Blogs

What is the Composition of Invar? A Comprehensive Overview

Introduction

In the realm of precision engineering, few materials rival the capabilities of Invar, a nickel-iron alloy celebrated for its remarkably low thermal expansion properties. Since its discovery in the early 20th century, Invar has become a cornerstone in applications demanding unparalleled dimensional stability, from intricate measuring instruments to the rigorous demands of aerospace technology.

As industries increasingly prioritize performance and precision, understanding the unique characteristics and diverse applications of Invar is essential for procurement managers seeking to optimize their material choices.

This article delves into the significance of Invar, its chemical composition, and the strategic advantages it offers, providing insights that are crucial for informed decision-making in today’s competitive landscape.

Understanding Invar: Definition and Significance

The nickel-iron alloy is renowned for its exceptionally low thermal expansion, making it invaluable in sectors requiring precise dimensional stability. Unearthed in the early 20th century, its unique properties have resulted in extensive utilization in areas such as:

- Precision instruments

- Clocks

- Measuring devices

The low thermal expansion coefficient of this alloy ensures that components maintain their shape and size despite fluctuations in temperature, enhancing the performance and accuracy of sensitive instruments.

Significantly, Carpenter Technology’s Free-Cut ’36’® material (UNS K93600) provides enhanced machinability for uses where high parts productivity is crucial, aligning perfectly with the requirements of procurement managers concentrated on operational efficiency. Recent advancements in alloy applications in 2024 highlight its growing importance across various industries, where superior performance and precision are paramount. As industries increasingly prioritize low thermal expansion materials, this alloy stands out as a critical component for achieving operational excellence in precision engineering.

To further enhance decision-making efficiency, it is essential to address communication breakdowns within procurement processes by maintaining clear channels, open dialogue, and regular check-ins. Additionally, the case study of resolving data accuracy conflicts illustrates the real-world challenges faced in the use of precision instruments, demonstrating the need for strategic solutions in procurement.

