Blogs

How to Choose the Right Invar 36 Suppliers: A Step-by-Step Guide

Overview:

To choose the right Invar 36 suppliers, procurement managers should prioritize quality control, technical expertise, vendor reputation, compliance with standards, and cost competitiveness. The article outlines these criteria in detail, emphasizing that a thorough evaluation of potential suppliers based on these factors ensures the sourcing of high-quality materials that meet stringent operational demands.

Introduction

In the intricate landscape of modern manufacturing and procurement, the selection of materials and suppliers can significantly impact operational success. Among these materials, Invar 36—a specialized iron-nickel alloy—stands out for its exceptional dimensional stability, making it indispensable in high-precision applications such as aerospace components and precision instruments.

Understanding the unique properties of Invar 36, along with the criteria for selecting reliable suppliers, is crucial for procurement managers aiming to maintain quality and performance in their supply chains. This article delves into the essential aspects of Invar 36, from its composition and properties to the pivotal strategies for evaluating suppliers and nurturing long-term relationships, ensuring that organizations are well-equipped to navigate the complexities of sourcing in today’s competitive environment.

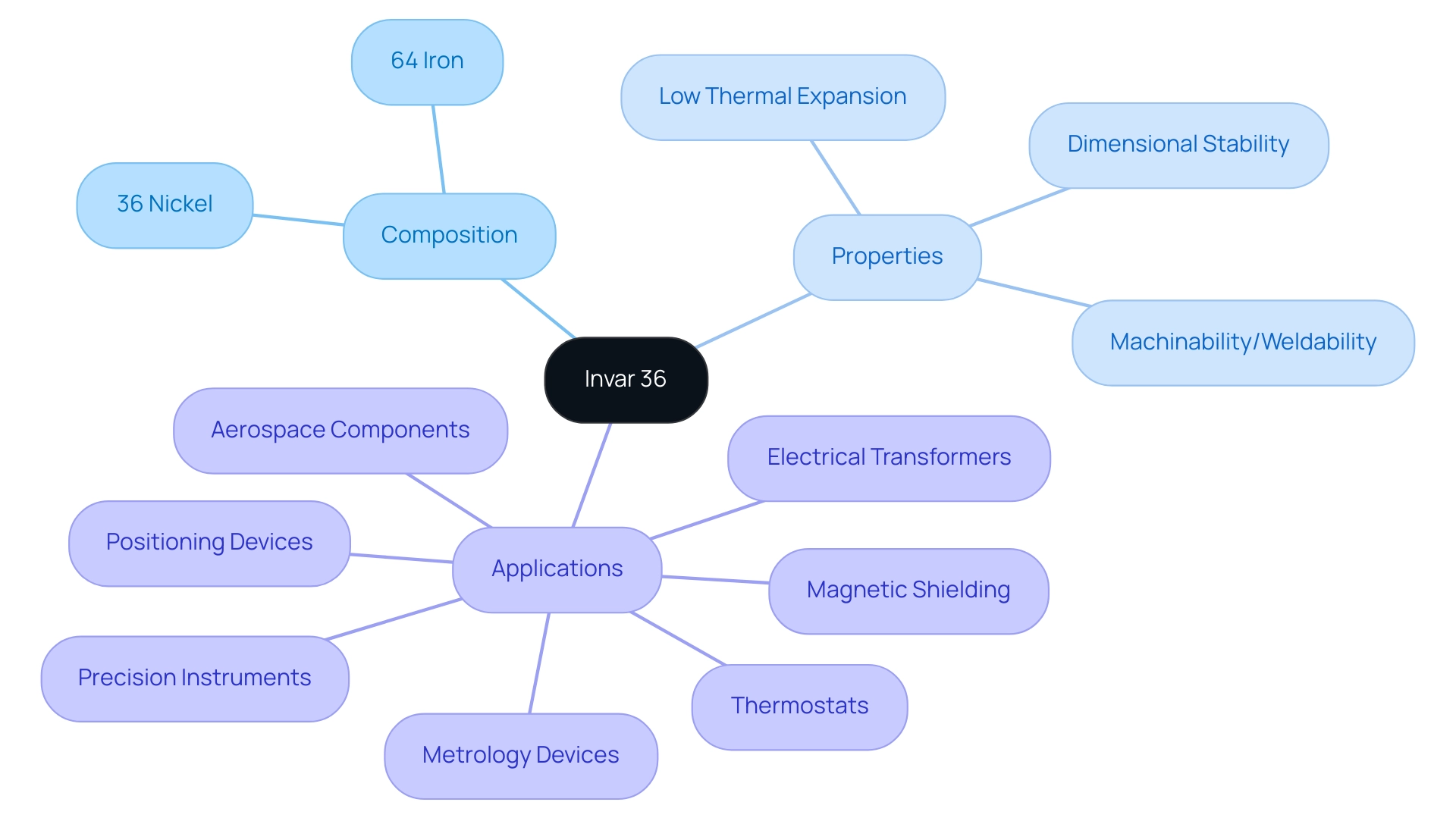

Understanding Invar 36: Composition and Properties

