Blogs

Understanding Monel Distributors: A Complete Tutorial on Sourcing and Applications

Overview

Monel distributors play a crucial role in sourcing nickel-copper materials, particularly the widely used alloy 400, which is valued for its exceptional corrosion resistance and mechanical properties. The article emphasizes the importance of selecting reliable distributors based on criteria such as reputation, certification, stock availability, and technical support, ensuring that procurement managers can optimize their sourcing strategies and meet industry standards effectively.

Introduction

In the realm of materials procurement, Monel alloys stand out for their unique combination of properties that cater to the demanding requirements of various industries. With Monel 400 at the forefront, these alloys offer exceptional corrosion resistance, strength, and weldability, making them indispensable in applications ranging from aerospace to marine engineering.

As procurement managers navigate the complexities of sourcing these high-performance materials, understanding the specifications, applications, and compliance standards becomes crucial.

This article delves into the multifaceted world of Monel alloys, providing insights that will empower decision-makers to optimize their sourcing strategies and enhance operational efficiency in a competitive landscape.

Exploring the Properties and Specifications of Monel Alloys

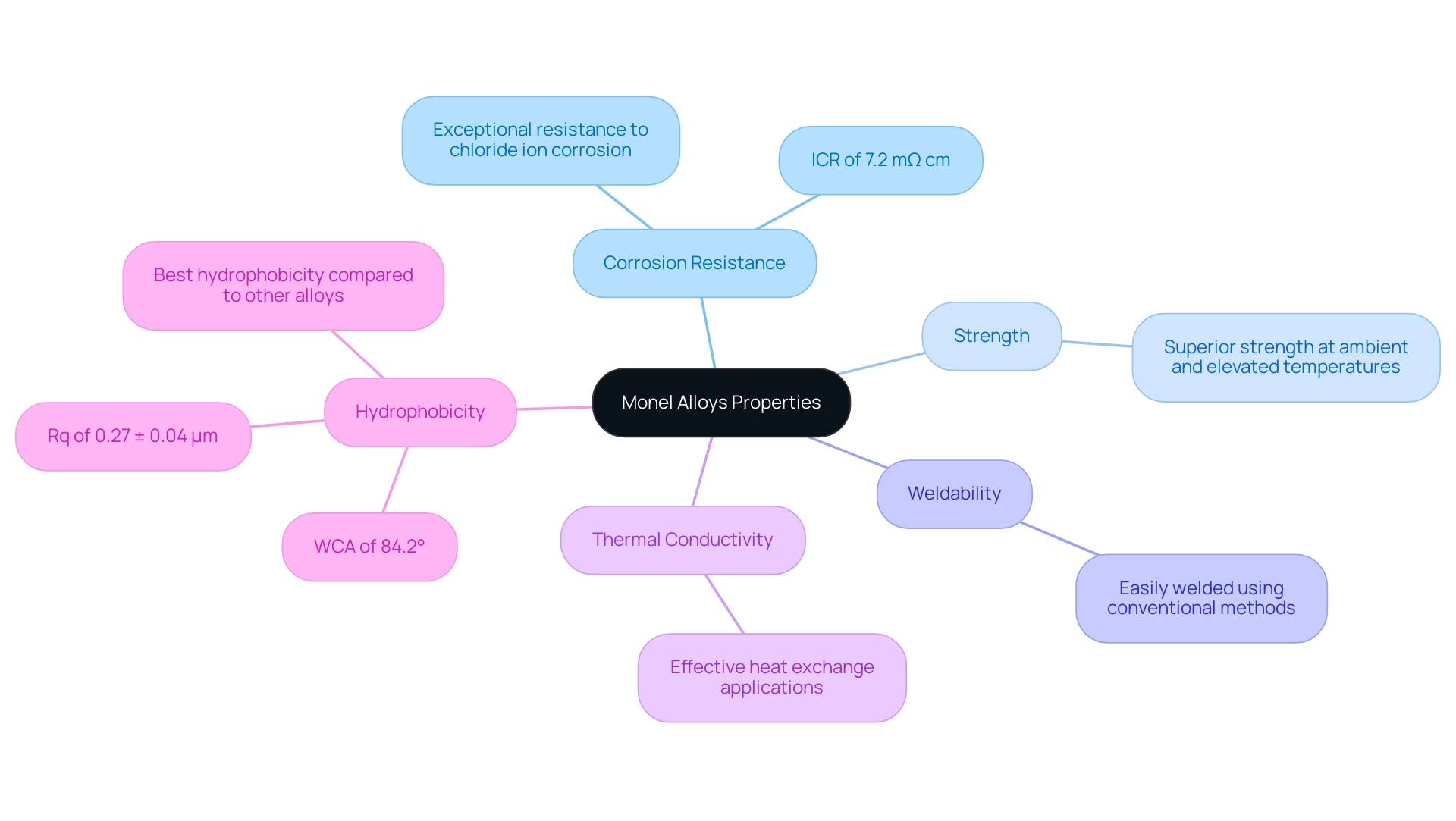

Nickel-copper materials, especially the commonly used 400 grade, are recognized for their remarkable resistance to corrosion and mechanical characteristics. This mixture consists of approximately 67% nickel and 28% copper, supplemented by trace amounts of manganese, carbon, and silicon. The key characteristics of these materials are crucial for procurement managers evaluating their use:

