Blogs

What Are Invar Uses? A Comprehensive Overview of Applications

Introduction

Invar, a remarkable nickel-iron alloy, is celebrated for its unparalleled low coefficient of thermal expansion, making it an essential material for industries where precision is paramount. Comprising 36% nickel and 64% iron, Invar’s unique properties not only ensure dimensional stability across varying temperatures but also provide impressive mechanical strength, weldability, and environmental resistance.

From precision instruments to aerospace applications, Invar’s role is critical in maintaining accuracy and reliability in high-stakes environments. As industries evolve and demand for advanced materials rises, understanding the diverse applications and future trends surrounding Invar is vital for procurement managers seeking to leverage its capabilities for strategic advantage.

This exploration delves into the composition, applications, and future potential of Invar, highlighting its significance in contemporary engineering and manufacturing landscapes.

Understanding Invar: Composition and Unique Properties

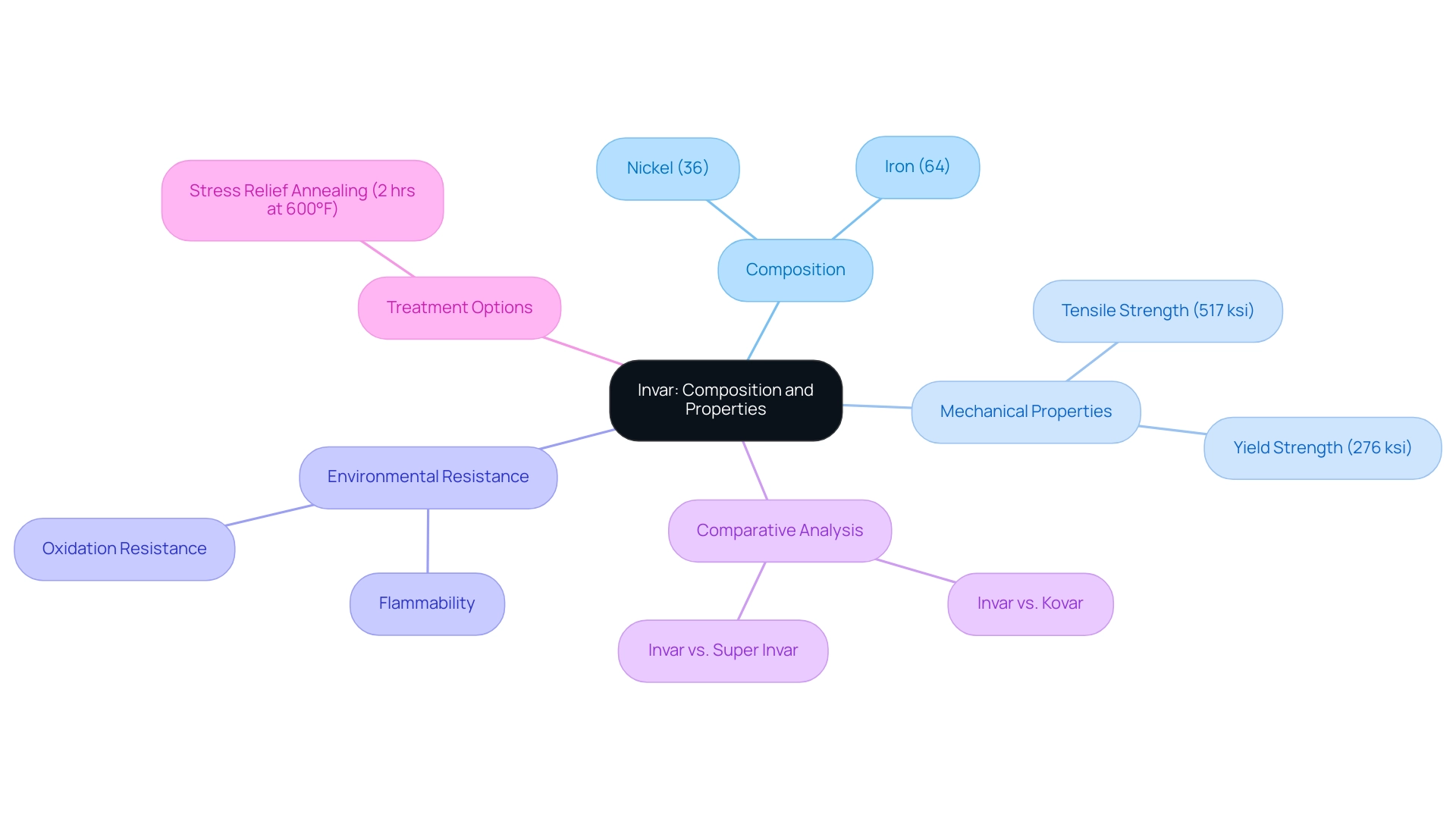

This specialized nickel-iron alloy is renowned for its exceptionally low coefficient of thermal expansion (CTE), which highlights its invar uses in scenarios where high dimensional stability is critical. This alloy predominantly comprises 36% nickel and 64% iron, factors that contribute to its exceptional resistance to temperature-induced dimensional changes. The stability of its unique crystalline structure across varying temperatures is a key attribute that enhances its performance.

Furthermore, this material exhibits impressive mechanical properties in the annealed condition, with a tensile strength of 517 ksi (approximately 3575 MPa) and a yield strength of 276 ksi (approximately 1905 MPa). Its weldability further enhances its versatility, allowing for a wide variety of engineering uses. Alongside its low thermal expansion and strong mechanical properties, this alloy’s environmental resistance encompasses different degrees of flammability and oxidation resistance, rendering it appropriate for various uses.

A comparative case study titled ‘Invar vs. Other Low Expansion Alloys’ reveals that the invar uses showcase this material as having the lowest CTE among common alloys, while other nickel and iron-nickel alloys like Kovar and Super Invar offer varying properties and costs. Additionally, the optional stress relief annealing process, requiring 2 hours at 600°F, can optimize the material’s properties for particular uses. This combination of low expansion, environmental resistance, and treatment options positions this alloy as a vital material in exact engineering and other demanding sectors, particularly for invar uses.

