Blogs

Understanding Invar Melting Point: A Complete Tutorial on Properties and Applications

Introduction

Invar 36, a remarkable nickel-iron alloy, is celebrated for its unparalleled low thermal expansion coefficient, making it an essential material in industries where precision is non-negotiable. With applications spanning aerospace, medical devices, and precision engineering, this alloy’s ability to maintain dimensional stability under fluctuating temperatures is critical for successful outcomes.

As North America positions itself to lead the Invar alloy market, understanding the properties and advantages of Invar 36 becomes paramount for procurement managers and engineers. This article delves into the unique characteristics of Invar 36, its applications across various sectors, and the challenges that professionals must navigate to leverage this vital material effectively in their projects.

Introduction to Invar 36: Properties and Significance

The nickel-iron alloy known as 36, composed of approximately 36% nickel and 64% iron, is renowned for its exceptionally low thermal expansion coefficient. This characteristic renders it indispensable in precision-critical applications where maintaining dimensional stability across varying temperatures is paramount. Sectors like aerospace, medical devices, and precision engineering heavily depend on Alloy 36 for its distinctive properties.

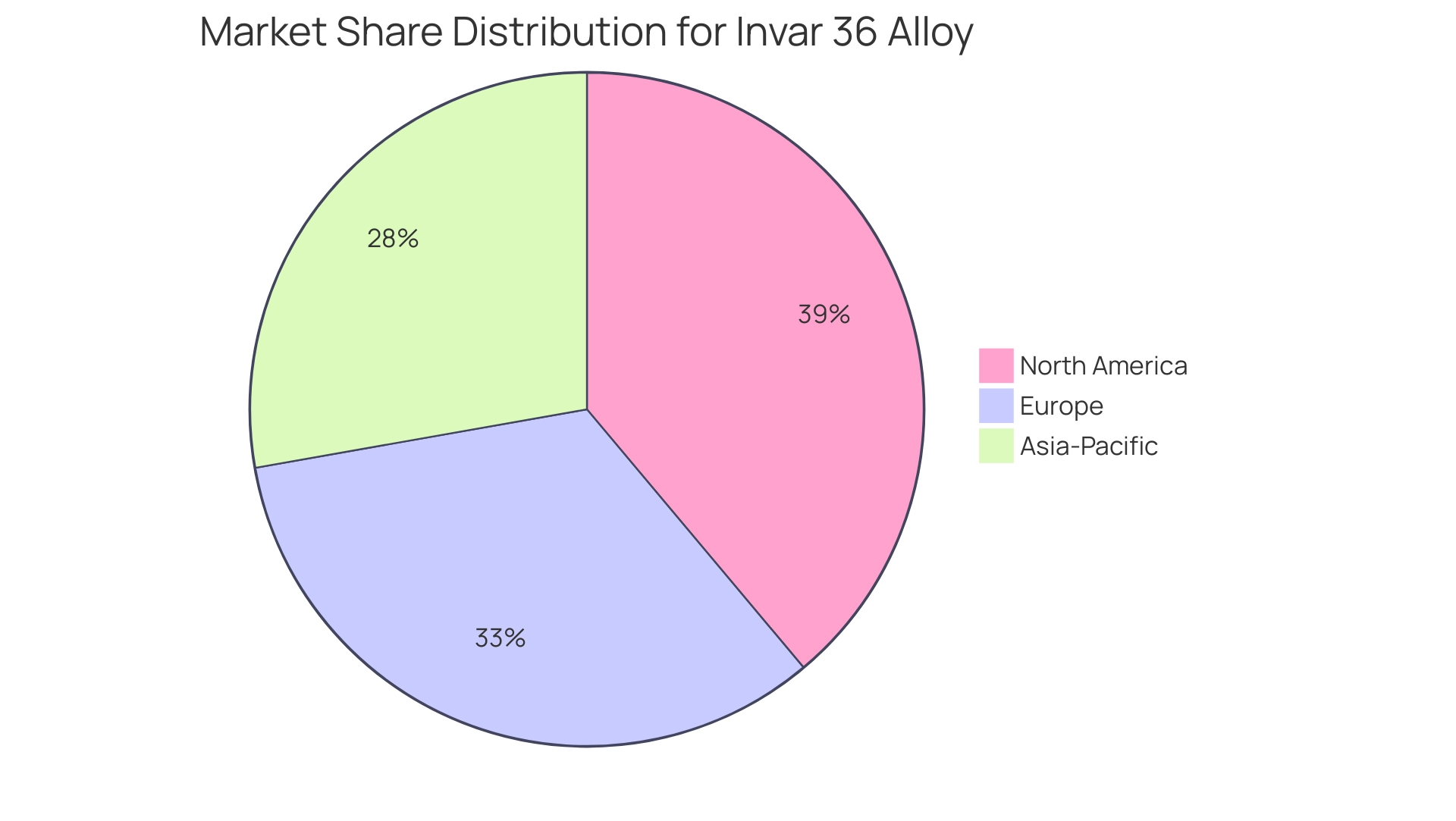

Recent analyses indicate that North America is set to dominate the alloy market with a projected share of 35%, followed by Europe at 30% and Asia-Pacific at around 25%. This growth is driven by advancements in manufacturing technologies and robust sectors such as aerospace and defense, particularly in the United States. As Dr. Yong He, an assistant researcher at the Laboratory for Reactor Fuel and Materials, observes, ‘The preparation and post-processing of substances like alloy 36 are crucial for improving their performance in high-stakes applications.’

Comprehending the characteristics of the alloy 36 is crucial for procurement managers and engineers seeking to utilize this material effectively in their projects.

