Blogs

Understanding Invar Strip: A Complete Tutorial on Properties and Applications

Overview:

The article provides a comprehensive tutorial on Invar strip, highlighting its unique properties such as low thermal expansion and high magnetic permeability, which make it essential in precision engineering applications across various industries, particularly aerospace and electronics. This is supported by detailed discussions on its applications, sourcing best practices for procurement managers, and emerging market trends, emphasizing the alloy’s critical role in maintaining dimensional stability and reliability in high-performance environments.

Introduction

Invar, a unique alloy primarily composed of iron and nickel, stands out for its exceptional low coefficient of thermal expansion, making it a cornerstone in precision engineering and advanced manufacturing. As industries increasingly demand materials that maintain dimensional stability under varying temperatures, Invar’s applications span critical sectors such as:

- Aerospace

- Electronics

- Scientific instrumentation

Coupled with Mica Tape products, known for their impressive electrical insulation and high-temperature resistance, these materials form an integral part of modern engineering solutions. Understanding the intricate properties of Invar and its comparative advantages over other alloys is essential for procurement managers tasked with making informed decisions in sourcing high-performance materials. This article delves into the key characteristics of Invar, its diverse applications, best sourcing practices, and emerging trends that underscore its growing significance in technology and industry.

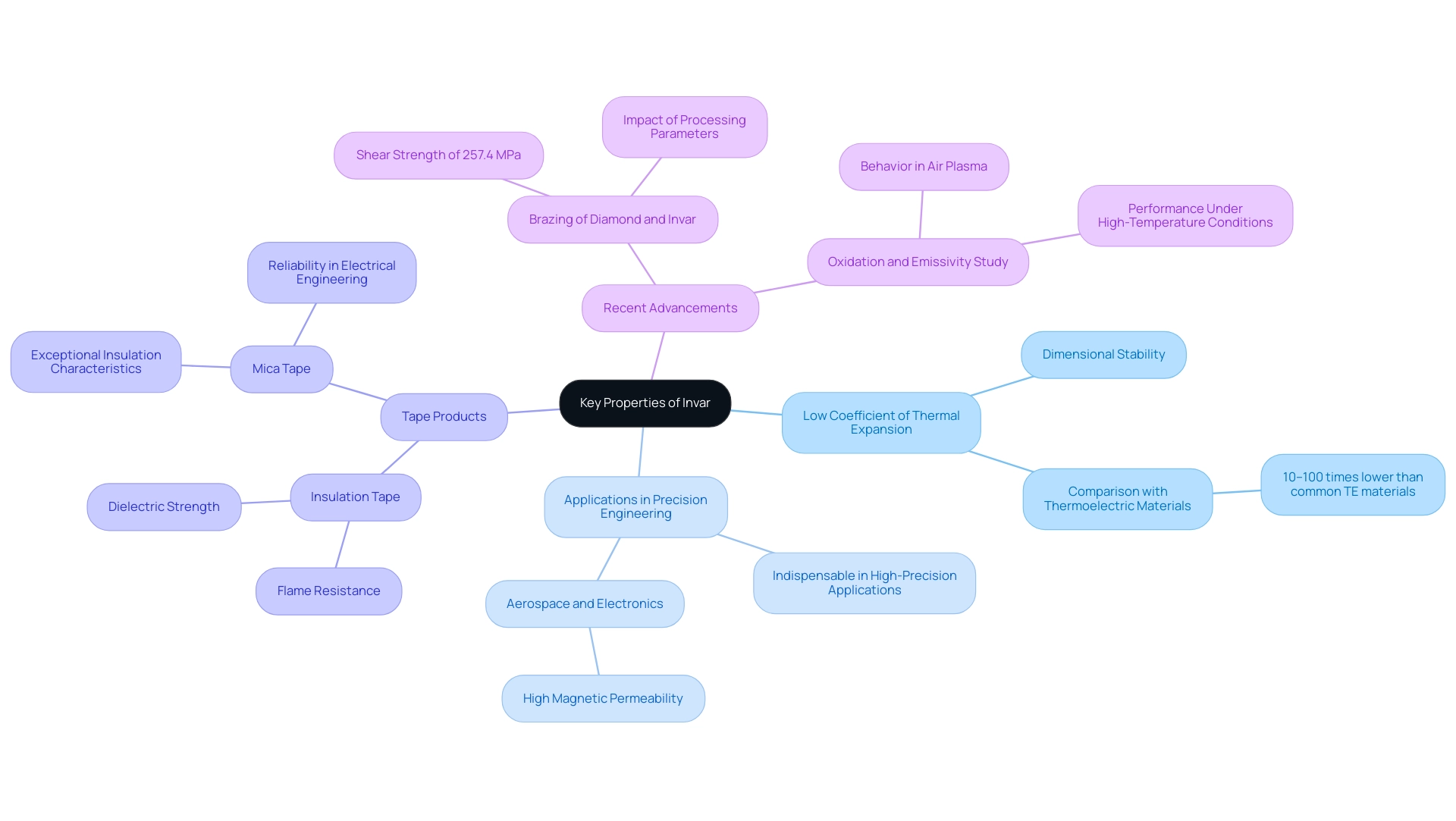

Key Properties of Invar: Understanding Its Unique Characteristics