Invar 36, a specialized iron-nickel alloy, is distinguished by its remarkable dimensional stability over a broad temperature range, exhibiting a thermal expansion of just .010″. Comprising approximately 36% nickel and 64% iron, this alloy exhibits exceptionally low thermal expansion, a critical characteristic for applications that demand precise dimensional integrity. Such properties make Invar 36 particularly suitable for high-stakes environments, including precision instruments and aerospace components, where even the slightest deviation can lead to significant operational issues.

Notably, Invar 36 is utilized alongside high expansion alloys in applications requiring motion with temperature changes, such as in bimetallic thermostats and rod and tube assemblies for temperature regulators. Furthermore, its outstanding machinability and weldability expand its applicability across various manufacturing sectors. As procurement managers evaluate potential vendors, a thorough understanding of these properties is essential to ensure that the materials sourced will fulfill the stringent requirements of their specific applications.

For instance, Mica Tape products, known for their high-temperature resistance and electrical insulation, feature excellent flame resistance and dielectric strength, making them indispensable in critical applications such as the manufacture of fire-resistant cables and other electrical insulation systems. According to industry experts, ‘Thermally induced tool distortion can be minimized by controlling heat up and cool down during full anneal heat treatment,’ underscoring the importance of proper processing techniques. Recent developments highlight Invar 36’s role in advanced technologies, further underscoring its relevance in modern engineering challenges, much like the innovative solutions provided by leaders in the field.

