Blogs

Understanding Low CTE Materials: An In-Depth Tutorial for Engineers

Introduction

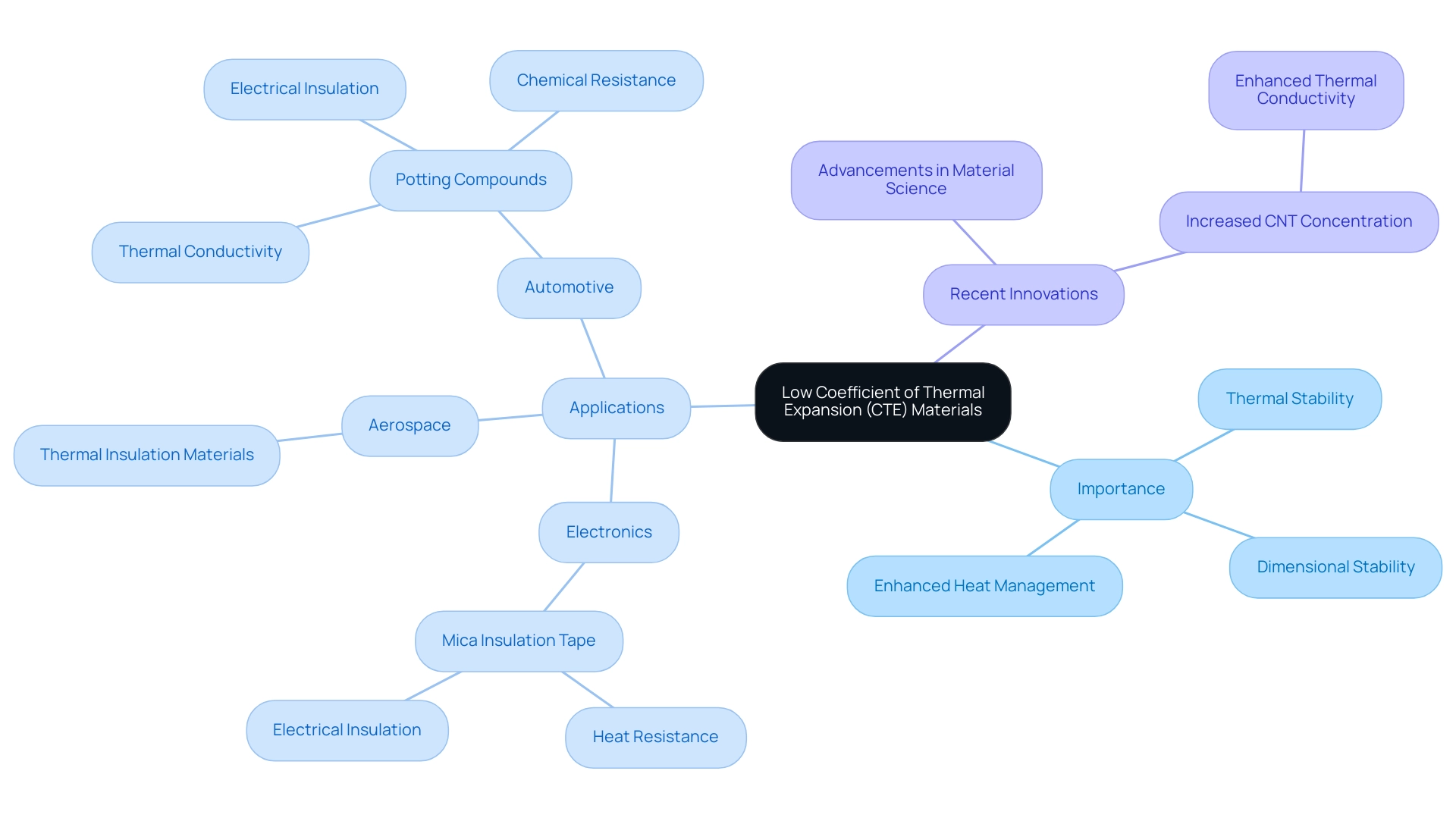

In the realm of advanced engineering, the significance of Low Coefficient of Thermal Expansion (CTE) materials cannot be overstated. As industries strive for greater precision and reliability, these specialized materials have emerged as essential components in sectors such as electronics, aerospace, and automotive. Their ability to maintain dimensional stability under varying thermal conditions directly impacts the performance and longevity of critical systems.

