Blogs

Understanding Monel Pistons: A Complete Tutorial for Musicians

Overview

Monel pistons are favored by musicians for their exceptional corrosion resistance, durability, and ability to produce a warm, resonant sound, making them ideal for brass instruments like trumpets and tubas. The article supports this by detailing the alloy’s properties, such as its high strength and seamless operation, which enhance both the longevity and playability of musical instruments, thus enriching the overall musical experience.

Introduction

In the world of musical instruments, the choice of materials can significantly influence both performance and durability. Monel, a unique nickel-copper alloy, stands out for its remarkable properties that enhance sound quality while ensuring longevity. As musicians and manufacturers alike seek to balance exceptional acoustic performance with resilience against wear and environmental challenges, Monel emerges as a compelling option.

This article delves into the multifaceted applications of Monel in the realm of music, exploring its benefits in:

- Brass instruments

- The advantages of Monel pistons

- The ongoing innovations that are shaping its future

By understanding the strategic advantages of Monel, procurement managers and industry professionals can make informed decisions that elevate the quality of musical instruments and enrich the overall musical experience.

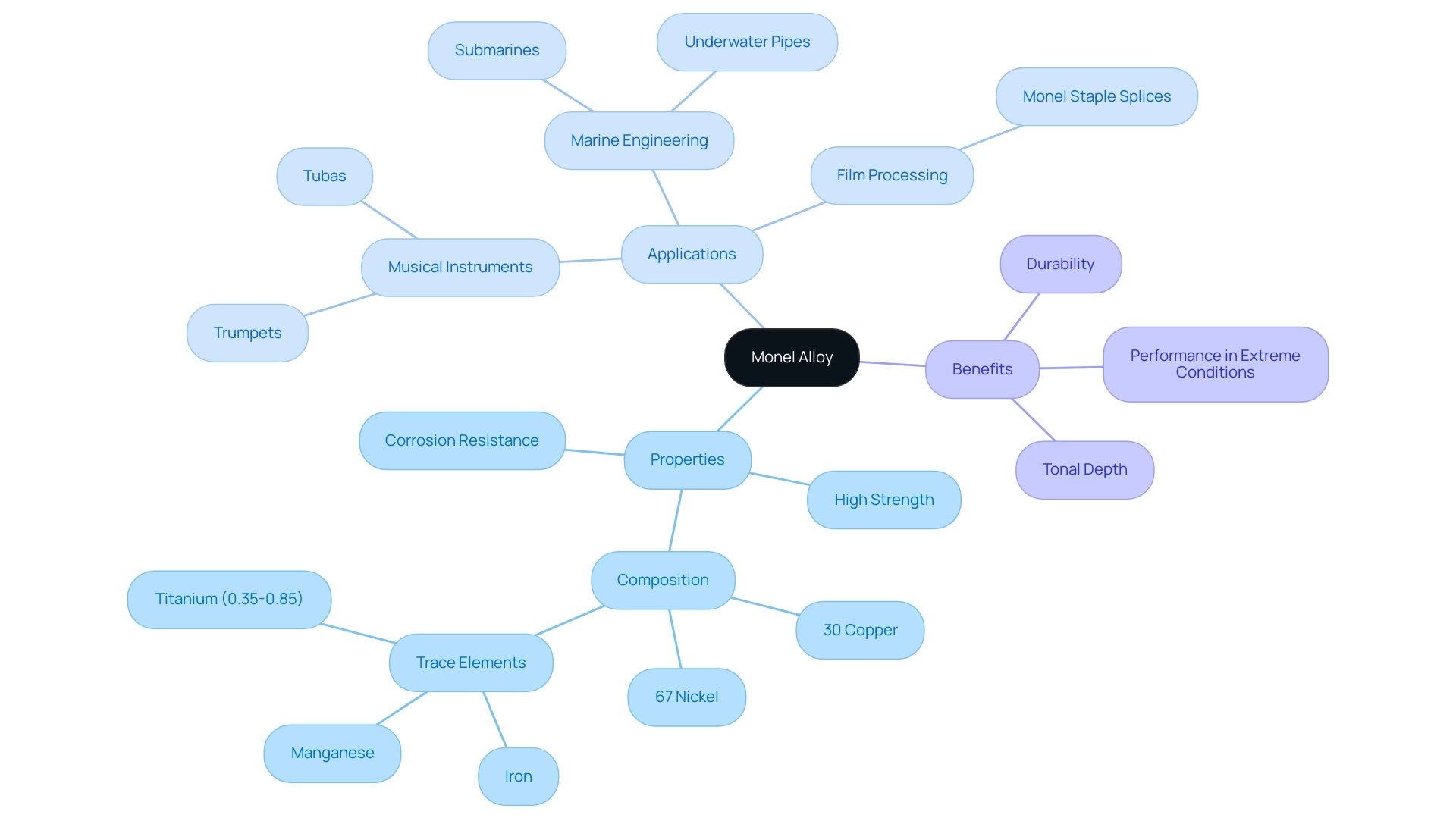

Exploring Monel: Properties and Applications in Music

This nickel-copper alloy is renowned for its distinctive properties, which include exceptional corrosion resistance, high strength, and a warm, resonant sound quality that is particularly prized in musical applications. Typically composed of approximately 67% nickel and 30% copper, this alloy also contains trace amounts of elements such as iron, manganese, and titanium, with the K-500 variant containing 0.35-0.85% titanium, which enhances its overall performance. These qualities make this alloy an excellent option for brass musical devices, improving not only their durability but also their tonal depth.

Musicians often choose monel pistons for their smooth operation and responsiveness, greatly enhancing the sound generated in devices such as trumpets and tubas. Furthermore, the durable capability to withstand extreme temperatures and pressures ensures optimal performance in demanding musical environments, thereby preserving the integrity of the instruments over time. Additionally, alloy 400’s corrosion resistance to seawater highlights its versatility, making it commonly used in marine engineering applications, such as submarines and underwater pipes and valves.

As illustrated by the case study on this metal in film processing, where staple splices made from it are utilized due to their corrosion resistance in photochemical tanks, its properties extend beyond music, reinforcing its credibility and relevance across various industries. As mentioned by expert Mansoor Ahmed, Nice information, its distinctive characteristics provide a compelling advantage in the creation of high-quality musical tools.