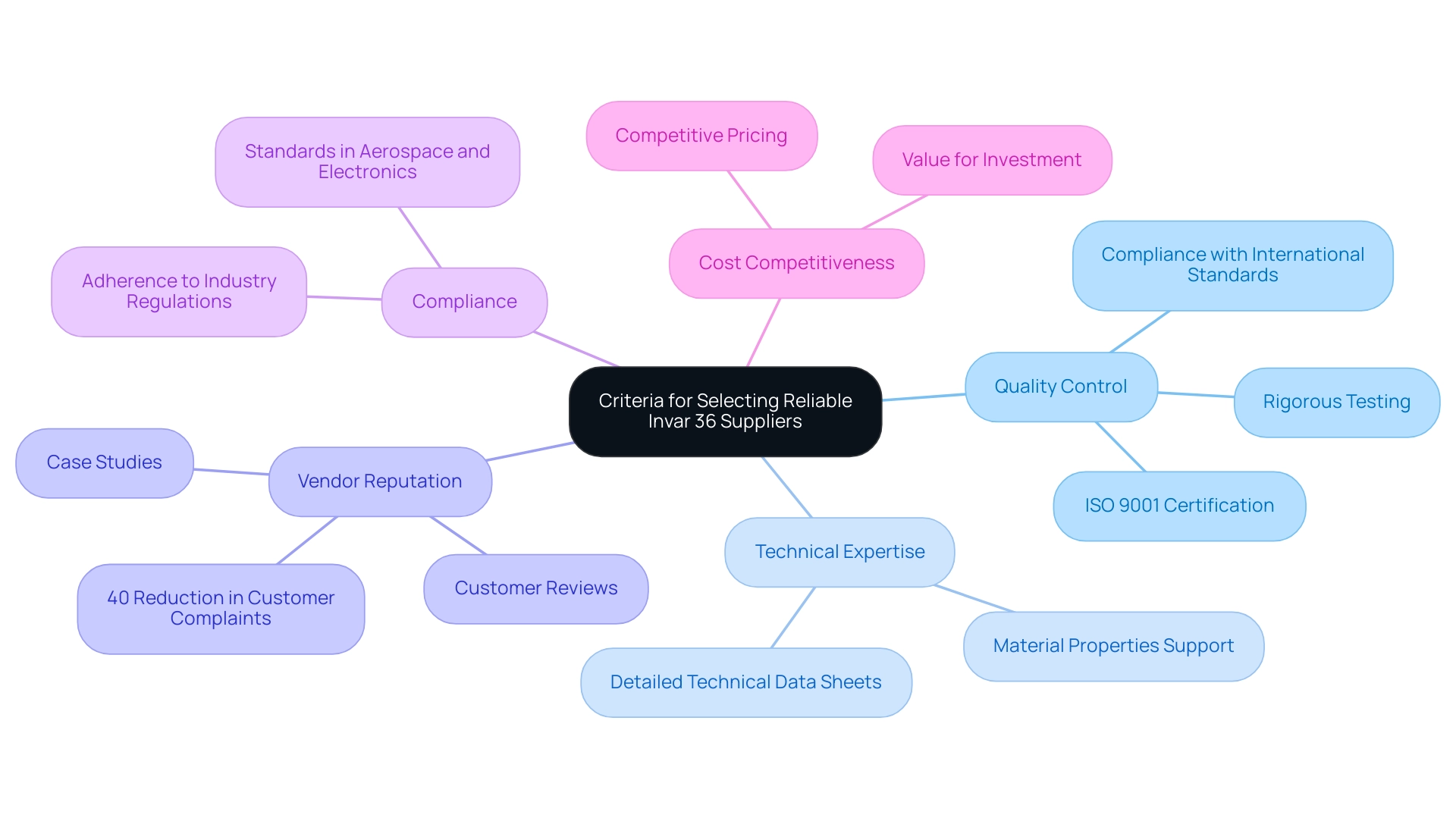

Criteria for Selecting Reliable Invar 36 Suppliers

Choosing the appropriate invar 36 suppliers is essential for guaranteeing material standards and performance. Here are key criteria to consider:

Quality Control: Prioritize suppliers like Domadia, which show a commitment to excellence through rigorous testing and compliance with international standards.

Their pure nickel products, for instance, undergo stringent control measures, ensuring that they meet the highest industry standards. Certifications such as ISO 9001 serve as benchmarks, indicating adherence to rigorous quality protocols.Technical Expertise: Evaluate providers based on their proficiency with Invar 36 and its applications.

A capable vendor should provide detailed technical data sheets and support, ensuring a thorough understanding of the material’s properties and performance characteristics.Vendor Reputation: Investigate potential vendors’ standing within the industry.

Collecting reviews, case studies, and testimonials from other procurement managers can offer valuable insights into their reliability and service standards.

For instance, companies investing in quality management practices report a 40% reduction in customer complaints, highlighting the tangible benefits of prioritizing quality in vendor selection.Compliance: Confirm that suppliers comply with pertinent international standards and regulations, particularly vital in sectors such as aerospace and electronics where precision is paramount.

The company, for example, ensures compliance with rigorous standards in their Mica Tapes, reinforcing their reliability and customer-centric approach.Cost Competitiveness: While keeping an emphasis on excellence, it is essential to evaluate cost structures.

Domadia provides competitive pricing without sacrificing standards, making it a valuable option for procurement managers. This cost-effectiveness, combined with their dedication to excellence, guarantees that you receive the best value for your investment.

