Blogs

Understanding Spring Steel Alloys: A Complete Tutorial for Engineers

Introduction

Spring steel alloys are a cornerstone of modern engineering, celebrated for their exceptional elasticity and strength. These materials are not just ordinary steel; they are meticulously designed to endure repeated stress while retaining their original shape, making them indispensable in various applications. From automotive components like suspension springs to critical elements in electronics, the versatility of spring steel is evident across multiple industries.

As procurement managers navigate the complexities of material selection, understanding the unique properties and manufacturing processes of these alloys becomes paramount. This article delves into the characteristics, applications, and future trends of spring steel alloys, offering valuable insights that can guide strategic decisions and enhance performance in high-stress environments.

Introduction to Spring Steel Alloys: Properties and Applications

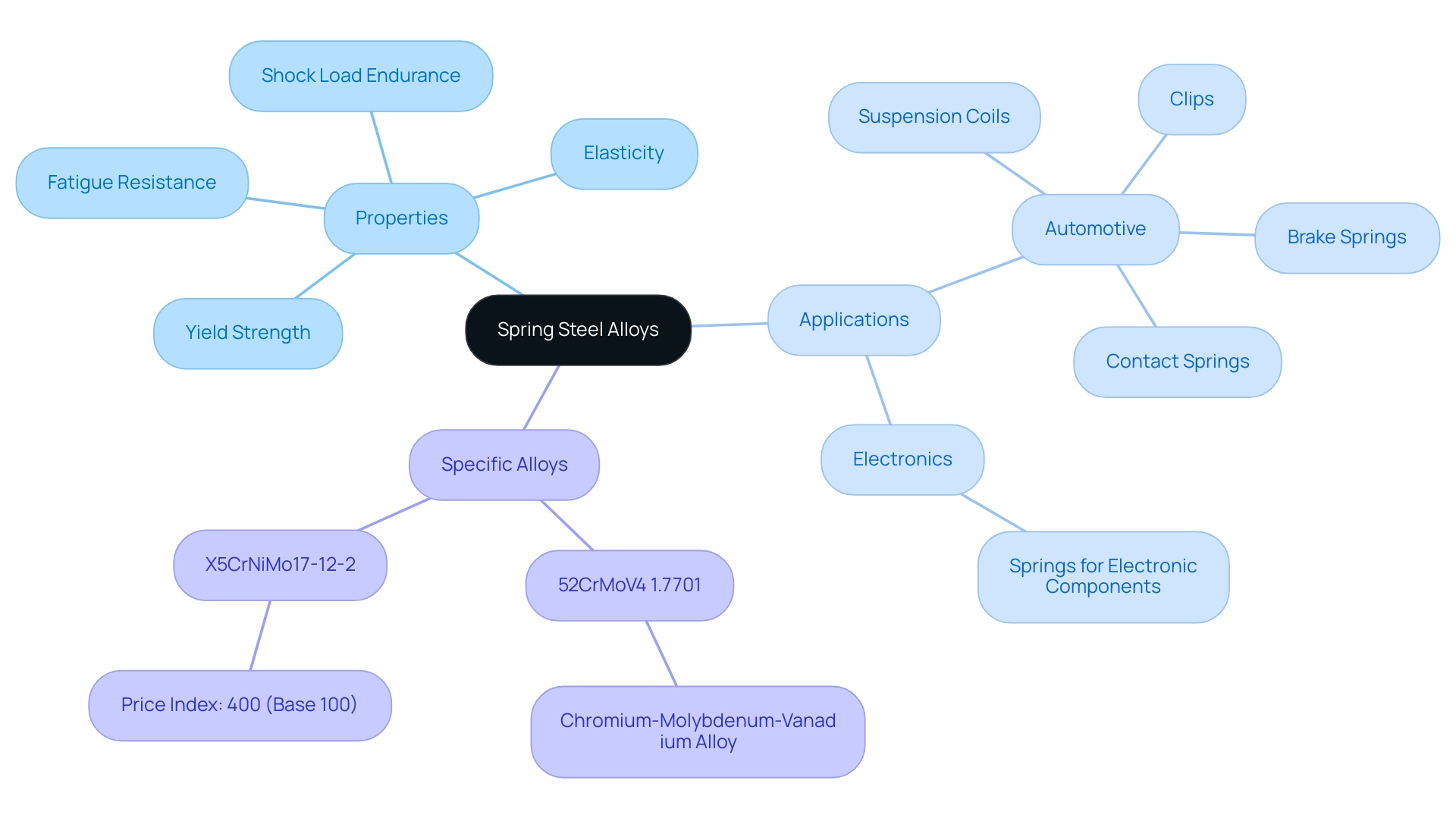

Spring steel alloys represent a specialized class of material distinguished by their remarkable elasticity and strength, characteristics that make them indispensable in applications where components must revert to their original shape following deformation. Among the key properties of spring steel alloys are their formidable yield strength, exceptional fatigue resistance, and the capacity to endure shock loads without permanent deformation. Significantly, 52CrMoV4 1.7701 is a chromium-molybdenum-vanadium alloy, which improves its mechanical characteristics.

In the automotive sector, the characteristics of spring steel alloys are essential for components like:

- Suspension coils

- Clips

- Various elements exposed to repeated stress

For example, brake coils and contact coils illustrate the varied uses of spring steel alloys, showcasing their adaptability in numerous industries and fulfilling both mechanical and electronic needs. The price index for spring steel type X5CrNiMo17-12-2 stands at 400 (with a base of 100), reflecting its market value and demand.

