Blogs

Why Is Beryllium Copper Dangerous? Understanding the Health Risks

Introduction

In the realm of industrial applications, Beryllium Copper stands out as a material of exceptional strength and versatility, yet it carries inherent health risks that demand careful consideration. This alloy, prized for its remarkable electrical conductivity and resistance to corrosion, is essential in sectors such as aerospace and precision manufacturing.

However, the very properties that make Beryllium Copper valuable also pose significant hazards, particularly during machining processes that can release harmful dust and fumes. With statistics revealing that exposure can lead to chronic beryllium disease and even lung cancer, understanding the implications of beryllium exposure is crucial for professionals tasked with safeguarding worker health.

This article delves into the composition and applications of Beryllium Copper, the health effects associated with its use, and the stringent safety measures necessary to mitigate risks in the workplace. By exploring regulatory standards and effective strategies for reducing exposure, it aims to equip procurement managers and safety officers with the insights needed to foster a culture of safety while leveraging the benefits of this powerful alloy.

Understanding Beryllium Copper: Composition and Health Risks

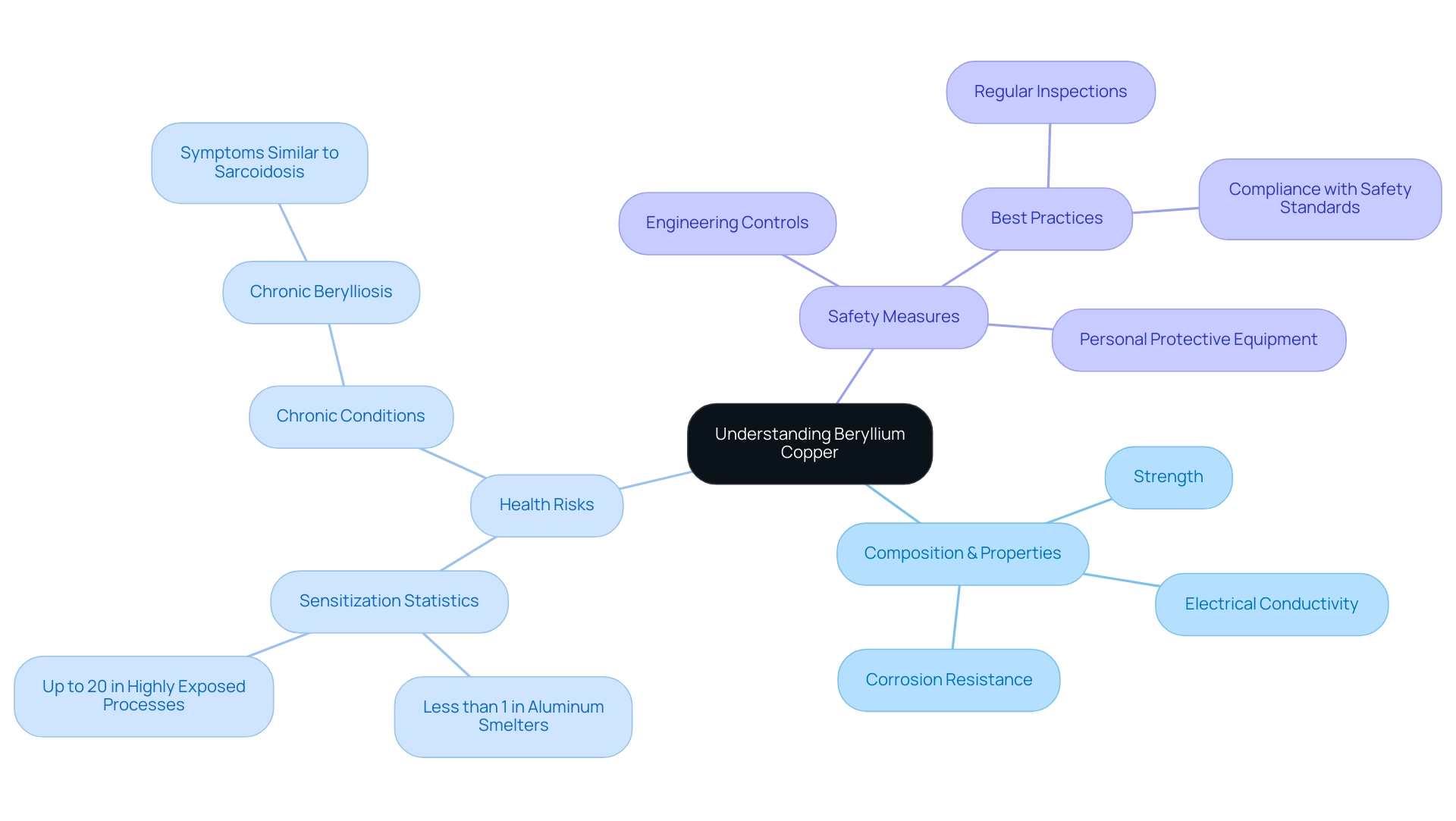

Beryllium copper, a strong alloy mainly made of copper, is renowned for its exceptional strength, excellent electrical conductivity, and notable resistance to corrosion. At Domadia, we take pride in supplying high-performance Beryllium Copper Plates, which have become indispensable in various industrial applications. Our innovative manufacturing processes ensure that every plate meets rigorous quality standards, tailored to the specific needs of our clients.

These attributes make Beryllium Copper an invaluable resource, especially in aerospace and precision applications, where its exceptional load-bearing capacity is crucial. However, the inclusion of this element raises significant health concerns, especially when discussing if beryllium copper is dangerous during machining or processing activities that generate fine dust or fumes. Current statistics indicate that the prevalence of sensitization among exposed workers can be as low as 1% in aluminum smelters but may reach up to 20% in highly exposed processes.

Such contact can culminate in serious respiratory issues and chronic conditions, such as chronic berylliosis, which exhibits symptoms akin to sarcoidosis, as noted by experts in the field. Comprehending the pathways of exposure to this element is essential for evaluating risk factors linked to chronic disease (CBD). Therefore, it is crucial for professionals in industries that use copper alloy to stay alert regarding whether is beryllium copper dangerous.

Implementing effective engineering controls and personal protective equipment to mitigate risks is essential. At Domadia, we emphasize safety by providing comprehensive guidance on best practices and adherence to stringent public health regulations, including regular inspections and compliance with international safety standards. Our commitment to high-quality Beryllium Copper solutions is underscored by rigorous quality control, ensuring that we provide the best products tailored to our clients’ needs and enhancing overall customer satisfaction.