- Corrosion Resistance: These substances demonstrate exceptional resistance to chloride ion corrosion, making them especially beneficial for marine applications and settings with high salinity. Notably, the material 400 demonstrates an ICR of 7.2 mΩ cm at 140 N/cm, highlighting its superior performance compared to other substances.

- Strength: These materials maintain superior strength at both ambient and elevated temperatures, essential for applications demanding durability and reliability.

- Weldability: These materials can be welded effortlessly using conventional methods, providing flexibility and efficiency in manufacturing processes.

- Thermal Conductivity: With commendable thermal conductivity, these materials are well-suited for applications that necessitate effective heat exchange.

At Domadia, we offer a diverse range of copper nickel materials, including 400 and other variants, that are ideal for industries such as marine engineering, automotive, and electronics, and we collaborate with monel distributors. Recent measurements reveal that alloy 400 features a root mean square roughness (Rq) of 0.27 ± 0.04 μm, contributing to its outstanding hydrophobic properties. A hydrophobicity evaluation case study demonstrated that a specific metal achieved a water contact angle (WCA) of 84.2°, significantly outperforming other materials, which recorded WCAs below 75°.

Chunwang Zhao, who conceived and designed the experiments, noted potential competing interests related to financial support from the National Natural Science Foundation of China. This combination of properties not only enhances performance in diverse environments but also assures longevity, making alloy 400 a strategic choice for procurement managers aiming to optimize application outcomes. We invite you to explore our extensive product catalog to find the perfect copper nickel mixture solution tailored to your project needs.