For further information on properties of substances, Total Materia serves as a comprehensive resource, providing extensive data on metallic and non-metallic properties, global standards, and heat treatment information. By thoroughly grasping these properties and their implications, engineers can make informed choices regarding material selection, thus ensuring optimal performance and longevity in high-stress scenarios.

Exploring Different Grades of Spring Steel Alloys: Composition and Characteristics

Spring steel alloys are classified into various grades, particularly 5160, 6150, and 9254, each characterized by distinct compositions and mechanical properties designed for specific uses. The manufacturing method for these alloys includes cold drawing, which enhances their strength and durability. For example, spring steel alloys like 5160, with a carbon content of 0.56-0.64%, are known for their outstanding toughness and ductility, making them suitable for high-stress applications such as leaf springs and automotive parts.

In contrast, 6150 alloy, classified among spring steel alloys and containing 0.50-0.60% carbon, demonstrates superior strength and is frequently utilized in automotive manufacturing, where performance and reliability are crucial. The 9254 grade spring steel alloys, which have a higher carbon content of approximately 0.52-0.60%, are optimized for applications that require high fatigue resistance.

Furthermore, understanding the electrical characteristics of substances like VDSiCr steel, which has moderate electrical conductivity of 7.3% IACS for equal volume and 8.5% for equal weight, is essential for procurement managers. This knowledge is particularly significant in environments where substances must endure high temperatures up to 650 °F.

Additionally, incorporating Mica Tape products, such as Mica Insulation Tape and Mica Sheet Tape, known for their high-temperature resistance and electrical insulation, into project planning can further enhance safety and performance. Mica Insulation Tape is ideal for critical applications in electrical engineering, while Mica Sheet Tape provides robust insulation for large flat surfaces, making them indispensable in various industries.

Assessing these substances, along with their corrosion resistance and electrical properties, is crucial for ensuring alignment with the specific mechanical demands of projects.