Health Effects of Beryllium Exposure: Risks and Long-term Consequences

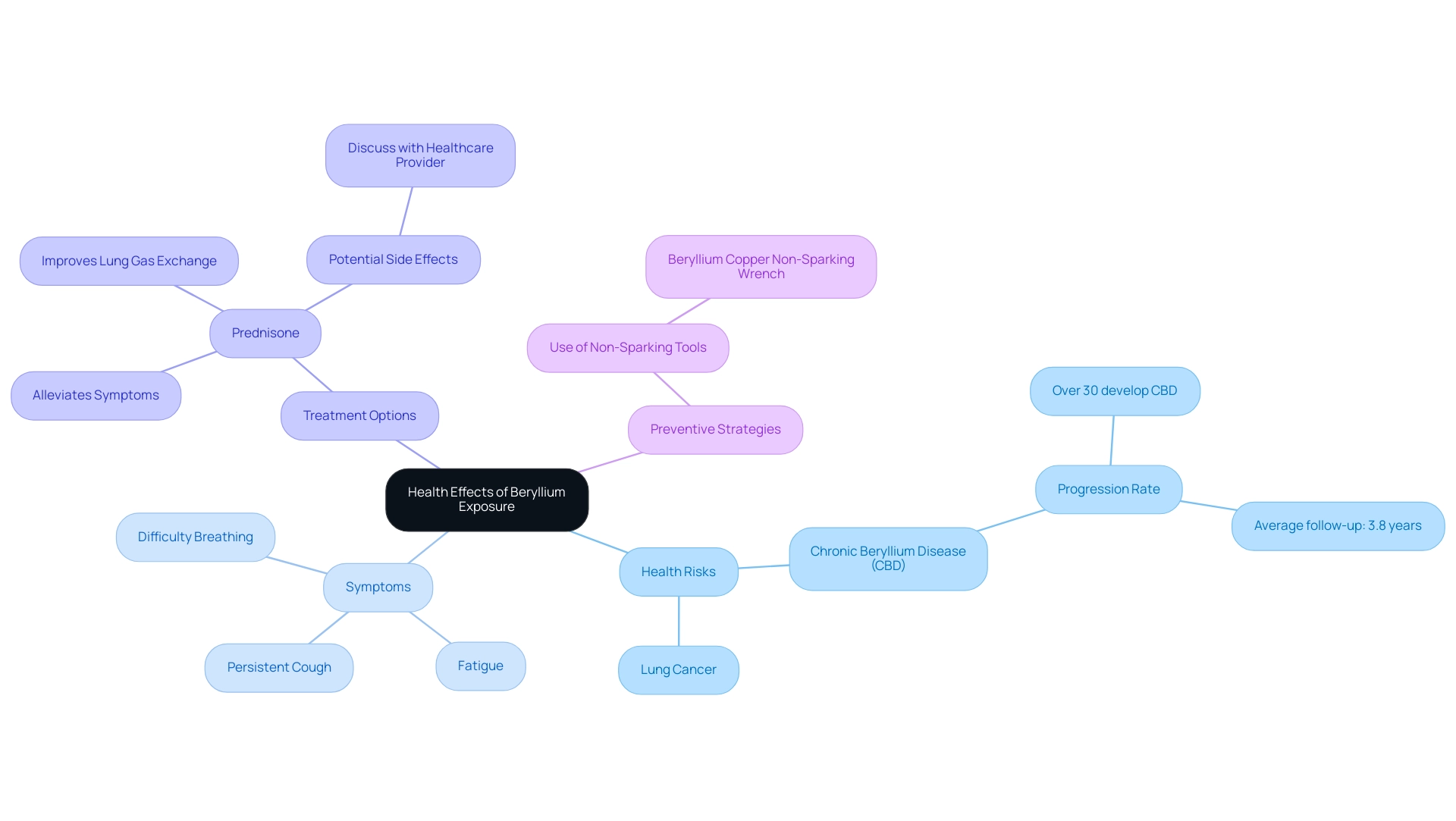

Extended contact with the metal, especially in industrial environments where instruments such as the Copper Non-Sparking Wrench are utilized, raises concerns about whether is beryllium copper dangerous, as it can result in chronic beryllium disease (CBD), a severe and possibly debilitating lung illness. Symptoms of CBD often manifest as a persistent cough, fatigue, and difficulty in breathing, which can progressively worsen to severe respiratory failure. Alarmingly, over 30% of individuals sensitized to this element develop CBD within an average follow-up period of 3.8 years.

While treatment options such as Prednisone can alleviate symptoms and improve lung gas exchange, potential side effects must be discussed with a healthcare provider. Furthermore, research signifies a notable correlation between exposure to this element and an increased risk of lung cancer, leading to the concern of whether is beryllium copper dangerous, with a latency period for these diseases ranging from several years to decades. Precise diagnosis of CBD is essential, depending on both sensitization and granulomatous inflammation noted in lung biopsies.

This emphasizes the importance of adopting preventive strategies to protect workers in settings where copper alloy is used, thus ensuring employee well-being and minimizing possible long-term liabilities for firms that overlook these hazards. The Beryllium Copper Non-Sparking Wrench is specifically designed for use in hazardous environments, featuring non-sparking properties that prevent ignition in flammable settings. Its applications encompass maintenance and repair duties in sectors like oil and gas, chemical processing, and mining, where protection is paramount.

As pointed out by Paul F. Wambach, a thorough comprehension of the metal’s contact consequences is crucial for efficient wellness management and regulatory adherence.