Diverse Applications of Invar in Industry

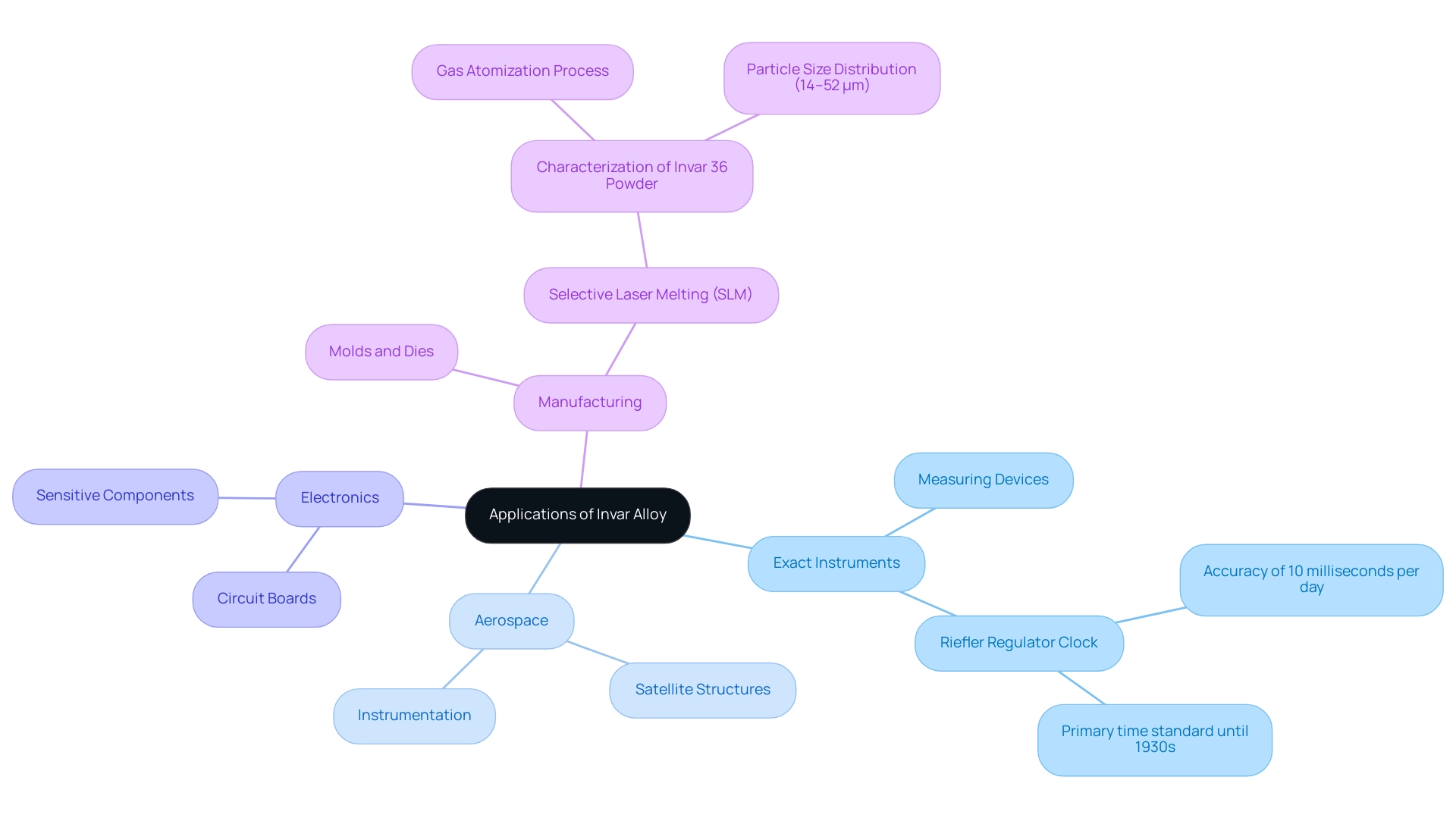

The distinctive characteristics of this alloy render it essential in various sectors, especially in accurate instruments and aerospace uses. In the domain of exact instruments, this alloy is vital for the creation of measuring devices and gauges, where its slight heat expansion is critical for preserving accuracy. Significantly, the Riefler regulator clock, created in 1898 by inventor Clemens Riefler, was the first clock to use a special pendulum, achieving an impressive accuracy of 10 milliseconds per day.

This innovation set a standard for timekeeping in naval observatories and national time services until the 1930s. Recent research, including one by Liu et al., has explored expansion anomalies influenced by entropy, further highlighting the stability and reliability of this alloy in precision applications. In aerospace, the invar uses of this alloy are increasingly employed in the fabrication of components that require exceptional dimensional stability under fluctuating temperature conditions, such as satellite structures and instrumentation.

Furthermore, the latest 2024 insights reveal that this material is utilized in the electronics industry for its thermal stability, particularly in circuit boards and sensitive components. The characterization of a specific alloy powder for Selective Laser Melting (SLM) shows that gas atomization produces nearly spherical particles with a size distribution ranging from 14 to 52 μm. This precise particle morphology is crucial for ensuring the quality of fabricated components, as it directly impacts the performance and reliability of the end products.

Additionally, this material is available in various forms and sizes from EFINEA, providing procurement managers with practical sourcing options. Its role in the production of molds and dies further emphasizes its significance, where accuracy is paramount for successful outcomes.