Manufacturing Processes of Spring Steel: From Raw Material to Finished Product

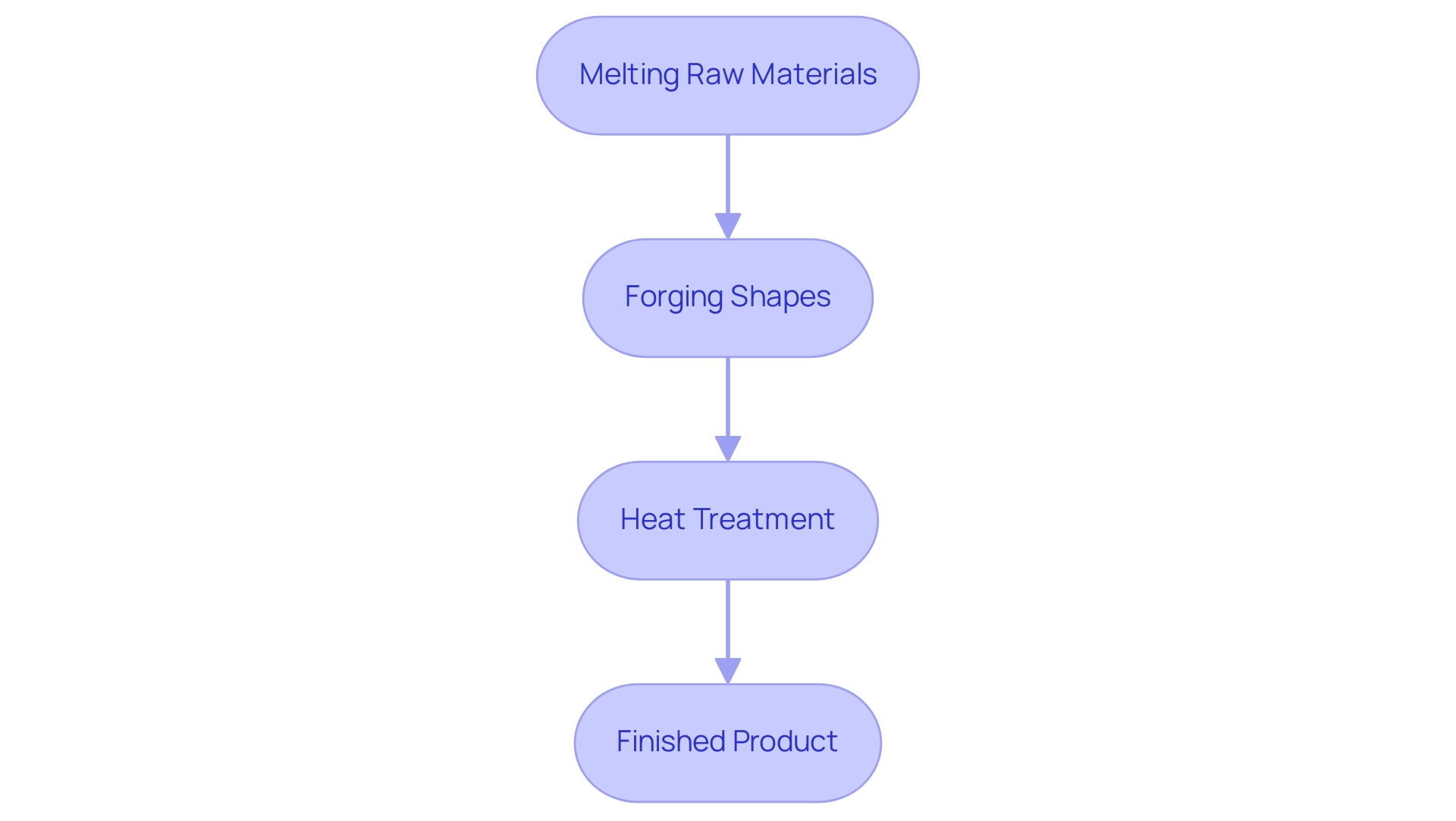

The manufacturing process of spring steel alloys encompasses several essential stages, each contributing significantly to the final product’s performance. Initially, high-quality raw materials, including iron ore and various alloying elements, are melted in an electric arc furnace. This molten metal is then meticulously forged into the desired shapes, ensuring consistency and precision throughout the process.

A pivotal step follows: heat treatment, which involves techniques such as quenching and tempering. These processes are not merely procedural but critical, as they dramatically influence the mechanical properties of the metal, including yield strength and toughness. As emphasized by industry specialists, ‘Proper heat treatment is essential for attaining optimal performance in coil materials.’

