Blogs

How to Use Beryllium Copper to Control Fission Reactions: A Step-by-Step Guide

Introduction

In the realm of advanced materials, beryllium copper stands out as a critical alloy, expertly bridging the gap between high-performance requirements and safety standards in demanding applications. This specialized alloy, known for its exceptional electrical conductivity and impressive tensile strength, plays an indispensable role in sectors such as aerospace and nuclear technology.

As organizations strive to enhance operational efficiency while adhering to stringent safety protocols, understanding the unique properties of beryllium copper becomes essential for procurement managers.

This article delves into the significance of beryllium copper, its pivotal role in fission reaction control, and best practices for selecting the right alloy for specific applications.

With a focus on quality control and supplier management, it provides invaluable insights that equip professionals with the knowledge needed to navigate the complexities of sourcing this vital material.

Understanding Beryllium Copper: Properties and Significance

A specialized alloy mainly made up of a metal and another element, is renowned for its remarkable properties, including exceptional electrical conductivity, high tensile strength, and excellent resistance to wear and corrosion. These attributes render it indispensable in precision-driven applications within the aerospace and nuclear sectors. Notably, DOMADIA Beryllium Copper complies with international standards such as UNS and ASTM, reinforcing its reliability in critical applications.

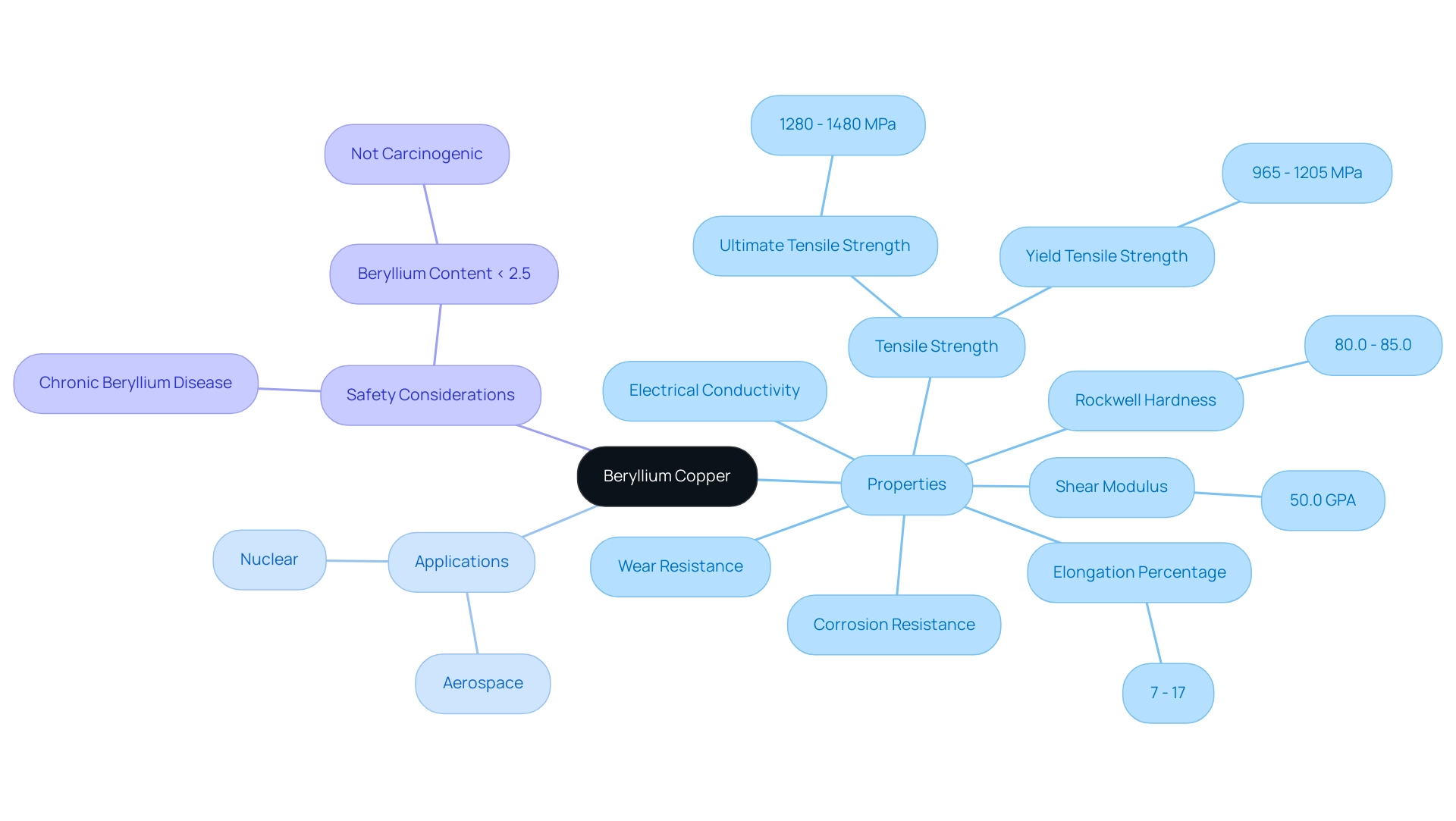

The alloy’s mechanical performance is characterized by:

- Rockwell hardness ranging from 80.0 to 85.0

- Ultimate tensile strength of 1280 to 1480 MPa

- Yield tensile strength of 965 to 1205 MPa

Its capability to endure extreme environmental conditions while preserving conductivity is particularly critical in fission reactors, where it is essential to control fission reaction with beryllium copper and manage heat effectively. Furthermore, with a low elongation percentage ranging from 7% to 17%, this alloy maintains structural integrity under high stress and temperature variations, making it a favored choice for components that demand both durability and performance.

As mentioned by industry specialists, the aerospace sector is increasingly centered on energy efficiency and sustainability, emphasizing the necessity for advanced materials such as a specific alloy that can fulfill stringent performance standards. Furthermore, it is essential to take into account the safety factors linked to beryllium; breathing in beryllium dust, mist, or fumes can result in chronic beryllium disease, highlighting the significance of utilizing beryllium alloys that contain less than 2.5% beryllium, which are not categorized as carcinogens. This information is vital for procurement managers when assessing material options.

The mechanical properties of UNS C17200 metal, including a shear modulus of 50.0 GPA, further reinforce the credibility of its performance claims and underscore DOMADIA’s commitment to high-quality alloy solutions through innovative manufacturing and rigorous quality control. Moreover, our dedication to customer satisfaction ensures that we provide tailored solutions that meet the specific needs of our clients.