The Advantages of Invar in Precision Engineering

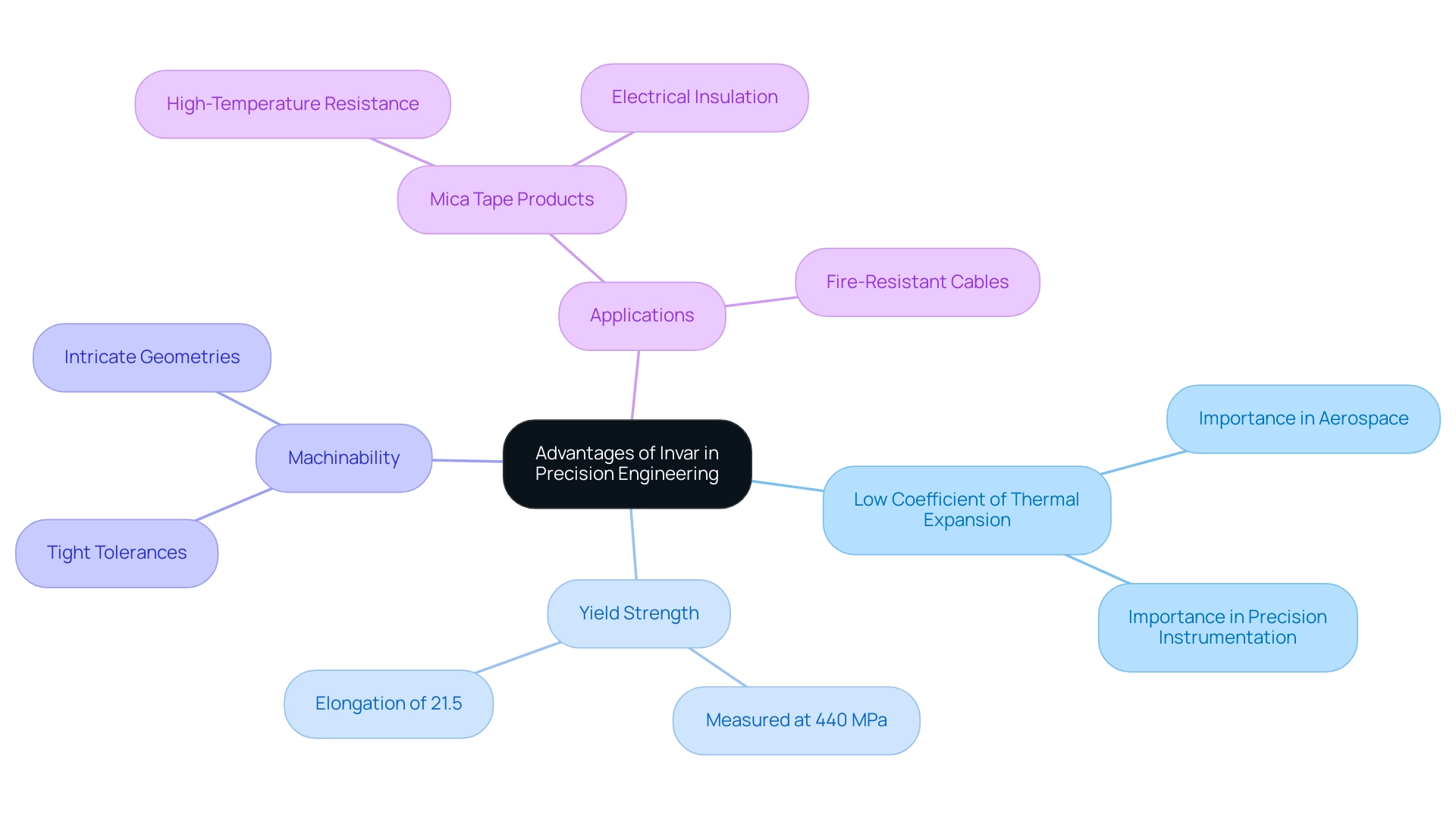

The notably low coefficient of thermal expansion is a crucial benefit, particularly in exact engineering and manufacturing applications. This characteristic enables components made from this alloy to preserve their dimensional integrity even amid significant temperature variations, which is essential in sectors like aerospace and precision instrumentation. Merkel emphasizes this property, stating,

Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Alloy 36,

underscoring its importance in ensuring reliability.

Additionally, the yield strength of the alloy samples is measured at 440 MPa with an elongation of 21.5% under 10 kN, further solidifying its reputation for durability and performance. In the realm of electrical insulation, Mica Tape products are essential due to their high-temperature resistance and electrical insulation capabilities. These tapes are commonly utilized in the manufacture of fire-resistant cables and other critical electrical insulation systems, making them ideal for various sectors.

