Blogs

Understanding Magnetic Permeability of Beryllium Copper: A Complete Tutorial for Retractable Antenna Design

Overview:

The article focuses on the significance of magnetic permeability in beryllium copper for retractable antenna design, highlighting its role in enhancing signal reception and transmission. It supports this by detailing how the magnetic permeability, combined with the alloy’s excellent conductivity and strength, contributes to improved antenna efficiency and performance, particularly in demanding applications like telecommunications and aerospace.

Introduction

The intricate world of antenna design is heavily influenced by the materials chosen for their construction, with magnetic permeability and the properties of alloys like beryllium copper playing pivotal roles. As industries such as telecommunications and aerospace demand ever-greater performance, understanding how these materials interact with magnetic fields and their physical characteristics becomes essential.

Magnetic permeability not only determines how effectively an antenna can transmit and receive signals, but it also shapes the future of design innovations. Beryllium copper, renowned for its impressive electrical and thermal conductivity, alongside its strength and durability, emerges as a top contender for applications where reliability is paramount.

However, the journey to optimize these materials is fraught with challenges, from cost considerations to regulatory compliance. This article delves into the fundamental aspects of magnetic permeability, the unique properties of beryllium copper, and the evolving landscape of antenna technology, offering insights that are crucial for procurement managers navigating this complex field.

Fundamentals of Magnetic Permeability in Materials

The magnetic permeability of beryllium copper for retractable antennas quantifies a substance’s capacity to support the establishment of a magnetic field within itself, represented as the ratio of magnetic flux density to magnetic field strength. In design, the use of the magnetic permeability of beryllium copper for retractable antennas significantly improves signal reception and transmission abilities, which is especially vital in fields like telecommunications and aerospace, where performance is crucial. Grasping the distinction between relative permeability, which describes how a substance’s permeability compares to that of a vacuum, and absolute permeability, the intrinsic property of the substance itself, is crucial.

These parameters dictate how substances interact with magnetic fields, particularly the magnetic permeability of beryllium copper for retractable antennas, directly affecting antenna efficiency and overall system performance. Recent advancements in magnetic permeability substances have underscored their significance. For example, the results of Denk and Hofbauer highlight the precision of simulation models in forecasting substance behavior, with Hofbauer stating,

- “The simulation models were compared with the corresponding Hall sensor measurements, which proved the high accuracy experimental validity of the models established in this paper.”

This ongoing exploration of the magnetic permeability of beryllium copper for retractable antennas plays a crucial role in optimizing antenna design, further illustrated by the case study on Gd–Al–Co-doped M–type barium hexaferrite, which examines its microwave absorption and electromagnetic properties, relevant for various technological applications. Additionally, the proposed method for measuring materials with varying magnetic permeability effectively highlights the practical implications of this research, making magnetic permeability a focal point for future innovations.

Properties of Beryllium Copper Relevant to Antenna Design

Beryllium copper is recognized for its exceptional electrical and thermal conductivity, paired with impressive strength characteristics, making it the strongest copper alloy available. Domadia, a leader in supplying and manufacturing high-performance Beryllium Copper Plates, ensures that this alloy is particularly valued in retractable applications due to its outstanding resistance to corrosion and wear, guaranteeing long-lasting durability. As noted by P. M. O’Donnell, ‘Film of beryllium fluoride protects beryllium against corrosion and stress corrosion cracking in water containing chloride ion concentrations,’ highlighting the protective qualities that enhance the longevity of Beryllium Copper components.

Furthermore, the magnetic permeability of beryllium copper for retractable antennas, which is statistically significant at approximately 0.5 to 0.8, enhances electromagnetic performance, making it an optimal choice for both receiving and transmitting signals. These properties collectively ensure that devices crafted from Beryllium Copper maintain high performance across diverse environmental conditions. Materials scientists underline the significance of these attributes, noting that the alloy’s performance metrics are crucial in applications demanding reliability and efficiency.

For instance, the magnetic permeability of beryllium copper for retractable antennas contributes to its ability to effectively manage electromagnetic interference, positioning it as a preferred material in advanced transmission device design. At Domadia, we offer customized Beryllium Copper Plates tailored to meet the specific needs of your projects, backed by our expert support to ensure your success across various sectors, including aerospace, defense, and telecommunications. Contact us today to discover how our solutions can elevate your project.

