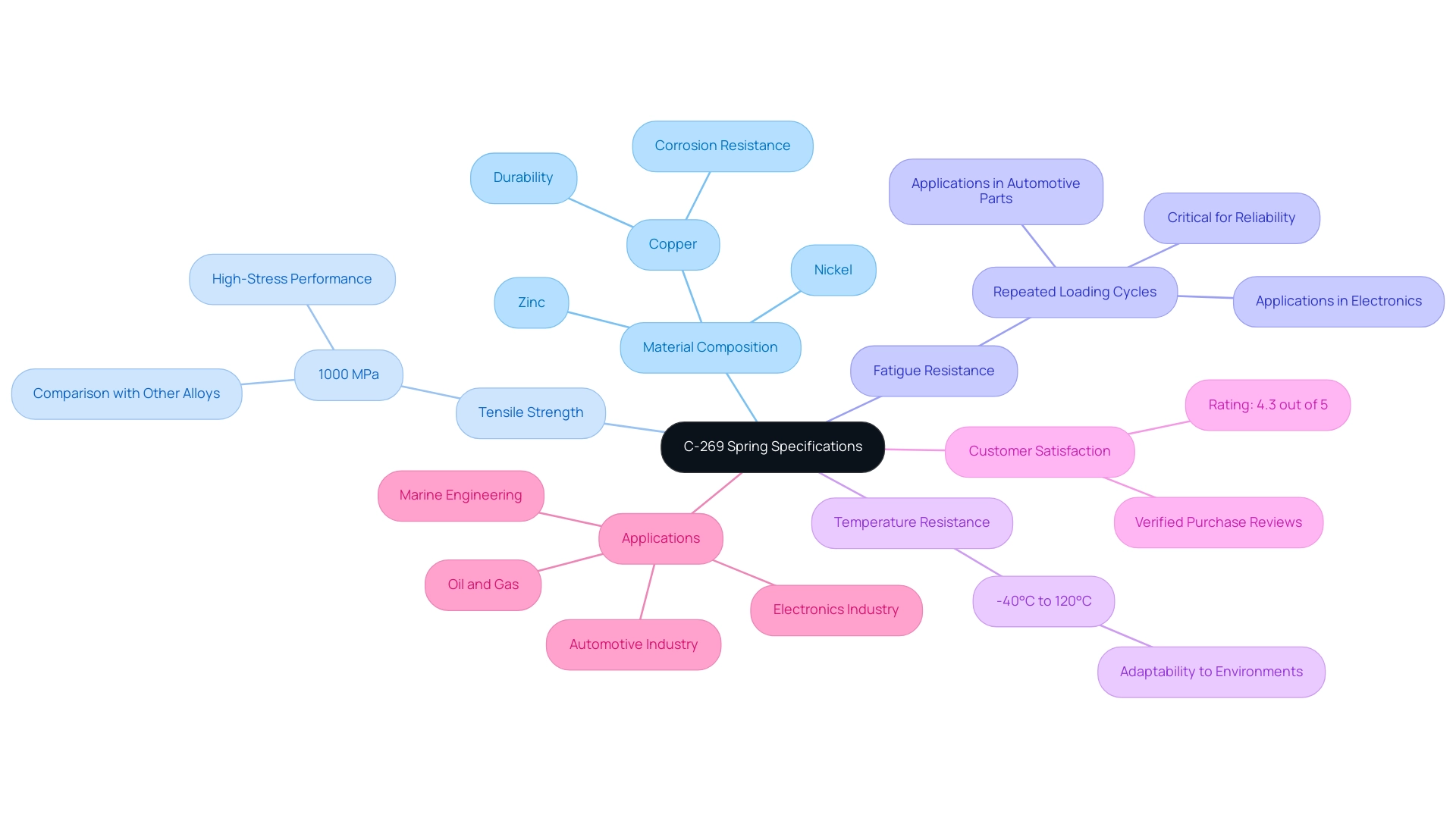

Overview of C-269 Spring Specifications

The coils are designed from a high-performance copper nickel alloy, recognized for its exceptional mechanical characteristics, rendering them a favored option in challenging industrial uses. The key specifications of C-269 springs include:

- Material Composition: Composed primarily of copper with small percentages of nickel and zinc, this alloy enhances durability and corrosion resistance, ensuring longevity in various environments, including marine engineering and electronics.

