Blog

Understanding the Combination of High Electrical and Thermal Conductivity of Beryllium Copper for Electromagnetic (EMI) Shielding: An In-Depth Tutorial

Introduction

In the landscape of modern manufacturing and technology, beryllium copper emerges as a cornerstone material, renowned for its unique blend of electrical and thermal conductivity. This alloy not only facilitates superior performance in demanding applications across sectors such as aerospace, defense, and telecommunications, but it also addresses critical challenges such as electromagnetic interference (EMI) shielding.

As industries evolve and the complexity of electronic systems increases, understanding the strategic value of beryllium copper becomes paramount for procurement managers. From navigating market fluctuations and regulatory hurdles to leveraging innovative manufacturing techniques, this article delves into the multifaceted benefits and challenges associated with sourcing and utilizing beryllium copper, providing essential insights for professionals aiming to enhance operational efficiency and maintain a competitive edge.

Key Properties of Beryllium Copper: Electrical and Thermal Conductivity

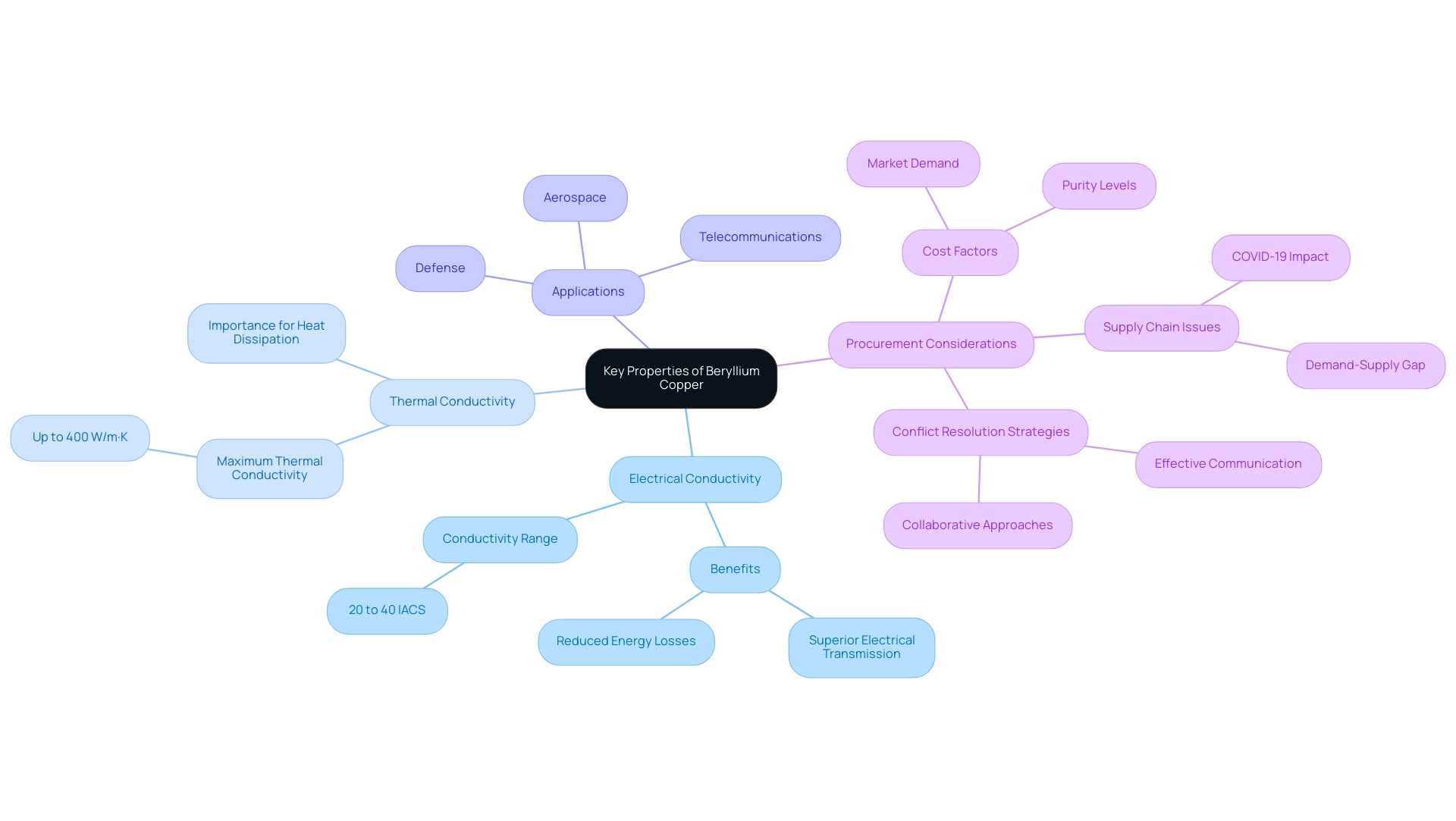

Beryllium alloy is distinguished by its exceptional properties, particularly the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (emi) shielding, making it an optimal choice for a range of demanding applications in aerospace, defense, and telecommunications. Current data indicates that the electrical conductivity of this alloy typically ranges from 20% to 40% IACS (International Annealed Copper Standard), significantly surpassing many alternative alloys. This elevated conductivity is a result of the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (emi) shielding, which translates into superior electrical transmission capabilities and reduced energy losses in electronic components, critical in high-performance environments.

Moreover, the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (emi) shielding enables this alloy’s thermal conductivity to reach up to 400 W/m·K, facilitating effective heat dissipation and reducing the risk of overheating in electronic devices. The unique synergy of these properties, particularly the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (emi) shielding, enhances the performance of individual components while prolonging their operational lifespan, thereby boosting overall system efficiency. Such advantages highlight the strategic importance of integrating DOMADIA Copper—compliant with international standards UNS C17200 and ASTM B194—into advanced applications, particularly as industries adjust to changing technological requirements.

In terms of procurement, it’s also essential to consider cost factors; the price of a certain metal scrap fluctuates based on market demand, purity, and current metal prices. For instance, higher purity levels can lead to increased prices due to their rarity and demand in specialized applications. At Domadia, we are committed to offering fair and transparent pricing for all transactions, ensuring our rates remain competitive and attractive.

Additionally, the recent disruptions caused by COVID-19 have affected production and supply activities across major industries, leading to shortages and a widening demand-supply gap. Effective communication and conflict resolution strategies are crucial for navigating these challenges, as demonstrated in the case study titled ‘Resolving Conflict Over New Analysis Methods,’ which illustrates how procurement teams can address divisions over decisions by employing collaborative approaches and ensuring alignment with organizational goals.