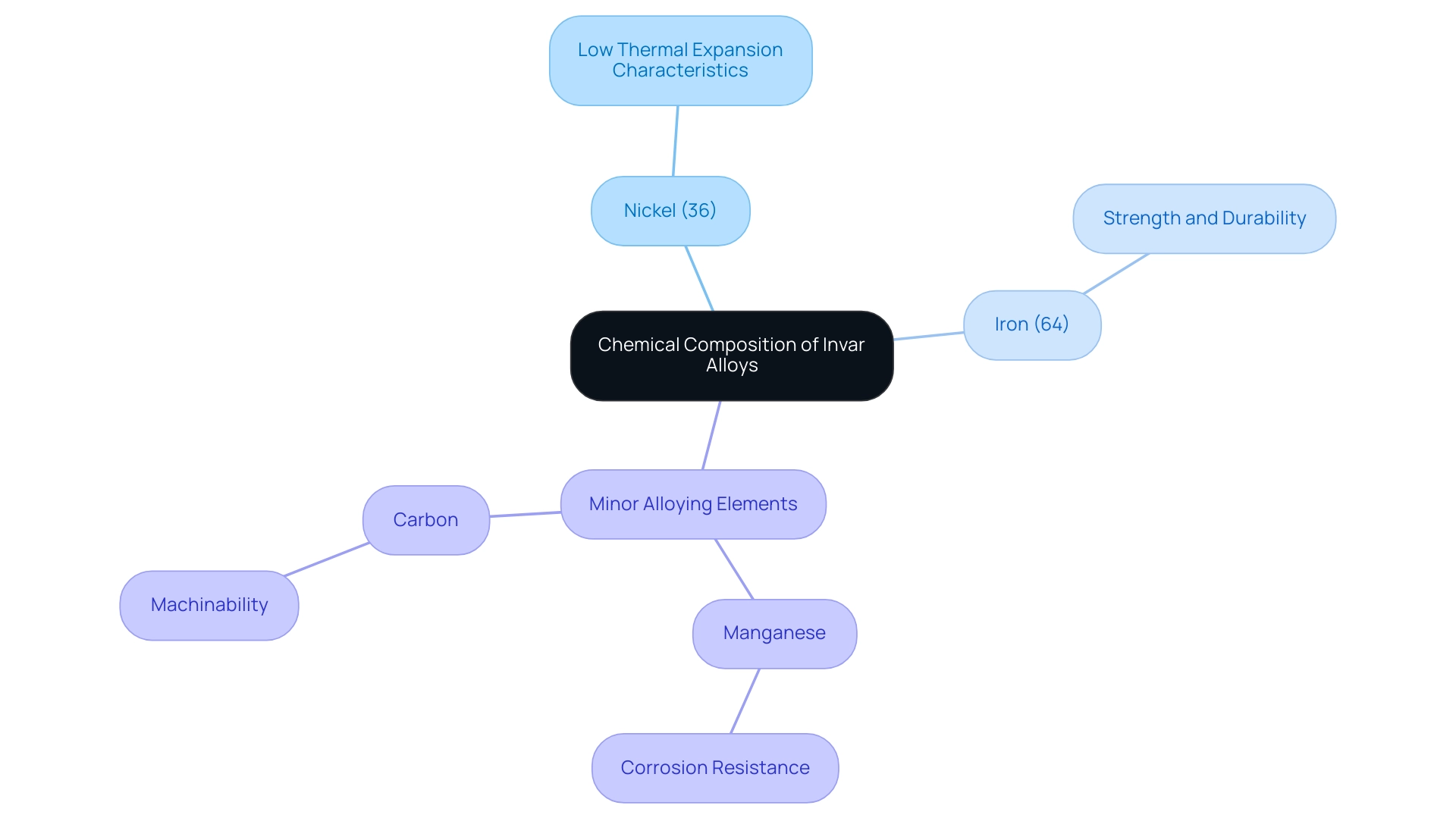

Chemical Composition of Invar Alloys: Key Elements and Their Roles

The composition of invar materials is mainly around 36% nickel and 64% iron, although changes may occur depending on particular uses. The nickel content is especially important, as it is responsible for giving the mixture its outstanding low thermal expansion characteristics, which are crucial in precision uses. Iron contributes to the overall strength and durability of the mixture, making it suitable for demanding environments.

Additionally, minor alloying elements such as manganese and carbon may be incorporated to improve characteristics like corrosion resistance and machinability. For example, a 50 kg ingot of Fe-33.6Ni-6.5Cr-0.19C metal was prepared and processed for mechanical characteristics measurements, illustrating the practical uses of its chemical composition. Comprehending the composition of invar and other compositional nuances is essential for procurement managers when choosing the suitable material for various applications, ensuring both optimal performance and compliance with industry standards.

In contrast, soft magnetic iron-nickel mixtures, which usually have comparable compositions, are recognized for their outstanding magnetic characteristics and are frequently utilized in transformer cores and inductors. As mentioned by metallurgist Huifen Peng, ‘Strengthening of the Fe-Ni Mixture Through Chromium,’ ongoing research emphasizes the significance of chemical composition in improving the characteristics of such materials. Additionally, a case study named ‘Acoustic-Mode Vibrational Anharmonicity in Certain Alloys’ investigates the connection between acoustic-mode vibrational anharmonicity and the unusual thermal expansion noted in these iron mixtures, enhancing comprehension of the thermal characteristics of these substances.

This knowledge offers a strategic benefit in material choice and use in industry, especially when assessing the performance metrics of certain alloys versus soft magnetic iron-nickel alloys.