- Tensile Strength: With a tensile strength typically around 1000 MPa, these components excel in high-stress scenarios, outperforming numerous other alloys under comparable conditions.

- Fatigue Resistance: Specifically designed to endure repeated loading cycles without failure, these components are critical for applications demanding high reliability, such as automotive parts and electronic devices.

- Temperature Resistance: These components maintain their performance across a wide temperature range of -40°C to 120°C, making them adaptable to diverse operational environments.

These specifications collectively position the components as an optimal solution for sectors requiring both performance and resilience, including automotive and electronics industries. Recent advancements in the production of high-performance copper nickel alloys further enhance the capabilities of these components, ensuring they meet the evolving demands of various applications. Notably, the C-269 spring components have received a customer rating of 4.3 out of 5 stars, reflecting strong user satisfaction.

As Paul aptly puts it, “It’s a spring…exactly what it states,” reinforcing the reliability of this product.

Our team possesses unmatched expertise in crafting tailored solutions for copper nickel alloys, ensuring we deliver precisely what you need. Moreover, the importance of non-sparking tools in explosive environments cannot be overstated. These tools offer secure options for contexts where conventional instruments may present risks, making them vital in sectors like oil and gas.

Additionally, our Mica Tape Products are designed for high-temperature resistance and electrical insulation, further showcasing our commitment to providing comprehensive solutions for various uses. This comprehensive understanding of alloys and tools underscores our unmatched expertise in delivering tailored solutions for your specific needs.