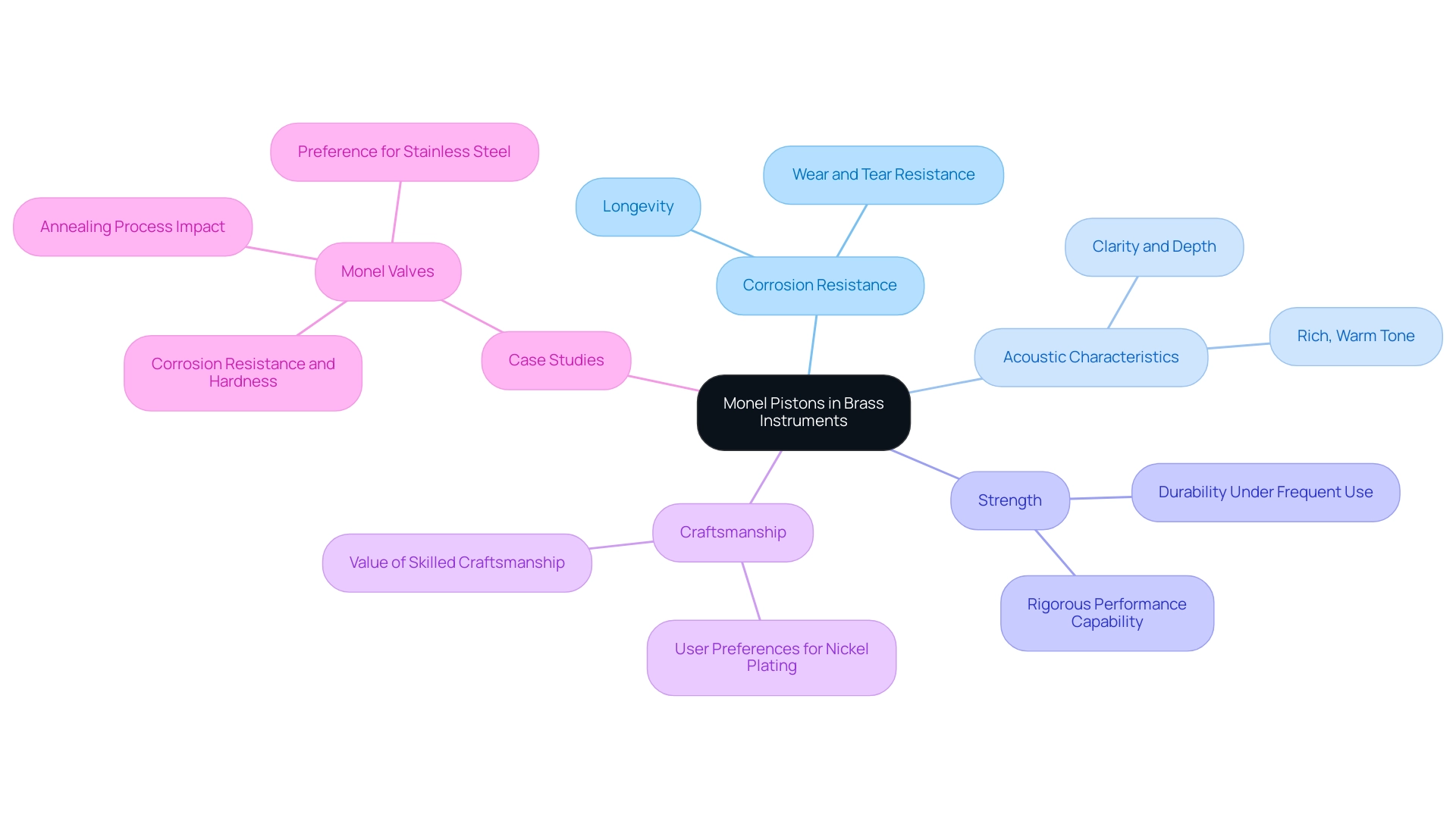

The Role of Monel Pistons in Brass Instruments: Benefits and Features

These components play an essential role in the performance of brass devices, providing advantages that distinguish them from traditional materials. A standout feature of this alloy is its exceptional corrosion resistance, which effectively combats wear and tear under demanding playing conditions—this property significantly prolongs the longevity of the instrument. Artists value the seamless functioning of metal cylinders, which enables swift and agile movements that improve overall playability.

Furthermore, the acoustic characteristics of this material contribute to a rich, warm tone that many performers find appealing, promoting clarity and depth in sound production. The material’s high strength also ensures that these monel pistons can endure the rigors of frequent use, making them an excellent choice for both professional musicians and students alike. As one user, referred to as ‘bloke,’ noted,

‘I believe I prefer nickel plating that was applied by a highly-skilled craftsman who is now retired, Mr. David Secrist.’

This perspective highlights the value placed on craftsmanship in material selections for brass devices. Furthermore, a case study on these valves shows that while this alloy is recognized for its corrosion resistance and hardness, the annealing process during assembly can weaken the material, leading some companies to prefer stainless steel valves for advanced equipment. As a result, investing in brass instruments equipped with special valves not only enhances results but also enriches the overall musical experience, even as debates persist on the advantages of alternative materials such as nickel plating.