With innovations like Domadia’s Mica Insulation Tape, which combines high-temperature resistance with excellent electrical insulation, the landscape of material science is evolving rapidly. This article delves into the properties, applications, and challenges associated with low CTE materials, providing procurement managers and engineers with the insights needed to navigate this complex field and make informed decisions that enhance thermal management solutions.

Introduction to Low CTE Materials: Importance and Applications

Low Coefficient of Thermal Expansion (CTE) substances play a crucial role in scenarios where thermal stability is of utmost significance. These specialized substances exhibit minimal expansion when subjected to heat, making them indispensable in the electronics, aerospace, and automotive sectors, where precision and stability are non-negotiable. For instance, Domadia’s Mica Insulation Tape is designed for high-temperature resistance and electrical insulation, ensuring reliability and durability in various applications, from household appliances to industrial machinery.

This makes Mica Tape an excellent choice for mitigating stress and deformation in components during temperature fluctuations, thereby enhancing overall performance and longevity. Recent advancements in low CTE materials have revealed their growing importance, especially in 2024, as they aid in enhanced heat management solutions. In the automotive industry, potting compounds must balance heat conductivity with electrical insulation and chemical resistance, demonstrating the versatility of low CTE materials.

According to P. Vizureanu from the Technical University of Iasi, an increase to CNT concentration leads to an overall enhancement in conductivity, underscoring the ongoing innovations in material science. Furthermore, the Mica Sheet Tape provided by Domadia offers robust solutions for insulating large flat surfaces, with high mechanical strength and resistance to high temperatures, essential for challenging environments. Low CTE materials provide improved dimensional stability, which is essential for structures that must adjust to changing temperature conditions.

Additionally, the Mica Tape for electrical applications features excellent flame resistance and dielectric strength, making it ideal for fire-resistant cables and other critical electrical insulation systems. This knowledge enables engineers and procurement managers to make informed choices when selecting resources, ensuring that systems are designed with outstanding heat management capabilities in mind.