Comprehending these manufacturing subtleties allows engineers and procurement managers to evaluate the quality and appropriateness of alloy materials for particular uses efficiently. Recent advancements in heat treatment techniques, such as controlled cooling rates and innovative tempering methods, have been shown to improve the yield strength of spring steel alloys by up to 20%, showcasing the dynamic evolution of spring manufacturing. Furthermore, case studies have demonstrated that employing advanced heat treatment processes can enhance toughness by 15%, thereby significantly impacting performance in high-stress applications.

This information underscores the importance of effective communication in procurement decisions, as managing expectations around product capabilities is essential for successful outcomes.

Applications of Spring Steel Alloys in Engineering and Industry

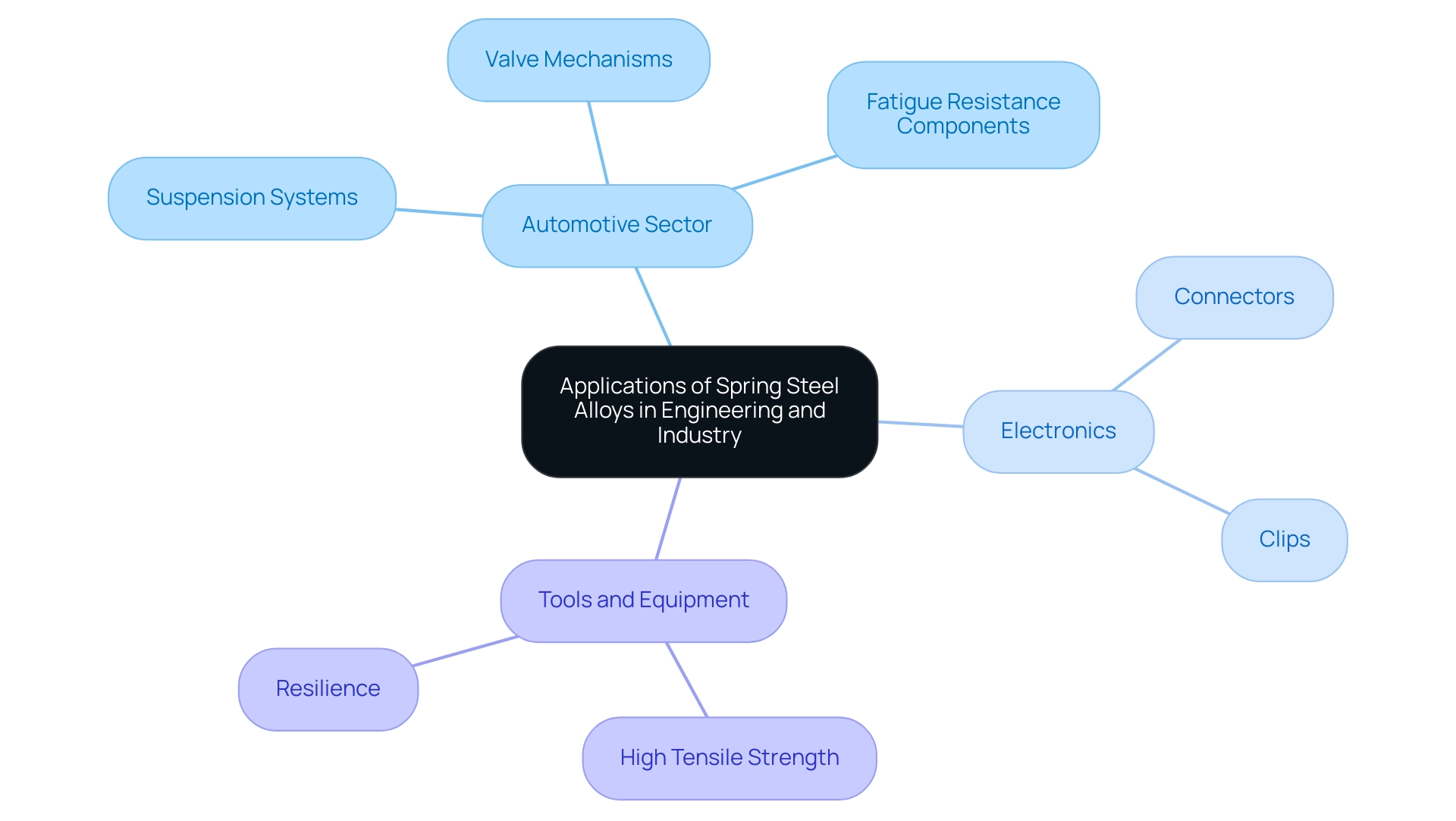

Spring steel alloys are essential to a multitude of industries, primarily due to their outstanding mechanical properties. In the automotive sector, spring steel alloys are extensively utilized in:

- Suspension systems

- Valve mechanisms

- Other essential components that require high fatigue resistance

Recent advancements indicate that high entropy alloys, for example, exhibit strength levels that are up to 30% greater than conventional materials, further underscoring the importance of material selection in engineering contexts.

As one engineer observed, ‘The dependability of coil alloy in automotive uses is unparalleled, especially in parts that endure continuous pressure.’ In the field of electronics, coil metal plays a vital role in the creation of connectors and clips, where reliability and durability are essential. Furthermore, the production of tools and equipment also utilizes the high tensile strength and resilience of spring steel alloys, making them a favored option for engineers.

A case study on the use of elastic metal in automotive parts demonstrated that its utilization led to a 15% increase in component lifespan, showcasing its effectiveness. By thoroughly grasping these uses and acknowledging that metal remains essential in the sector, experts can make knowledgeable choices concerning substance selection that align with performance criteria and industry benchmarks.