The Role of Beryllium Copper in Enhancing Fission Reaction Control

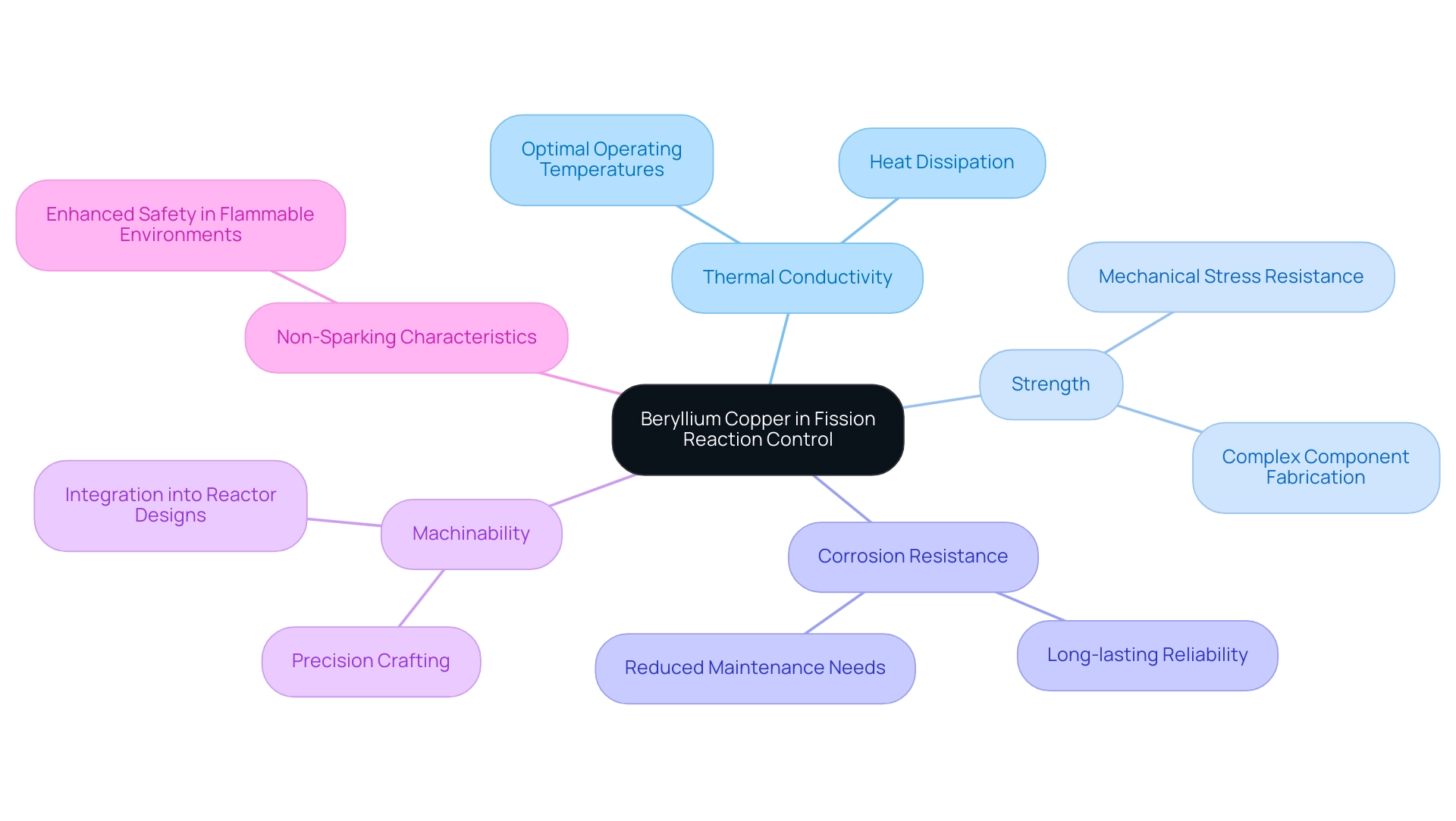

The alloy of beryllium plays a crucial role in the management of fission reactions due to its exceptional thermal conductivity, which enhances heat dissipation in nuclear reactors. This property is essential for maintaining optimal operating temperatures, thereby preventing overheating and reducing the risks of unsafe conditions. The alloy’s inherent strength supports the fabrication of complex components that withstand the mechanical stresses encountered during fission processes.

Combined with its corrosion resistance, this alloy ensures long-lasting reliability, reducing the need for replacements and maintenance interventions. Its machinability allows for precision crafting of components that integrate seamlessly into sophisticated reactor designs, ultimately boosting the safety and efficiency of nuclear energy production. Additionally, the non-sparking characteristics of Copper significantly enhance safety in environments where flammable materials are present.

Recent advancements in technologies that control fission reaction with beryllium copper leverage these properties to enhance reactor performance, underscoring the ongoing relevance of beryllium copper in advancing nuclear applications. Procurement managers can depend on Domadia’s high-quality, customized Copper Plates, backed by expert support, to ensure project success. Domadia is dedicated to offering clear pricing and upholding a strong inventory of Copper products, which is vital for satisfying the needs of nuclear technology applications.

For additional insights into best practices in sourcing this alloy, procurement managers can refer to the case study titled ‘Sourcing This Alloy: Best Practices for Procurement Managers’, which emphasizes the importance of identifying reputable suppliers and adhering to international standards, ensuring the reliability and quality of procurement.