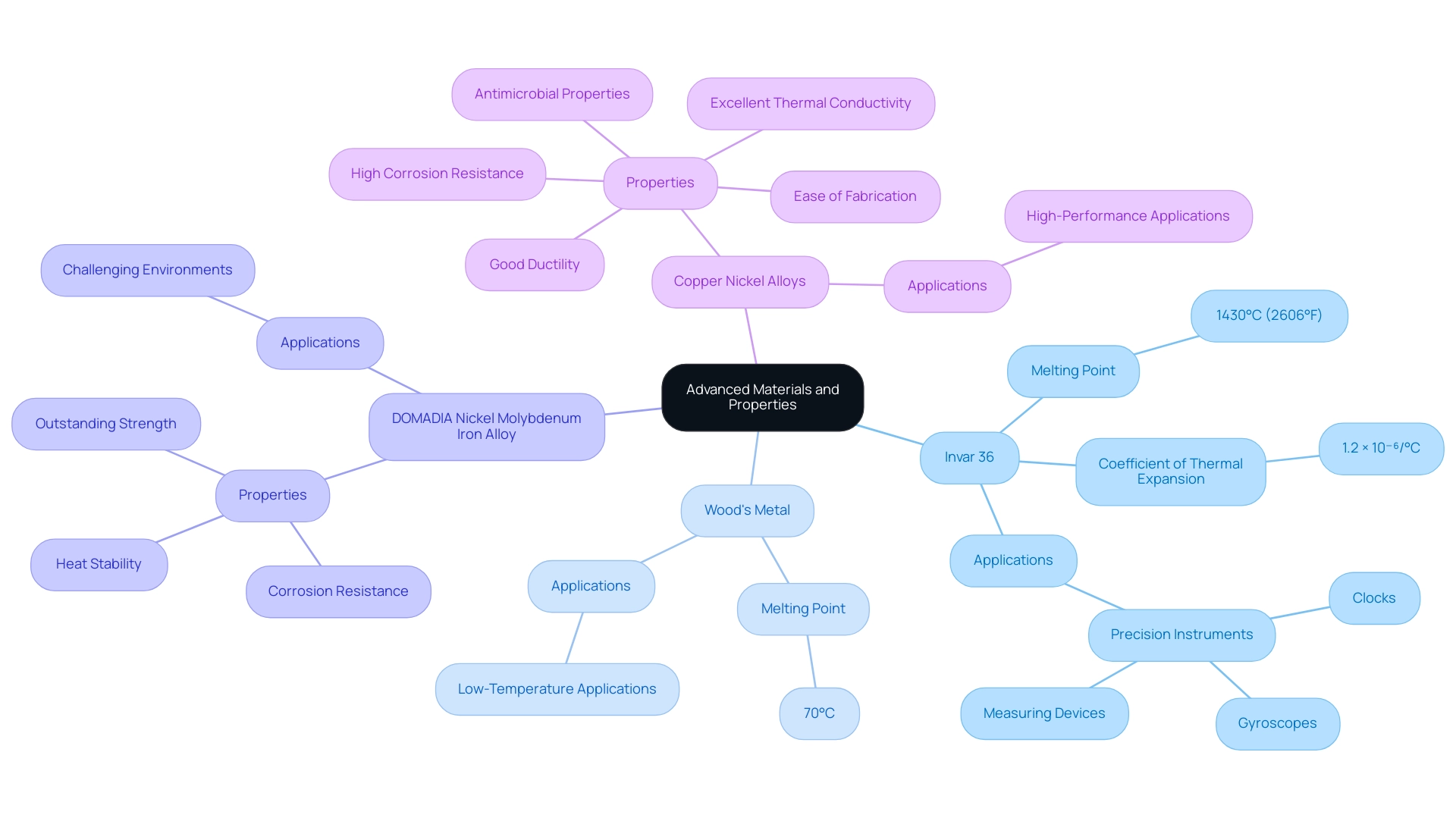

Understanding the Melting Point and Thermal Expansion of Invar

Alloy 36 boasts an invar melting point of approximately 1430°C (2606°F), positioning it favorably in comparison to other alloys such as Wood’s Metal, which has a melting point of just 70°C. Its most remarkable characteristic is its exceptionally low coefficient of heat expansion, measuring around 1.2 × 10⁻⁶/°C. This property enables this material to undergo minimal dimensional changes with temperature variations, making it particularly advantageous for precision instruments like clocks, gyroscopes, and measuring devices.

As Dr. Yong He, an assistant researcher at the Laboratory for Reactor Fuel and Materials, observes, ‘The distinctive heat behavior of Invar 36 is vital for uses requiring high precision under varying temperature conditions.’ For procurement managers, grasping these temperature-related characteristics is crucial in choosing substances that require exceptional precision.

Moreover, the distinct features of DOMADIA Nickel Molybdenum Iron Alloy, which encompass outstanding strength, corrosion resistance, and heat stability, render it perfect for crucial uses in challenging settings.

Additionally, Non-Sparking Tools play a vital role in explosive environments, offering a safe alternative where conventional substances might pose risks. Recent findings highlight the advantages of copper nickel alloys, including their high resistance to corrosion, excellent thermal and electrical conductivity, good ductility, ease of fabrication, and antimicrobial properties, making them suitable for various high-performance applications. Together, these insights reflect the critical role of advanced materials in ensuring the reliability and accuracy of devices operating under various conditions.