This alloy, primarily composed of iron and nickel, is distinguished by its remarkably low coefficient of thermal expansion (CTE), which is critical for maintaining dimensional stability across varying temperature conditions. This characteristic makes the invar strip indispensable in precision engineering applications, where even minute changes in size can lead to significant errors. While discussing high-performance substances, it’s essential to also consider Tape products, such as Insulation Tape and Sheet Tape, known for their exceptional high-temperature resistance and electrical insulation properties.

- Insulation tape, for instance, offers excellent flame resistance and dielectric strength, making it crucial in diverse applications—from household appliances to industrial machinery.

- The thermal expansion characteristic of alloy 36, for instance, is approximately 10–100 times lower than that of common thermoelectric materials at room temperature, as noted by M. Rasit Oner during a recent analysis.

- Furthermore, Mica Tape products offer unparalleled reliability thanks to their exceptional insulation characteristics, making them perfect for essential uses in electrical engineering.

Recent advancements include the successful brazing of Diamond and a specific alloy using an Ag-Cu-Ti filler, achieving a maximum shear strength of 257.4 MPa at 870 °C for 10 minutes. This emphasizes the alloy’s potential for strong interfacial structures in high-temperature settings. Additionally, the material’s high magnetic permeability enhances its utility in applications that involve magnetic fields, making it a preferred choice in sectors such as aerospace and electronics.

A comprehensive understanding of these properties, including the role of Mica Tapes in electrical insulation, is essential for procurement managers in selecting resources that ensure both stability and reliability in projects subjected to thermal fluctuations.