Application of Beryllium Copper in Retractable Antenna Design

Beryllium copper plays a pivotal role in the design of retractable devices, particularly in components such as the base and connector interfaces. The magnetic permeability of beryllium copper for retractable antennas significantly enhances the antenna’s ability to effectively capture and transmit radio frequencies. Engineers frequently select this alloy for applications where space and weight are crucial considerations; its remarkable tensile strength allows for the creation of thinner, lighter components that do not sacrifice durability.

At Domadia, we acknowledge the significance of safety linked to this element. Understanding the mechanisms of beryllium-induced carcinogenesis, which may involve altered gene expression and inflammatory responses, is essential for ensuring compliance with safety standards. As Finch et al.

The genotoxicity of these compounds has been documented and the consensus is that it does cause mutation independently of the immune response. In response to safety concerns, ongoing research into alternatives, such as the Cu–7.4Ni–1.3Si–1.2Cr alloy, illustrates the development of safer substitutes for toxic beryllium bronzes, particularly for mold tooling applications. This alloy, processed using powder metallurgy, exhibited an average tensile strength of up to 820 Mpa, suggesting that procurement managers have viable options to consider when selecting materials for retractable devices. Domadia’s extensive range of Beryllium Copper products, including foils, sheets, rods, and wires, along with custom fabrication options, ensures that you have access to quality solutions that prioritize safety and performance.

Recent innovations in retractable antenna designs highlight the adaptability and efficiency of these alloys, especially focusing on the magnetic permeability of beryllium copper for retractable antennas, which reinforces their strategic use in enhancing RF transmission capabilities.

Challenges in Utilizing Beryllium Copper for Antennas

Despite the numerous benefits that this alloy offers, its use is not without difficulties. The price of a certain alloy can surpass that of substitute materials, raising concerns for budget-sensitive projects. Factors affecting the pricing of alloy scrap include market demand, purity, and current metal prices, with Domadia dedicated to providing fair and transparent pricing to manage these complexities.

Recent reports indicate that fluctuations in global economic conditions and currency values can complicate pricing further. Furthermore, obtaining the alloy often requires maneuvering through strict international regulations, which complicates the procurement process. Domadia actively addresses these challenges by leveraging strong supplier relationships and staying informed about regulatory changes, ensuring a smoother procurement process.

Significantly, this element exhibits six times the specific stiffness of steel, which can justify its use in high-performance applications despite the cost. Furthermore, the dynamics of raw resource prices for copper and stainless steel, influenced by supply and demand, underscore the cost implications of choosing beryllium copper for retractable antennas, particularly considering its magnetic permeability of beryllium copper for retractable antennas. Additionally, while the substance’s brittleness at low temperatures can limit its applicability in certain designs, engineers must either seek alternative options or implement additional processing steps to address these limitations.

Recognizing these challenges is crucial for creating effective procurement strategies and ensuring that design considerations align with the realities of sourcing resources.