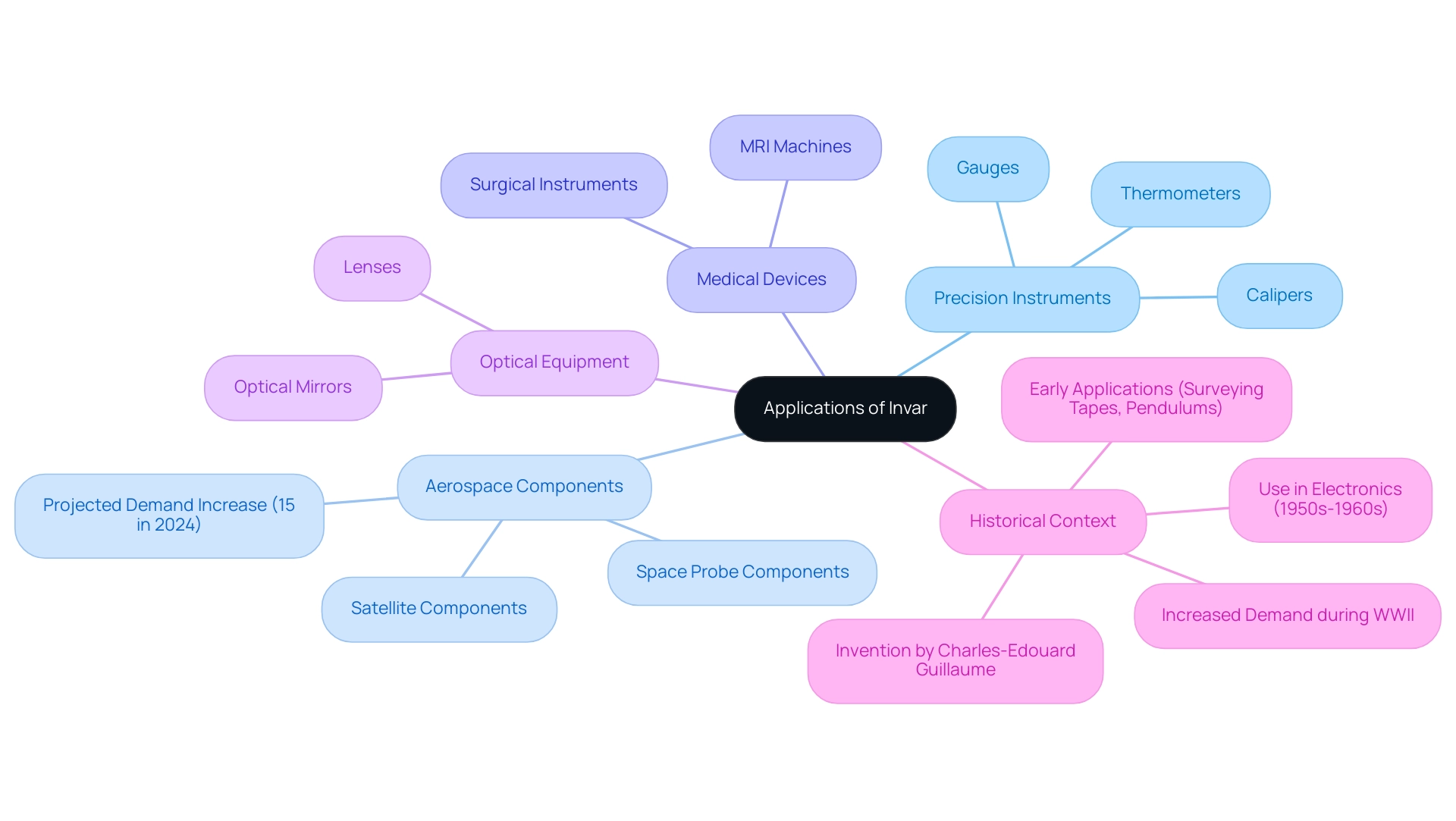

Applications of Invar: Where Precision Matters

This alloy is widely recognized for its exceptional dimensional stability, particularly in environments characterized by temperature fluctuations. This alloy is pivotal across various sectors where precision is paramount. Noteworthy applications include:

Precision Instruments: This alloy plays a crucial role in the fabrication of precision measuring tools, such as calipers, gauges, and thermometers. Its low thermal expansivity ensures that these instruments maintain accuracy even under variable thermal conditions.

Aerospace Components: Within the aerospace industry, this alloy is indispensable for components that require operational stability despite temperature changes. For instance, its application in satellite and space probe components is critical, as fluctuations in external temperatures can affect mission success. Recent statistics indicate that the use of this material in aerospace components is expanding, particularly in innovative designs and materials for 2024, with a projected increase of 15% in demand for components based on it.

Medical Devices: In the medical field, this material is utilized in devices where precision is essential, such as MRI machines and surgical instruments. Its reliable performance contributes to the accuracy required for diagnostic imaging and surgical procedures, underscoring its importance in healthcare technology.

Optical Equipment: The alloy is also integral in producing high-quality optical mirrors and lenses, where stability and precision are vital for optimal performance. The alloy’s unique properties facilitate the manufacturing of equipment that requires stringent tolerances, thereby enhancing the quality of optical instruments.

Historically, this alloy has played a significant role since its invention by Charles-Edouard Guillaume, who noted that the expansion of his new material was ‘invariable,’ leading to its name. Early usages included surveying tapes and pendulums, showcasing its versatility. These tools emphasize the essential role that this material plays in areas where accuracy is vital, reinforcing its status as a key resource in contemporary technology and manufacturing.