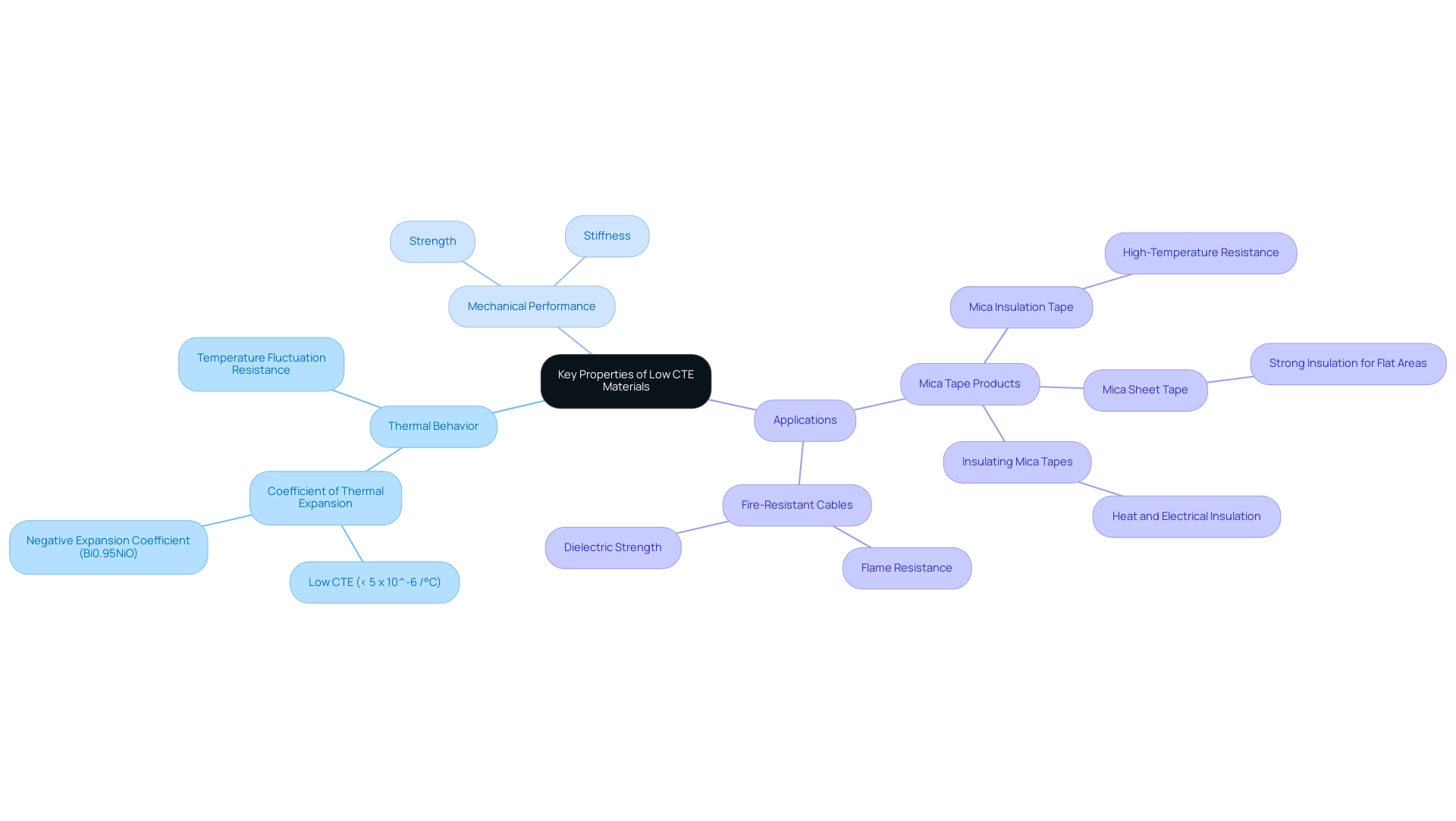

Key Properties of Low CTE Materials: Understanding Thermal Behavior

Low CTE materials are defined by their exceptionally low coefficient of expansion (CTE), typically below 5 x 10^-6 /°C, surpassing standard metals in this aspect. This decreased thermal expansion reduces the risks of thermal stress and distortion, rendering them especially beneficial in scenarios exposed to significant temperature fluctuations. Significantly, these materials do not compromise on mechanical performance; they often demonstrate outstanding strength and stiffness, which are crucial for structural use.

In this context, Domadia’s Mica Tape products exemplify high-temperature electrical insulation solutions, offering superior reliability in demanding environments. For example, the Mica Insulation Tape is crafted specifically for high-temperature resistance, ensuring durability across uses from household appliances to industrial machinery. Furthermore, the Mica Tape for Electrical uses boasts excellent flame resistance and dielectric strength, essential for manufacturing fire-resistant cables and critical electrical insulation systems.

The Mica Sheet Tape provides strong insulation for expansive flat areas, rendering it appropriate for demanding settings in the aerospace and automotive sectors, while Insulating Mica Tapes offer outstanding heat and electrical insulation qualities, essential in the fabrication of coils and capacitors. Moreover, the Bi0.95NiO substance exhibits a significant negative expansion coefficient of -82 × 10^-6 K^-1, which effectively counteracts the positive expansion of epoxy resins, highlighting its potential in uses that necessitate expansion suppression. As Markus Merkel emphasizes, attaining a minimum and stable coefficient of expansion through advanced heat treatment processes improves the performance of substances like Invar 36 in specialized applications.