Applications of Beryllium Copper in Electromagnetic Interference Shielding

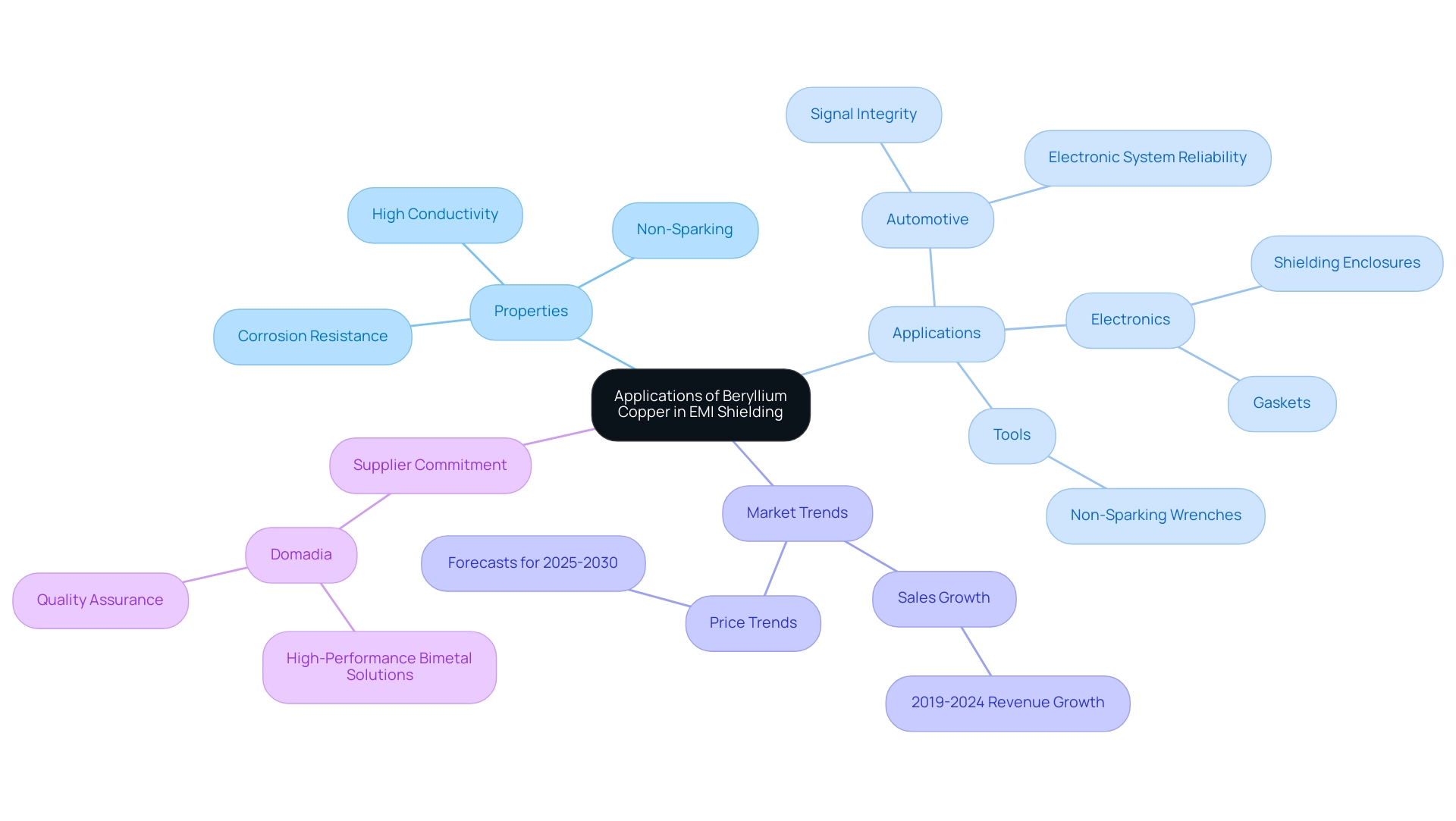

Beryllium bronze (BeCu) is a pivotal material in the realm of electromagnetic interference (EMI) shielding, celebrated for its exceptional conductivity, which includes the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding, as well as its outstanding mechanical attributes and non-sparking properties. Its applications span across the automotive and electronics sectors, where it is utilized in critical components such as connectors, housings, and circuit boards that demand robust protection against electromagnetic interference. In automotive environments, specific metal alloys play a crucial role in preserving signal integrity and safeguarding sensitive electronic systems from disruptive electromagnetic fields, thereby enhancing vehicle safety and operational reliability.

Furthermore, in the electronics industry, the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding is utilized in shielding enclosures and gaskets, effectively mitigating EMI and ensuring adherence to stringent electromagnetic compatibility (EMC) standards. Notably, its non-sparking characteristics make it an ideal choice for tools such as non-sparking wrenches, which are essential in environments where flammable gases or liquids are present. The material’s durability, coupled with its corrosion resistance, not only extends its lifespan in these demanding applications but also positions it as the material of choice for manufacturers committed to delivering superior quality and performance.

Domadia, as a prominent supplier and manufacturer, is committed to delivering high-performance bimetal solutions through innovative production and strict quality assurance. According to data from Guangzhou Yulong Electronics, the sales of materials utilizing the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding have shown a steady increase from 2019 to 2024, with a projected revenue growth rate of X% annually, highlighting its market relevance. Furthermore, case studies show that automotive producers utilizing the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding have noted substantial enhancements in electronic system reliability.

As Kairav Domadia aptly states, ‘Its unique properties continue to drive innovation across multiple industries,’ underscoring the ongoing relevance of beryllium in advancing technology and enhancing performance standards. Recent news suggests that the price information for global EMI Shielding Material made with the metal is anticipated to vary according to market demand, offering procurement managers with prompt insights into current pricing trends and inventory availability.