The regional variability in the alloy 36 market emphasizes how advanced areas, such as North America and Europe, utilize its characteristics for high-precision uses, while developing economies are starting to acknowledge its potential. Moreover, the material’s exceptional machinability enhances its appeal, permitting manufacturers to attain tight tolerances and intricate geometries. This synergy of heat stability, alongside the robust characteristics of materials like Mica Tape and copper nickel alloys—recognized for their corrosion resistance, excellent heat and electrical conductivity, good ductility, and ease of fabrication—establishes this alloy as the preferred material for applications that involve invar uses, demanding unparalleled accuracy and reliability, making it indispensable in contemporary manufacturing environments.

Invar’s Role in Specialized Applications: Optics and Aerospace

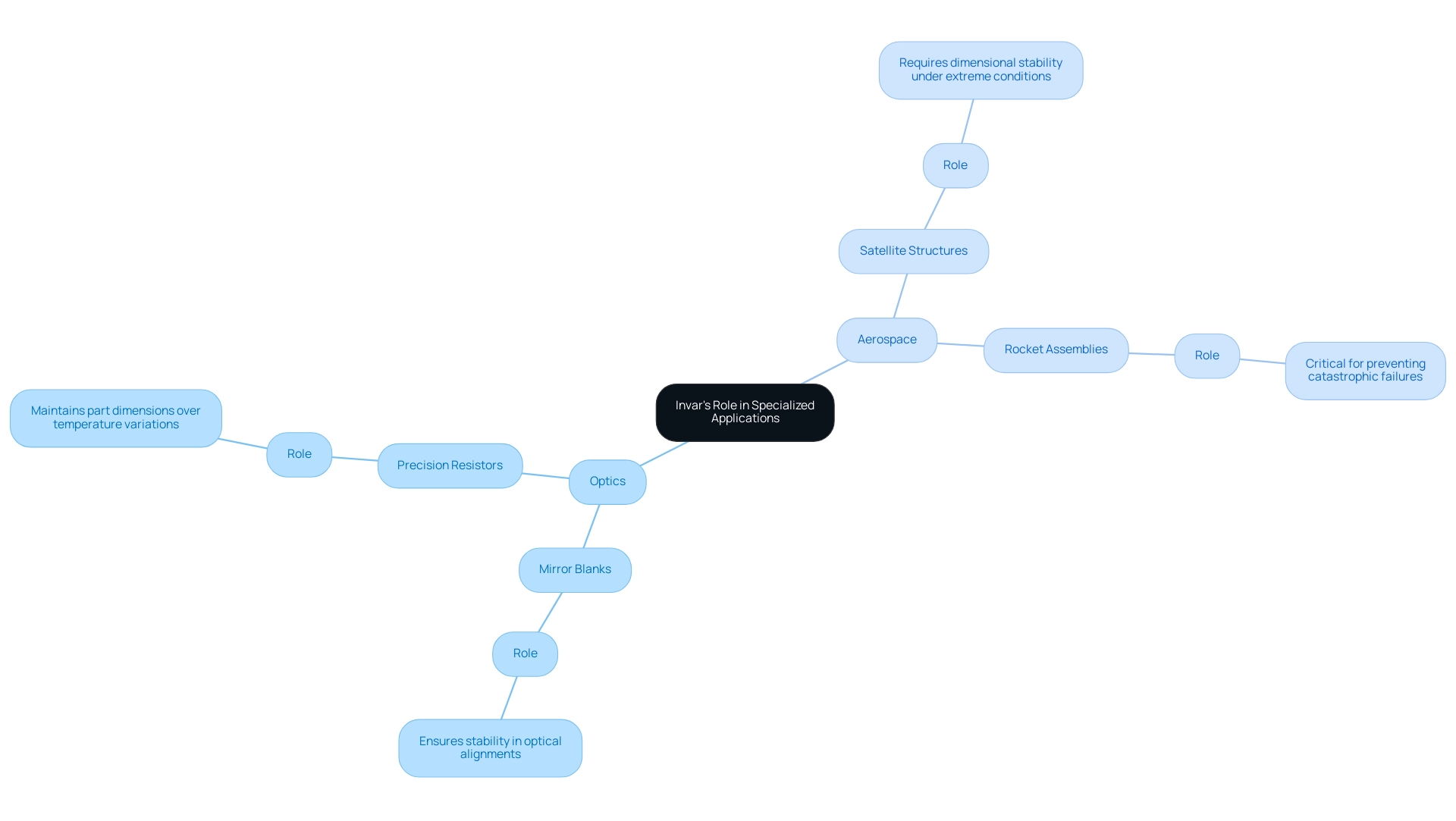

This alloy is essential to invar uses in optics and aerospace, where its low coefficient of expansion is crucial for preserving accuracy under fluctuating temperatures. In optical instruments, invar uses a special alloy to create accurate mounts and frames, ensuring that optical alignments remain stable despite thermal variations. This stability is essential for high-performance optical systems, such as those needed for scientific instruments and telescopes.

Specific applications of the alloy powder, which exemplify invar uses, include:

- Mirror blanks for optical instruments

- Precision resistors that are critical for maintaining part dimensions and accuracy over temperature variations

In aerospace, invar uses are important for components subjected to extreme conditions, particularly in satellite structures and rocket assemblies. The precise dimensional control that this alloy provides is crucial, as even minor deviations can result in catastrophic failures.

Super alloy, with a CTE of approximately 0.4 x 10^-6/°C and a composition of 32% Ni, balance Fe, plus Co additions, demonstrates its reliability in high-demand environments. Additionally, the ongoing research into the performance of these components reveals their superior reliability, which is essential for ensuring the success of aerospace missions and the functionality of optical devices. As David Mercier aptly stated,

Our vision is of material intelligence integrated throughout education R&D, and the product lifecycle,

emphasizing the need for innovative substances in advancing technology.

Furthermore, findings regarding the Poisson’s ratios of metamaterials highlight the importance of material performance in aerospace and optics, further reinforcing the essential role of this alloy in these industries.