Applications of Monel Alloys in Various Industries

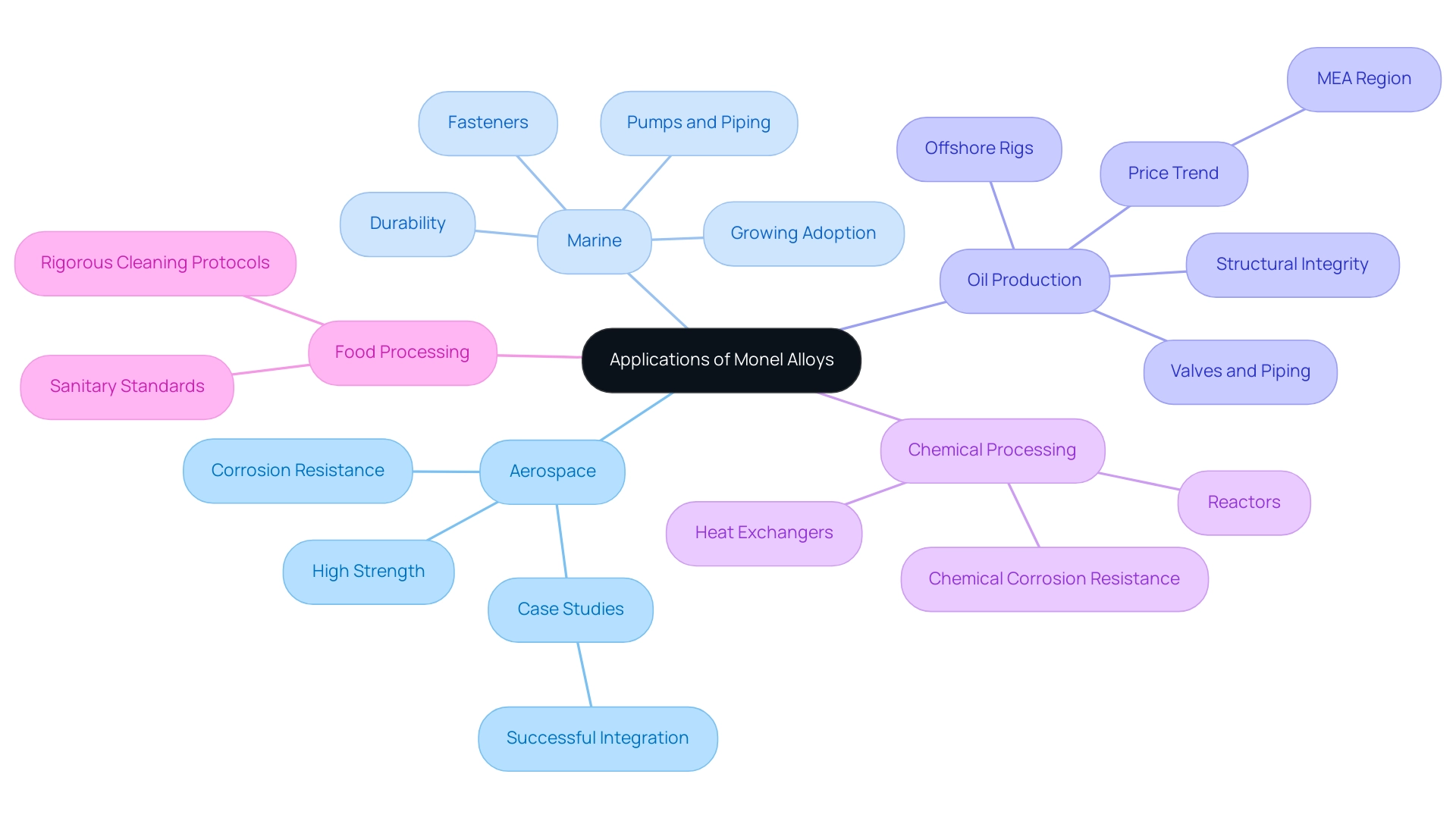

Nickel-copper materials are highly valued for their exceptional characteristics, leading to their extensive use across multiple industries. Key applications include:

Aerospace: Certain metal mixtures are integral to aircraft components such as exhaust valves, turbocharger parts, and fuel tanks.

Their high strength and corrosion resistance are critical in these applications, addressing the stringent demands of the aerospace sector. Recent case studies highlight the successful integration of nickel-copper alloys in various aerospace components, showcasing their performance under rigorous conditions.Marine: In marine environments, this alloy is a preferred choice for pumps, piping, and fasteners.

Its remarkable ability to resist corrosive saltwater conditions makes it indispensable for durability and reliability in marine applications. Usage statistics indicate a growing trend in the adoption of this material within the marine industry, reflecting its effectiveness in challenging conditions.Oil Production: The oil and gas sector depends on specific metal mixtures for offshore rigs and refineries, where they are employed in valves, piping, and other parts that must withstand tough conditions.

These alloys ensure the structural integrity and longevity of critical equipment. The price trend of the alloy in the MEA region, which exhibited a slight decline due to reduced domestic demand and increased supply, highlights the importance of strategic procurement in this sector.Chemical Processing: This alloy’s resistance to chemical corrosion makes it an ideal material for equipment in chemical processing plants.

It is commonly employed in reactors and heat exchangers, where exposure to aggressive chemicals is a concern. The focus on technological sophistication in material selection further highlights the significance of these specialized metals in this industry.Food Processing: In the food processing sector, certain metal blends are employed in applications that demand high sanitary standards, ensuring that equipment can endure rigorous cleaning and hygiene protocols.