Benefits of Using Beryllium Copper for EMI Shielding

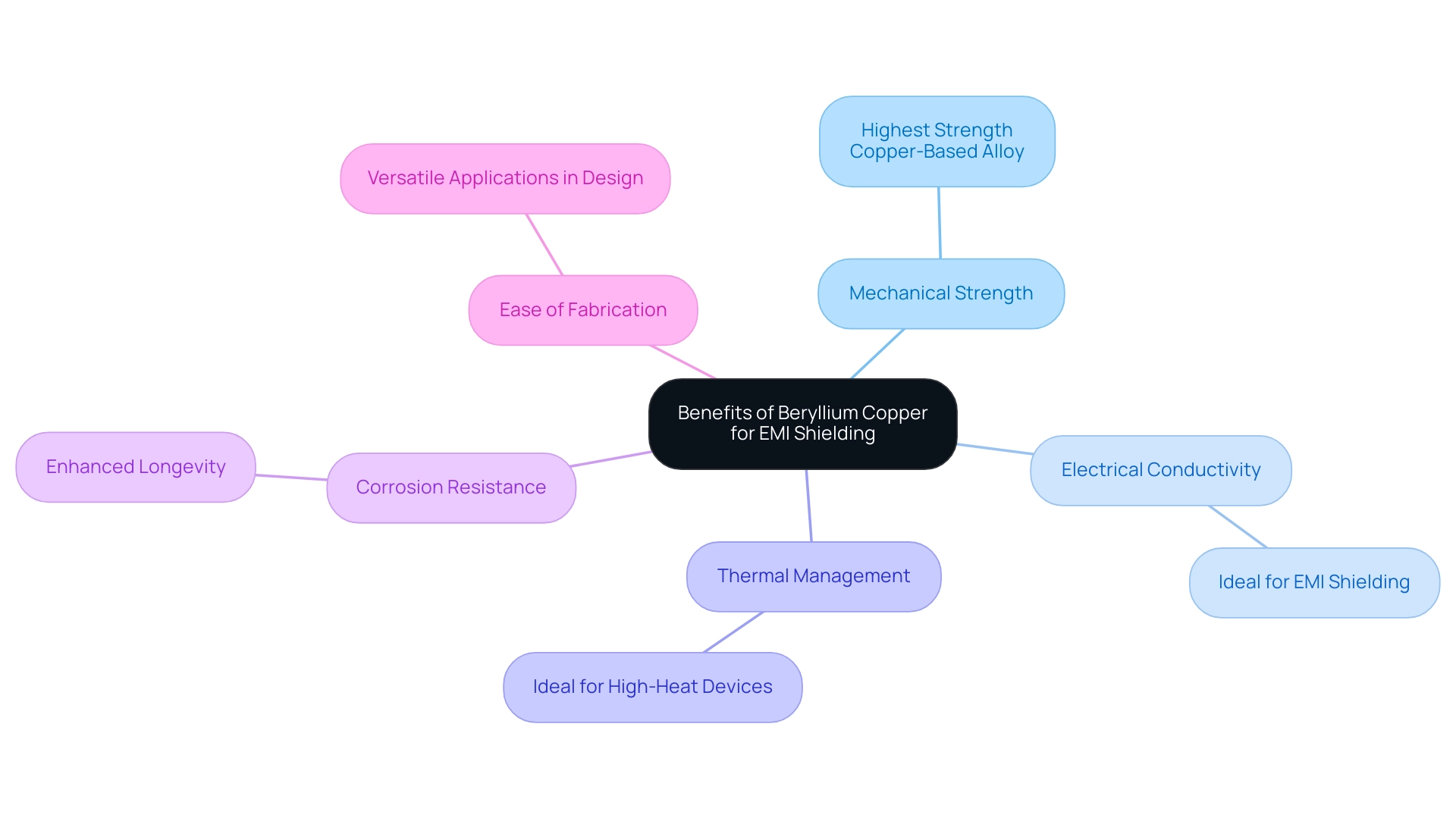

The exceptional balance of mechanical strength and electrical conductivity in copper alloy, along with the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding, makes it a premier choice for EMI shielding and the highest-strength copper-based alloy available. This alloy is particularly advantageous for applications where both durability and performance are critical. Notably, its superior thermal management capabilities render it ideal for devices that generate considerable heat.

The material’s inherent resistance to corrosion and oxidation significantly enhances its longevity, thereby minimizing the frequency of replacements and maintenance activities, which translates into a lower total cost of ownership for manufacturers. As procurement managers look for dependable materials, Domadia’s dedication to high-quality tailored alloy plates, along with our vast product selection including foils, sheets, rods, and wires, guarantees project success, backed by our expert team. As one of our pleased clients mentioned, ‘Domadia’s alloy solutions have significantly enhanced our project’s efficiency and reliability.’