Selecting the Right Beryllium Copper Alloy for Fission Applications

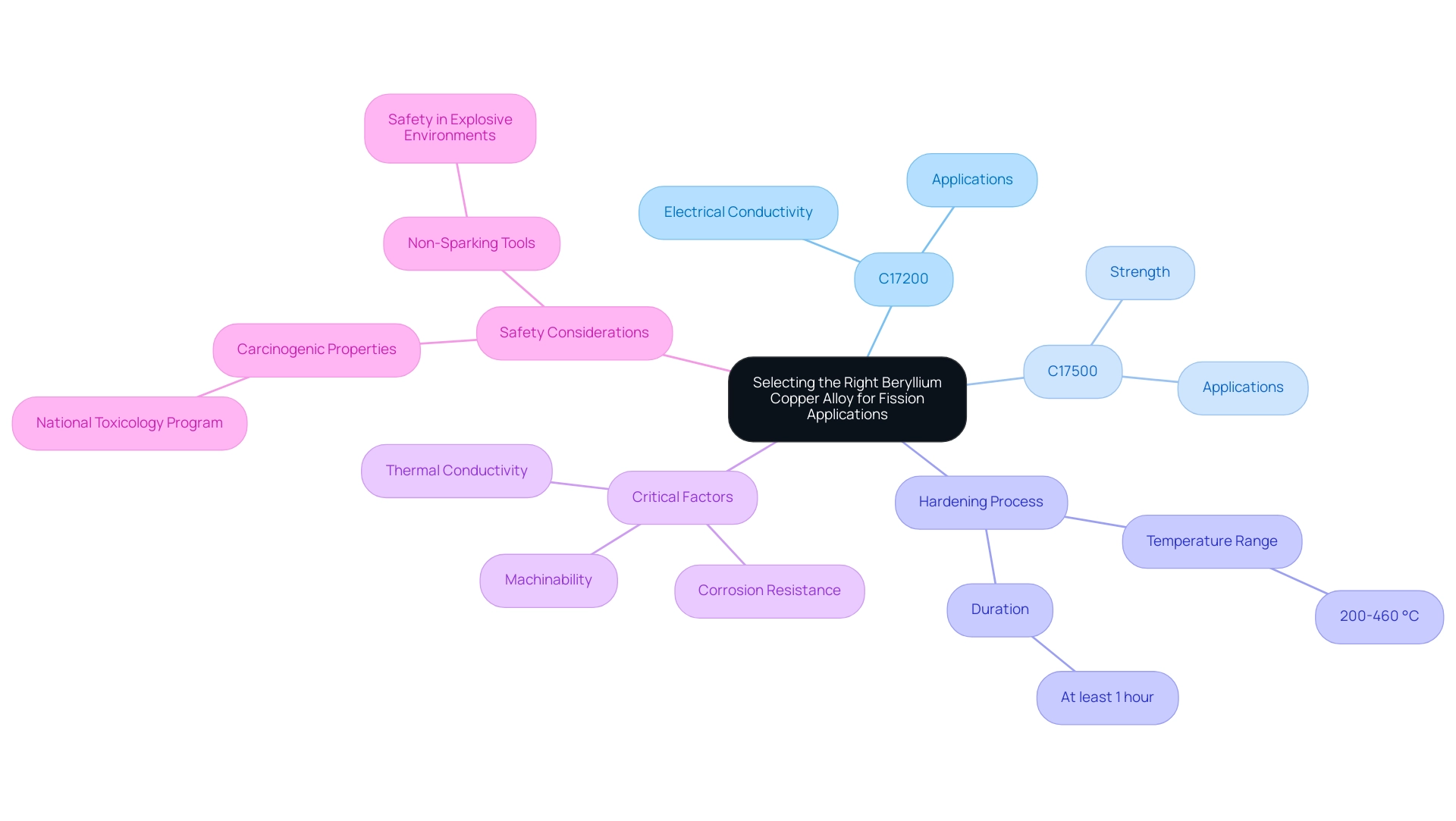

Choosing the suitable alloy to control fission reaction with beryllium copper for fission applications necessitates a comprehensive grasp of the reactor design and its operational parameters. Among the commonly utilized grades, C17200 and C17500 stand out for their distinct properties.

- C17200 is renowned for its superior electrical conductivity, making it ideal for components that demand high electrical performance.

- C17500 boasts enhanced strength, rendering it suitable for high-stress applications.

Additionally, the hardening process for these alloys involves maintaining the metal at 200-460 °C for at least an hour, which is crucial for achieving their optimal properties. When making your selection, it is essential to evaluate critical factors such as:

- Thermal conductivity

- Corrosion resistance

- Machinability

These attributes are crucial to control fission reaction with beryllium copper and significantly influence performance and longevity in nuclear environments.

In explosive potential environments, utilizing Non-Sparking Tools is vital for ensuring safety and compliance. These tools are crafted from materials that prevent sparks during use, significantly reducing the risk of ignition in volatile settings. Their ergonomic design and robust construction enhance usability while ensuring reliability in sensitive industries. Domadia stands as your trusted partner for Beryllium Copper solutions, offering an extensive product range that includes both non-sparking tools and customizable options designed to help you control fission reaction with beryllium copper to meet your specific needs.