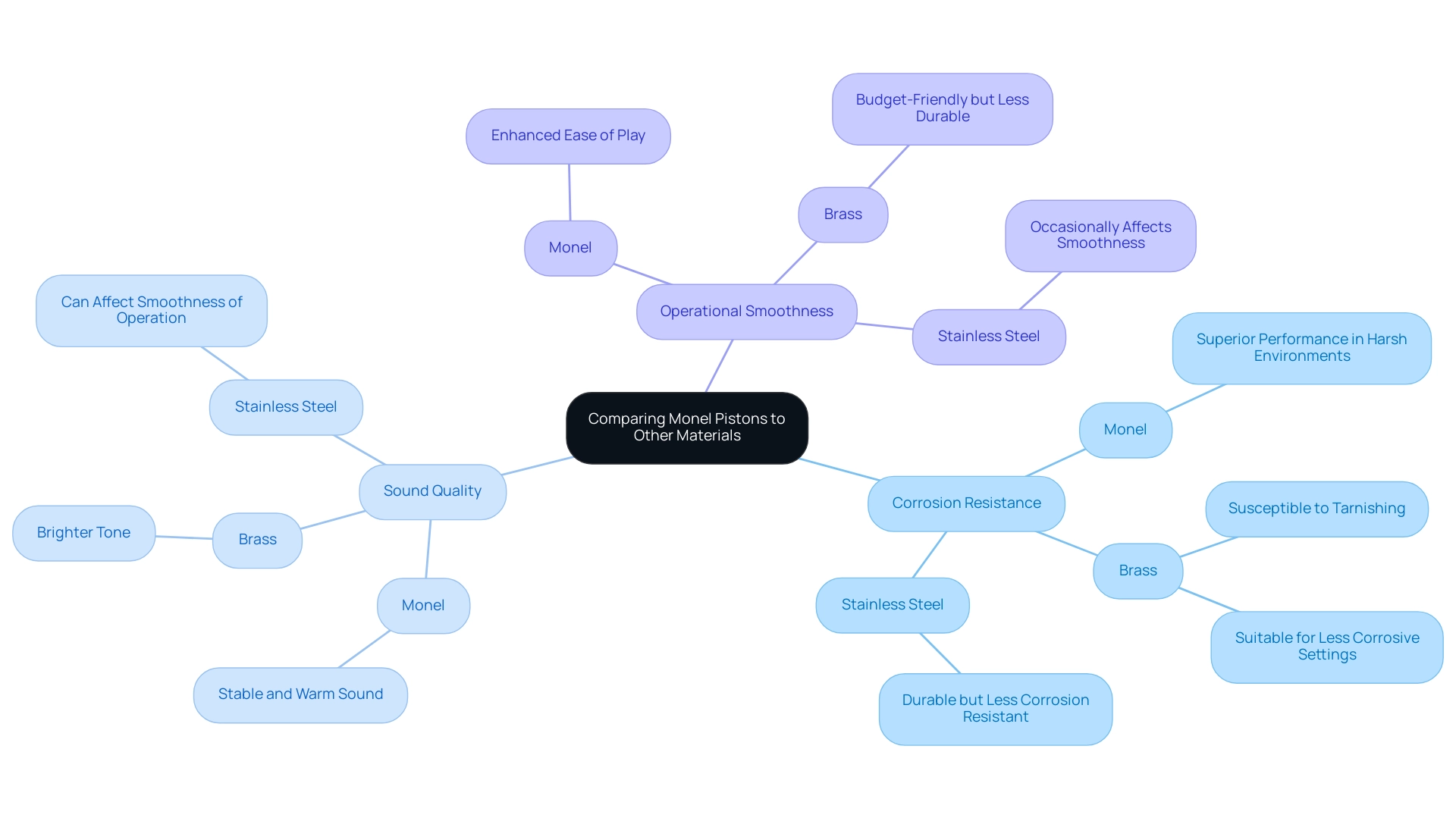

Comparing Monel Pistons to Other Materials: A Performance Perspective

When assessing monel piston materials against conventional options like brass and stainless steel, several critical performance factors emerge. The remarkable corrosion resistance of this alloy significantly surpasses that of brass, which consists of approximately 70% copper and 30% zinc and is susceptible to tarnishing and deterioration over time. This longevity makes this material an ideal choice for demanding environments, particularly in marine and chemical applications where durability is paramount.

A case study on corrosion resistance comparison illustrates that the monel piston alloy exhibits superior performance in harsh environments, reinforcing its value. Furthermore, the denser structure of the alloy components contributes to a more stable and consistent sound, enhancing the overall musical experience. In contrast, brass components, while budget-friendly, tend to produce a brighter tone that often lacks the warmth appreciated by musicians.