Conduct thorough comparisons of pricing while ensuring that the integrity of quality is not sacrificed.

By applying these criteria, procurement managers can effectively curate a shortlist of invar 36 suppliers that are capable of delivering high-quality materials tailored to their specific operational demands. Additionally, insights from market volume and value analysis by certification, industry, and region can further inform the decision-making process.

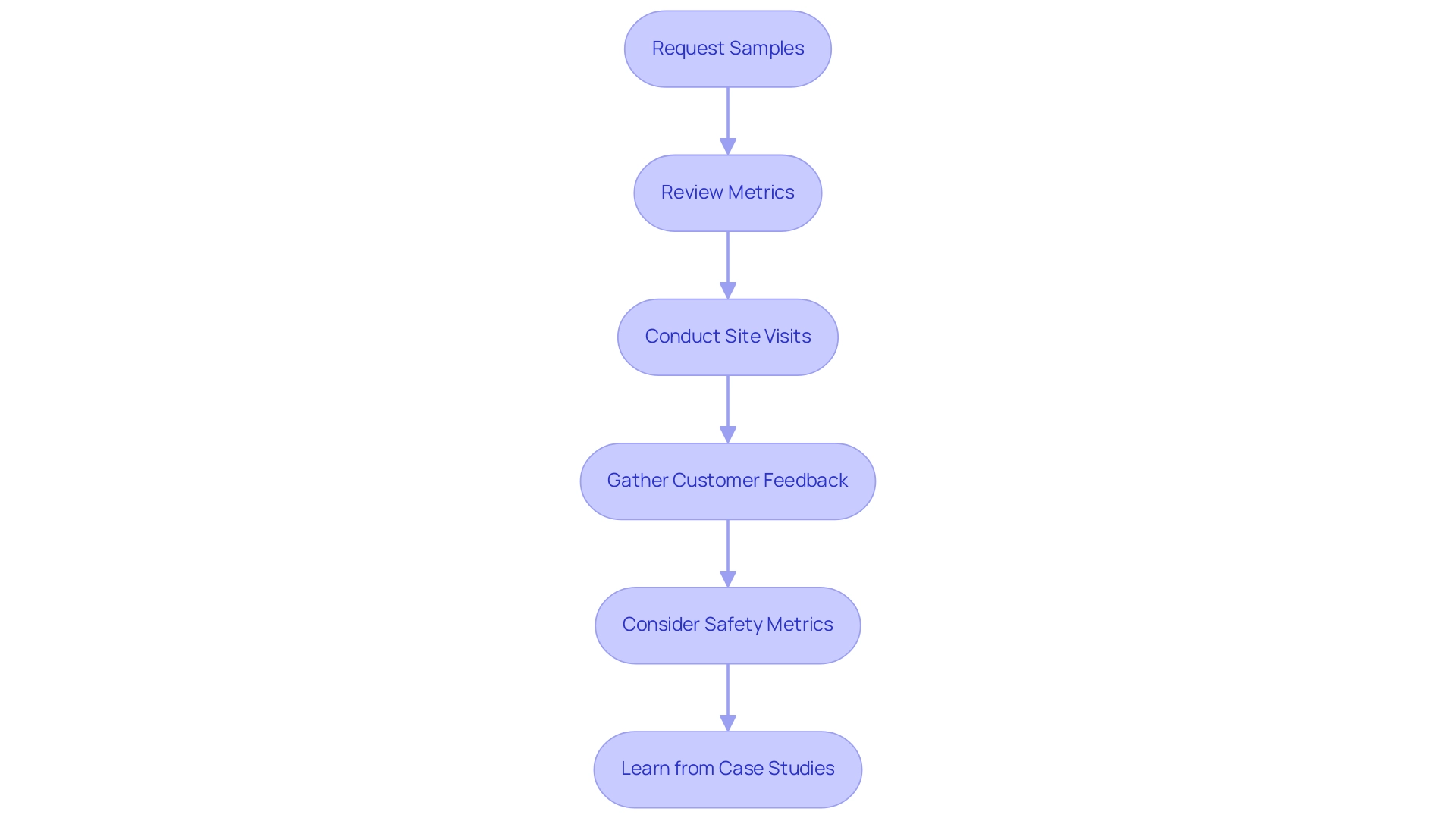

Evaluating Supplier Capabilities and Performance

To effectively assess provider capabilities and performance for Invar 36, a systematic approach is essential. By selecting this Mica Tape provider, you acquire not only an outstanding product but also a partner committed to fostering your business’s growth through dependable and genuine service. Here are key steps to take:

Request Samples: Engage potential vendors, including Domadia, by requesting samples of Invar 36. This initial step allows for a direct assessment of material quality, enabling you to evaluate compliance with specifications and functioning under relevant operational conditions.

Review Metrics: It is crucial to analyze suppliers’ metrics, such as on-time delivery rates, defect rates, and responsiveness to inquiries. For instance, this company has consistently achieved a 98% on-time delivery rate, reflecting their reliability and commitment to maintaining high-quality standards. Tracking delivery performance by monitoring the number of orders delivered on time versus late is vital for procurement decisions.

