Blogs

Understanding 0.002 Offset Yield Strength: An In-Depth Tutorial for Engineers

Introduction

In the realm of engineering, the 0.2% offset yield strength emerges as a cornerstone in material selection and structural integrity. This essential metric not only delineates the point at which materials transition from elastic to plastic deformation but also serves as a critical guide for engineers tasked with ensuring safety and performance across various applications.

From the automotive industry to aerospace engineering, understanding the implications of yield strength is paramount, influencing design choices that can mean the difference between success and failure. As advancements in testing methodologies continue to evolve, procurement professionals must stay abreast of these developments to make informed decisions that uphold the highest standards of quality and reliability.

This article delves into the intricacies of 0.2% offset yield strength, exploring its significance, measurement techniques, and practical applications in modern engineering practices.

Defining 0.002 Offset Yield Strength: Key Concepts and Importance

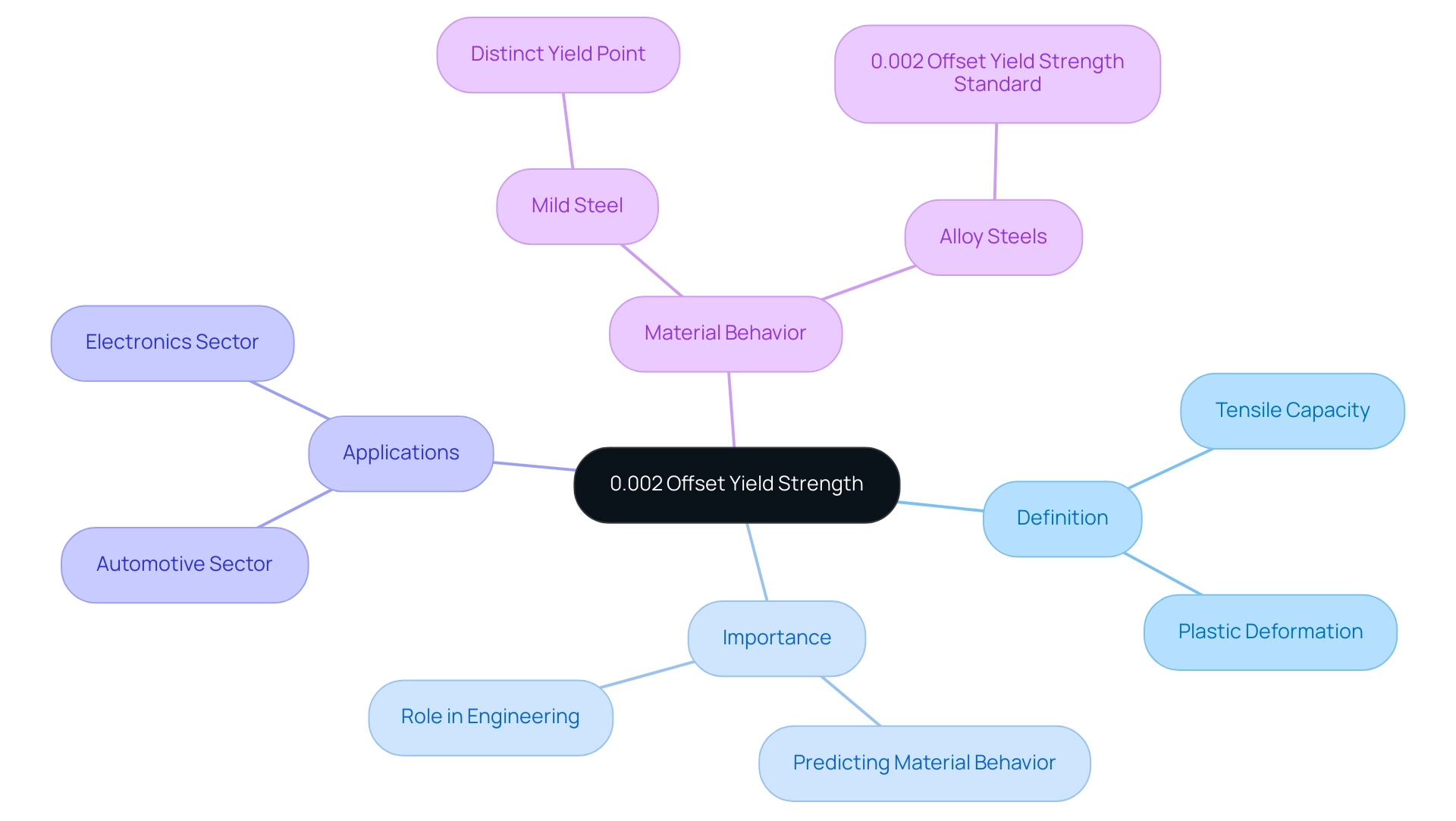

The 0.2% deviation tensile capacity is defined as the stress at which a substance shows a specified level of plastic deformation, quantified as 0.002 (or 0.2%). This critical measure assists engineers in predicting how substances will behave under load, ensuring that structures and components can endure operational stresses without succumbing to failure. Significantly, the 0.2% offset is the most prevalent adjustment for tensile properties, emphasizing its importance in testing substances.

The importance of tensile capability goes further than just a simple property; it plays a crucial part in choosing substances across different sectors, especially in automotive and electronics, where safety and performance are essential. For example, the tensile test uncovers significant engineering characteristics of substances, including resilience and ductility, through a uniaxial tensile assessment. The stress-strain curve varies based on the metal tested and temperature, showcasing different yielding behaviors for mild steel and alloy steels.

- Mild steel shows a distinct point of deformation, whereas alloy steels employ the 0.002 offset yield strength as a standard for performance, which is essential for designing steel frameworks and pressure containers.

- Comprehending tensile capacity not only guides design decisions but also emphasizes the importance of thorough testing and assessment, particularly since the elastic limit indicates the highest stress that can be applied to a substance without causing plastic deformation. This limit is particularly relevant when considering the yielding behaviors of different substances.

Recent advancements in measurement techniques for output resilience further enhance the accuracy and reliability of these assessments, making it essential for procurement professionals to stay informed about evolving standards and methodologies.