Safety Precautions for Handling Beryllium Copper

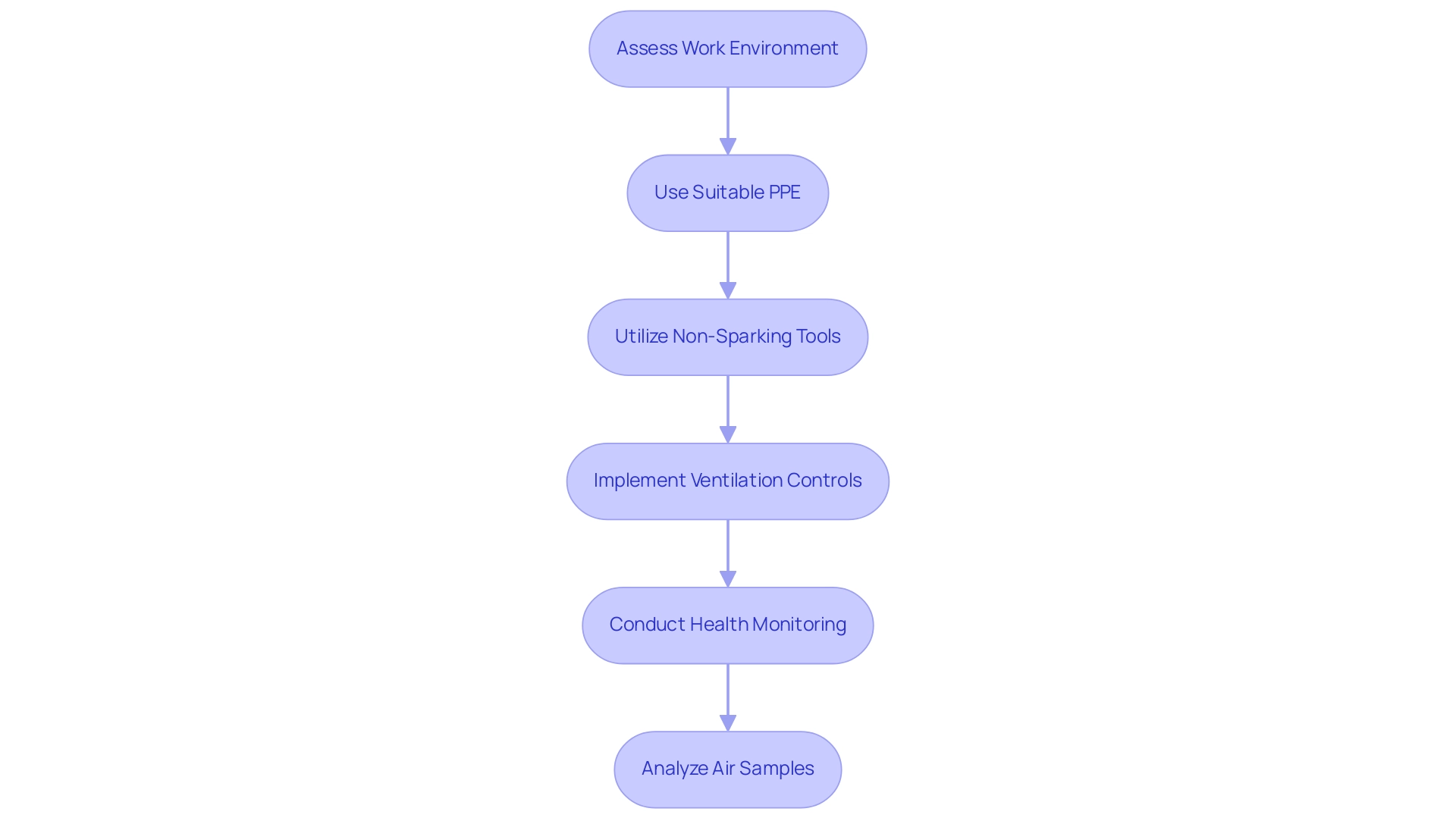

When working with copper alloy, enforcing strict safety measures is crucial to protect employees and ensure adherence to safety regulations. This encompasses the required use of suitable personal protective equipment (PPE), such as respirators, gloves, and protective clothing, which are essential in reducing risk. Evidence indicates that effective PPE greatly decreases the chances of health problems linked to exposure to harmful substances.

Moreover, in explosive potential environments, utilizing non-sparking tools, such as those made from beryllium copper, improves protection by minimizing the risk of ignition. Domadia’s non-sparking tools are specifically designed to meet the highest standards of security and quality, ensuring they are suitable for high-risk applications. These tools are rigorously tested to prevent sparks during use, providing peace of mind for industries operating in hazardous environments.

Employers must ensure that all feasible controls are utilized to minimize exposure before relying solely on respiratory protection. Work environments must be adequately ventilated, and dust control measures—such as wet machining techniques or local exhaust ventilation—should be in place to diminish airborne particles. Regular training sessions on safe handling practices empower employees to recognize hazards, while health monitoring ensures ongoing compliance with safety standards.