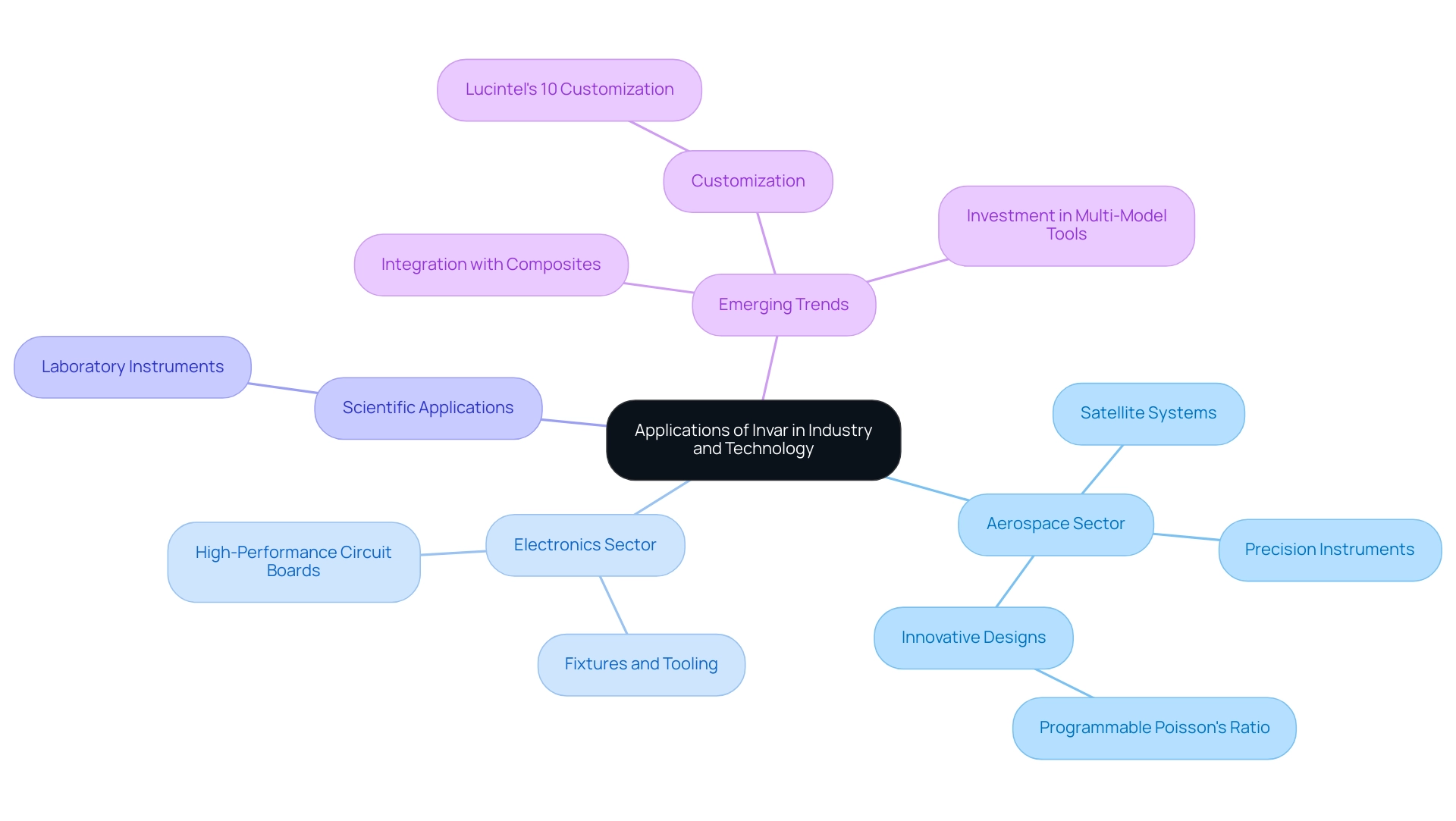

Applications of Invar in Industry and Technology

This alloy, known as invar strip, is a critical material in industries where precision is essential, particularly within the aerospace sector. Its unique properties make it ideal for manufacturing components in satellite systems and precision instruments, where even the slightest dimensional changes can result in catastrophic failures. In 2024, the aerospace sector keeps observing a rise in the utilization of invar strip, with aerospace engineers recognizing its crucial function by stating,

Its low thermal expansion and stability make it essential for high-precision uses.

In the electronics sector, this alloy is widely employed in the production of fixtures and tooling, as well as in the fabrication of high-performance circuit boards. Its stability under varying temperatures is essential in these uses, especially as testing shows that temperatures between 200 °C and 600 °C can induce the coarsening of the γ phase, significantly affecting performance.

Furthermore, the uses of this material span diverse scientific areas, including laboratory instruments that require exceptional precision. As procurement supervisors evaluate resources for their projects, comprehending its varied uses and developing trends—such as the greater integration of it with composite substances—can aid in making informed choices. This strategic method not only improves product quality but also strengthens performance across sectors in aerospace and electronics manufacturing.

Additionally, Lucintel highlights the importance of customization in this sector, stating,

‘Yes, Lucintel provides 10% Customization Without any Additional Cost.’ Furthermore, the case study titled

‘Programmable Poisson’s Ratio in Mechanical Metamaterials’ demonstrates real-world uses of invar strip in aerospace, highlighting how innovative designs can lead to significant advancements in material performance.

Comparative Analysis: Invar vs. Other Alloys

Q1. What makes DOMADIA Nickel Molybdenum Iron Alloy unique?

DOMADIA Nickel Molybdenum Iron Alloy stands out for its exceptional strength, corrosion resistance, and thermal stability.