Applications and Uses of C-269 Springs

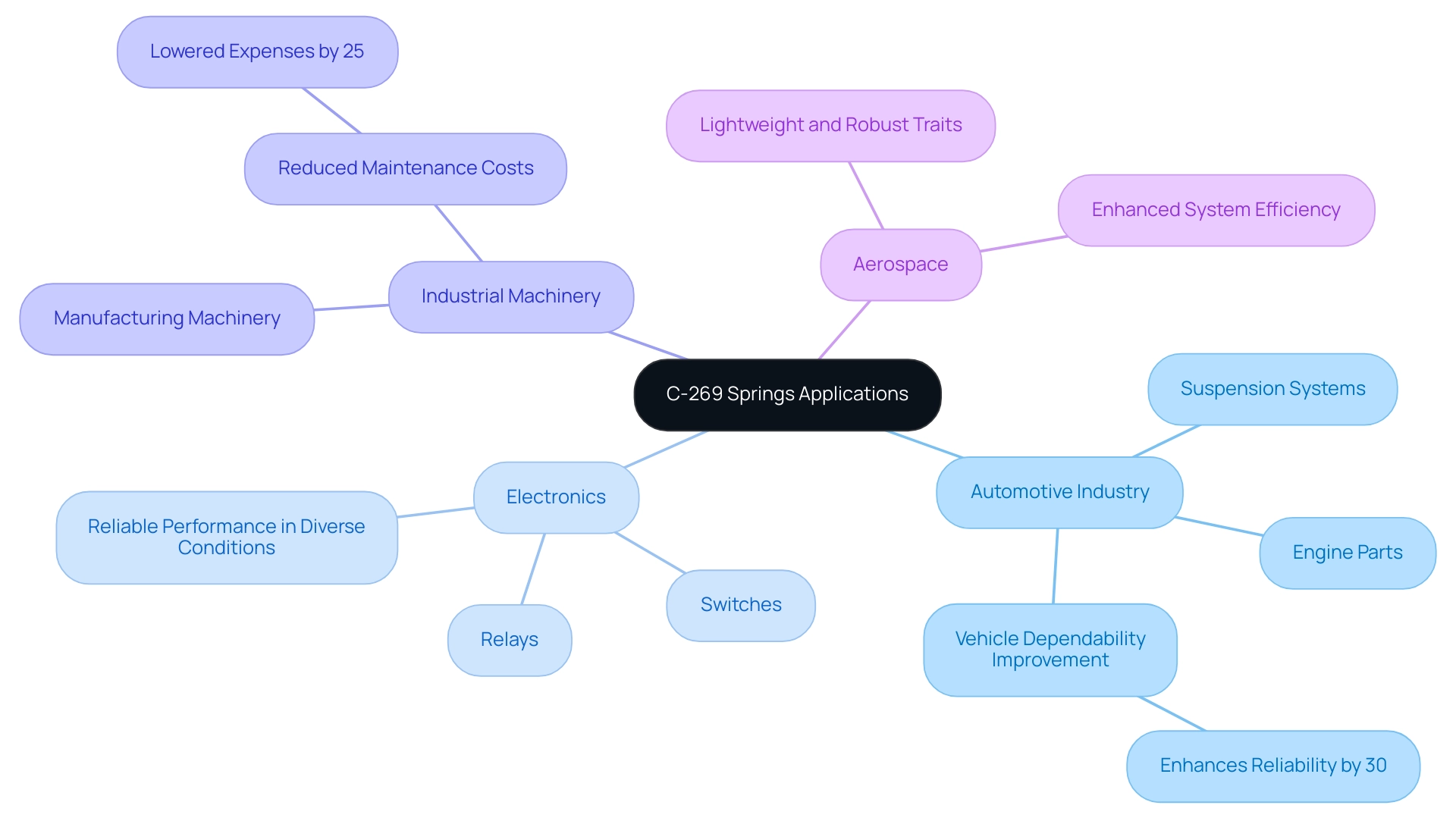

The component plays a vital role in various sectors, demonstrating its adaptability and performance-boosting characteristics. Their applications encompass:

Automotive Industry: In this sector, these components are crucial for suspension systems and engine parts. Based on industry data, the utilization of these components can enhance vehicle dependability by as much as 30%. Their high strength and fatigue resistance are critical for ensuring vehicle reliability and safety. As highlighted by automotive specialist Gary Olson, Ph.D., ‘The performance of these components significantly contributes to the overall durability of contemporary vehicles.’

Electronics: These components are integral to devices such as switches and relays, where precise mechanical movement is paramount. The capability of these components to provide reliable performance in diverse conditions makes them a favored option in the electronics industry.

Industrial Machinery: These elements are employed in manufacturing machinery that functions under high stress. Their reliability ensures that machinery functions efficiently, minimizing downtime and maintenance costs. A recent case study emphasized a manufacturing facility that lowered maintenance expenses by 25% after incorporating specific components into their machinery.

Aerospace: In aerospace uses, these components are preferred for their lightweight yet robust traits, which enhance overall system efficiency. The demand for high-performance materials in this sector highlights the importance of these components in advancing aerospace technologies.

These varied uses demonstrate the versatility of these products in meeting the specific requirements of different industries, rendering them an essential element in modern engineering solutions.

