Blogs

What Are Monel Rustproof Staples? Understanding Their Benefits and Uses

Overview

Monel rustproof staples are fasteners made from a nickel-copper alloy known for exceptional corrosion resistance and durability, particularly in marine environments. The article explains that their unique properties, such as high strength and resistance to rust in harsh conditions, make them ideal for various applications, including boat building and construction, thereby reinforcing their value as a reliable fastening solution.

Introduction

In the realm of fasteners, Monel rustproof staples stand out as a premier choice, particularly for applications requiring exceptional durability and corrosion resistance. Crafted from a specialized nickel-copper alloy, these staples are engineered to thrive in the most demanding environments, including marine settings where exposure to saltwater and extreme conditions is a constant challenge. Their unique properties not only ensure structural integrity but also elevate their performance above traditional fasteners like stainless steel and plastic alternatives.

As industries increasingly recognize the advantages of Monel staples, understanding their benefits, applications, and best practices for use becomes essential for procurement managers seeking reliable and long-lasting fastening solutions. This article delves into the remarkable features of Monel staples, exploring their strategic advantages and providing insights into their optimal application across various sectors.

Introduction to Monel Rustproof Staples: What They Are and Their Unique Properties

Monel rustproof staples are made from a nickel-copper alloy known for its exceptional resistance to corrosion, especially in challenging environments. This unique alloy excels in situations where traditional metals typically succumb to rust and degradation. Monel rustproof staples are fasteners designed to maintain their structural integrity in both fresh and saltwater, making them highly appropriate for marine uses.

Among their notable properties are high strength and durability, along with the capability to endure extreme temperatures, which collectively enhance their reliability across various settings. The average voltage during the deposition of these items is recorded at 14.8 V, further indicating the precision involved in their manufacturing process. Recent research highlights that minor cold deformation is required to increase the yield stress of the WAAM layer to match that of the hot-rolled alloy, suggesting new opportunities for WAAM technology development.

This progress creates new opportunities for employing monel rustproof staples in various applications, thereby strengthening their reputation as a preferred choice for rustproof fastening requirements in demanding conditions. A case study proposes a new technology involving wire arc additive manufacturing followed by heat treatment and cold deformation, aiming to produce K500 components with hardness and strength comparable to hot-rolled products. Expert assessments highlight the exceptional performance of monel rustproof staples, with observations indicating that these fasteners not only meet but frequently surpass the resistance to rust of similar materials, reinforcing their role in construction and marine sectors.

As noted by O.M., ‘The authors declare that this study received funding from DMTC Limited (Australia),’ emphasizing the research’s credibility.

Benefits of Monel Rustproof Staples: Durability and Corrosion Resistance

Monel rustproof staples offer outstanding benefits, particularly in terms of durability and rust resistance, which are essential in challenging settings. Unlike traditional metal fasteners, monel rustproof staples are resistant to rust and corrosion when subjected to moisture, saltwater, or different chemicals. This characteristic makes monel rustproof staples invaluable in marine applications, where harsh conditions are common.

Their robust design allows these fasteners to endure significant loads without bending or breaking, thereby ensuring long-lasting performance even in high-stress situations. For instance, case studies have demonstrated that alloy 400 is extensively utilized in the oil and gas industry, ensuring safety and reliability in wellhead components and subsea pipelines, where it withstands extreme conditions and contributes to operational integrity. Additionally, considering the recent pricing shift in the market, Stainless Steel 316 has experienced its price increase from approximately 2951 USD/MT in January 2024 to 3406 USD/MT in June 2024, making nickel-copper alloy fasteners a cost-effective alternative for projects that require reliable fastening solutions.

As noted by industry expert Kat de Naoum, ‘It’s sometimes called ‘inox’ or rustless steel and is made of around 70–80% iron, with at least 10.5% chromium for the protective oxide layer bonus.’ The durability and environmental resilience of these fasteners not only offer a strategic advantage but also signify a wise investment for projects that require dependable fastening solutions. The distinctive resistance to rust of monel rustproof staples provides unmatched advantages that further increase their appeal in construction and marine environments.

Applications of Monel Rustproof Staples: Ideal Uses in Marine and Other Settings

Rust-resistant fasteners are crucial in marine settings, renowned for their outstanding durability against saltwater damage. Their main use is in boat building, where they are essential in the construction, repair, and maintenance of marine equipment. A performance analysis of Monel alloys indicates that monel rustproof staples excel in preventing deterioration and leaks, which are essential factors for longevity in maritime use.