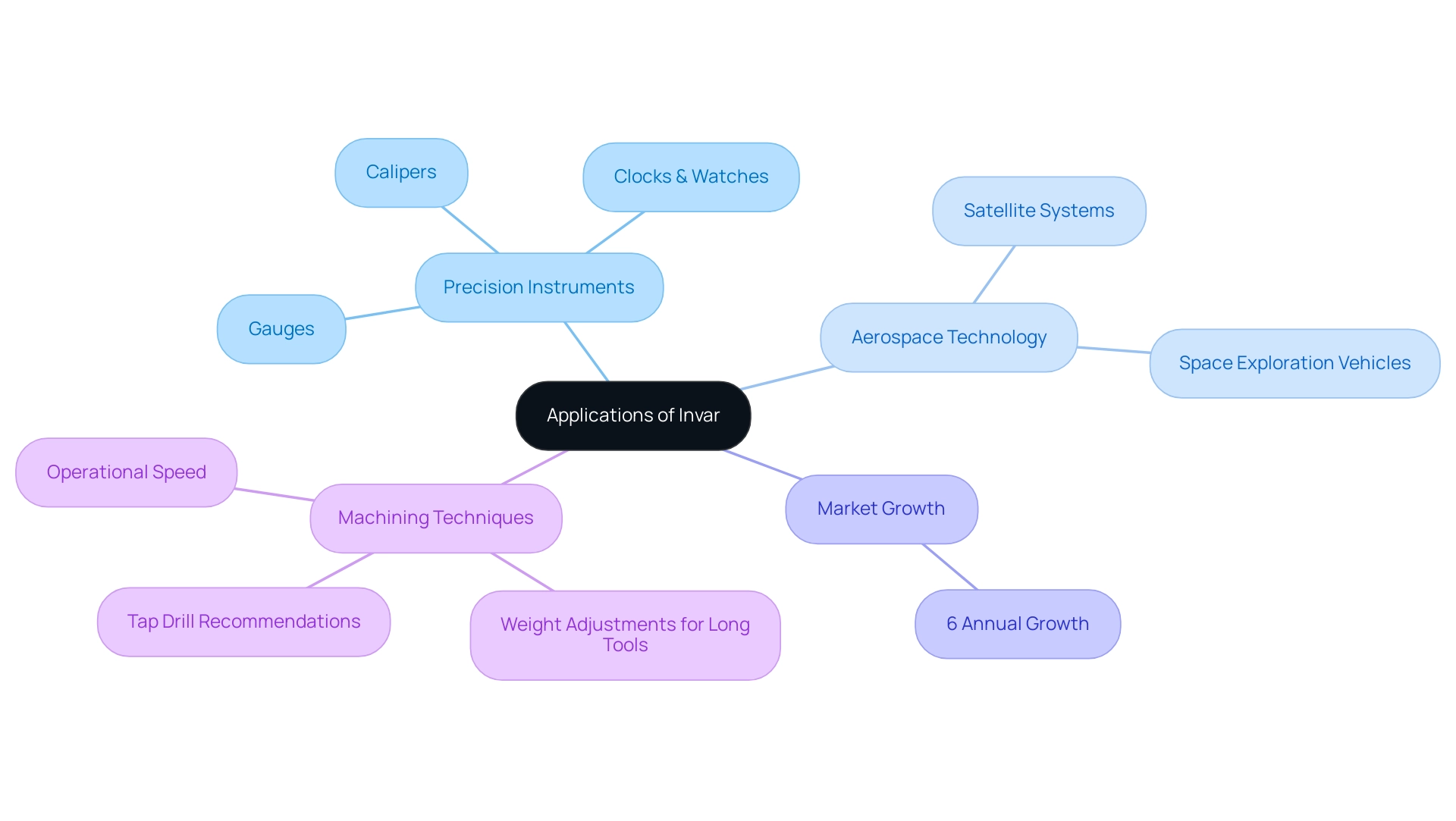

Applications of Invar: From Precision Instruments to Aerospace

The distinctive characteristics of this material make it crucial in multiple uses, especially in precision devices and aerospace technology. In the realm of precision measuring devices, such as gauges and calipers, this alloy is favored for its minimal thermal expansion, ensuring that even minute temperature changes do not lead to significant errors. This characteristic is crucial in industries where accuracy is non-negotiable.

Furthermore, the aerospace sector increasingly depends on a specific alloy for components designed to endure extreme temperature fluctuations without sacrificing structural integrity. Significantly, the 36 alloy fulfills the criteria of specification Boeing D-33028, emphasizing its significance in aerospace applications. For instance, in satellite systems and space exploration vehicles, this material plays a vital role in maintaining performance under harsh conditions.

The market for this specialized tooling is projected to grow at a robust rate of 6% annually over the next seven years, indicating a rising demand for this high-performance material. Additionally, this material is utilized in the production of precision instruments such as clocks and watches, reinforcing its critical contribution to technology that prioritizes accuracy. Experts in the field emphasize the need for specialized machining techniques, such as using a tap drill slightly larger than the standard drill and a two or three-fluted tapping tool on automatic machines, with operational speeds around 20 feet per minute.

For tools exceeding 8 feet in length, weights may be added to the ends and/or center of the tool as required to further assist in maintaining contour. These practices further highlight the meticulous approach required when working with this material to ensure optimal performance in precision applications. Moreover, investment opportunities exist in companies focused on precision engineering and sustainability, as the demand for high-performance materials rises, making the alloy market poised for growth.