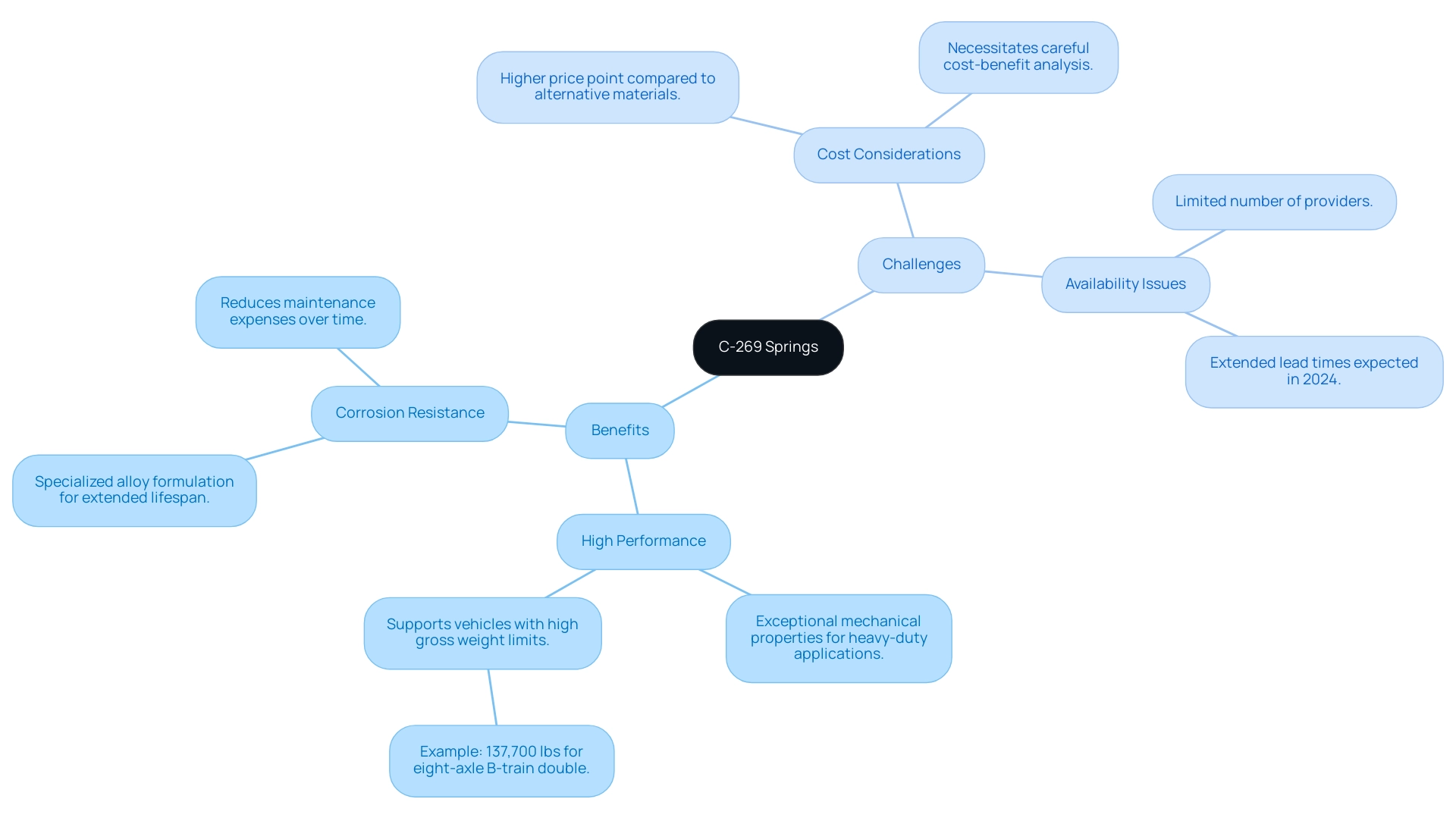

Benefits and Challenges of C-269 Springs

C-269 springs present a compelling choice for various applications, offering a range of benefits that enhance performance and durability:

- High Performance: These springs exhibit exceptional mechanical properties, making them reliable in high-demand scenarios. Their design is particularly suited for heavy-duty applications where performance is critical. For example, an eight-axle B-train double has a gross vehicle weight limit of 137,700 lbs, showcasing the high-performance standards that these components can uphold.

- Corrosion Resistance: The specialized alloy formulation of these components ensures an extended lifespan, which significantly reduces maintenance expenses over time. This resilience makes them ideal for environments where exposure to corrosive elements is a concern.

Nevertheless, procurement professionals must consider specific challenges when integrating C-269 springs into their operations:

- Cost Considerations: C-269 springs typically come at a higher price point compared to alternative materials, which can affect overall budget allocations. A careful cost-benefit analysis is essential to justify this expenditure in the context of long-term savings and performance reliability.

- Availability Issues: Obtaining the specific components may present challenges because of a restricted number of providers. Lead times can be extended, particularly in 2024, which necessitates proactive planning and communication with suppliers to ensure timely procurement.

These insights allow procurement managers to make informed choices by considering the benefits of these components against their possible sourcing difficulties. As highlighted in Arizona’s Revised Statutes, “The Director of the State Department of Transportation is authorized to issue permits for the operation of vehicles that exceed State weight limits,” reflecting the importance of ensuring compliance with regulations, a principle that parallels the need for adherence to procurement standards. Additionally, the case study on waste tires transport illustrates how annual permits allow the movement of waste tires exceeding weight limits, supporting recycling efforts while ensuring compliance with safety standards.

In general, grasping these dynamics is vital for enhancing procurement strategies associated with the components.