Conduct Site Visits: Whenever feasible, organize site visits to manufacturers’ production facilities, including those of Domadia. Observing their processes, control measures, and overall operational capabilities provides invaluable insights and reassurance regarding their competencies. As Soren Kaplan, Co-Founder of upBOARD, aptly stated, > Digitize your manufacturing process 10x faster at one-tenth the cost <—an indicator of the efficiencies you might witness during such visits.

Gather Customer Feedback: Collecting feedback from other customers who have interacted with the vendors can offer a broader perspective. This can be accomplished through references or active participation in industry forums. For instance, numerous clients of Domadia have commended their responsive customer service and dedication to excellence, greatly influencing your evaluation of reliability and service standards.

Consider Safety Metrics: Incorporating health and safety incidence rates into your evaluation process is crucial, as it reflects the provider’s commitment to maintaining a safe working environment. The health and safety incidence rate is calculated as (# of OSHA-recorded injuries and illnesses X 200,000) / total employee hours worked, which can provide insight into the operational risks associated with a supplier.

Learn from Case Studies: Reference real-world challenges in measuring vendor quality, such as those faced by manufacturing managers due to variability between vendors and data accuracy issues. Customizing metrics for each provider and automating data collection can mitigate these challenges and improve decision-making.

Incorporating these steps into your procurement strategy not only enhances your evaluation process but also optimizes your decision-making when selecting partners for Invar 36, ensuring that you collaborate with organizations like Domadia that are committed to your success.