Comprehending the expansion properties of these mica tapes is essential for procurement managers responsible for choosing low CTE materials that ensure reliability and performance in environments subjected to temperature cycling. This article’s insights are timely, having been published shortly after rigorous peer review, ensuring the relevance of the research presented.

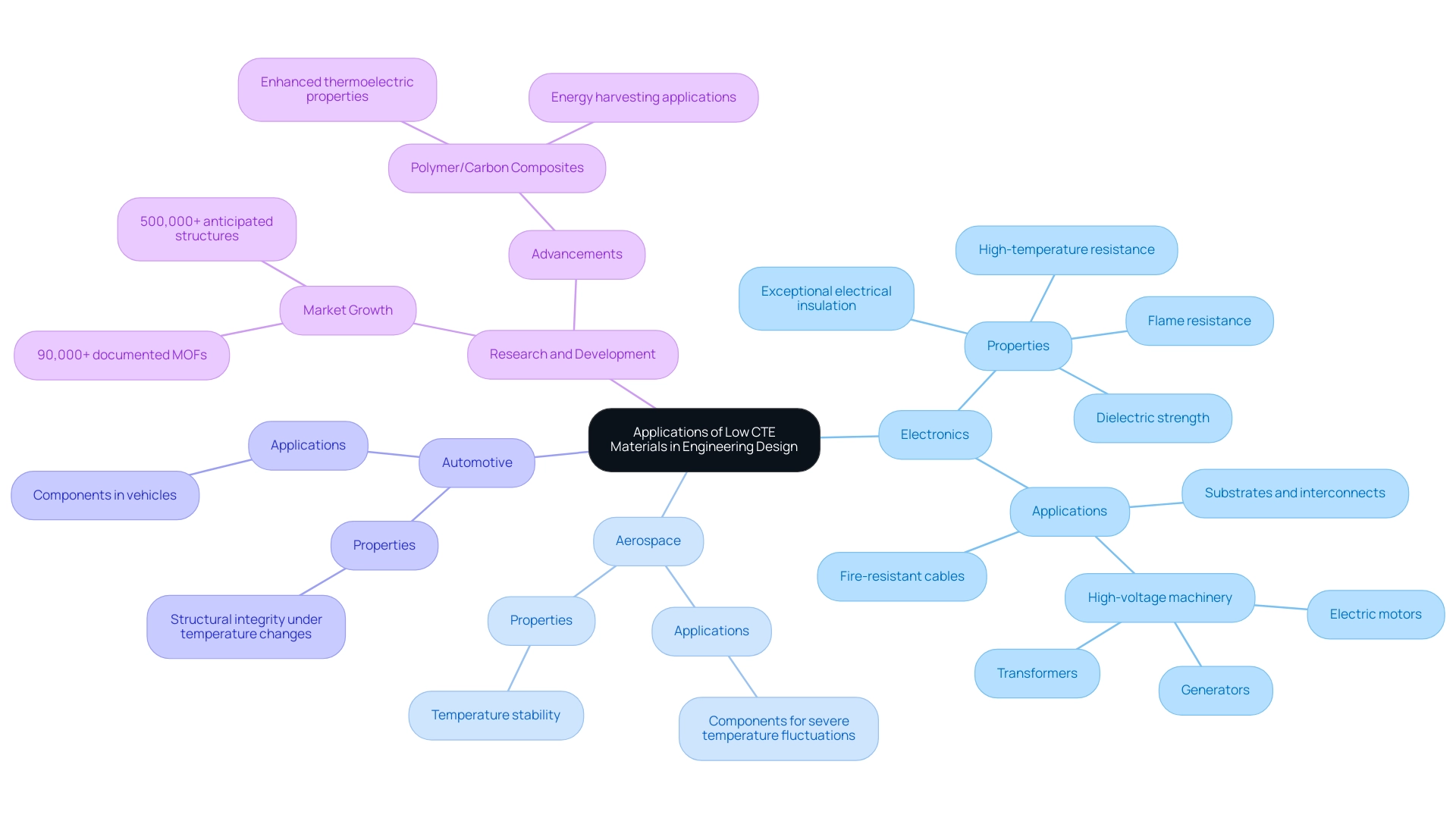

Applications of Low CTE Materials in Engineering Design

Low coefficient of expansion (CTE) substances have become crucial in the electronics sector, especially in the production of substrates and interconnects where heat stability is critical for performance and reliability. Among these substances, Domadia’s Mica Tapes stand out for their:

- High-temperature resistance

- Exceptional electrical insulation properties

- Flame resistance

- Dielectric strength

These properties make them ideal for critical applications in high-voltage machinery such as electric motors, generators, and transformers, as well as in the production of fire-resistant cables. The combination of these substances guarantees that devices can withstand temperature cycles without decline, thereby prolonging their functional lifespan.

Current statistics reveal that the market for low CTE materials in electronics continues to grow, driven by the increasing demand for precision in manufacturing. Significantly, more than 90,000 metal-organic frameworks (MOFs) have been documented, with over 500,000 anticipated structures, emphasizing the extensive research and development in substances that can improve heat stability. Furthermore, in optical devices, the precision and minimal thermal expansion provided by low CTE materials are crucial for maintaining alignment, which is vital for optimal functionality.

In the aerospace and automotive sectors, Mica Tapes are employed in components that must endure severe temperature fluctuations without compromising structural integrity. Recent advancements in polymer/carbon composites, as discussed in the case study titled ‘Polymer/Carbon Composites for Thermoelectric Applications,’ have demonstrated enhanced thermoelectric properties, making them suitable candidates for energy harvesting applications in wearable technology. Such innovations not only highlight the versatility of low CTE materials but also underscore their significance in advancing engineering design across diverse sectors.

As one industry expert aptly states,

Address your team’s resource requests effectively without compromising on project goals. Evaluate, explore alternatives, and communicate clearly.

This advice resonates particularly well in the context of low CTE materials, as effective communication during the procurement process can significantly impact the selection and integration of low CTE materials, ensuring that project objectives are met optimally.