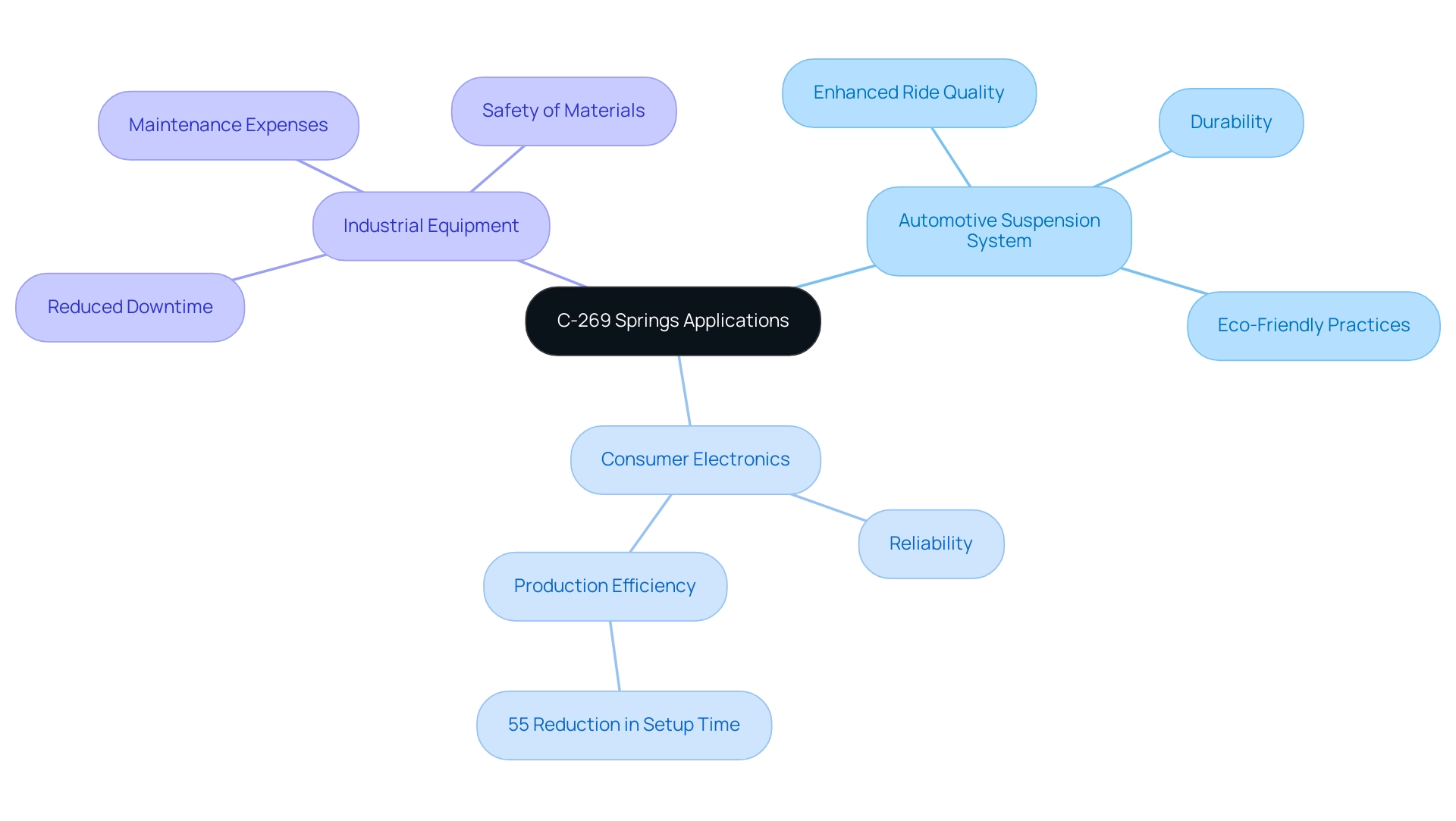

Case Studies: Real-World Applications of C-269 Springs

Automotive Suspension System: A leading vehicle manufacturer successfully incorporated specialized coils into their latest suspension design. This innovative adoption resulted not only in enhanced ride quality but also in significant improvements in durability compared to conventional materials. These advancements align with industry trends that prioritize consumer comfort and vehicle longevity. Furthermore, the application of these components can be viewed as part of a larger shift towards eco-friendly practices, as they may aid in establishing a safer indoor atmosphere in vehicles by lowering microbial hazards linked to conventional materials.