Determining 0.002 Offset Yield Strength: Methods and Calculations

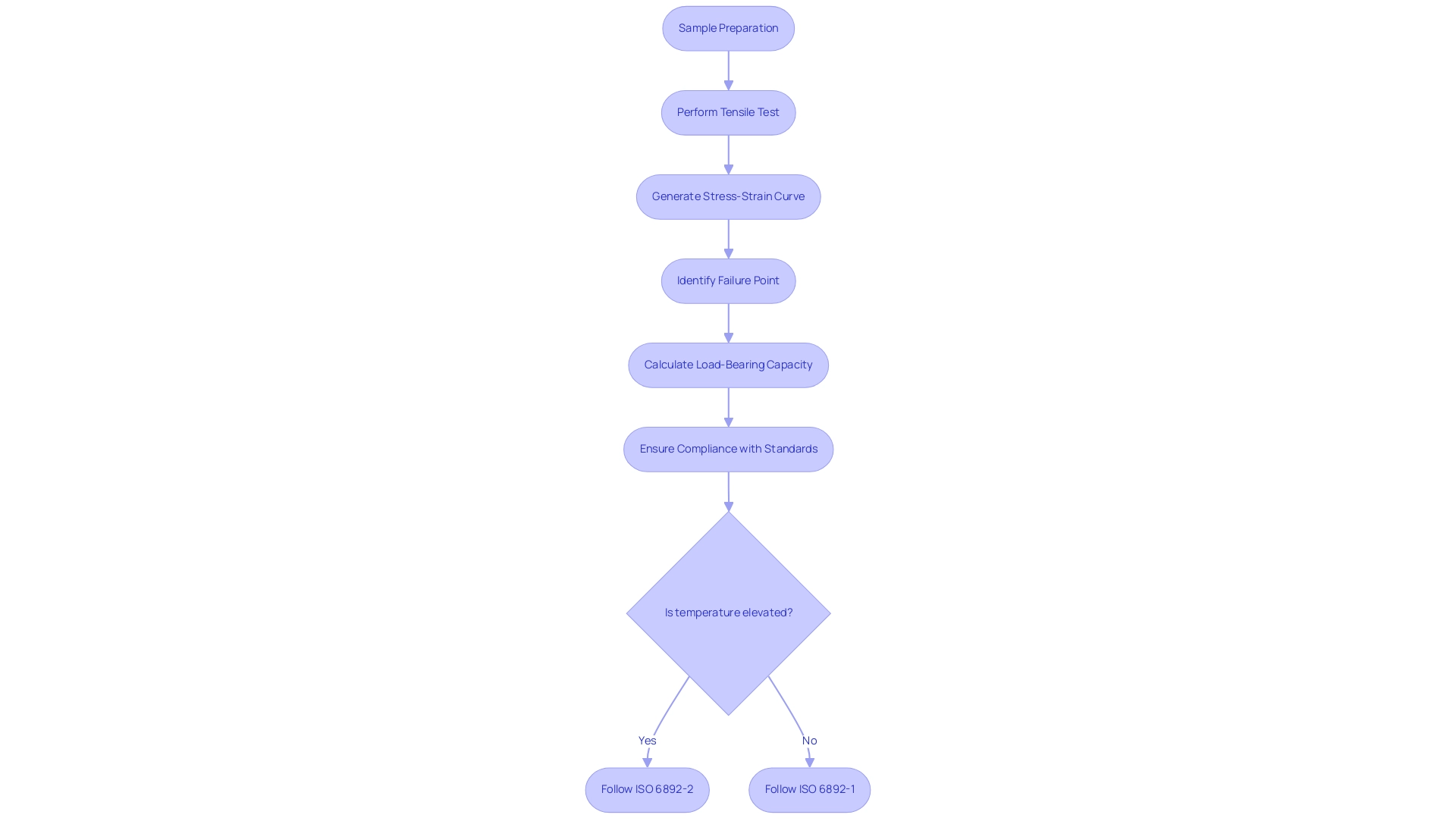

Establishing the 0.002 offset yield strength involves performing a tensile test, where a sample material, such as Mica Insulation Tape, is subjected to a carefully controlled tensile load until it shows deformation. This process produces a stress-strain curve, which facilitates the recognition of the failure point at the moment where the curve diverges from linearity, corresponding to the 0.002 offset yield strength. The load-bearing capacity can be quantitatively determined using the formula:

- Load-Bearing Capacity = Load at Limit / Cross-sectional Area.

To achieve accurate results, it is imperative to adhere to established testing standards such as ASTM E8 and ISO 6892, which outline specific requirements for specimen preparation, testing conditions, and methodologies for tensile testing. Notably, ISO 6892-1 ensures consistency and reliability in determining mechanical properties at ambient temperature, while ISO 6892-2 is required for evaluating metal mechanical properties at elevated temperatures, emphasizing the critical nature of compliance to obtain precise measurements of 0.002 offset yield strength.

High-grade substances such as Mica Tape, recognized for their excellent insulation characteristics, flame resistance, and dielectric capability, are essential in electrical engineering applications, especially in the production of fire-resistant cables and other vital insulation systems, ensuring safety and performance during testing.

As emphasized by Instron, ‘Thousands of customers around the globe depend on Bluehill Universal ® to assess their substance to ISO 6892-1,’ which highlights the significance of standardized testing in the procurement and quality assurance processes. Furthermore, the case study on ISO 6892-2 illustrates how tensile testing methodologies differ at elevated temperatures, providing practical insights into the application of these standards.