These diverse applications highlight the versatility of these materials, emphasizing their critical role across various sectors. For purchasing supervisors, comprehending these applications is crucial for recognizing appropriate suppliers, such as monel distributors, and materials that fulfill particular industry standards. As one industry expert noted, ‘Overcome resistance to your innovative ideas by listening actively, presenting data, and building alliances to gain support.’

This understanding is essential for purchasing managers when evaluating the implementation of nickel-copper materials in their operations.

Identifying Reliable Monel Distributors

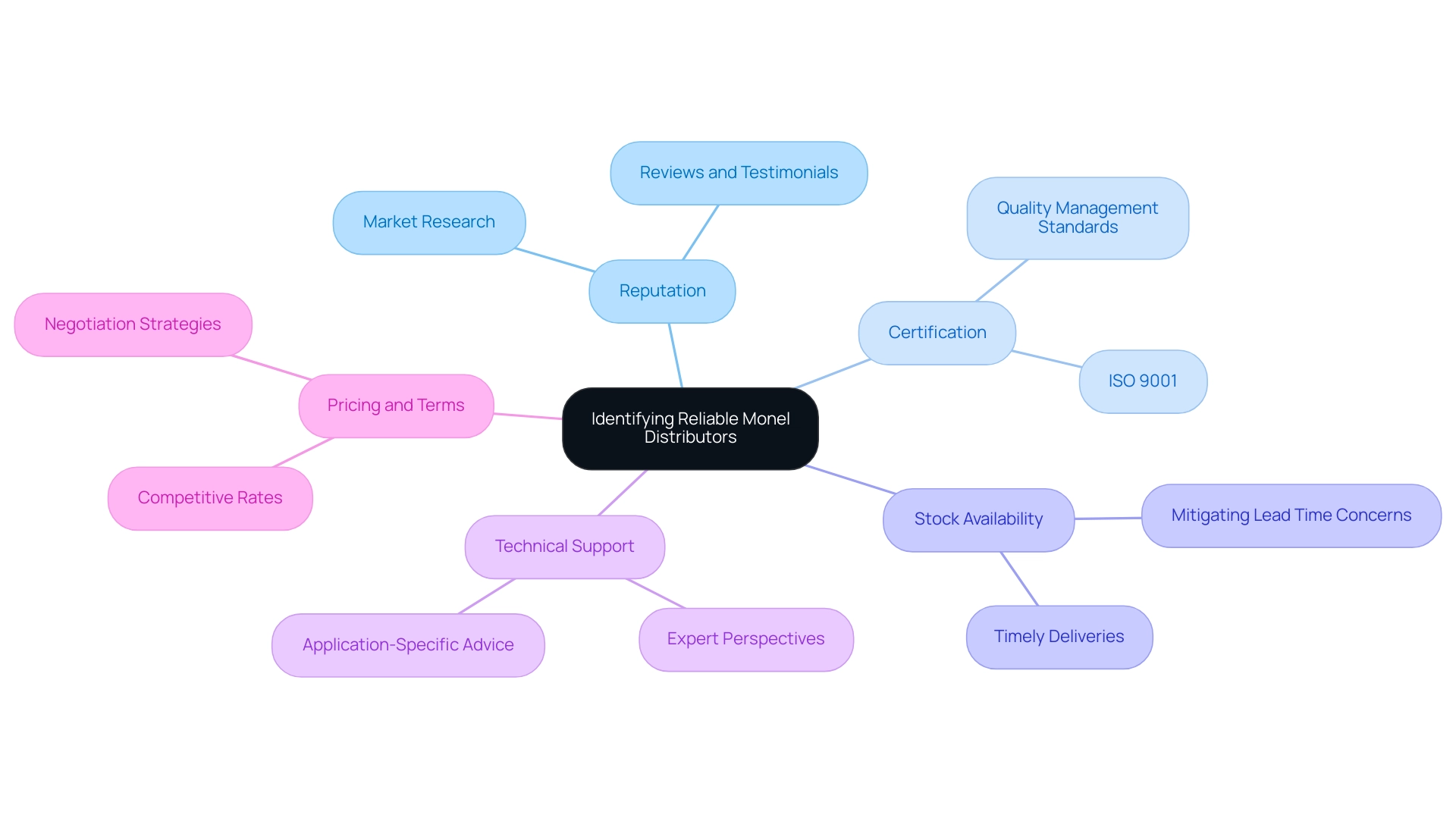

When sourcing nickel-copper materials, it is imperative to identify monel distributors who not only meet industry standards but also ensure consistent quality while supporting sustainable practices. Here are several critical criteria to consider in your evaluation:

- Reputation: Conduct thorough research on the distributor’s market reputation by examining reviews, testimonials, and referrals from fellow procurement professionals. A strong reputation often correlates with reliability and trustworthiness.

- Certification: Verify that the distributor holds relevant certifications, such as ISO 9001. These certifications indicate adherence to established quality management standards, which is vital for ensuring product integrity. As emphasized in industry discussions, “Certification standards are essential for ensuring that the materials sourced contribute to sustainable manufacturing practices.”

- Stock Availability: A reliable supplier should keep a thorough stock of nickel-copper materials. This preparedness ensures timely deliveries and mitigates lead time concerns that can disrupt operations.

- Technical Support: Seek out distributors who offer robust technical support. They should be able to offer expert perspectives on the best nickel-copper materials for specific applications, enhancing your decision-making process.

- Pricing and Terms: Assess pricing structures carefully and engage in negotiations to secure competitive rates while ensuring that quality remains uncompromised.

By carefully assessing these factors, procurement managers can establish collaborations with trustworthy monel distributors, thereby enhancing their sourcing strategies for metal materials. Such diligence is crucial in a landscape where the focus on sustainability is prompting manufacturers to enhance the recyclability of these materials, further underscoring the need for reliable sourcing.