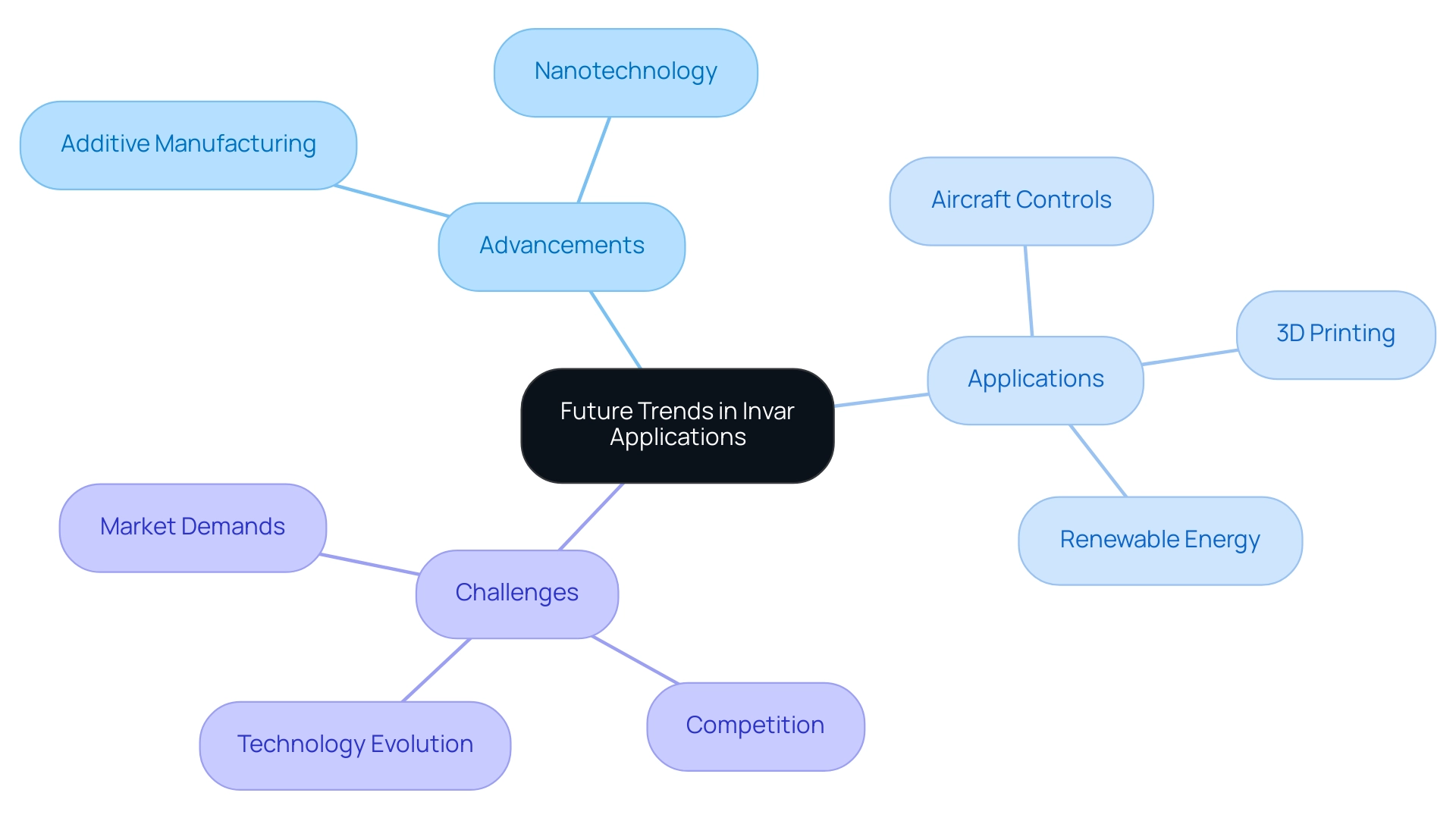

Future Trends: Advancements in Invar Applications

The future of this material’s uses is set for considerable growth, especially propelled by progress in additive manufacturing and nanotechnology. As industries increasingly adopt 3D printing, its exceptional properties, particularly its low thermal expansion, provide opportunities to create highly precise components designed for invar uses. A notable example is Carpenter Technology’s Free-Cut 36 Alloy, which offers improved machinability for applications requiring high parts productivity, successfully utilized in aircraft controls and various electronic devices.

Moreover, the increase in demand for high-performance materials across areas like renewable energy and advanced electronics is expected to stimulate innovative applications of this alloy. As materials scientists have pointed out, the alloy 36 market faces challenges such as:

- Intense competition

- Rapidly evolving technology

- The need to adapt to changing market demands

This underscores the necessity for continuous innovation. As these technological advancements unfold, the invar uses are expected to emerge as a material of choice, addressing future engineering challenges and contributing to the development of cutting-edge solutions across various industries.

Conclusion