Furthermore, copper nickel alloys demonstrate significant advantages over stainless steel, particularly in marine environments due to their superior corrosion resistance and mechanical strength. Common applications of copper nickel alloys include:

– Ship hulls

– Offshore platforms

– Seawater piping systems

– Automotive systems for brake lines and hydraulic systems

– Electronics

– Heat exchangers

This versatility allows them to perform reliably in demanding conditions, including construction tasks where secure fastening of roofing materials and other components is necessary. As Robert C. noted, ‘I use a lot of fasteners in my T50 stapler.’ These fasteners would not function on hard wood but do work on pine.

‘Won’t buy again.’ This feedback illustrates the practical uses of metal fasteners in different environments. As industries continue to recognize the advantages of both nickel-copper alloys and the use of monel rustproof staples, their usage in sectors requiring durable and corrosion-resistant solutions is on the rise.

Additionally, the product dimensions of the metal fasteners are as follows:

– Width: 0.52 in

– Length: 4.25 in

– Height: 2.88 in

This underscores their suitability for a range of fastening applications.

Comparing Monel Staples to Other Fasteners: Why Choose Monel?

When assessing fastener choices for construction, especially in marine settings, the benefits of certain metal fasteners over options such as stainless steel and plastic are considerable. These fasteners demonstrate improved rust resistance, particularly against saltwater exposure, preserving their structural integrity under severe conditions. In a case study titled ‘Metal Bolts vs. Stainless Steel,’ it was noted that alternative bolts provide improved resistance to saltwater and general corrosion compared to stainless steel, which often falls short in highly saline environments.

For example:

- Alloy 400 demonstrates slightly better strength compared to standard 316 bolts.

- Alloy K500 offers more than double the strength of these widely used fasteners.

This performance is crucial in marine contexts where durability is paramount. Furthermore, although plastic fasteners are lightweight and immune to rust, they lack the load-bearing capacity and strength essential for demanding projects.

Kat de Naoum, a writer and content expert, points out that ‘these fasteners are a superb option for marine uses because of their unmatched durability in tough conditions.’ Therefore, when durability and corrosion resistance are essential, these fasteners emerge as the optimal choice, ensuring both performance and reliability in critical constructions. It is also important to recognize that there are over 100 grades of stainless steel, which can further contextualize why this material may be a superior choice in specific applications.