The Role of 0.2% Offset in Engineering Material Properties

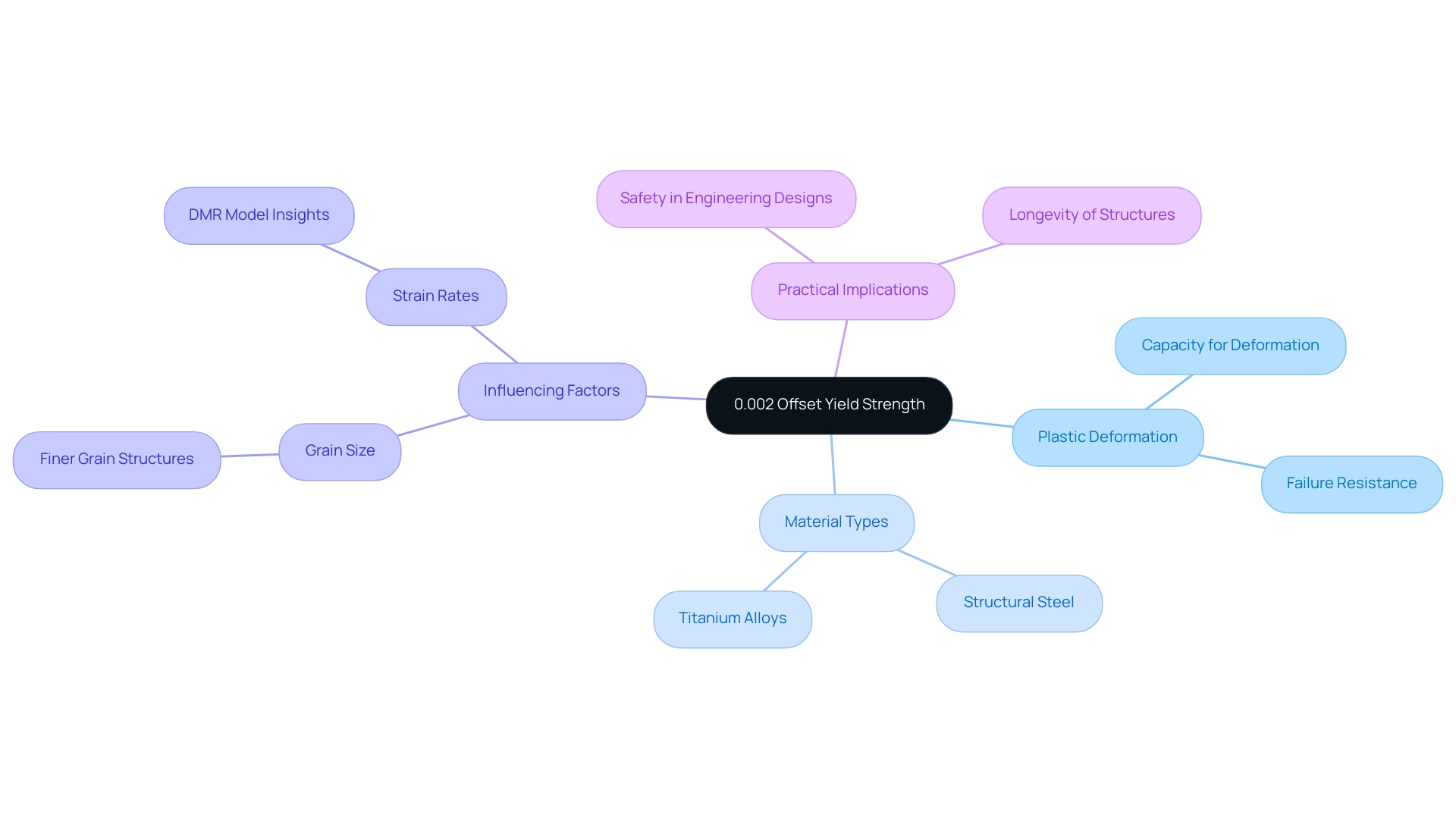

The 0.002 offset yield strength serves as an essential standard in evaluating a substance’s capacity for plastic deformation before it breaks. This measurement of the 0.002 offset yield strength is essential for engineers as it directly affects how substances will respond under various loading conditions. For example, substances demonstrating high tensile capacities, such as structural steel and specific titanium alloys, can support substantial loads without deformation, which is crucial in structural applications.

This capability not only enhances the safety of engineering designs but also contributes to their longevity. Insights from experts in the field underscore this point, with Jayakumar C.K. Mukhopadhyay claiming that comprehending load capacity is essential in substance selection for engineering uses.