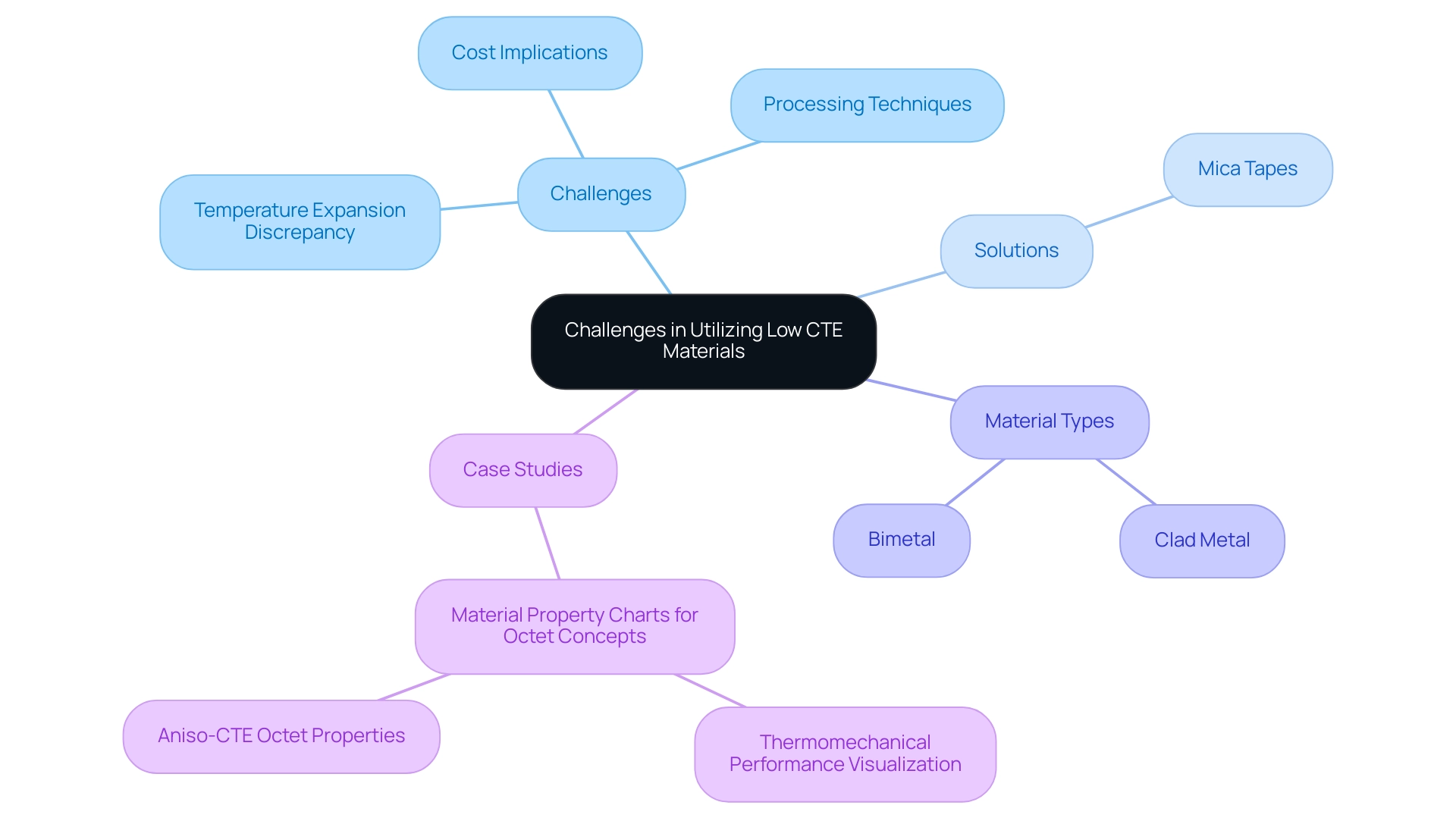

Challenges in Utilizing Low CTE Materials: Compatibility and Performance

Low CTE materials provide notable advantages but also introduce a set of challenges that procurement managers and engineers must navigate. A notable concern is the temperature expansion discrepancy that may occur when these substances are combined with conventional substances. For instance, exotic substances such as aluminum nitride, which possesses a low CTE value ranging from 4.3 to 5.8 ppm/°C, may not be compatible with copper, resulting in stress concentrations and possible failures at joints, especially in dynamic applications where vibration is a significant mechanical factor contributing to solder fatigue in solder joints.

In fact, studies indicate that the compressive strength of BST/Al composites reaches as high as 800 MPa, yet this strength does not reduce the risks associated with expansion mismatches. Moreover, the processing techniques for low CTE materials often differ from those used for conventional substances, necessitating meticulous planning and execution during production. Engineers must be cognizant of how these differences can influence production timelines and outcomes.

Furthermore, sourcing specialty low CTE materials can introduce significant cost implications, impacting project budgets and overall feasibility.

To address these challenges, exploring solutions such as Domadia’s Mica Tapes for high-temperature electrical insulation can be beneficial. These tapes are created to endure harsh conditions, offering dependable insulation for uses needing exceptional temperature control. Specifically, Mica Tapes can help mitigate thermal expansion mismatches, ensuring greater reliability in applications that utilize low CTE materials.

Moreover, understanding the differences between Clad Metal and Bimetal is crucial, as:

- Clad Metal refers to a composite substance created by bonding two or more different metals.