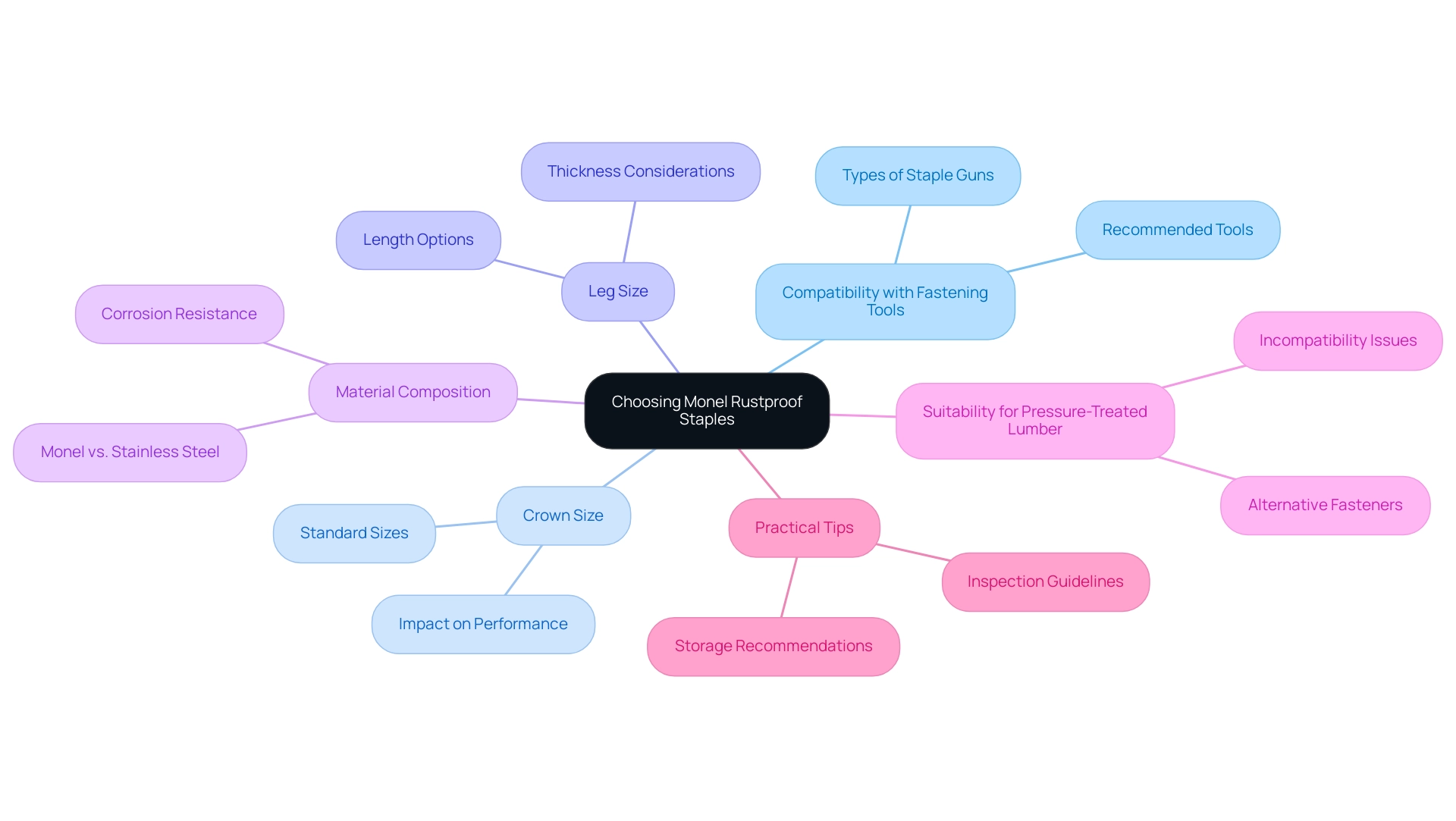

Choosing and Using Monel Rustproof Staples: Tips for Best Results

Choosing monel rustproof staples as rust-resistant fasteners necessitates thoughtful evaluation of your project’s unique requirements, including material thickness and the environmental conditions they will encounter. As noted by Renewed Warriors, it is important to recognize that Monel fasteners are incompatible with pressure-treated lumber, which can influence your choice of connectors. It is crucial to choose the correct gauge and length to guarantee optimal performance.

A Lieutenant Commander recently switched to galvanized fasteners for roofing felt after running out of stainless steel ones, illustrating real-world decision-making in fastener selection. Utilizing the right tools during installation can significantly enhance the effectiveness of these fasteners. To achieve the best results, store essentials in a dry environment to mitigate potential damage.

Moreover, regularly inspecting installed fasteners for signs of wear or corrosion is particularly important in marine applications, where exposure to harsh conditions can compromise the integrity of fastened materials. The case study titled ‘Criteria for Choosing Fasteners’ highlights key factors such as:

- Compatibility with fastening tools

- Crown size

- Leg size

- Material composition

- Suitability for pressure-treated lumber

By adhering to these best practices, you can maximize the performance and longevity of monel rustproof staples, ensuring that your projects are executed with precision and reliability.

Conclusion

Monel rustproof staples offer a compelling solution for industries demanding reliable and durable fastening options. Their unique nickel-copper alloy composition ensures exceptional corrosion resistance, particularly in harsh marine environments where traditional fasteners often fail. By outperforming alternatives like stainless steel and plastic fasteners, Monel staples maintain their structural integrity and strength, making them indispensable in critical applications ranging from boat building to oil and gas infrastructure.

The numerous advantages of Monel staples, including their high strength, durability, and cost-effectiveness, reinforce their value in construction and marine settings. As industries increasingly recognize the financial and operational benefits of these fasteners, the trend towards their adoption is expected to grow. Moreover, understanding the best practices for selecting and using Monel staples enhances their effectiveness, ensuring that projects meet the highest standards of quality and safety.

In conclusion, Monel rustproof staples represent a strategic investment for procurement managers seeking to enhance their fastening solutions. By prioritizing durability and corrosion resistance, these staples not only contribute to the longevity of projects but also provide peace of mind in demanding environments. As the need for reliable fastening solutions continues to evolve, Monel staples stand out as a premier choice that delivers exceptional performance across various applications.