Significantly, copper’s non-magnetic qualities also make it suitable for down-hole wireline tools, further broadening its application context in nuclear technology.

Furthermore, it is important to recognize that this element is classified as a carcinogen by the National Toxicology Program, underscoring the need for safety considerations in procurement decisions. Engaging with suppliers to acquire material certifications and ensuring adherence to international standards is paramount, as this diligence is vital for maintaining safety and operational effectiveness within the nuclear sector. Additionally, Beryllium Copper tools are ideal for use in explosive environments due to their excellent corrosion resistance, durability, outstanding thermal and electrical conductivity, and ability to control fission reaction with beryllium copper.

Best Practices for Procurement and Supply Chain Management

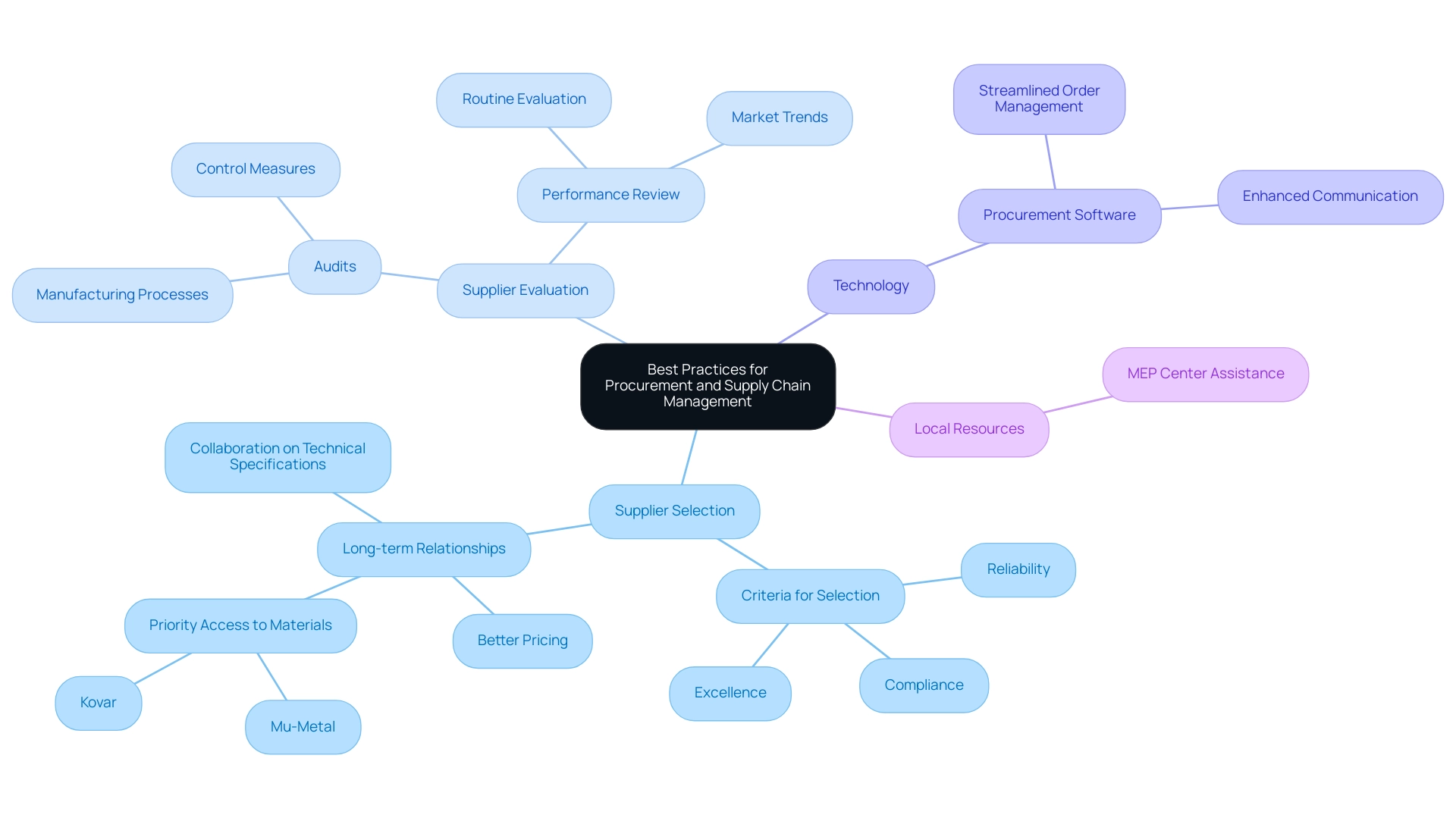

To efficiently enhance the procurement of a specific alloy, it is crucial to set up thorough standards for supplier selection that emphasize excellence, compliance, and reliability. A rigorous evaluation of potential suppliers, including those offering Electrical Insulation Paper and High-Temperature Fabrics, should consist of detailed audits of their manufacturing processes and control measures. Long-term relationships with suppliers not only foster better pricing but also provide priority access to crucial materials, including Kovar and Mu-Metal, and facilitate improved collaboration on technical specifications.

As Joselina Peralta, Founder of STRACTIX, states, ‘In my humble 2 cents, the criteria for partnerships are a function of who you want to be in a long-term commitment. Based on common values, capabilities, and culture, this will drive the best selection process.’ Embracing technology, particularly procurement software, can significantly streamline order management and enhance communication channels with suppliers.

It is also vital to routinely review supplier performance alongside current market trends. This continual evaluation enables the adjustment of procurement strategies, ensuring that your supply chain remains agile and responsive to the evolving demands of the industry. As Art Thomas, who has more than 30 years of experience in manufacturing operations, emphasizes, a proactive approach to supplier management is crucial for sustained success.

Additionally, your local MEP Center can assist in improving the supplier selection process, providing practical guidance that can enhance your procurement strategies.