Recent studies published in Heliyon emphasize that the variability in average grain size greatly influences tensile capacity, with data showing that finer grain structures result in enhanced tensile capacity in engineering substances. Additionally, the DMR model illustrates how strain hardening effects are precisely characterized under different strain rates, emphasizing the practical significance of failure resistance in real-world situations. As we persist in enhancing our comprehension of these characteristics, the significance of the 0.002 offset yield strength remains crucial in ensuring optimal performance of the substance, particularly concerning the structural parameters that affect flow stress.

Comparing Yield Strength Measures: 0.2% Offset vs. Other Methods

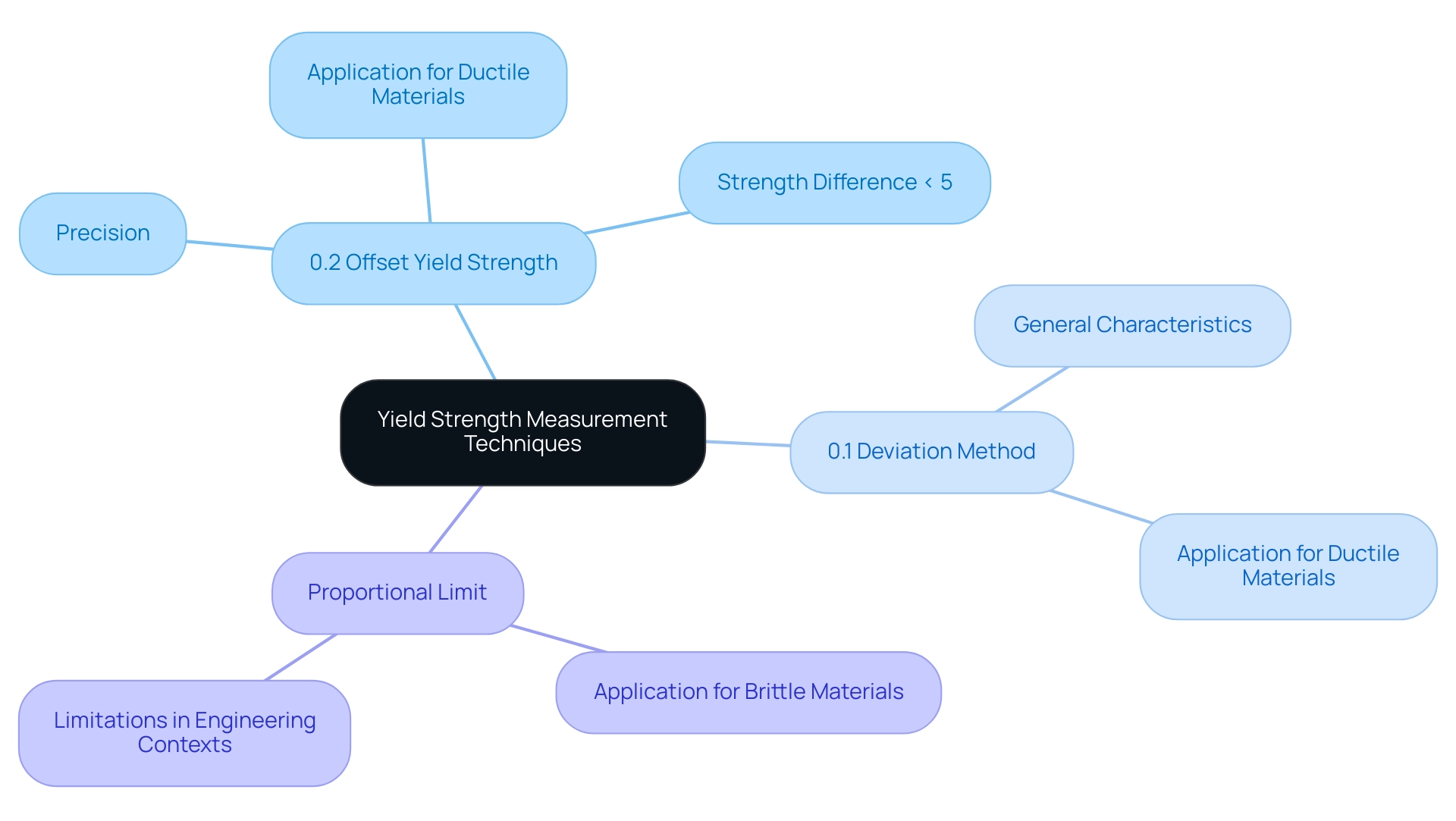

Yield strength can be evaluated through several measurement techniques, including:

- The 0.002 offset yield strength method

- The 0.1% deviation method

- The proportional limit

Among these, the 0.2% adjustment technique distinguishes itself for its capacity to balance precision and practicality, especially when working with ductile substances. This approach has gained traction due to its effectiveness in delivering reliable results, which is crucial for sectors where performance under stress is paramount.

Significantly, a suggested approach to enhance the assessed accuracy of strength indicates a strength difference of less than 5% for steels exhibiting Leaders behavior, emphasizing the precision of the 0.002 offset yield strength method. Conversely, the proportional limit method is often utilized for brittle substances; however, its application in engineering contexts can be limited due to inherent variability. A comparative study of statistical methods highlights the nuances in yield stress analysis, as noted by A. Abu-Sinna, who remarked, “A comparative study of statistical methods used in analyzing the proficiency testing results of yield stress”.

Understanding these distinctions is essential for engineers, enabling them to make informed decisions regarding the most suitable method for their material testing needs. This consideration is especially vital in areas like aerospace and automotive, where, as demonstrated in the case study titled ‘Evaluating Tensile Properties at Yield Requirements for Different Industries,’ prioritizing optimal tensile values directly affects structural integrity and safety.

Practical Implications of 0.002 Offset Yield Strength in Engineering

The importance of 0.002 offset yield strength in engineering cannot be overstated. This critical parameter directly informs the design process, compelling engineers to choose substances capable of withstanding anticipated loads without yielding. Such considerations are particularly crucial in sectors like automotive and aerospace, where safety remains a top priority.