Understanding Compliance and Quality Standards for Monel Alloys

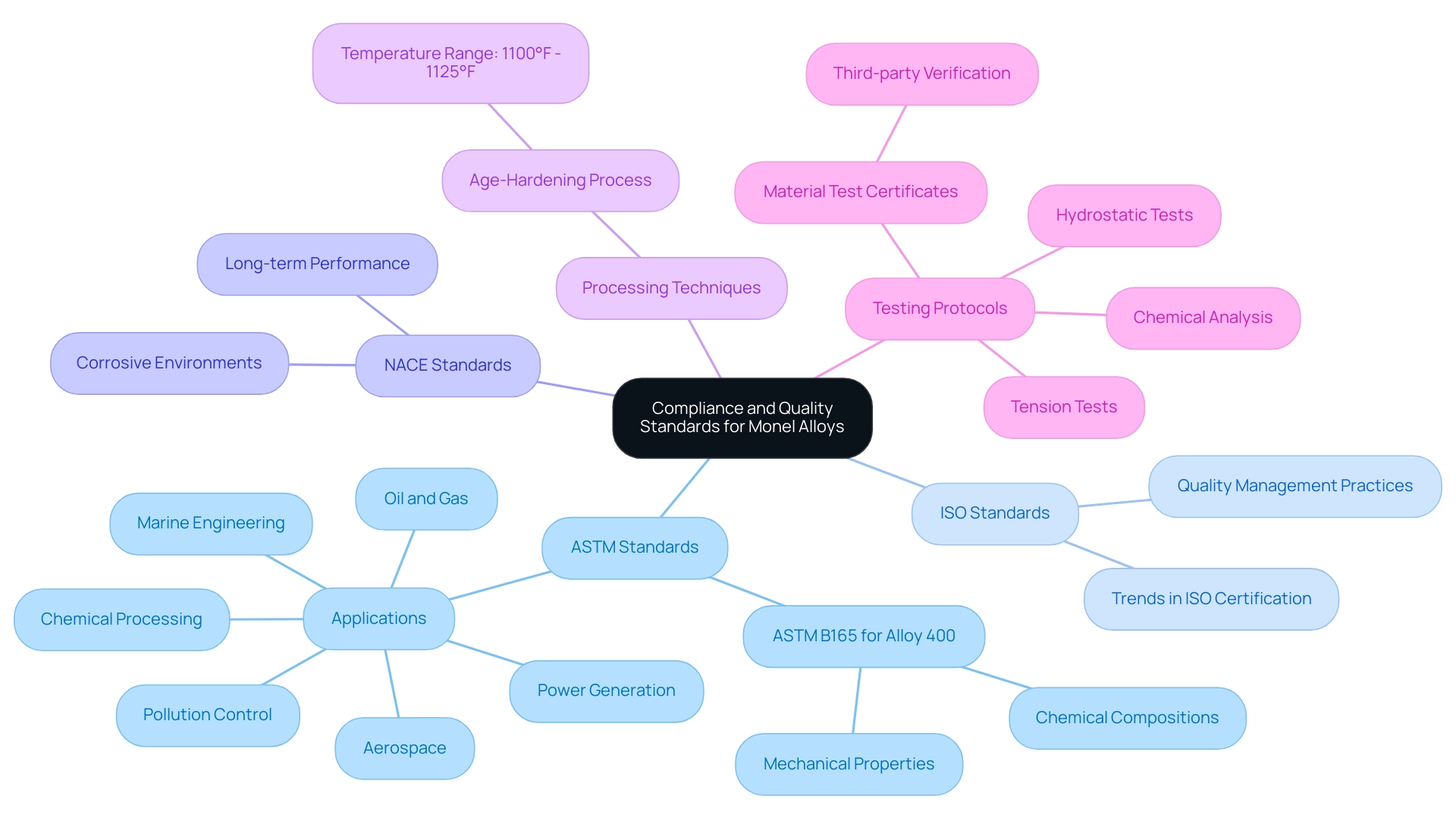

Adherence to global standards is crucial for guaranteeing the quality and performance of these materials. Key standards that purchasing managers should prioritize include:

- ASTM Standards: It is crucial for nickel-copper alloys to adhere to specifications such as ASTM B165 for alloy 400, which delineates critical chemical compositions and mechanical properties. Alloy 400, specified under ASTM B165/ASME SB165, is commonly used in marine engineering, chemical processing, oil and gas, aerospace, power generation, and pollution control industries due to its exceptional corrosion resistance, durability, and ability to perform in harsh environments. These standards are particularly important as they ensure the material’s integrity in demanding applications.

- ISO Standards: Understanding relevant ISO standards is vital in the procurement process, as these standards promote adherence to quality management practices among suppliers. This is supported by recent statistics indicating a growing trend in ISO certification among Monel distributors, which ensures a commitment to quality and reliability.

- NACE Standards: For applications in corrosive environments, compliance with the National Association of Corrosion Engineers (NACE) standards is imperative. These standards are intended to ensure the long-term performance of materials subjected to severe conditions, thus improving the durability of specific metals in critical applications.

Besides these standards, it is crucial to take into account the technical aspects of processing these metals. The age-hardening process involves aging at a temperature range typically between 1100°F and 1125°F, which is crucial for achieving the desired mechanical properties and ensuring compliance with performance standards.