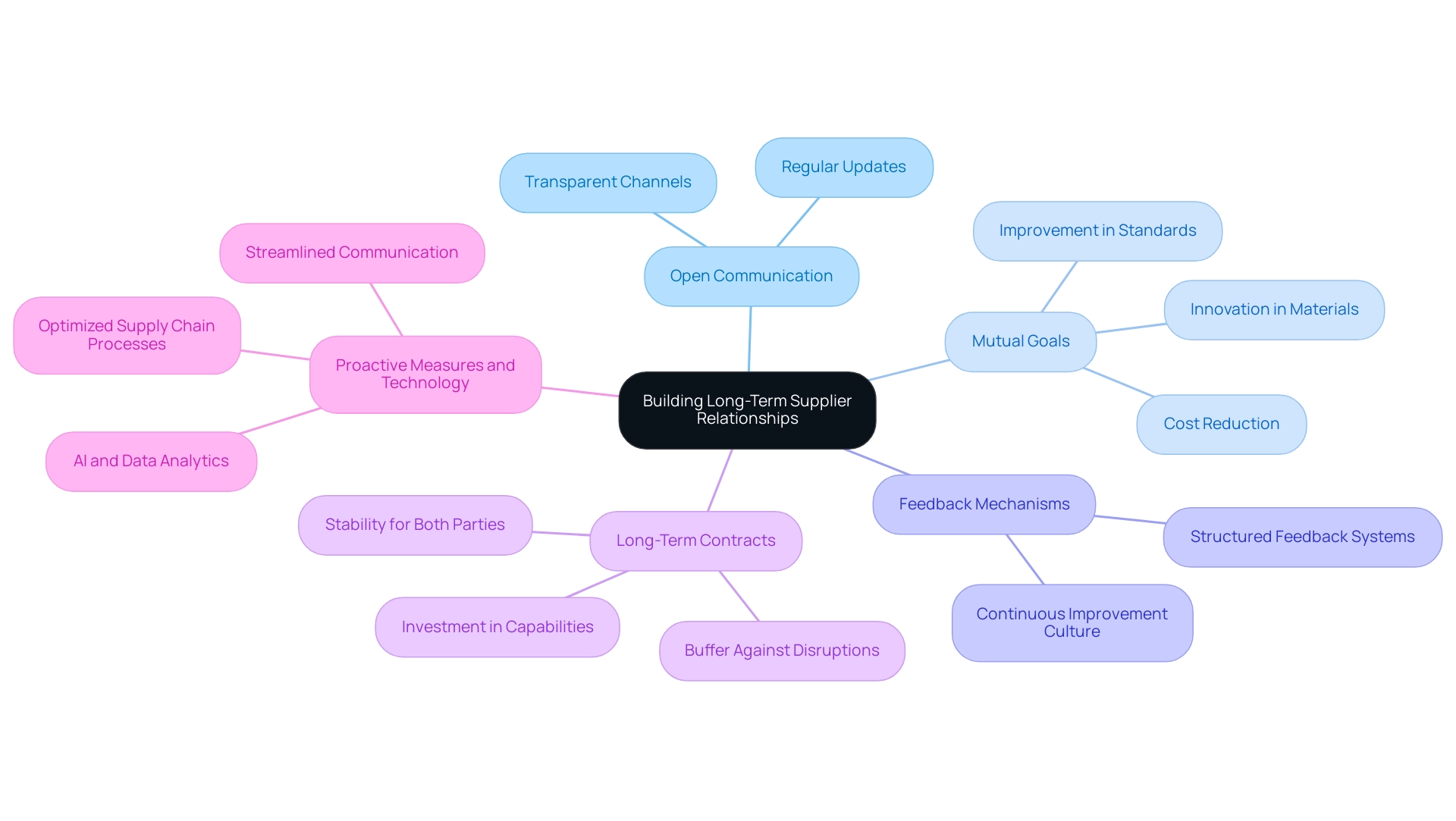

Building Long-Term Supplier Relationships

To cultivate enduring relationships with Invar 36 suppliers, implement the following strategies:

Open Communication: Prioritize establishing transparent communication channels with vendors. This fosters trust and ensures that expectations, challenges, and collaborative opportunities are regularly addressed. Consistent dialogue not only mitigates misunderstandings but also enhances problem-solving capabilities.

Mutual Goals: Align your objectives with those of your vendors. Collaborate to achieve common objectives such as cost reduction, improvement in standards, and innovation in materials. By fostering a sense of partnership, both parties can drive improved outcomes that benefit the entire supply chain. Just as the company emphasizes building strong relationships with its clients through reliable and sincere services, your organization should seek similar partnerships with Invar 36 suppliers. For instance, Domadia has helped clients reduce material costs while improving quality through innovative solutions, demonstrating the value of collaboration.

Feedback Mechanisms: Develop structured feedback systems to assess vendor performance continually. Providing constructive feedback encourages a culture of continuous improvement, reinforcing the partnership and ensuring that both parties adapt to changing market demands.