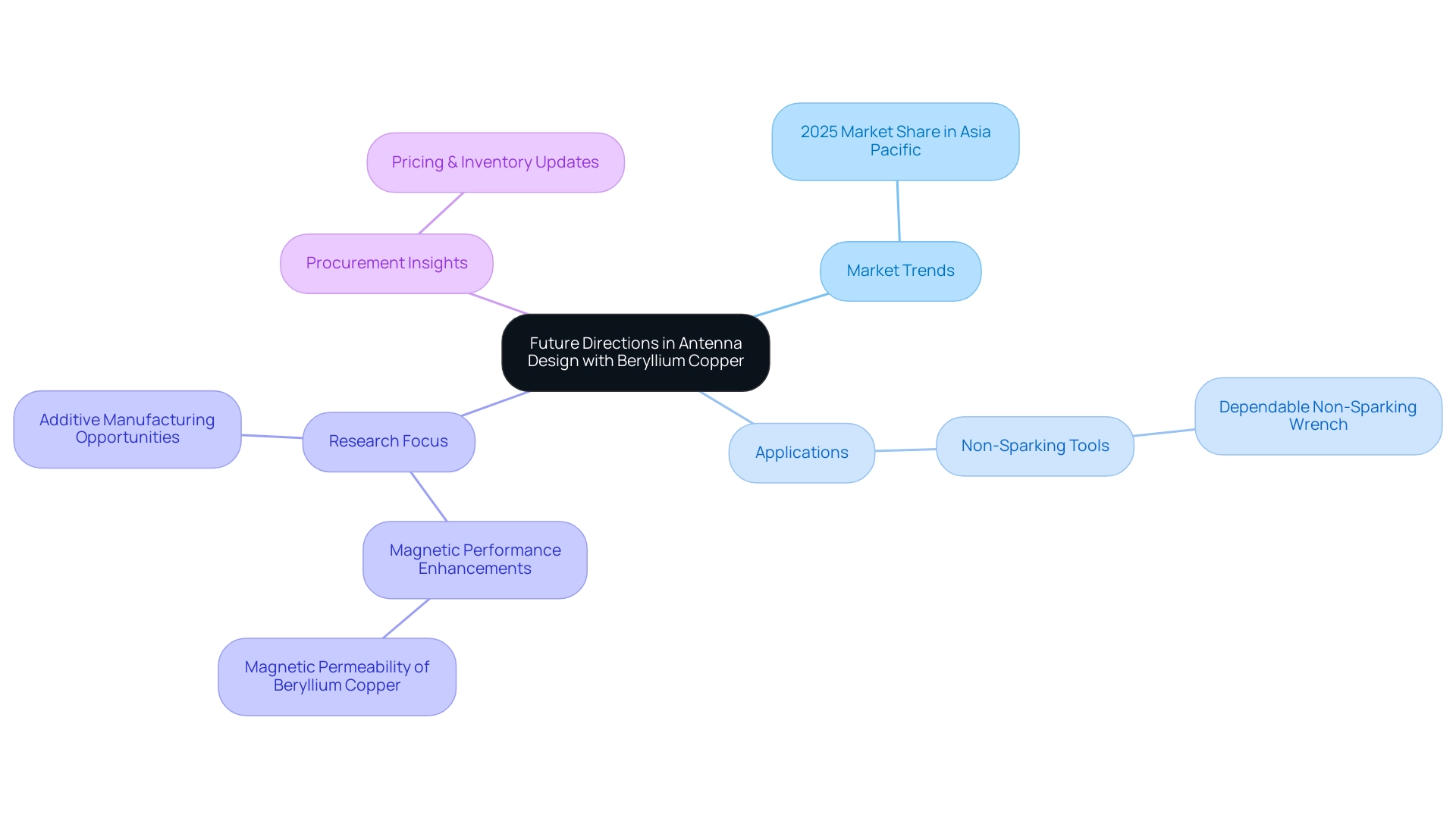

Future Directions in Antenna Design with Beryllium Copper

As antenna technology progresses, the need for substances that merge lightweight characteristics with superior performance, such as certain metal alloys, is expected to increase. In 2025, the Asia Pacific region is expected to hold the largest market share in the Antenna Market, highlighting the importance of enhancing the characteristics of this alloy in this competitive environment. Our most recent blog updates from February 2, 2022, May 16, 2022, and May 18, 2022, emphasize the uses of a specific alloy in non-sparking tools, including the dependable non-sparking wrench, which is crucial for safety in hazardous settings because of its durability and resistance to sparking.

Future research will likely concentrate on enhancing the alloy’s magnetic performance, focusing on the magnetic permeability of beryllium copper for retractable antennas, while achieving cost reductions. Advancements in production methods, especially additive manufacturing, could open new opportunities for utilizing specialized alloys in design frameworks, enabling the development of more complex shapes and improving overall performance. For procurement managers, staying informed about these developments—along with specific pricing and inventory details of beryllium copper strips and tools—is crucial to harnessing the best materials for upcoming projects.

Embracing these trends and innovations will be essential for maintaining a competitive advantage in the rapidly evolving landscape of antenna technology.

Conclusion

The exploration of magnetic permeability and the unique properties of beryllium copper underscores their critical importance in antenna design. As highlighted, magnetic permeability directly influences how materials interact with magnetic fields, impacting the efficiency of signal transmission and reception. The advancements in understanding these parameters pave the way for enhanced antenna performance, particularly in sectors that demand high reliability, such as telecommunications and aerospace.

Beryllium copper emerges as a superior choice for antenna applications due to its exceptional electrical and thermal conductivity, strength, and resistance to corrosion. These attributes make it particularly suited for retractable antennas, where space and weight are significant factors. However, procurement managers must navigate the challenges associated with its cost, regulatory compliance, and potential safety concerns. Strategies to address these challenges can ensure that the advantages of beryllium copper are fully realized without compromising budgetary constraints or safety standards.

Looking ahead, the future of antenna design is poised for innovation, with beryllium copper at the forefront. As market demands evolve and new manufacturing techniques emerge, such as additive manufacturing, the potential for optimizing this alloy’s properties will continue to expand. Staying informed about these developments is essential for procurement managers to leverage the best materials for their projects and maintain a competitive edge in an increasingly complex landscape. Embracing these insights will not only enhance antenna technology but also contribute to the strategic success of projects across various industries.