Invar stands out as a pivotal material in modern engineering, primarily due to its exceptional low coefficient of thermal expansion and remarkable mechanical properties. Comprising 36% nickel and 64% iron, this nickel-iron alloy not only ensures dimensional stability in fluctuating temperatures but also offers impressive strength and versatility across a myriad of applications. Its role in precision instruments, aerospace, and even emerging technologies like additive manufacturing underscores its critical importance in maintaining accuracy and reliability in high-stakes environments.

The diverse applications of Invar, from precision gauges and satellite structures to optical devices, highlight its indispensable nature in fields where precision is paramount. The historical significance of Invar, exemplified by innovations such as the Riefler regulator clock, combined with contemporary advancements, showcases its enduring relevance. As industries evolve, the demand for materials that exhibit stability and durability under varying conditions continues to grow, reinforcing Invar’s position as a strategic asset for procurement managers.

Looking ahead, the future of Invar applications appears promising, driven by technological advancements and the increasing embrace of new manufacturing methods. The integration of Invar into sectors like renewable energy and advanced electronics will likely accelerate as engineers seek materials that can meet the challenges of tomorrow. To harness the full potential of Invar, continuous innovation and adaptation to market dynamics will be essential, ensuring that this remarkable alloy remains at the forefront of engineering solutions.