Notably, air samples must be analyzed by a laboratory that can measure the element to an accuracy of plus or minus 25 percent within a statistical confidence level of 95 percent. Employers must remember that if the copper alloy causes skin irritation, it raises the question of whether beryllium copper is dangerous, which may indicate vulnerability to chronic copper disease (CBD), necessitating immediate attention. Furthermore, the case study titled ‘Health Effects of Beryllium Exposure‘ highlights that inhalation of airborne substances or skin contact with materials containing this element can lead to adverse health effects, which raises concerns about whether beryllium copper is dangerous and underscores the importance of these safety measures.

Additionally, it is imperative to label materials containing at least 0.1 percent of the element and ensure they are cleaned before disposal, recycling, or reuse to prevent contamination. By following these current best practices and using Domadia’s non-sparking tools, organizations can effectively reduce the dangers linked to this substance and promote a safer workplace.

Regulatory Standards and Workplace Safety for Beryllium Exposure

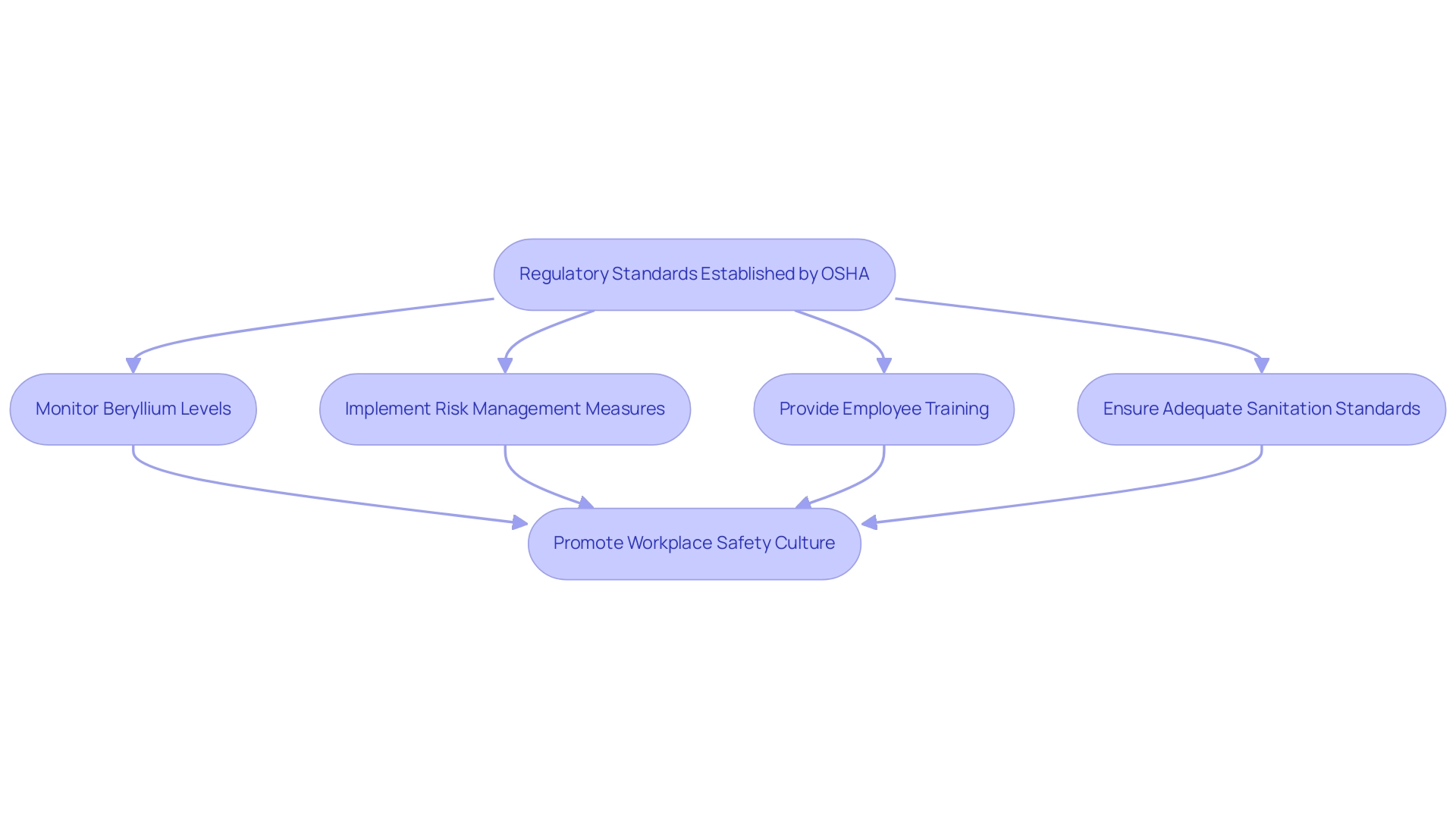

Regulatory agencies, especially the Occupational Safety and Health Administration (OSHA), have established strict standards to protect workers from the dangers linked to contact with this substance. Employers must actively monitor levels of the substance in the workplace, ensuring that concentration amounts remain below permissible limits. This involves the execution of effective risk management measures and the provision of training programs that inform employees about whether is beryllium copper dangerous and the crucial precautions required for safety.

Significantly, three borderline BeLPTs may also suggest sensitization, emphasizing the critical nature of monitoring contact levels closely. As NJH wisely emphasizes,

It is crucial to guarantee that special safeguards are established to shield workers from harmful substances.

Such regulations emphasize the critical need for procurement managers and compliance officers to grasp these requirements fully.

Furthermore, recent updates to OSHA regulations for 2024 emphasize the importance of maintaining sanitation standards, which mandate employers to provide adequate washing facilities and change rooms, as well as to enforce policies that prohibit food and beverages in hazardous areas. Additionally, OSHA’s decision to tailor standards based on the lack of sufficient data regarding exposure outside of abrasive blasting and welding illustrates the ongoing regulatory challenges. In this context, it is essential for procurement managers to consider suppliers of Beryllium Copper tools, including non-sparking wrenches, and to ask whether is beryllium copper dangerous, as these tools are vital for protection in explosive environments.

Comprehending these changing standards, including regulatory flexibility certification and environmental effects, is essential for ensuring workplace safety adherence and promoting a culture of well-being in settings where this element is present.