Consumer Electronics: In the field of technology, a prominent company utilized specialized components in its new smart device collection. This strategic choice led to enhanced reliability in mechanical switches, which are subjected to frequent usage. The incorporation of these components has proven essential in ensuring the longevity and performance of consumer electronics in an increasingly competitive market. Furthermore, the implementation of the specified components can possibly improve production efficiency, as highlighted by the Ergonomic SMED (ESMED) Model, which stresses a 55% decrease in setup time.

Industrial Equipment: A notable manufacturing firm reported a remarkable decrease in downtime after transitioning from traditional components to innovative alternatives in their machinery. This shift not only boosted productivity but also led to reduced maintenance expenses, highlighting the adaptability and effectiveness of these components in industrial applications. However, it is vital to consider the safety of materials utilized; as noted, continuous addition of fullerenes can cause negative effects on animal health, emphasizing the significance of choosing environmentally friendly materials in procurement choices.

These case studies collectively illustrate the effective incorporation of these components across various sectors, yielding substantial advantages that underscore their strategic value in procurement choices.

Key Takeaways on C-269 Springs

The model 269 components symbolize a flexible answer extensively employed in various sectors, such as automotive, electronics, and aerospace. Their high-performance capabilities, along with exceptional corrosion resistance, make them dependable under significant stress, ensuring longevity in challenging uses. Especially in high-performance settings, these components excel in providing the durability required for essential functions.