These unique features make it perfect for crucial uses across various sectors, including:

- Aerospace

- Automotive

- Petrochemical

- Electronics

- Renewable energy

Its excellent hardness enhances its suitability for demanding applications, showcasing a performance edge in environments where strength and durability are non-negotiable. Unlike substances known for their dimensional stability due to a low thermal expansion rate, DOMADIA provides unparalleled performance in situations where both strength and thermal stability are essential.

This makes it a preferred choice for procurement managers seeking dependable resources for high-precision instruments and components.

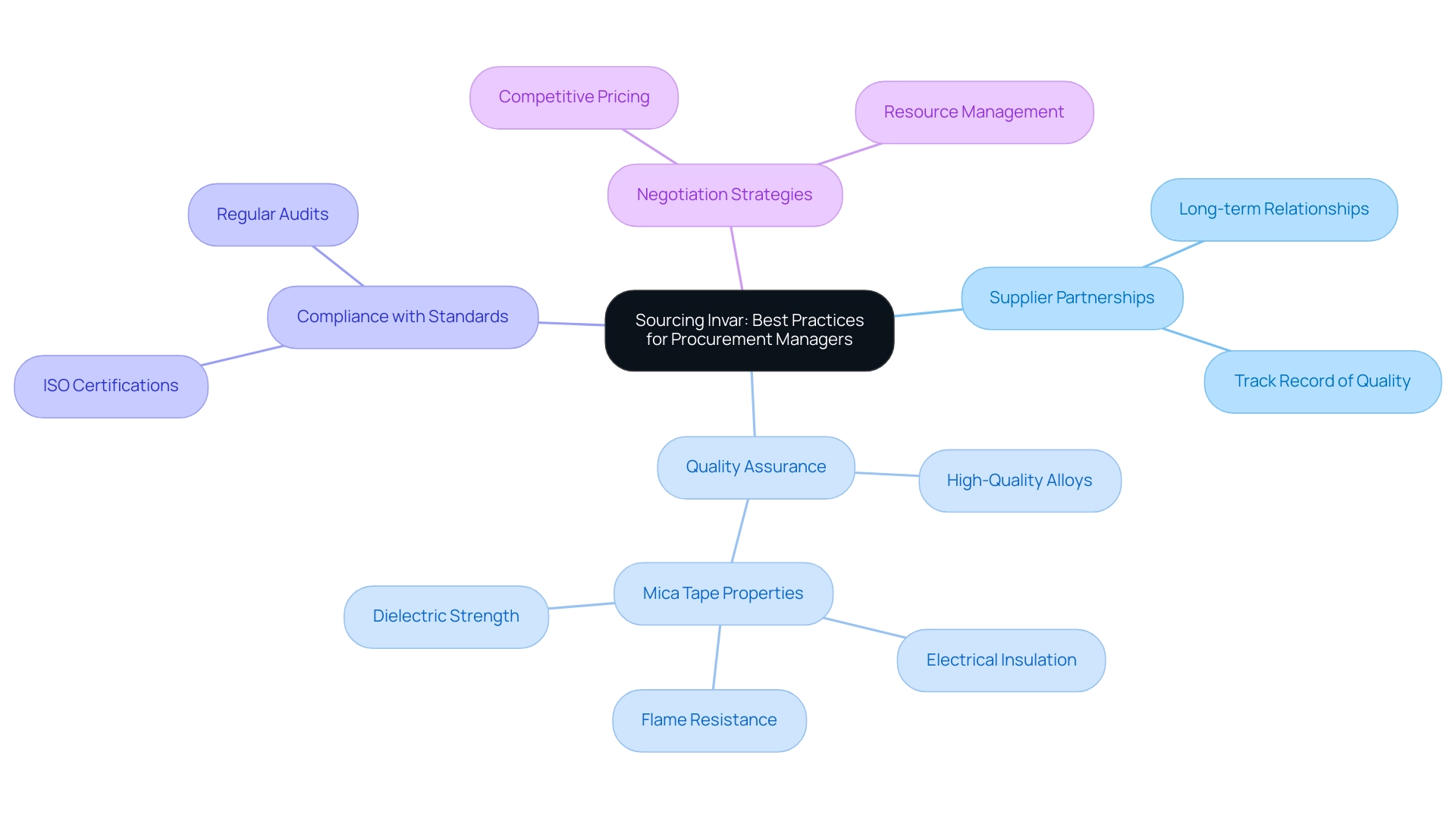

Sourcing Invar: Best Practices for Procurement Managers

In the quest for sourcing invar strip, procurement managers must prioritize partnerships with suppliers that demonstrate a solid track record in delivering high-quality alloys. This involves evaluating providers of electrical insulation substances, like Domadia’s Tape products, which are essential for uses needing high-temperature resistance and dependability. Domadia’s Mica Insulation Tape, known for its superior electrical insulation properties, flame resistance, and dielectric strength, can serve as an essential component in various critical applications, from household appliances to industrial machinery.

Long-term partnerships with reliable suppliers not only promote trust but also provide benefits such as competitive pricing, consistent quality, and preferential treatment during times of resource shortages. As Meghan Rexer aptly noted, ‘Juggling inventory, logistics, and technology challenges can be overwhelming.’ This reinforces the critical need for reliable supplier relationships to navigate the complexities of procurement effectively.

Moreover, ensuring that suppliers comply with international standards, particularly ISO certifications, is essential for preserving the integrity of resources. Regular audits and assessments serve as necessary measures to uphold these standards and promote transparency throughout the supply chain. By leveraging strategic partnerships and sourcing high-quality materials like Mica Tape, procurement managers can enhance negotiation outcomes, ultimately improving procurement efficiency.

This approach is especially significant in sectors like aerospace, where the use of invar strip is essential for maintaining dimensional stability under extreme temperature fluctuations, ensuring the accuracy and reliability of components. Therefore, sourcing this material requires a strategic focus on supplier relationships, quality assurance, and adept negotiation practices, enhanced by the exceptional offerings from partners like Domadia.