While stainless steel cylinders provide durability, they can occasionally affect the smoothness of operation in comparison to other materials, possibly resulting in a less enjoyable experience. As noted, the higher cost is justified by its exceptional properties, making it the best choice for musicians prioritizing durability, sound quality, and ease of play, ensuring an enhanced overall experience in their instruments.

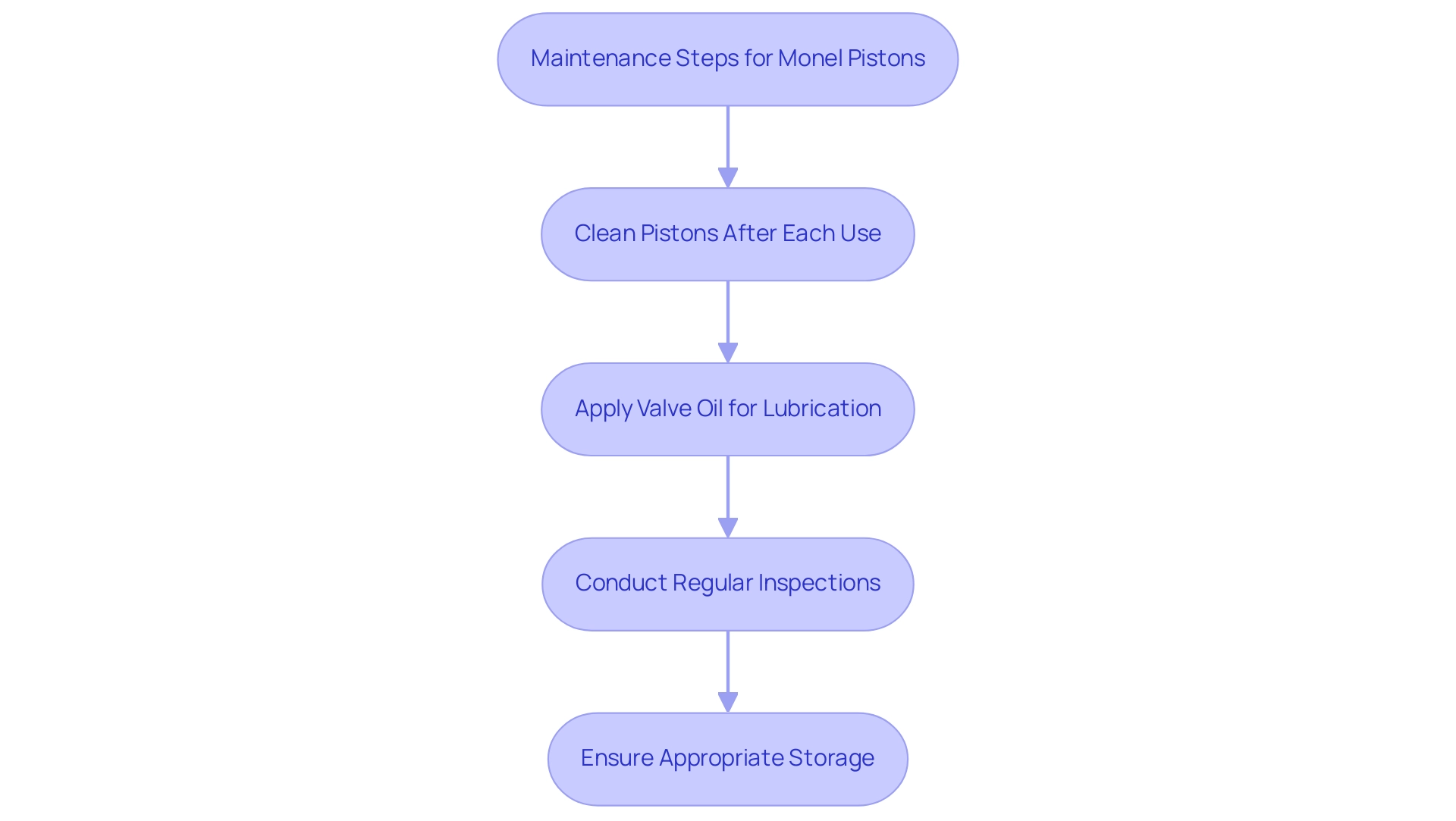

Maintenance Tips for Monel Pistons: Ensuring Longevity and Performance

To enhance the durability and functionality of the Monel piston components, especially in crucial applications like hydrogen refueling stations (HRSs), establishing a regular maintenance schedule is vital. In the context of HRSs, where reliable structural materials are paramount, musicians—akin to industrial users—should:

- Clean the pistons after each use with a soft cloth to eliminate moisture and prevent tarnishing, preserving the integrity of the material.

- Apply a suitable valve oil for lubrication to ensure smooth operation and mitigate the risk of sticking, which is crucial for maintaining performance standards in high-pressure environments.

Regular inspections should be conducted to identify any signs of wear or damage, as early detection can avert more significant problems later, aligning with the safety and efficiency standards outlined in the HRS infrastructure case study.

Appropriate storage is similarly essential; maintaining tools in a regulated setting that prevents extreme temperatures and humidity aids in safeguarding metal components from degradation. By adhering to these expert-recommended maintenance practices, musicians can significantly extend the life and functionality of their Monel pistons, ultimately enhancing their musical experience while also reflecting the stringent requirements of industrial applications like HRSs, where each station has a capacity of 160 kg/day, sufficient to fuel 300 hydrogen fuel cell vehicles.