Advantages of Invar in Manufacturing and Engineering

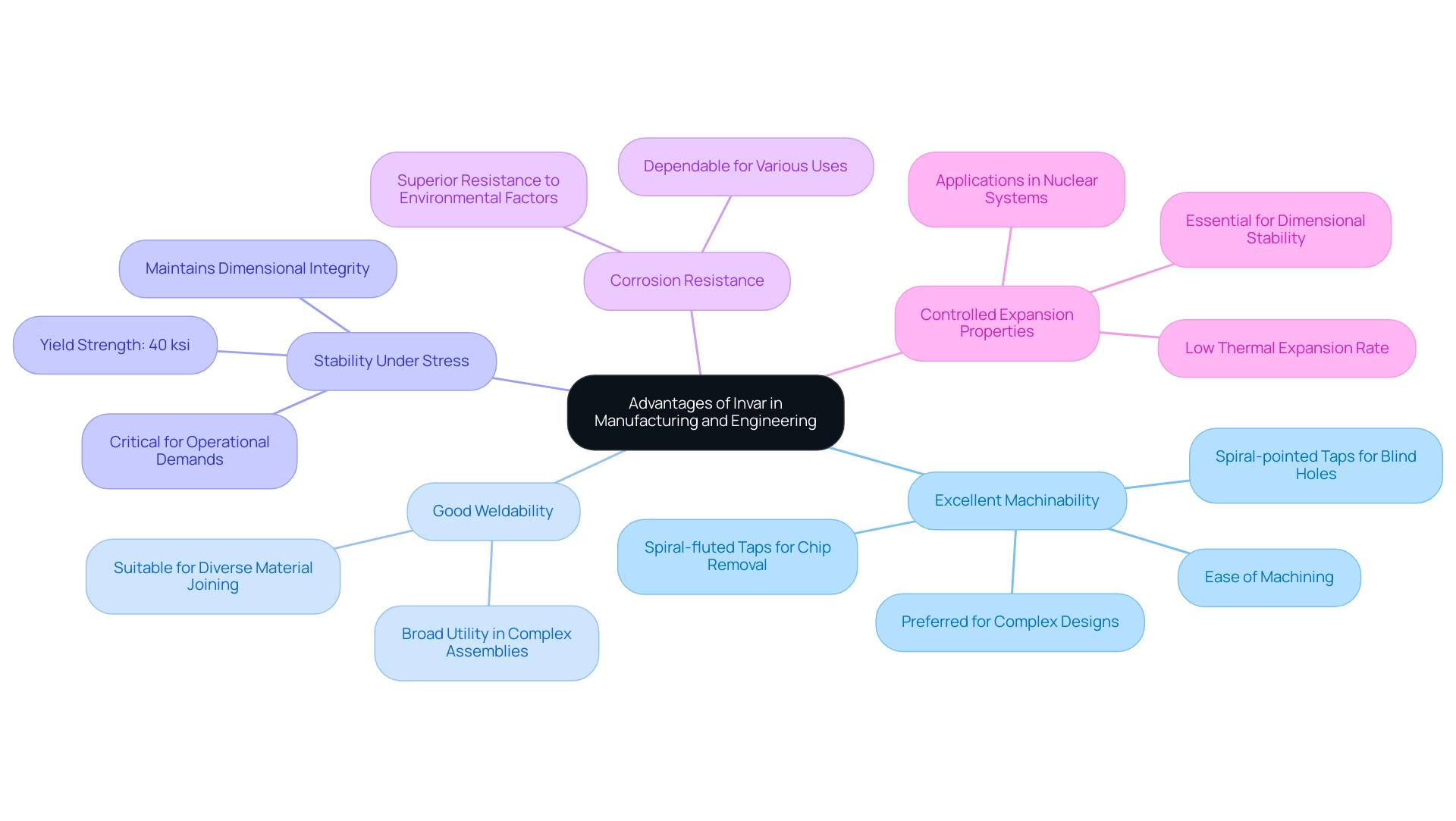

This alloy stands out as a premier choice for manufacturing and engineering applications due to its exceptional properties. Key advantages include:

Excellent Machinability: This alloy is renowned for its ease of machining, facilitating the precise fabrication of intricate shapes and components. This characteristic is crucial for industries that demand high accuracy in their manufacturing processes. Recent advancements have introduced special spiral-pointed bottoming taps for blind holes; however, spiral-fluted taps are preferred for effectively drawing chips out, enhancing overall machining efficiency. When compared to other metals, this alloy’s machinability is often superior, making it a preferred choice for complex designs.