Future Trends: The Role of Invar in Emerging Technologies

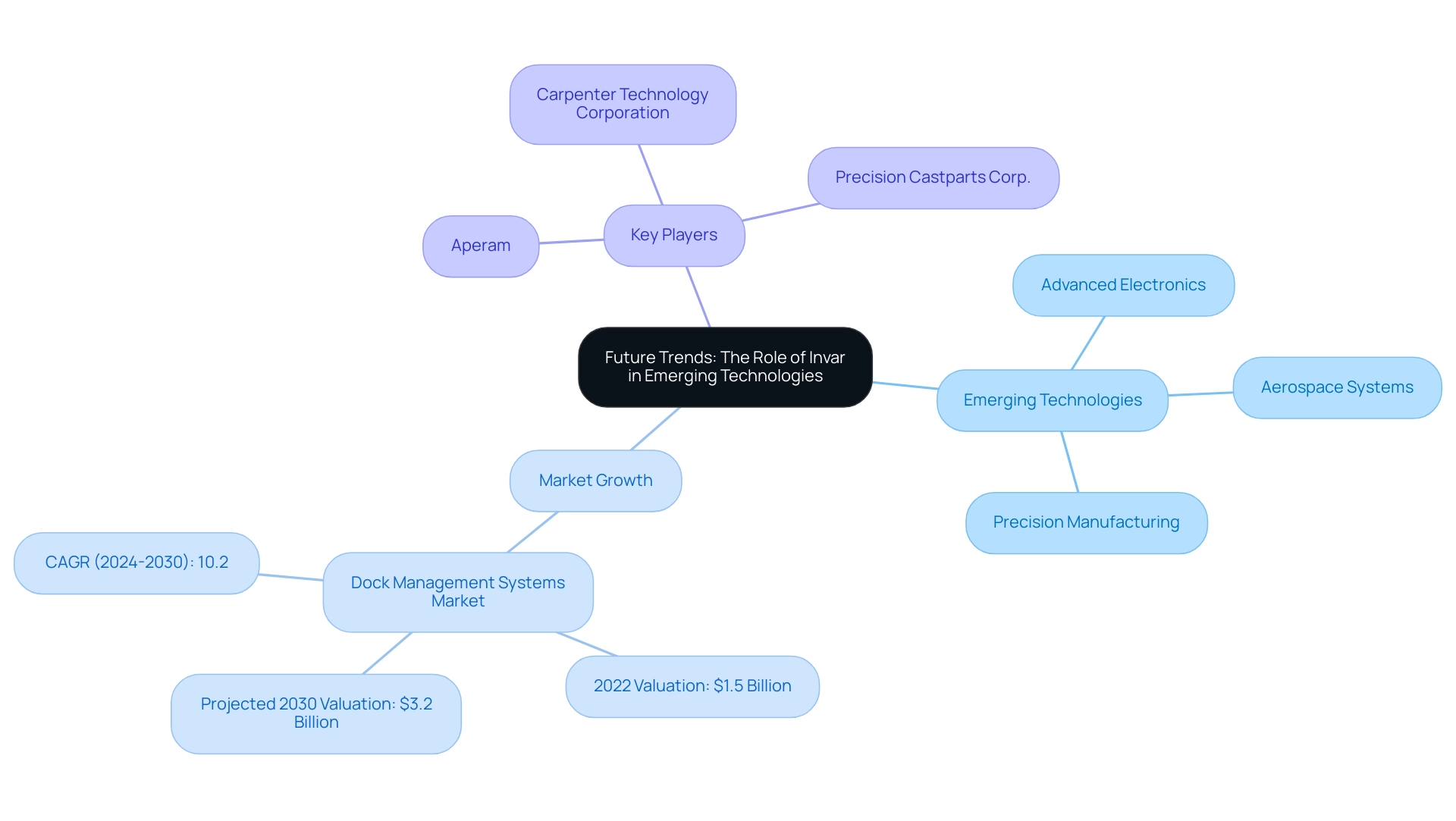

Its unique properties render it a crucial component for the progress of emerging technologies, especially in fields such as advanced electronics, aerospace systems, and precision manufacturing. With the dock management systems market valued at $1.5 billion in 2022 and expected to reach $3.2 billion by 2030, the demand for high-performance substances is set for considerable growth. Key players in the Invar 36 market, including Aperam, Carpenter Technology Corporation, and Precision Castparts Corp., are focusing on innovation and strategic partnerships to meet this growing demand.

Innovations in fields such as quantum computing and high-precision instrumentation underscore the necessity for materials that provide exceptional dimensional stability and reliability. In this context, tape products play a critical role, known for their high-temperature resistance, flame resistance, and superior dielectric strength. These tapes are essential in uses such as fire-resistant cables and insulation systems for advanced technologies.

Tape products not only improve the safety and effectiveness of electrical insulation systems but also enhance a specific alloy in applications demanding high-temperature resistance and electrical insulation. As a representative from a Global Consulting Firm noted, ‘Our company has been working with for some years now and we are very happy with the quality of the reports provided by the company.’ This highlights the significance of obtaining premium substances like certain alloys and minerals in cutting-edge technologies.

As procurement managers navigate these evolving trends, it is crucial to align sourcing strategies with the anticipated surge in demand for materials like invar strip, Mica, and other high-performance options. By staying informed about these developments, procurement professionals can ensure they are strategically positioned to meet the future needs of their organizations.

Conclusion

Invar’s unique properties, particularly its low coefficient of thermal expansion, make it an invaluable asset in precision engineering across various industries, including aerospace, electronics, and scientific instrumentation. The alloy’s ability to maintain dimensional stability under temperature fluctuations ensures that critical components function accurately, mitigating the risks associated with even the slightest changes in size. Coupled with Mica Tape products, which offer excellent electrical insulation and high-temperature resistance, Invar stands at the forefront of advanced manufacturing solutions.

As industries evolve, the applications of Invar continue to expand, particularly in high-stakes sectors where precision is paramount. Procurement managers must recognize the significance of sourcing high-quality materials, emphasizing the importance of partnerships with reliable suppliers that adhere to international standards. By fostering these relationships, organizations can enhance product quality, ensure consistent performance, and navigate the complexities of material procurement with greater ease.

Looking ahead, the demand for Invar and Mica Tape products is set to rise, driven by advancements in emerging technologies such as quantum computing and high-precision instrumentation. Staying informed about these trends will empower procurement professionals to strategically position their sourcing strategies, ensuring that their organizations are well-equipped to meet the future challenges of technology and industry. Embracing Invar’s capabilities not only supports immediate project needs but also paves the way for innovation and growth in an increasingly competitive landscape.