Mitigating Health Risks: Strategies for Reducing Beryllium Exposure

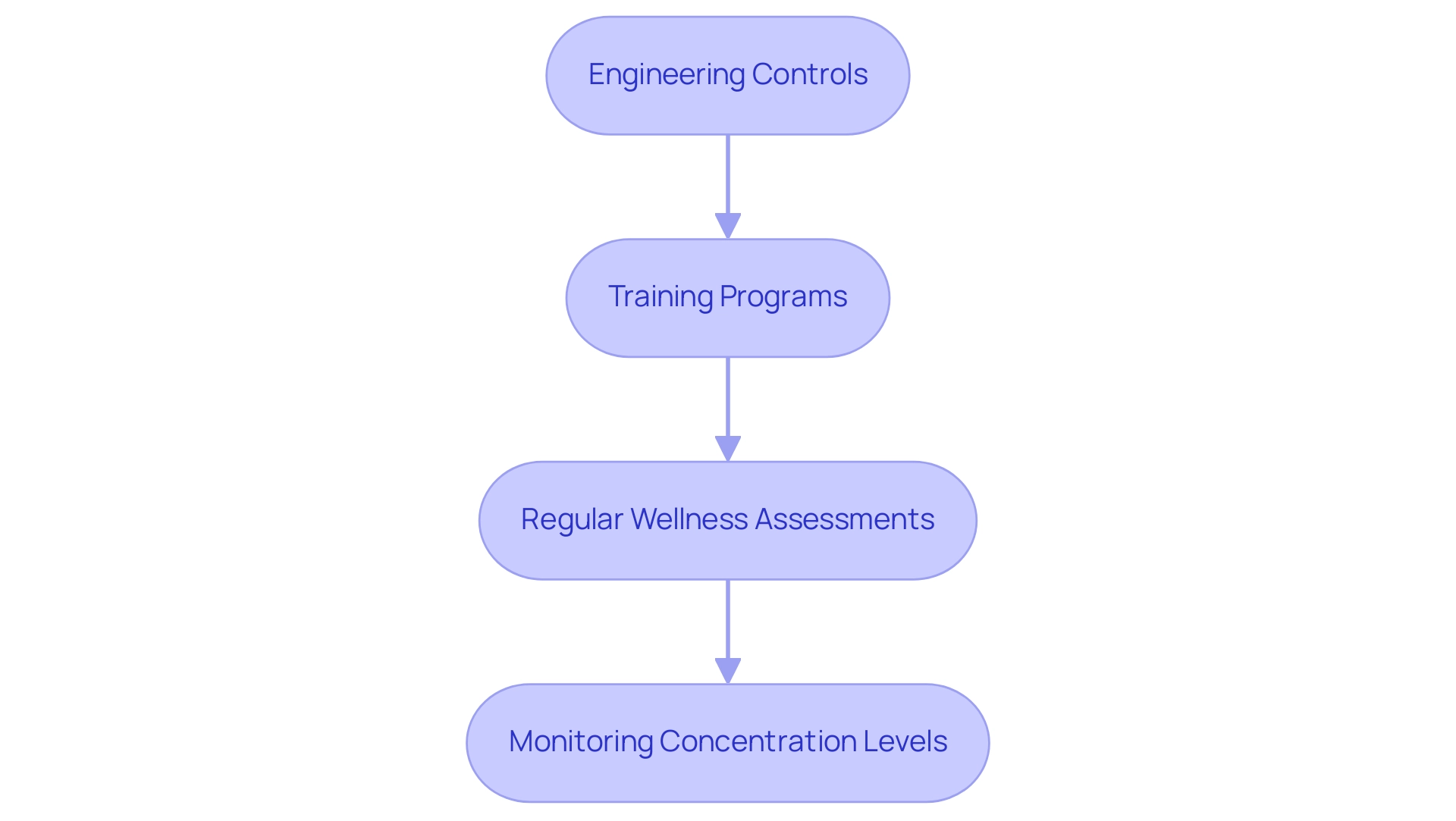

To effectively tackle the health hazards related to this substance’s contact, organizations are encouraged to adopt a comprehensive, multi-faceted approach that aligns with best practices in the industry. Central to this strategy are engineering controls, which play a crucial role in minimizing risk. Automated machining methods are one instance that can greatly lessen human contact, while advanced air filtration systems are crucial for trapping airborne particles, thus ensuring a safer environment.

Moreover, training programs that thoroughly educate employees about the risks, particularly concerning if beryllium copper is dangerous, and safe handling procedures for Beryllium Copper are imperative. As Ms. Fitch from the United Steelworkers emphasizes,

‘In addition to abrasive blasting using contaminated slags, workers in the maritime industry use non-sparking tools made from alloys, and a significant concern is whether beryllium copper is dangerous, given its unique properties, including exceptional strength, high electrical conductivity, and excellent corrosion resistance, making it ideal for such applications.’

Conducting regular wellness assessments and ongoing monitoring is also essential for the early identification of potential medical concerns linked to exposure.

The maximum peak concentration for beryllium and beryllium compounds is 25 μg/m for a maximum duration of 30 minutes, serving as a critical reference point for protective measures. Such proactive measures not only foster a safer work environment but also align with Domadia’s commitment to providing high-quality Beryllium Copper solutions through