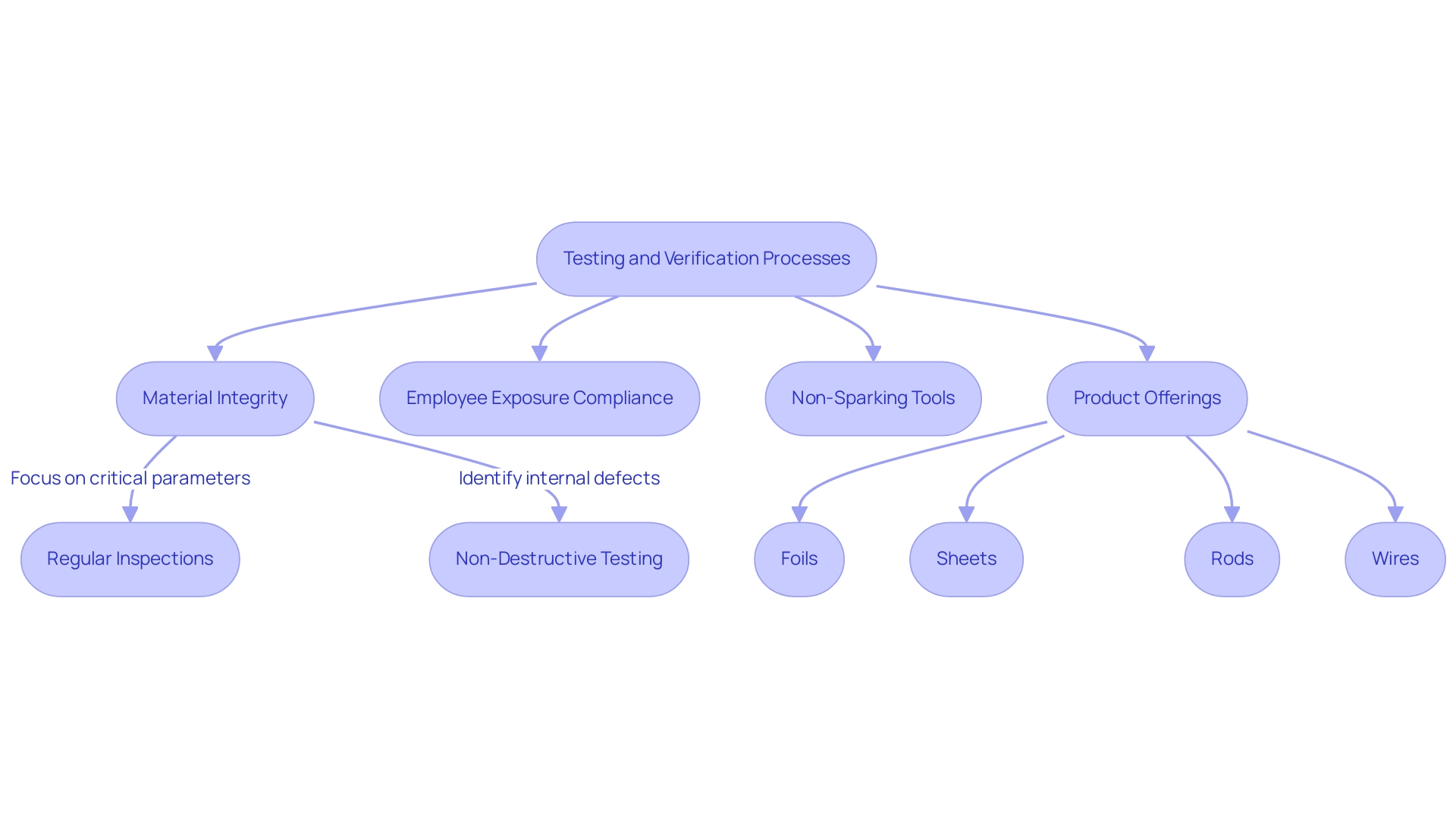

Quality Control Measures for Beryllium Copper in Nuclear Applications

Efficient control measures for copper in nuclear applications requires a comprehensive system of testing and verification processes to ensure material integrity and adherence to industry standards. Employers must demonstrate that employee exposure to beryllium remains below the action level as an 8-hour TWA under any foreseeable conditions, underscoring the importance of safety in control measures. Furthermore, the application of non-sparking tools, particularly Beryllium Copper non-sparking wrenches from Domadia, is critical in explosive potential environments, enhancing safety and reliability in operations.

Domadia offers an extensive product range, including:

- Foils

- Sheets

- Rods

- Wires

with customization options available to tailor solutions to specific project needs. Implementing ISO 9001 establishes a framework for consistent management throughout the supply chain, thereby enhancing overall product reliability. Regular inspections of incoming materials should focus on critical parameters such as:

- Chemical composition

- Mechanical properties

- Surface integrity

to detect any discrepancies.

Additionally, applying non-destructive testing methods, such as:

- Ultrasonic testing

- Eddy current testing

is essential for identifying internal defects that could potentially compromise performance. As OSHA notes, setting a permissible exposure limit (PEL) of 0.1 μg/m for some industries complicates compliance and enforcement, highlighting the regulatory challenges faced by organizations. Maintaining meticulous documentation of all control activities is crucial for facilitating traceability and meeting regulatory requirements.