Good Weldability: The alloy’s commendable weldability ensures it is suitable for applications requiring the joining of diverse materials, thus broadening its utility in complex assemblies.

Stability Under Stress: This material demonstrates remarkable stability under mechanical stress, maintaining its dimensional integrity even when subjected to operational demands. This is particularly vital in environments where consistency is imperative. The yield strength of this alloy is approximately 40 ksi, underscoring its robustness.

Corrosion Resistance: While not completely corrosion-proof, this alloy generally displays superior resistance to environmental factors compared to many other metals, making it a dependable choice for various uses.

These benefits together enhance its extensive use in high-performance sectors across various industries. The instance of controlled expansion alloy illustrates its importance; it has an exceptionally low thermal expansion rate—approximately one-tenth that of carbon steel at temperatures near 204°C—rendering it essential in scenarios requiring dimensional stability. Dr. Yong He, an assistant researcher at the Laboratory for Reactor Fuel and Materials in the Nuclear Power Institute of China, emphasizes the critical role of such materials in nuclear uses, stating, “The stability and precision of these alloys are essential for the safe and efficient operation of nuclear systems.”

This further validates the strategic importance of the company in manufacturing processes. Furthermore, CMM Optic’s proficiency in optical mirror fabrication and single point diamond turning emphasizes the practical uses of this material in creating parts that necessitate high precision and stability.