- Bimetal consists of two metals joined together that expand at different rates when heated.

This knowledge is essential for choosing suitable components for temperature-sensitive devices. A compelling case study titled ‘Property Charts for Octet Concepts’ highlights these challenges and showcases how property charts were employed to visualize the thermomechanical performance of Al6061-Ti-6Al-4V Octet concepts.

The findings showed that the Aniso-CTE Octet could modify its CTE from negative infinity to that of Ti-6Al-4V, making it an attractive option for situations requiring stability under heat. As D. Pasini highlights in his research on structurally efficient three-dimensional metamaterials, the controllable expansion properties of these substances emphasize the critical need to address expansion mismatches in engineering designs effectively. Comprehending these challenges is essential for the successful incorporation of low CTE materials into engineering applications.

For more information on how Mica Tapes can enhance your projects and to explore our range of products, please contact Domadia or visit our website today.

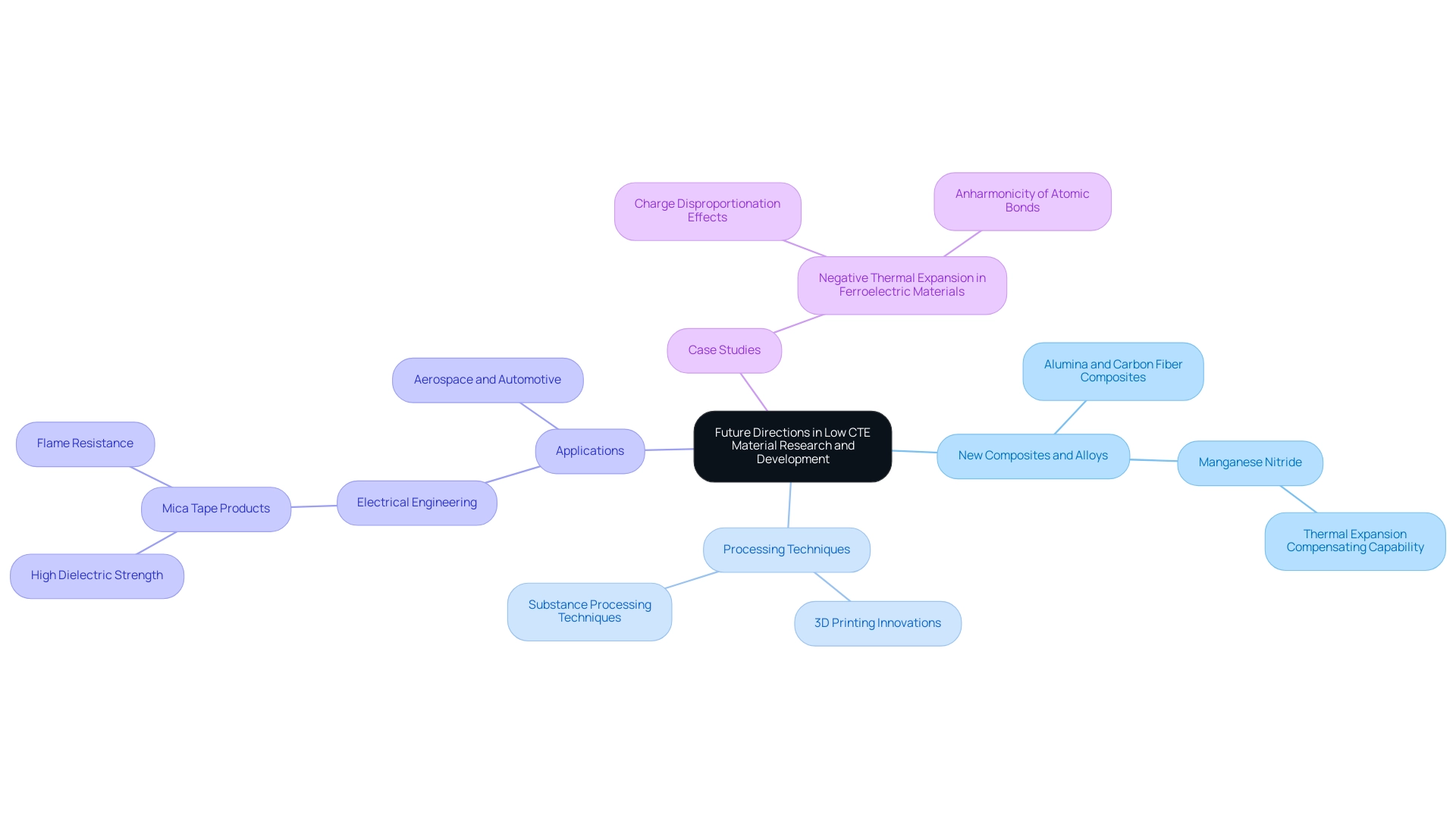

Future Directions in Low CTE Material Research and Development

Ongoing studies on low CTE materials are yielding significant progress in the development of new composites and alloys designed to reduce expansion while concurrently improving mechanical properties. Recent innovations in substance processing techniques, such as 3D printing, have demonstrated significant potential in optimizing the manufacturability of low CTE materials. For instance, work by Ji et al. (2020) showcased improvements in the heat conductivity of alumina and carbon fiber composites, indicating a promising direction for future developments. Additionally, the thermal conductivity of hexagonal BN has been measured at 0.86 W·m, providing a quantitative measure that underscores the importance of thermal performance in these materials. Such advancements not only enhance performance but also expand the range of uses in industries demanding high precision and reliability.

Notably, Domadia’s Mica Tape products exemplify high-temperature resistance and electrical insulation solutions essential for critical applications in electrical engineering. These tapes are indispensable for manufacturing fire-resistant cables and other critical electrical insulation systems, offering superior insulation properties, including high dielectric strength and excellent flame resistance, which ensure durability in various settings. Engineers and procurement managers should stay aware of these emerging trends, as they are set to impact resource selection and design techniques, ultimately enabling enhanced heat management solutions.