A case study on exposure monitoring uncovered that different options to adjust periodic monitoring requirements could reduce the annualized cost of compliance by amounts ranging from $4.3 million to $5.0 million, illustrating the real-world implications of effective control measures. By prioritizing these quality assurance measures and partnering with Domadia for your Beryllium Copper solutions, organizations can significantly improve the safety and reliability of components used to control fission reaction with beryllium copper in reactors.

Conclusion

Beryllium copper is an essential alloy for high-performance applications in aerospace and nuclear technology. Its outstanding electrical conductivity, tensile strength, and durability make it critical for precision components. For procurement managers, understanding these properties is vital for effective sourcing while maintaining safety standards.

The alloy plays a key role in fission reaction control by facilitating optimal heat dissipation, thus preventing overheating and ensuring operational safety. Its strength and machinability allow for the production of reliable components that enhance nuclear energy efficiency. Awareness of beryllium exposure safety is crucial, necessitating careful supplier selection and adherence to international regulations.

To optimize procurement, it is important to establish rigorous supplier evaluation criteria and foster long-term partnerships that prioritize quality and compliance. Stringent quality control measures further ensure the integrity of beryllium copper components in critical environments. Through comprehensive testing and verification, organizations can improve operational safety and reliability.

In summary, strategic sourcing of beryllium copper enhances operational efficiency and reinforces safety in demanding applications. A thorough understanding of material properties, combined with best practices in procurement and quality control, empowers organizations to effectively utilize this vital alloy while upholding the highest safety standards.