By familiarizing yourself with these compliance requirements, you can mitigate risks effectively and ensure that the alloys sourced meet the stringent industry expectations for quality and performance. This understanding is further reinforced by the rigorous testing protocols, such as chemical analysis, tension tests, and hydrostatic tests, that these seamless pipes undergo to verify compliance, documented in Material Test Certificates verified by third-party agencies. The case study titled ‘Testing and Quality Assurance for Alloy 400’ illustrates this process, showcasing how these tests ensure the material’s integrity and performance.

Such thorough due diligence not only assists purchasing professionals in making informed decisions but also aligns with best practices in the industry.

Evaluating Pricing Strategies for Monel Alloys

Pricing for nickel-copper materials is influenced by a multitude of factors that procurement managers must carefully evaluate. To develop effective pricing strategies, consider the following key elements:

- Market Demand Trends: Monitoring the fluctuations in market demand for Monel alloys is crucial, as prices are directly impacted by supply and demand dynamics. For instance, in Q4 2023, the MEA region experienced a slight decline in the metal market, with prices settling at USD 38,335/MT for Alloy 400 Sheet CFR Jebel Ali, driven by reduced domestic demand and increased supply, particularly in the UAE. Additionally, in Saudi Arabia, prices for Q2 2024 settled at USD 43,852/MT in June, reflecting broader market trends.