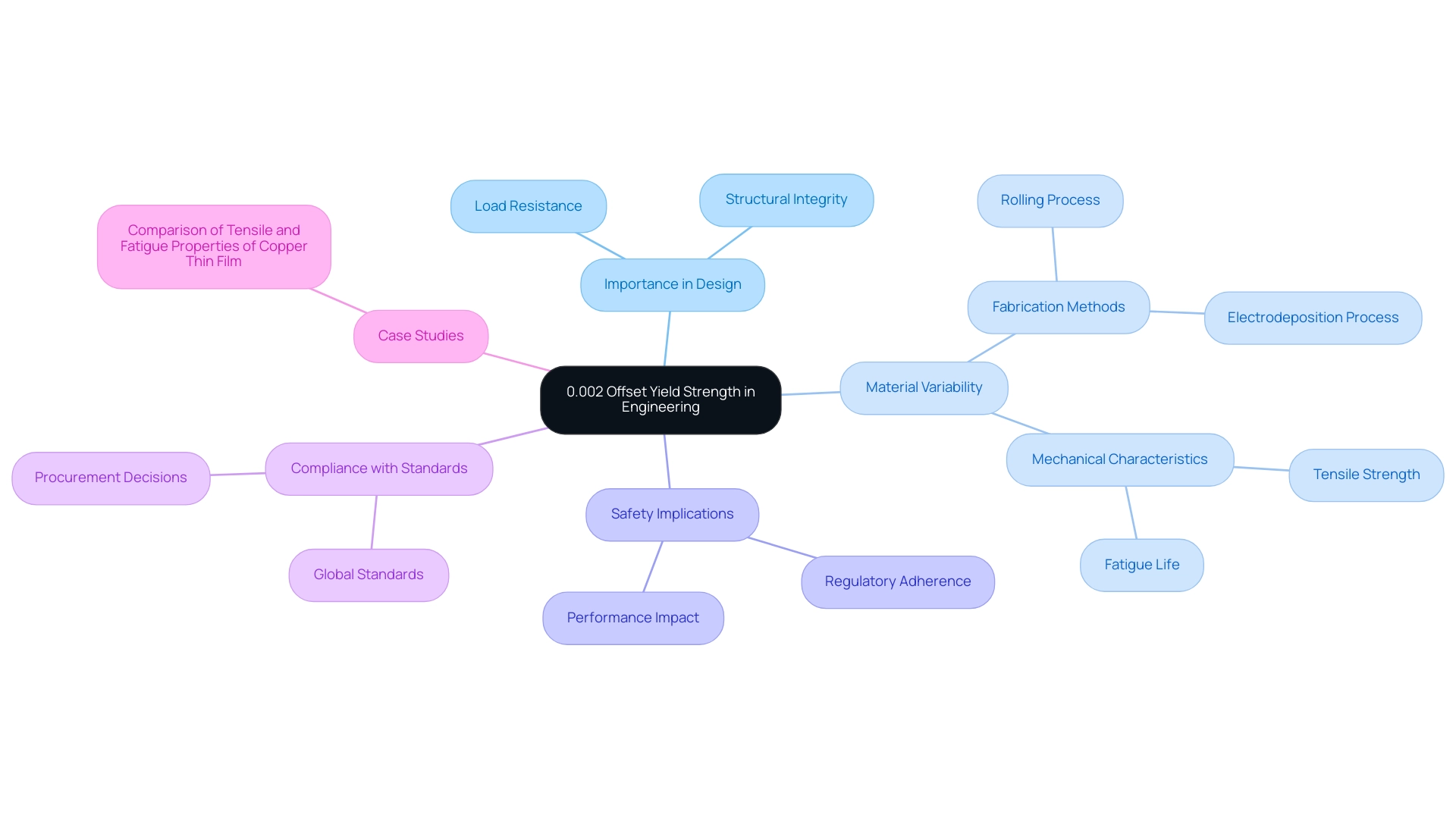

As highlighted in the case study “Comparison of Tensile and Fatigue Properties of Copper Thin Film Depending on Process Method,” the mechanical characteristics of materials, such as copper thin films, can vary significantly based on their fabrication methods, with implications for reliability in applications like flexible printed circuit boards. The research showed that although the elastic modulus was comparable for both rolling and electrodeposition methods, the rolling method produced greater 0.2% stress and ultimate tensile resilience, which is crucial for maintaining structural integrity in engineering design. In the automotive industry, for example, the connection between tensile capacity and structural integrity is crucial, affecting everything from safety performance to regulatory adherence.

Furthermore, comprehending adjusted tensile capability is crucial for complying with global standards, which direct procurement managers in making knowledgeable choices that align with quality and performance criteria. As Sun noted in his work on self-piercing riveting, the practical implications of 0.002 offset yield strength are critical for ensuring safety and efficiency in engineering applications. By grasping the intricacies of this property, engineers can design structures that not only meet but exceed safety and efficiency criteria, ultimately fostering innovation in engineering practices.

This article is listed as number 388 in volume 10, issue 1 of the journal, further supporting the credibility of these findings.

Conclusion

The exploration of 0.2% offset yield strength reveals its fundamental role in engineering and material selection. This critical measure not only signifies the transition point from elastic to plastic deformation but also serves as a guiding principle for engineers across various industries. By understanding yield strength, engineers can predict material behavior under stress, ensuring that structures and components maintain their integrity and safety.

Various methodologies for determining yield strength have been discussed, emphasizing the importance of adhering to established testing standards such as ASTM and ISO. These standards ensure consistency and reliability, enabling procurement professionals to make informed decisions regarding material selection. The comparative analysis of yield strength measurement methods underscores the advantages of the 0.2% offset method, particularly for ductile materials, making it a preferred choice in sectors where performance is critical.

Ultimately, the implications of understanding 0.2% offset yield strength extend beyond theoretical knowledge. They directly influence engineering design processes, safety protocols, and compliance with industry standards. By prioritizing this essential metric, engineers can foster innovation and enhance the safety and durability of their projects. As the industry continues to evolve, staying abreast of advancements in yield strength measurement will remain crucial for maintaining the highest standards of quality and reliability in engineering applications.