Furthermore, the ease with which this alloy can be fabricated allows for versatile applications in intricate geometries, positioning it as a preferred material in contemporary electronic system design. A practical example of its application is the case study titled ‘Design of an Ultra-Wideband Monopole Antenna,’ which successfully employed a specific alloy to suppress certain frequency bands, thus enhancing spectrum resource utilization and reducing EMI. As the demand for effective EMI shielding continues to grow, the advantages of the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding are becoming increasingly apparent across various sectors, especially in aerospace, defense, and telecommunications.

Reach out to Domadia today to discover how our copper alloy solutions can enhance your project.

Challenges in Sourcing Beryllium Copper

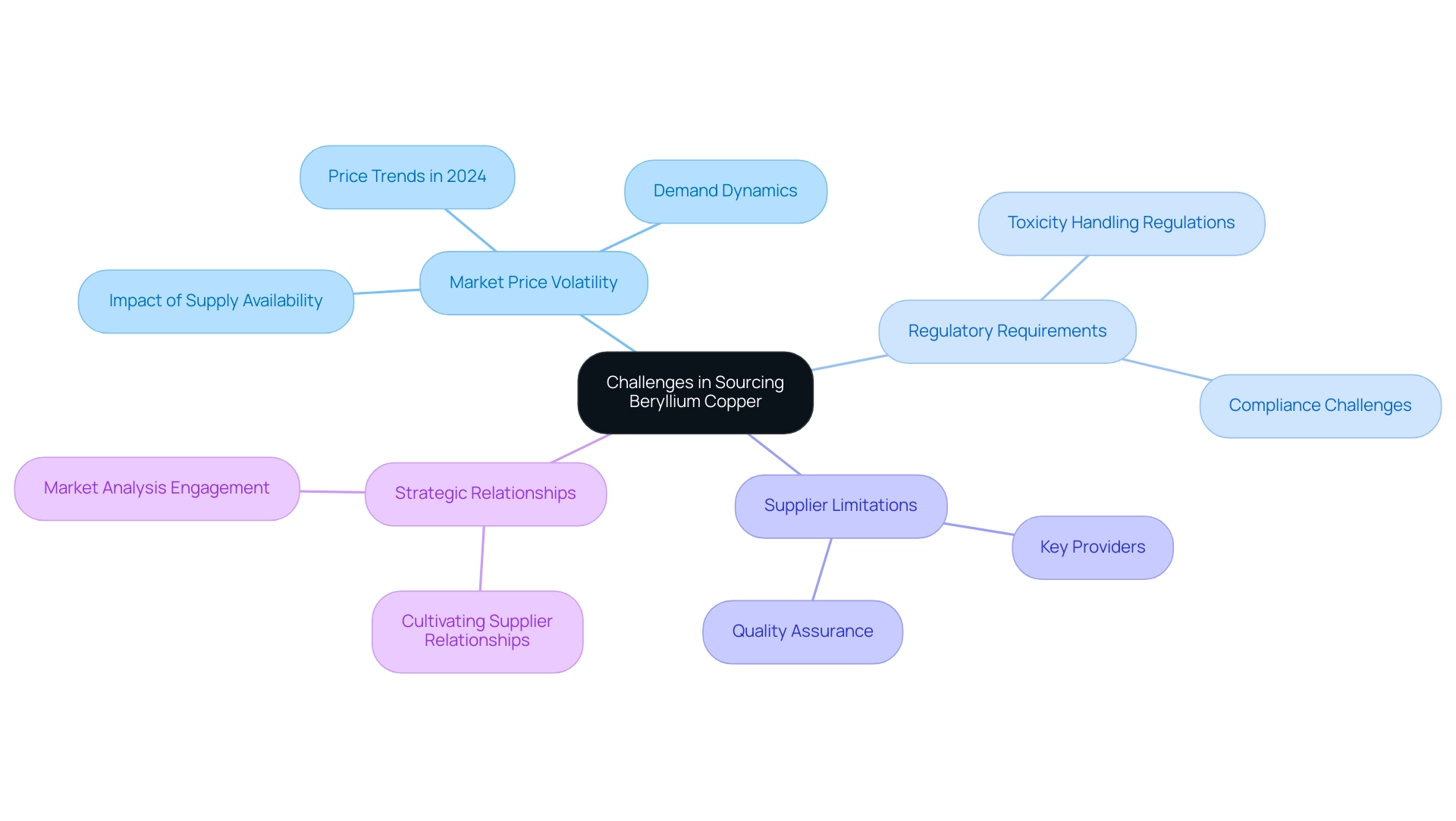

Sourcing beryllium copper, while advantageous due to its unique electrical properties, poses significant challenges for procurement managers. A main issue is the volatility of market prices for alloy strips, which can change significantly depending on supply availability and varying demand dynamics. According to recent market analysis, price trends in 2024 are expected to reflect ongoing uncertainties, making it critical for procurement managers to stay informed about pricing and inventory levels.