- Material Composition: The specific grade of the metal significantly affects pricing. Generally, mixtures with higher nickel content command higher prices due to the material’s rarity and increasing demand in specialized applications, such as the emerging indigenous Monel-400 metal tubes supplied by Monel distributors for space applications.

- Supplier Relationships: Establishing robust negotiations with suppliers is paramount. Strong partnerships can lead to more favorable pricing terms, especially when negotiating based on volume purchases or long-term contracts, allowing for better cost management.

- Shipping and Handling Costs: Don’t overlook the impact of shipping expenses on the overall price of these metals. Engaging with suppliers that offer competitive shipping rates can effectively reduce total expenditures.

By comprehensively understanding these factors, procurement managers can enhance their sourcing strategies, effectively balancing cost considerations with quality to optimize project outcomes. As highlighted by the IMARC Team, “The depth of analysis, accuracy of data, and actionable recommendations have greatly enhanced our strategic decision-making,” which emphasizes the significance of informed choices in navigating the metal market.

Case Study: The MEA region’s alloy market showed a slight decline in Q4 2023 due to reduced domestic demand and increased supply, particularly in the UAE. Prices concluded at USD 38,335/MT for Alloy 400 Sheet CFR Jebel Ali, indicating a stable yet challenging market.

Future Trends in Monel Alloy Sourcing

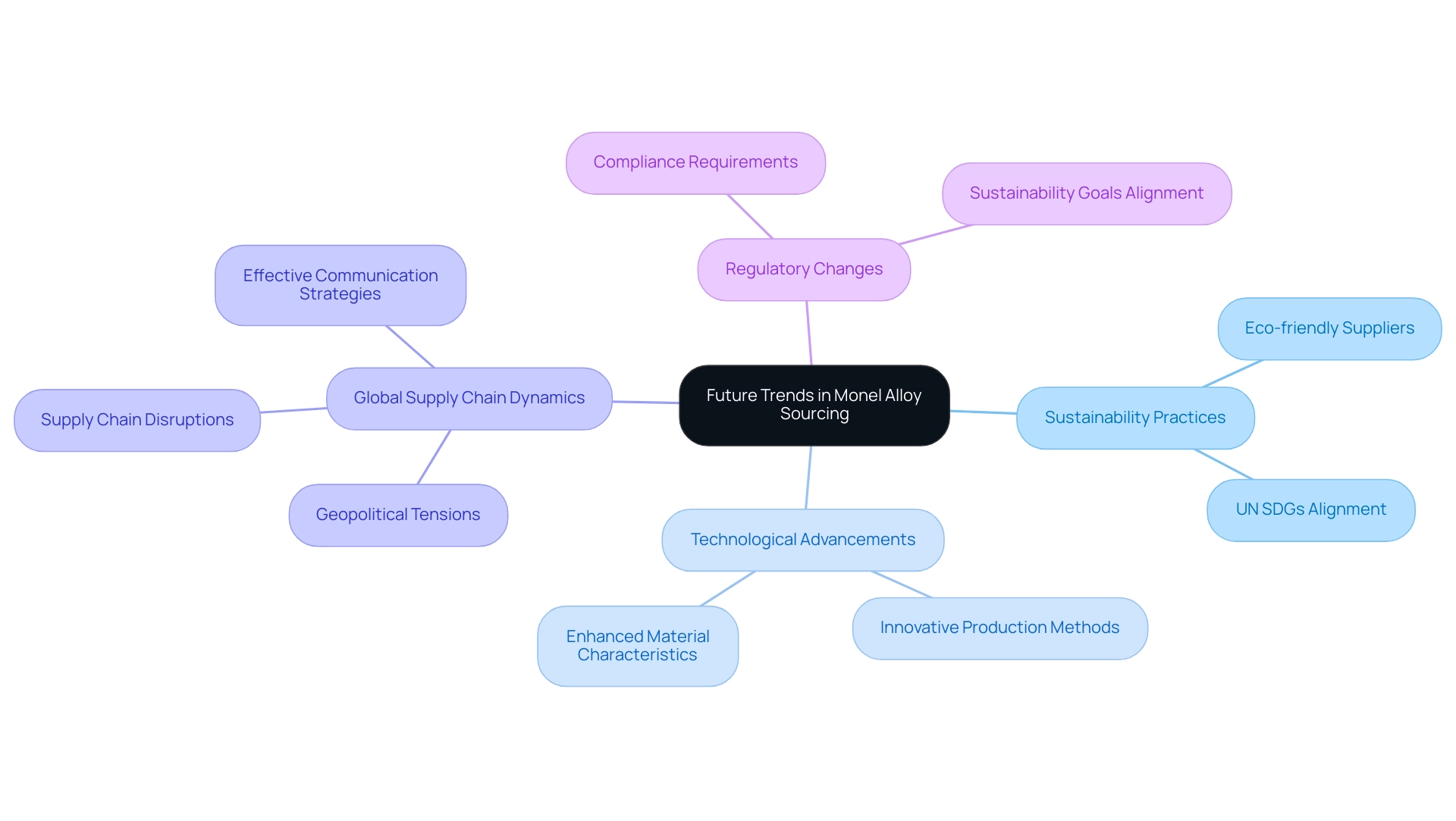

The changing market for nickel-copper materials presents several critical trends that purchasing managers must observe to make informed choices:

Sustainability Practices: Industries are increasingly prioritizing sustainable sourcing. Suppliers who commit to environmental responsibility and transparent practices are likely to become preferred partners, aligning with the growing demand for eco-friendly materials in purchasing. This corresponds with the UN Sustainable Development Goals, highlighting the significance of responsible sourcing.

Technological Advancements: Innovations in production methods and material compositions are paving the way for new variants with improved characteristics. These advancements not only enhance performance but may also affect sourcing choices as purchasing leaders consider the long-term advantages of these technologies. Understanding the influence of technological progress on Monel alloy characteristics can effectively guide acquisition strategies for Monel distributors.