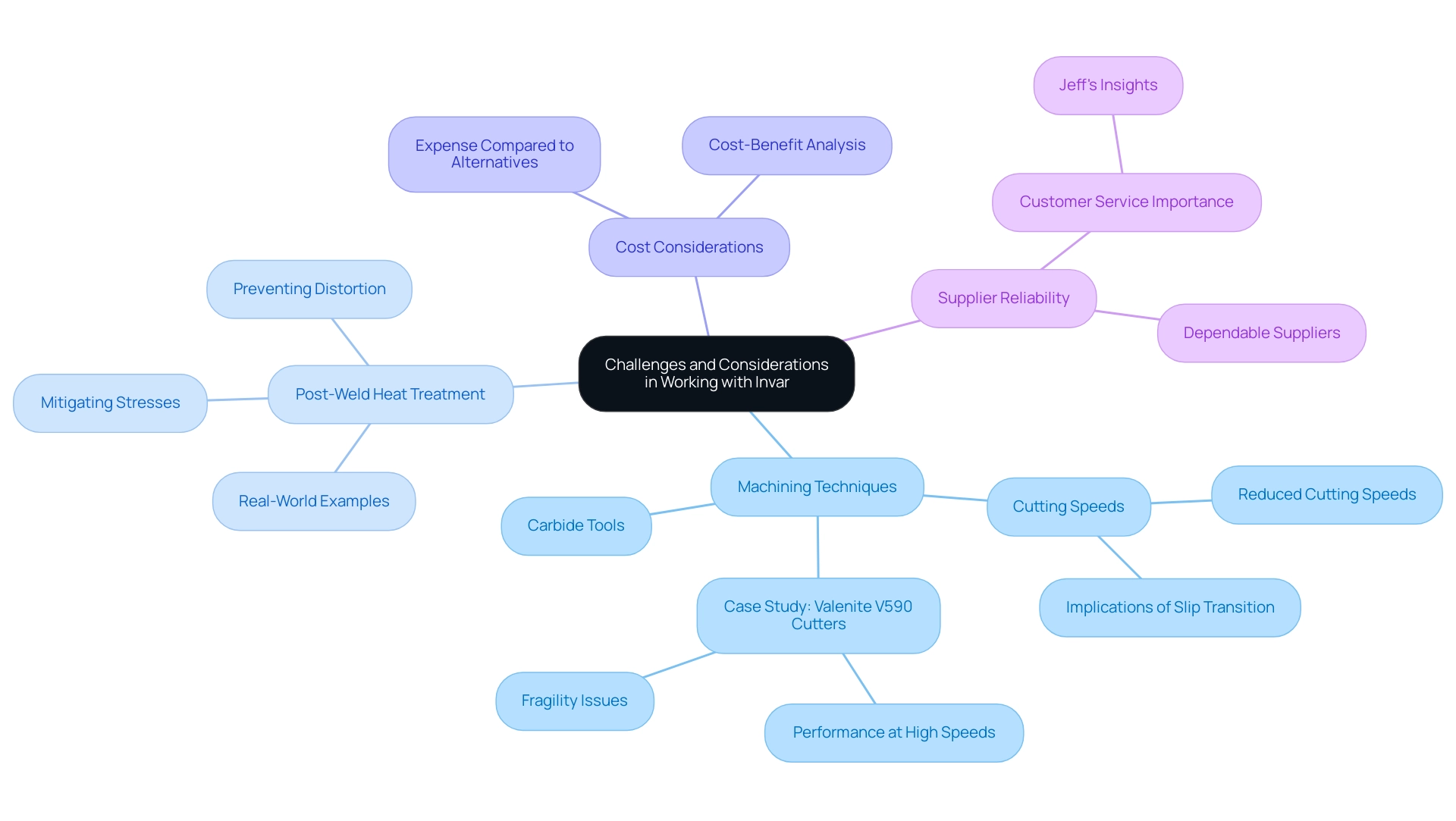

Challenges and Considerations in Working with Invar

Invar, while advantageous for various applications, poses several challenges that require careful consideration:

Machining Techniques: Due to the material’s unique low thermal expansion characteristics, with a coefficient of thermal expansion tested in the range of 0 °C–180 °C, specialized machining techniques are essential. Employing carbide tools and operating at reduced cutting speeds are recommended to minimize deformation. Research published in Materials Characterization has highlighted the implications of slip transition on work hardening, underscoring the necessity of precise machining practices for nickel-tungsten-iron alloys, including a specific type. A relevant case study titled “Challenges with Valenite V590 Cutters” illustrates the performance of these tools at high speeds, but also their fragility, emphasizing the need for robust tooling solutions in high nickel machining.

Post-Weld Heat Treatment: Implementing effective post-weld heat treatment is critical for mitigating stresses and preventing distortion. This step is essential in attaining the desired performance and dimensional stability in the final product. Real-world examples demonstrate that neglecting this process can lead to significant complications in the integrity of certain components.

Cost Considerations: The expense of this alloy frequently surpasses that of substitute substances. This factor can affect project budgets and necessitates a thorough cost-benefit analysis when choosing resources. Understanding these financial implications is crucial for procurement managers aiming to optimize resource allocation.

Supplier Reliability: Sourcing high-quality alloy from dependable suppliers is imperative to ensure adherence to specifications and consistency in material performance. Engaging with suppliers who demonstrate a commitment to outstanding customer service is essential for successful project execution. As Jeff, founder of a leading supply firm, emphasizes,