Furthermore, stringent regulatory requirements regarding the handling of beryllium—stemming from its toxic nature—add layers of complexity to the procurement process. Stakeholders must navigate these regulations diligently to ensure compliance, which can often hinder the speed of sourcing efforts. As emphasized in industry discussions, managing stakeholder expectations is essential, especially during periods of regulatory changes when data insights are inconclusive.

Furthermore, the restricted group of providers able to deliver high-quality alloy and other electrical insulation substances increases the risk of supply chain weaknesses. Particular product labels, such as copper alloys strips, Kovar, Mu-Metal, and Nickel, are essential for accurate sourcing. Insights from case studies on key industry players reveal that many are adopting acquisition strategies to enhance their portfolios and strengthen market positions, which can serve as a model for effective sourcing strategies.

To address these challenges effectively, procurement managers should focus on cultivating robust relationships with dependable suppliers, such as those specializing in electrical insulation and high-temperature materials, while engaging in comprehensive market analysis. By remaining vigilant about regulatory changes that may impact procurement strategies and considering pricing details, organizations can secure a consistent supply of high-quality Beryllium Copper, known for its combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (emi) shielding, along with Kovar and other essential materials, thereby ensuring their optimal use in critical applications across aerospace, defense, and telecommunications.

Future Trends in Beryllium Copper Utilization

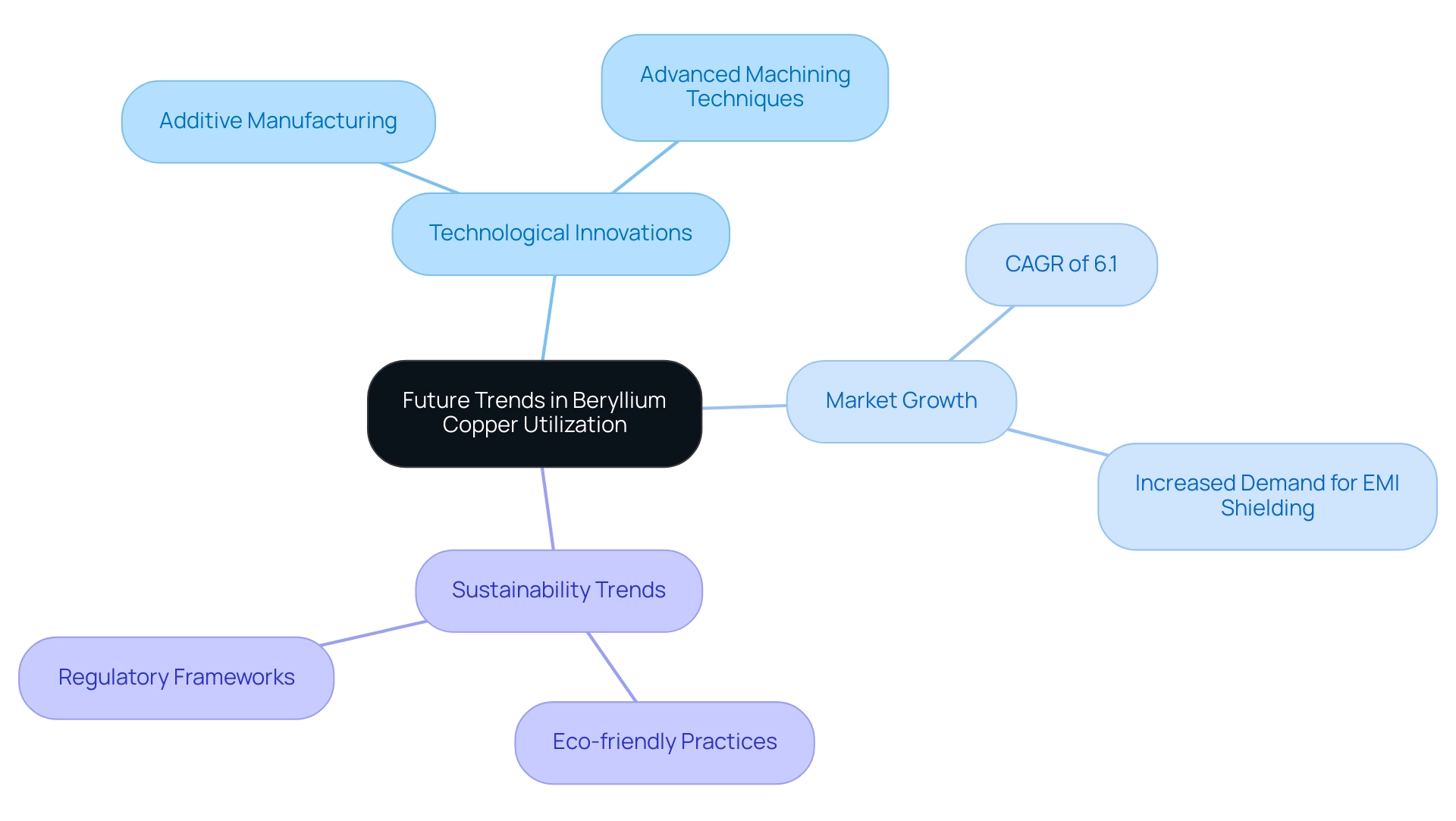

The expected growth in the use of a specific metal alloy is significantly influenced by new technologies and the rising demand for effective electromagnetic interference (EMI) shielding solutions, particularly highlighting the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding. Recent blog updates, including those from February 2, 2022, and May 16, 2022, emphasize that the alloy market is expected to demonstrate a compound annual growth rate (CAGR) of 6.1% from 2023 to 2032, indicating robust market interest, especially in non-sparking tools crucial for safety in hazardous environments. As highlighted by Statistique Canada, Canada’s crude oil output has increased for the third straight year in 2023, reflecting wider economic patterns that may influence material demand, including specific metal alloys.