Long-Term Contracts: Engage in long-term agreements with key partners, which can create stability for both sides. This approach motivates providers to invest in their capabilities and services, ultimately enhancing the reliability of the supply chain. Given the recent trends in supply chain resilience, including a reported 55.6% of businesses identifying cybersecurity as a top concern according to the Business Continuity Institute’s Supply Chain Resilience Report 2023, long-term commitments can also provide a buffer against potential disruptions. The case study titled “Cybersecurity Concerns in Supply Chains” highlights that businesses must prioritize cybersecurity to maintain supply chain integrity. Domadia’s commitment to supporting businesses includes offering guidance on best practices for cybersecurity, further underscoring the importance of these long-term relationships.

Proactive Measures and Technology: Implement proactive measures and leverage technology, such as AI and data analytics, to enhance vendor relationship management. Utilizing these tools can help anticipate challenges, streamline communication, and optimize supply chain processes.

By adopting these strategies, procurement managers can not only strengthen vendor relationships but also position their organizations for success in a rapidly evolving marketplace. Collaborating with outstanding providers can further enhance this journey, ensuring that you have the support needed for sustainable growth.

Monitoring and Reviewing Supplier Performance

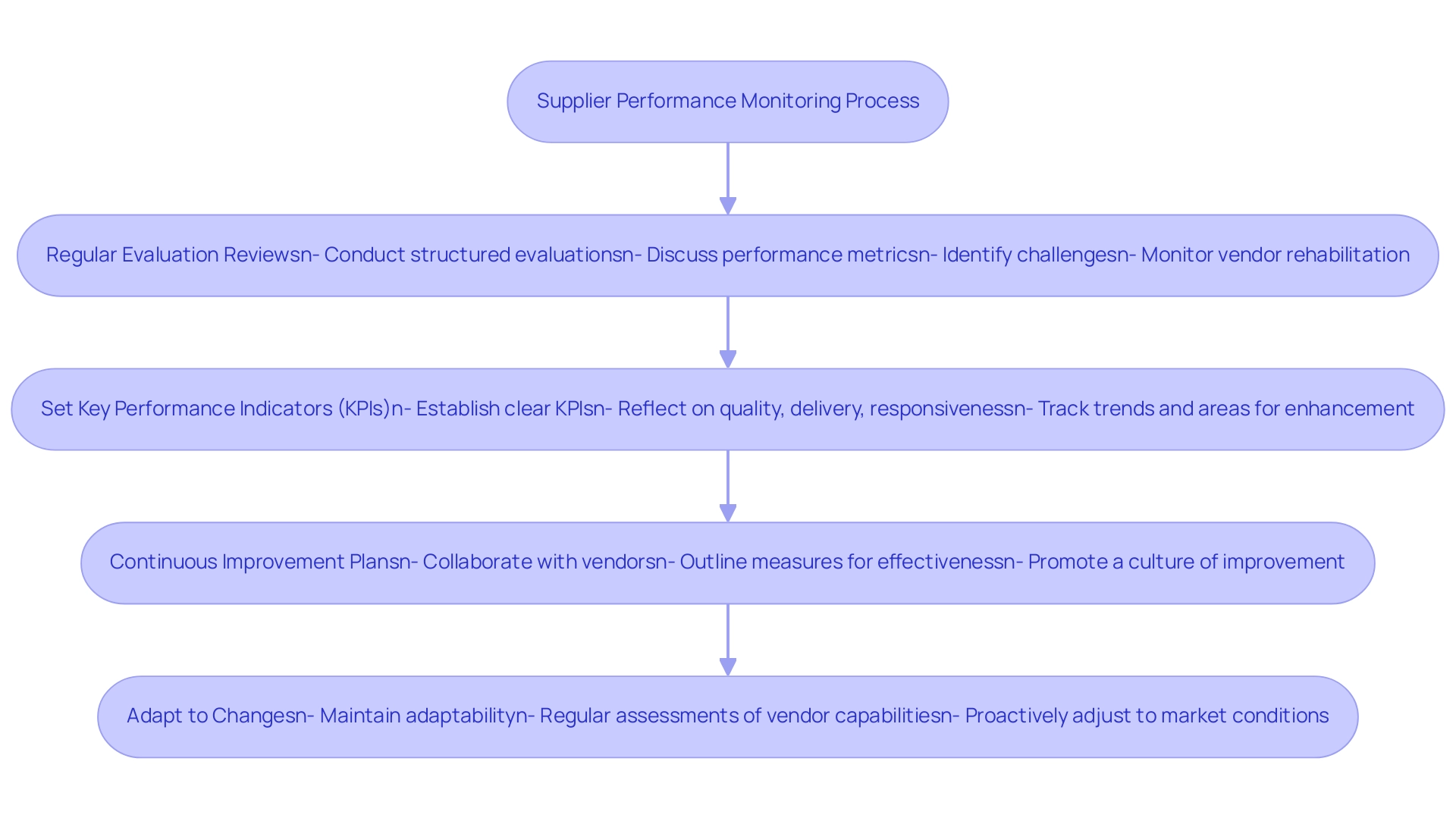

To effectively oversee and assess vendor results, procurement managers should adopt the following best practices:

Regular Evaluation Reviews: Conduct structured and documented evaluations with partners like Domadia, who are dedicated collaborators in your business’s growth. These sessions should focus on discussing performance metrics, identifying challenges, and exploring opportunities for improvement. Monitoring the number of vendors requiring rehabilitation or replacement is essential, as it highlights the significance of these regular evaluations in upholding a dependable supply chain.

Set Key Performance Indicators (KPIs): Establish clear KPIs that reflect critical areas such as quality, delivery, and responsiveness. The significance of these KPIs can differ across various sectors and providers, such as those specializing in electrical insulation and high-temperature materials, including Mica Tape. Regular assessment against these indicators enables teams to track trends and pinpoint areas needing enhancement. As Hugo Britt notes,Over time, this information can provide a clear indication of their reliability and trustworthiness.