Global Supply Chain Dynamics: Geopolitical tensions and supply chain disruptions can significantly affect the availability and pricing of Monel alloys supplied by Monel distributors. This reality requires that sourcing strategies stay nimble and flexible, enabling supervisors to handle uncertainties effortlessly. For instance, effective communication and conflict resolution strategies can assist teams in addressing sourcing challenges more efficiently.

Regulatory Changes: As regulations regarding material sourcing and environmental impacts evolve, those in charge of purchasing must stay informed about compliance requirements. Understanding these changes will help in developing sourcing strategies that align with both legal obligations and organizational sustainability goals. The case study on choosing between SMART and OKR goal-setting frameworks illustrates the decision-making processes that procurement managers might face when sourcing from Monel distributors for Monel alloys. By proactively addressing these trends, procurement managers can craft sourcing strategies that not only respond to industry shifts but also ensure a competitive advantage in the marketplace.

Conclusion

Monel alloys, particularly Monel 400, offer an unparalleled combination of corrosion resistance, strength, and weldability, making them essential in various industries such as:

- Aerospace

- Marine

- Oil production

- Chemical processing

- Food processing

Understanding the properties and specifications of these alloys enables procurement managers to make informed decisions that align with the specific demands of their applications. The article has highlighted the importance of evaluating reliable distributors, ensuring compliance with quality standards, and developing effective pricing strategies to optimize sourcing efforts.

As industries increasingly prioritize sustainability and technological advancements, staying abreast of future trends in Monel alloy sourcing becomes paramount. By focusing on reputable suppliers, adhering to international standards, and leveraging market dynamics, procurement managers can enhance operational efficiency and ensure the longevity of their applications.

In a competitive landscape, the strategic sourcing of Monel alloys is not merely a logistical task; it is a crucial component of achieving operational excellence. By implementing the insights outlined in this article, procurement professionals can navigate the complexities of the Monel market, ultimately driving success and innovation within their organizations.