Innovations in manufacturing processes, especially through additive manufacturing and advanced machining techniques, are enhancing the versatility of this material, making it increasingly accessible across various industries. As electronic devices evolve into more compact and intricate forms, the demand for effective shielding using the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding is likely to intensify. Moreover, sustainability trends, backed by regulatory frameworks, are encouraging producers to prioritize eco-friendly practices in both the manufacturing and disposal of alloy components.

The market segmentation of the alloy can be classified based on product type, application, and region, allowing procurement managers to implement focused strategies for improved comprehension and maneuvering through market dynamics. Moreover, comprehensive product specifications and pricing details are accessible for metal alloys and non-sparking tools, along with customer inquiry support, to aid procurement managers in making informed choices. With these industry developments in mind, procurement managers are advised to adapt their strategies accordingly to fully leverage the combination of high electrical and thermal conductivity of beryllium copper for electromagnetic (EMI) shielding in future applications.

Conclusion

Beryllium copper stands out as a vital material within modern manufacturing, particularly for its unique combination of electrical and thermal conductivity, which enhances performance across critical sectors like aerospace, defense, and telecommunications. Its exceptional properties not only ensure superior electrical transmission and effective heat dissipation but also contribute to the longevity and reliability of electronic components. As industries increasingly seek to mitigate electromagnetic interference, the role of beryllium copper in EMI shielding becomes even more pronounced, reinforcing its strategic importance in safeguarding sensitive electronic systems.

However, the procurement of beryllium copper is not without its challenges. Market volatility, stringent regulatory requirements, and a limited supplier base complicate sourcing efforts. It is imperative for procurement managers to remain vigilant and informed about market dynamics, pricing trends, and compliance issues to navigate these complexities successfully. Building strong relationships with reliable suppliers and adopting strategic sourcing practices can mitigate risks and enhance supply chain resilience.

Looking ahead, the future of beryllium copper is promising, driven by technological advancements and a growing demand for high-performance materials. As industries continue to evolve, the emphasis on sustainability and innovative manufacturing processes will further shape the utilization of beryllium copper. By adapting procurement strategies to these emerging trends, professionals can position their organizations to capitalize on the advantages offered by this versatile alloy, ensuring they remain competitive in an increasingly demanding market.