As Nakamura observed, ‘This result indicates a significantly greater value of the nitride filler (200 GPA) compared to the matrix (5 GPA), showcasing the outstanding expansion compensating capability of the manganese nitride,’ emphasizing the potential for further investigation in this field. Furthermore, the case study on negative thermal expansion in ferroelectric materials illustrates unique properties where charge disproportionation leads to a greater averaged bond length compared to uniform cases, resulting in distinct anharmonicity of atomic bonds, which could offer insights into future applications of low CTE materials. Moreover, mica tapes are also applicable in the aerospace and automotive industries, where their robust mechanical strength and high-temperature resistance are crucial for performance and safety.

Conclusion

The exploration of low coefficient of thermal expansion (CTE) materials reveals their pivotal role in enhancing the precision and durability of critical engineering applications across various sectors. With properties that minimize thermal expansion and maintain structural integrity under temperature fluctuations, materials such as Domadia’s Mica Insulation Tape stand out as essential components in electronics, aerospace, and automotive industries. Their ability to provide high-temperature resistance and excellent electrical insulation not only ensures operational reliability but also extends the lifespan of critical components.

However, the adoption of low CTE materials is not without challenges. Issues such as thermal expansion mismatches and the need for specialized processing techniques require careful consideration from procurement managers and engineers. Understanding these challenges is vital for effective material selection and integration, ensuring that engineering designs meet their performance objectives without compromising on reliability.

Looking ahead, ongoing research into advanced composites and innovative processing techniques promises to unlock new possibilities for low CTE materials. As the industry evolves, staying informed about emerging trends and technologies will be crucial for optimizing thermal management solutions. By leveraging these insights, professionals can make strategic decisions that enhance the performance and longevity of their systems, ultimately driving success in their respective fields.