Future Trends in Spring Steel Alloys: Innovations and Research Directions

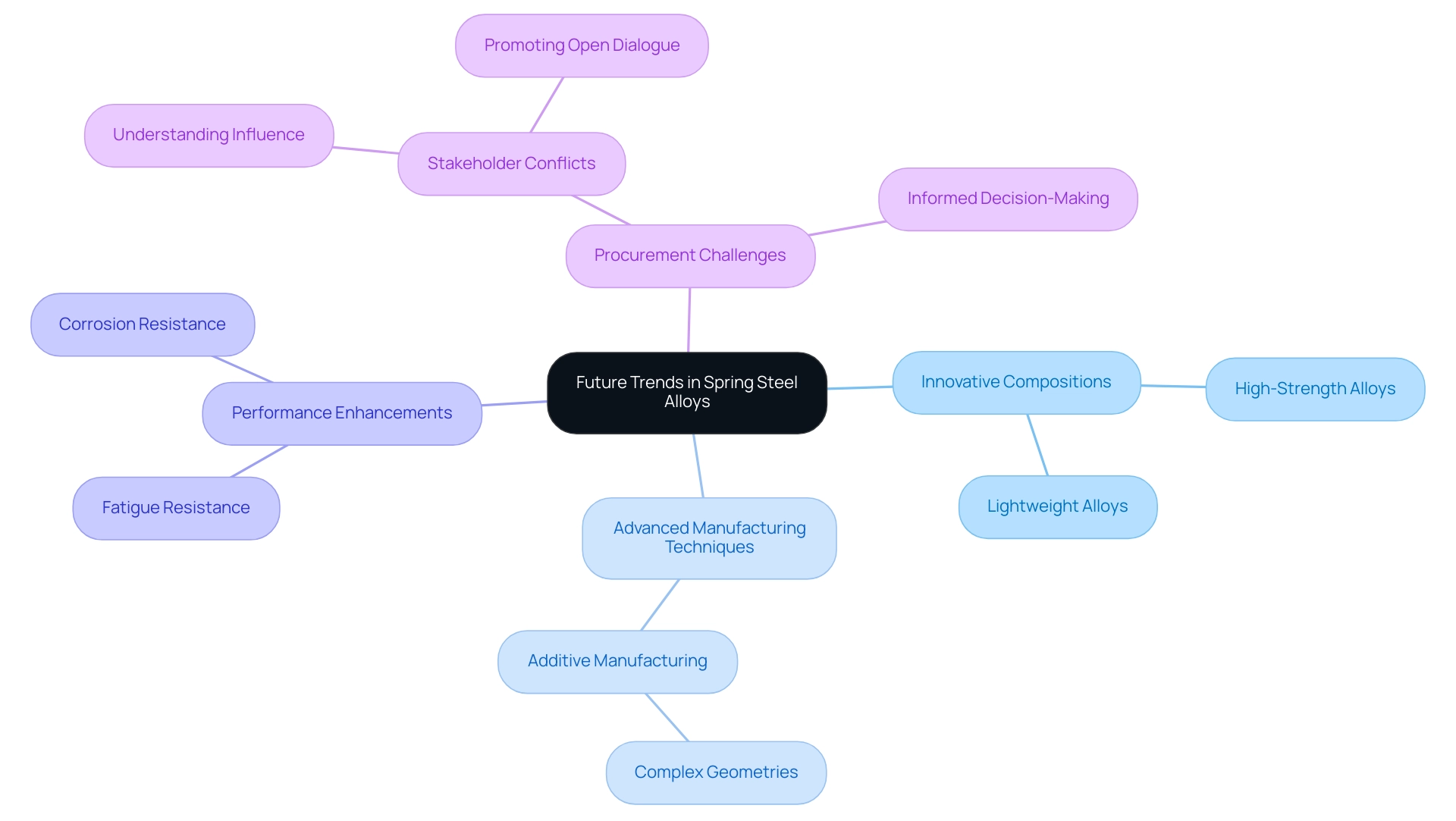

The landscape of spring steel alloys is rapidly evolving due to continuous research focused on enhancing performance through innovative compositions and advanced manufacturing techniques. Recent developments have yielded high-strength, lightweight alloys that demonstrate superior fatigue resistance and corrosion resistance, addressing the demands of modern engineering applications. Just as managing social media accounts with opposing views requires impartial language and finding common ground, procurement managers must navigate differing opinions on item selections to make informed decisions.

Furthermore, the exploration of additive manufacturing techniques is proving transformative, enabling the production of complex geometries that traditional methods struggle to achieve. As noted, ‘Boost your sales team’s confidence with effective training, practice, and mentorship.’ This sentiment aligns with the necessity for procurement managers to remain knowledgeable about these trends to improve their expertise in selection.

Recent contributions emphasize that teams have dedicated considerable time managing resistance to changes, highlighting the importance of being current with innovations in alloy materials. Additionally, case studies on managing stakeholder conflicts reveal that understanding influence and promoting open dialogue are essential when selecting materials amidst differing priorities. In today’s environment, where stakeholder clashes over feature priorities are common, effective management of spring steel alloys becomes crucial for successfully navigating the evolving landscape of technologies.

Conclusion

Spring steel alloys stand as a testament to the intersection of engineering innovation and practical application. Their remarkable elasticity, strength, and fatigue resistance make them a vital component across various industries, particularly in automotive and electronics. Understanding the unique properties and classifications of spring steels, such as 5160, 6150, and 9254, equips procurement managers with the knowledge necessary for informed decision-making. The significance of manufacturing processes, including heat treatment, cannot be overstated, as these techniques directly influence the performance and longevity of the final product.

The applications of spring steel alloys are vast, reinforcing their indispensable role in high-stress environments. From enhancing the reliability of automotive components to ensuring the durability of electronic connectors, the versatility of these materials is clear. As industries continue to evolve, embracing innovations such as high-strength lightweight alloys and additive manufacturing will be crucial for maintaining competitive advantage.

In conclusion, staying abreast of future trends and advancements in spring steel technology is essential for procurement professionals. By leveraging insights into material properties and manufacturing processes, strategic decisions can be made that not only enhance performance but also align with the evolving demands of modern engineering. This proactive approach will ultimately ensure that organizations remain at the forefront of innovation and efficiency in their respective fields.