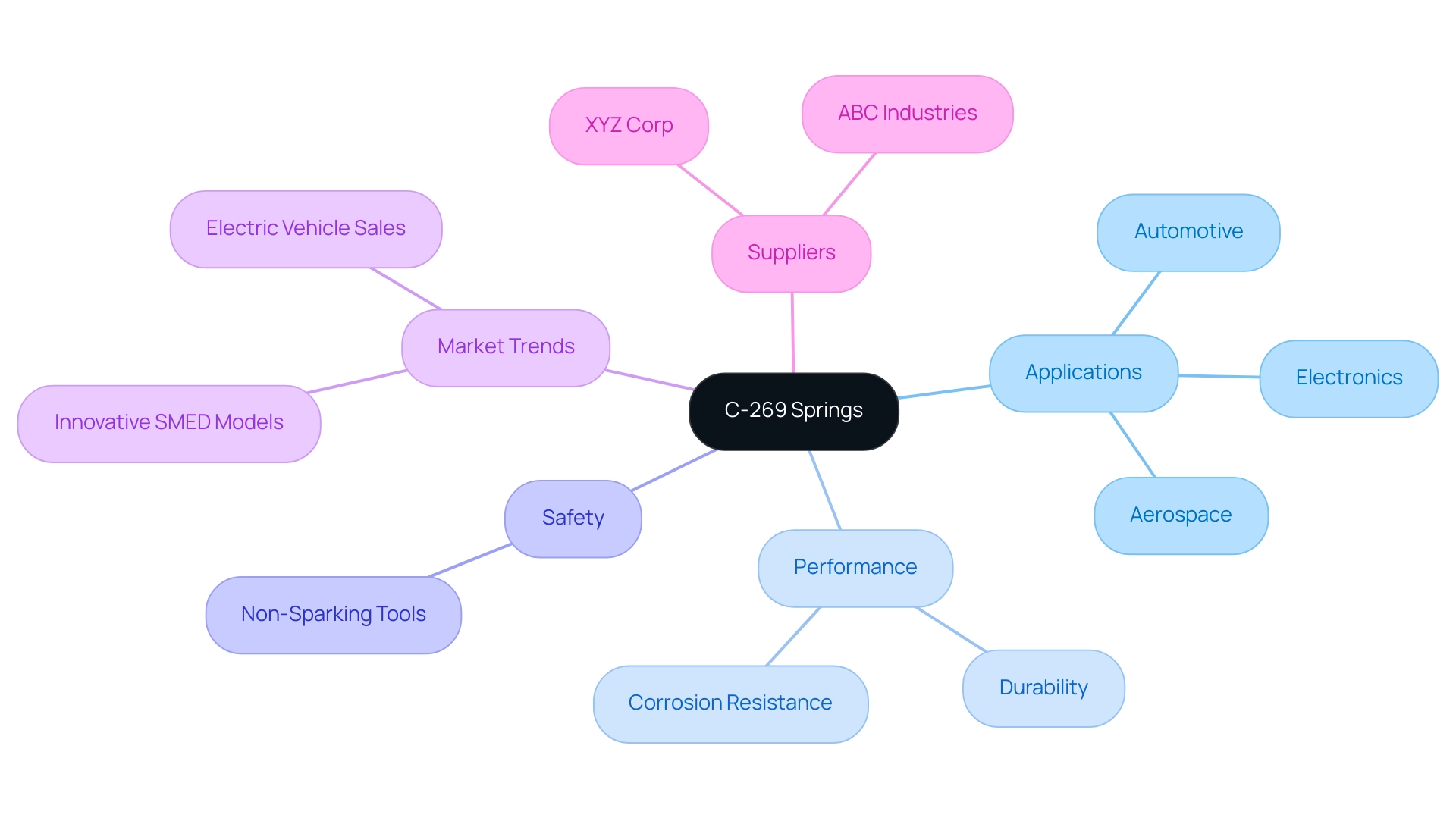

This reliability is especially crucial in explosive environments, where Non-Sparking Tools are recognized as essential alternatives, minimizing risk. Non-Sparking Tools, characterized by their ability to prevent sparks and reduce the potential for ignition in hazardous settings, are vital in ensuring safety in such applications. Key suppliers and producers of electrical insulation and high-temperature substances, such as XYZ Corp and ABC Industries, supply the essential components that enhance their use in these environments.

The increasing demand for high-performance components is emphasized by the fact that global electric vehicle sales surpassed 10 million units in 2022, underscoring the need for dependable resources in the automotive sector. Furthermore, recent suggestions for innovative ergonomic SMED models in automotive steel components indicate advancements that could further improve the uses of the c-269 spring elements. However, it is essential to acknowledge that these advantages may come with higher costs and potential sourcing challenges, particularly when selecting Non-Sparking Tools or other specialized resources.

A practical example can be seen in the DONGFENG MOTOR RUS LLC case study, where the DF6 pickup truck features a rear-dependent leaf spring, showcasing the application of such specialized components in real-world scenarios, particularly the integration of Non-Sparking Tools in its design. By grasping these key attributes and understanding current market trends, procurement managers can navigate the complexities of selection and make strategic decisions that align with project requirements. As noted by industry expert Brian Moore, VP of NICCA USA, Inc., ‘The quality of research they have done for us has been excellent,’ a testament to the rigorous evaluation that should accompany the procurement process for such specialized components, including Non-Sparking Tools and high-temperature materials.

Conclusion

C-269 springs stand out as a critical component in various industrial applications, driven by their exceptional mechanical properties and adaptability to challenging environments. Their composition from a high-performance copper nickel alloy ensures impressive tensile strength, fatigue resistance, and temperature resilience, making them a strategic choice for procurement managers across sectors such as automotive, electronics, and aerospace. The benefits of C-269 springs, including corrosion resistance and reliability, further enhance their appeal, though considerations around cost and availability remain pertinent.

Real-world applications underscore the value of C-269 springs, showcasing their successful integration in:

- Automotive suspension systems

- Consumer electronics

- Industrial machinery

These case studies illustrate not only the performance improvements achieved but also the long-term cost savings realized through reduced maintenance and increased efficiency. As industries continue to evolve, the strategic implementation of C-269 springs can lead to significant advancements in product reliability and operational effectiveness.

In summary, C-269 springs represent a versatile and high-performing solution that meets the demands of contemporary engineering challenges. For procurement managers, understanding the nuances of these springs—along with their benefits and potential sourcing challenges—is essential for making informed decisions that align with both performance standards and budgetary constraints. The ongoing development and adoption of C-269 springs not only reflect current market trends but also pave the way for future innovations in industrial applications.