innovative manufacturing and rigorous quality control. By integrating these strategies, organizations can enhance their commitment to health and safety while ensuring compliance with regulatory provisions, reflecting the insights shared in our latest blog updates on the question of whether beryllium copper is dangerous in its applications.

Conclusion

Beryllium Copper, with its unparalleled strength and conductivity, remains a cornerstone in various industrial applications. However, the associated health risks cannot be overlooked. The potential for chronic beryllium disease and lung cancer necessitates a proactive approach to managing exposure, particularly during machining processes where harmful dust and fumes are generated. Understanding these risks is essential for professionals in industries utilizing this alloy, underscoring the importance of stringent safety measures.

Implementing effective safety protocols, such as:

- Utilizing personal protective equipment

- Ensuring proper ventilation

is crucial in minimizing exposure risks. Regulatory standards set forth by bodies like OSHA highlight the need for continuous monitoring and compliance to protect worker health. By staying informed about these regulations and adopting best practices, procurement managers and safety officers can foster a culture of safety while maximizing the benefits of Beryllium Copper.

Ultimately, the balance between leveraging the unique properties of Beryllium Copper and maintaining a safe working environment is achievable through strategic planning and adherence to safety guidelines. By prioritizing health and safety, organizations not only protect their workforce but also position themselves as responsible leaders in their respective industries.