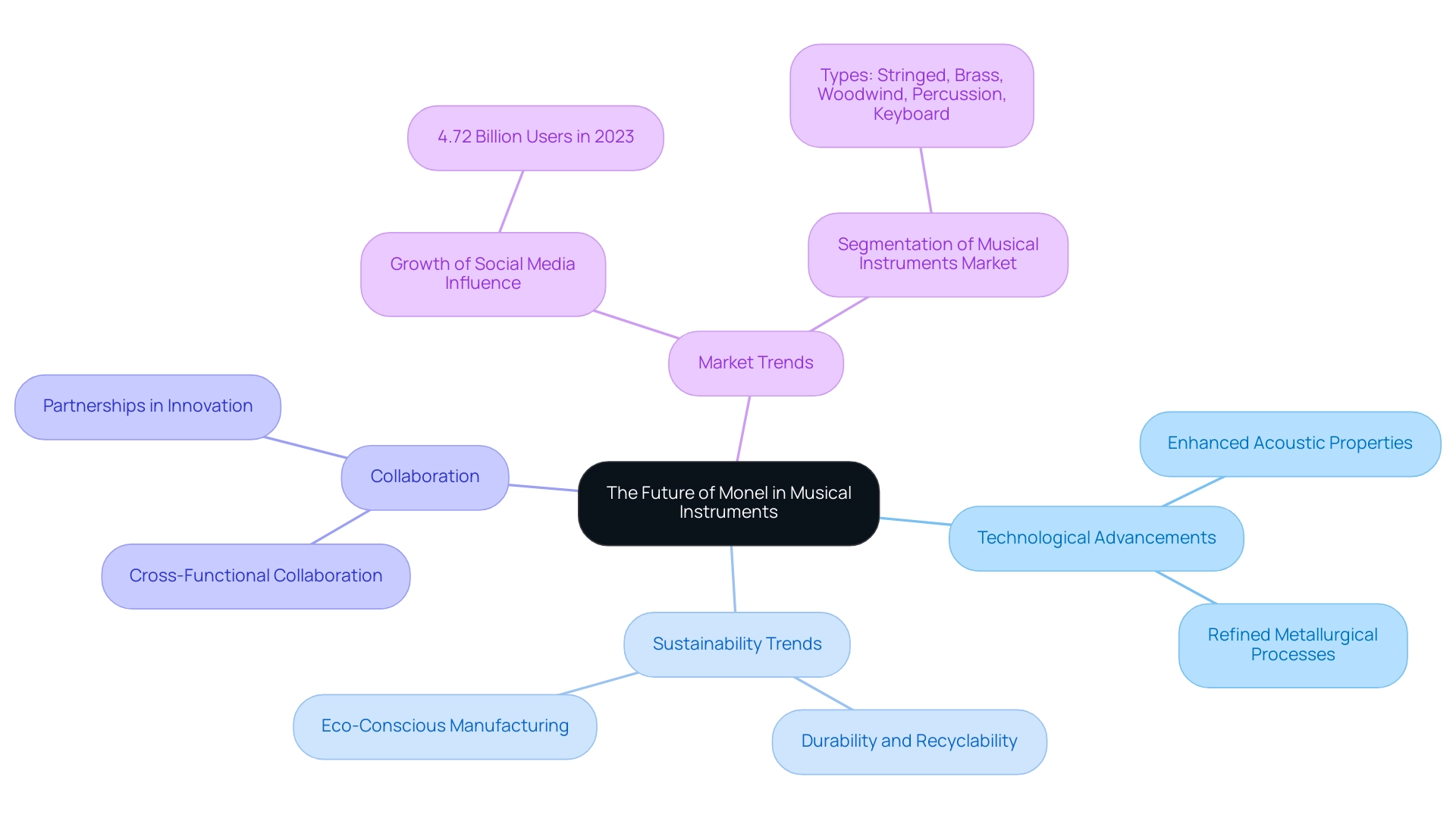

The Future of Monel in Musical Instruments: Trends and Innovations

The music sector is experiencing a significant change, integrating technological progress with creativity, and certain alloys are emerging as key contributors due to their unique characteristics that aid in manufacturing. Recent advancements in metallurgical processes are allowing manufacturers to refine specific alloys, thus significantly enhancing their acoustic properties and performance characteristics. These innovations not only enhance sound quality but also prolong the lifespan of musical tools, making them more attractive to musicians and producers alike.

In tandem with these developments, there is a notable trend toward sustainability in music production. This material’s inherent durability and recyclability position it as an appealing option for eco-conscious musicians and manufacturers aiming to minimize their environmental footprint.

As research into new applications and innovative combinations of the alloy with other materials progresses, we anticipate the emergence of advanced designs and functionalities in brass instruments that fully leverage its strengths. Industry expert Sneha Mali, a Research Analyst at Cognitive Market Research, emphasizes the significance of cross-functional collaboration in this dynamic landscape, stating, “Collaborating with cross-functional teams, Sneha remains an invaluable asset in the dynamic landscape of market research.” Such partnerships will be invaluable in pushing the boundaries of what Money can achieve in musical applications.

Additionally, as the number of social media users continues to grow, reaching 4.72 billion in January 2023, staying attuned to these trends will be essential for musicians and procurement managers looking to maintain a competitive edge in an increasingly sophisticated market.

Conclusion

Monel’s unique properties position it as a superior choice for musical instruments, particularly brass. Its corrosion resistance, strength, and warm tonal qualities not only enhance the durability of instruments but also enrich the sound they produce, making it a preferred material for both professional and student musicians. The use of Monel pistons exemplifies how this alloy can significantly improve the playability and longevity of brass instruments, offering a smooth and responsive action that is crucial for optimal performance.

In comparison to traditional materials like brass and stainless steel, Monel stands out for its ability to withstand harsh conditions, ensuring that musicians can rely on their instruments during demanding performances. The maintenance of Monel components also plays a critical role in preserving their benefits, with proper care extending the life and efficiency of these vital parts.

Looking ahead, the integration of Monel in musical instruments is poised for further innovation. As advancements in metallurgical processes enhance its properties and sustainability trends gain traction, Monel is likely to become even more integral to the music industry. By understanding the strategic advantages of Monel, procurement managers and industry professionals can make informed decisions that not only elevate the quality of musical instruments but also align with the evolving demands of musicians and the market. This proactive approach will ensure that both performance and durability remain at the forefront of instrument manufacturing, ultimately enriching the overall musical experience.