I have spent my life in the industry and pride myself on offering fair, efficient, trustworthy, knowledgeable, outstanding customer service.

His insights emphasize the significance of selecting suppliers who can effectively manage the challenges related to sourcing that material.

By acknowledging these challenges, procurement managers and engineers can better prepare for the complexities associated with working with Invar in their projects, ensuring both efficiency and effectiveness.

Conclusion

Invar 36 stands out as a critical material in precision-driven industries, thanks to its unique properties that ensure minimal thermal expansion and exceptional stability under temperature fluctuations. Its applications across sectors such as aerospace, medical devices, and precision engineering underscore its indispensable role in achieving accuracy and reliability. The growing demand for Invar 36 in North America reflects not only its robust performance but also the advancements in manufacturing technologies that enhance its utility.

However, working with Invar 36 does present challenges that professionals must navigate:

- From specialized machining techniques to the need for effective post-weld heat treatment, understanding these complexities is essential for procurement managers and engineers.

- Additionally, considerations regarding cost and supplier reliability play a significant role in ensuring the successful integration of Invar 36 into projects.

In summary, mastering the characteristics and applications of Invar 36 is vital for those in procurement and engineering roles. As the market for this alloy continues to expand, leveraging its advantages while addressing the associated challenges will be key to driving innovation and maintaining competitive advantage in precision-critical applications. The strategic use of Invar 36 is not just a choice; it is a necessity for achieving excellence in modern manufacturing and engineering endeavors.