Continuous Improvement Plans: Work collaboratively with vendors to formulate continuous improvement plans. For example, collaborators should outline particular measures focused on bridging gaps in effectiveness and enhancing overall standards, promoting a culture of continuous improvement. Suppliers should demonstrate ambition for growth and innovation, as their improvements are essential for a smooth supply chain and can provide strategic value.

Adapt to Changes: Maintain adaptability in response to shifting market conditions, regulatory changes, or evolving internal requirements. Regular assessments of vendors’ capabilities, such as those offered in the Mica Tape sector, to meet evolving demands are vital, enabling necessary adjustments to be made proactively.

By implementing these practices, procurement teams can enhance vendor performance monitoring, whether collaborating with established partners or new associates, and contribute significantly to the overall efficiency of their supply chains. Domadia’s exceptional Mica Tape products exemplify the quality and reliability that procurement managers should seek in their suppliers.

Conclusion

In summary, the selection and management of Invar 36 suppliers are pivotal for procurement managers aiming to uphold quality and precision in manufacturing. The unique properties of Invar 36, including its exceptional dimensional stability and low thermal expansion, make it a critical material in high-precision industries such as aerospace and instrumentation. Understanding these characteristics is essential for making informed sourcing decisions that meet stringent operational demands.

Selecting reliable suppliers requires a strategic approach that encompasses:

- Quality assurance

- Technical expertise

- Compliance with international standards

By prioritizing these criteria, procurement managers can assemble a shortlist of suppliers who not only meet material specifications but also demonstrate a commitment to excellence and innovation. Furthermore, engaging in thorough evaluations of supplier capabilities, including performance metrics and site visits, can provide deeper insights into their operational strengths and weaknesses.

Building long-term relationships with suppliers is equally important. Open communication, alignment of mutual goals, and structured feedback mechanisms foster a collaborative environment that drives continuous improvement. Additionally, monitoring supplier performance through regular reviews and the establishment of key performance indicators enables procurement teams to adapt to changes and ensure sustained quality over time.

As the landscape of manufacturing continues to evolve, leveraging strategic partnerships with suppliers like Domadia can significantly enhance procurement outcomes. By integrating these best practices into sourcing strategies, organizations can navigate the complexities of the supply chain with confidence, ensuring that they remain competitive in an ever-changing market.