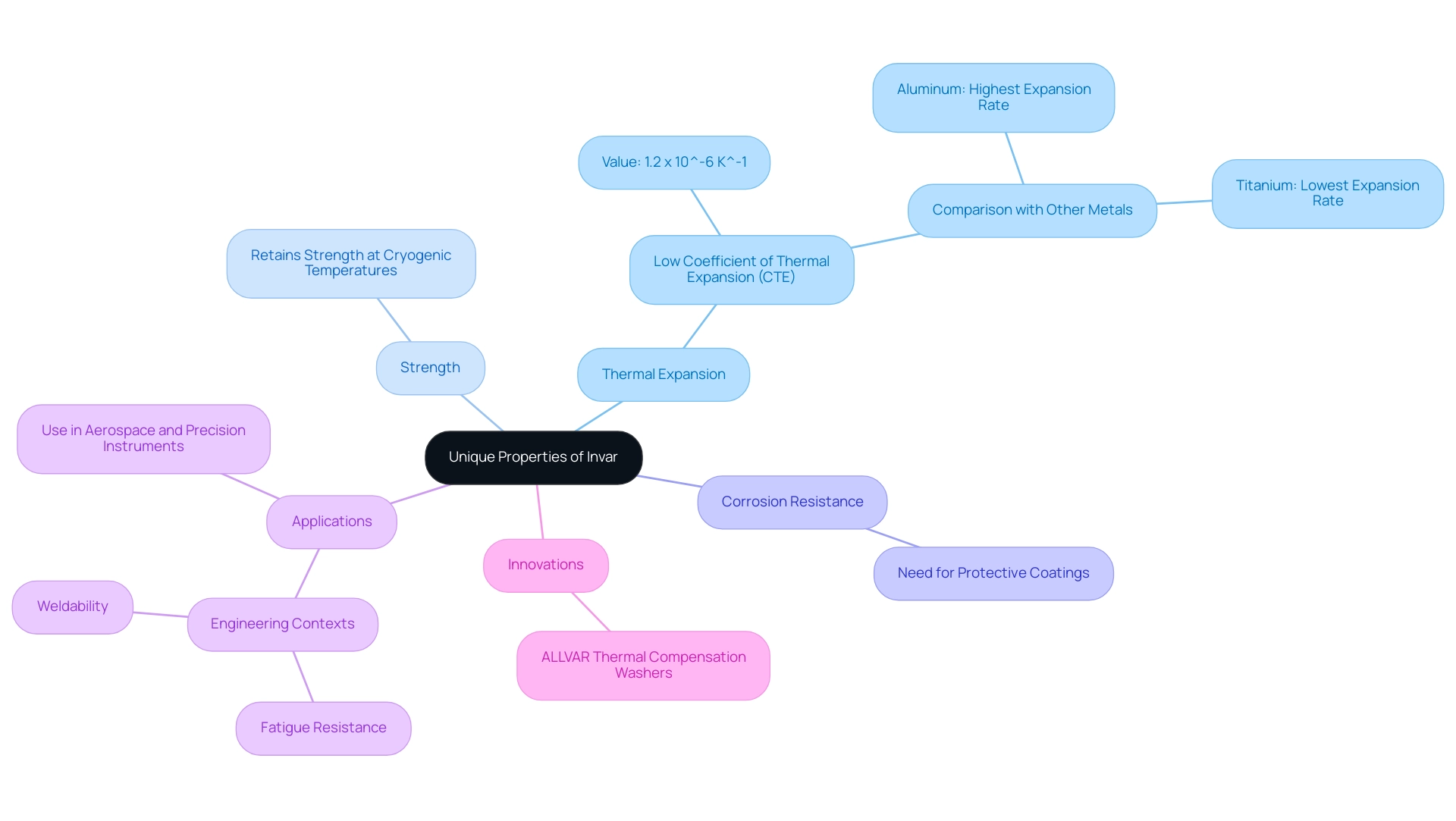

Unique Properties of Invar: Low Thermal Expansion and Beyond

This alloy’s defining characteristic is its remarkably low coefficient of thermal expansion (CTE), achieving values as low as 1.2 x 10^-6 K^-1. This property makes this alloy particularly beneficial for uses requiring high dimensional stability, as it experiences minimal expansion under temperature changes. Finnerty succinctly noted that, when you consider a ‘real world’ temperature range of say, -25 C to 200 C, the metal with the lowest CTE is an alloy known as ‘Invar’, which highlights the composition of invar and its superiority in this regard.

Furthermore, this alloy retains strength even at cryogenic temperatures, making it suitable for extreme conditions. In comparison to other metals:

– Aluminum has the highest expansion rate

– Titanium exhibits the lowest

This illustrates its exceptional performance. Along with its low CTE, these materials exhibit outstanding mechanical characteristics, featuring significant fatigue resistance and weldability, improving their applicability in diverse engineering situations.

However, it is essential to recognize that this material is prone to corrosion; thus, implementing protective coatings or treatments is advisable in certain environments. Simultaneously, copper nickel alloys are acknowledged for their high corrosion resistance, outstanding thermal and electrical conductivity, good ductility, ease of fabrication, and antimicrobial characteristics, rendering them appropriate for various uses, particularly in settings where cleanliness is essential. Recent advancements, such as ALLVAR thermal compensation washers, showcase innovative solutions for those employing this specific alloy.

A thorough grasp of these characteristics, along with the benefits provided by high-temperature materials such as mica tape, which offers outstanding thermal and electrical insulation as well as flame resistance, is essential for engineers and procurement experts, guaranteeing knowledgeable material selection customized to specific usage needs.

Exploring Variations of Invar: Super Invar and Other Alloys

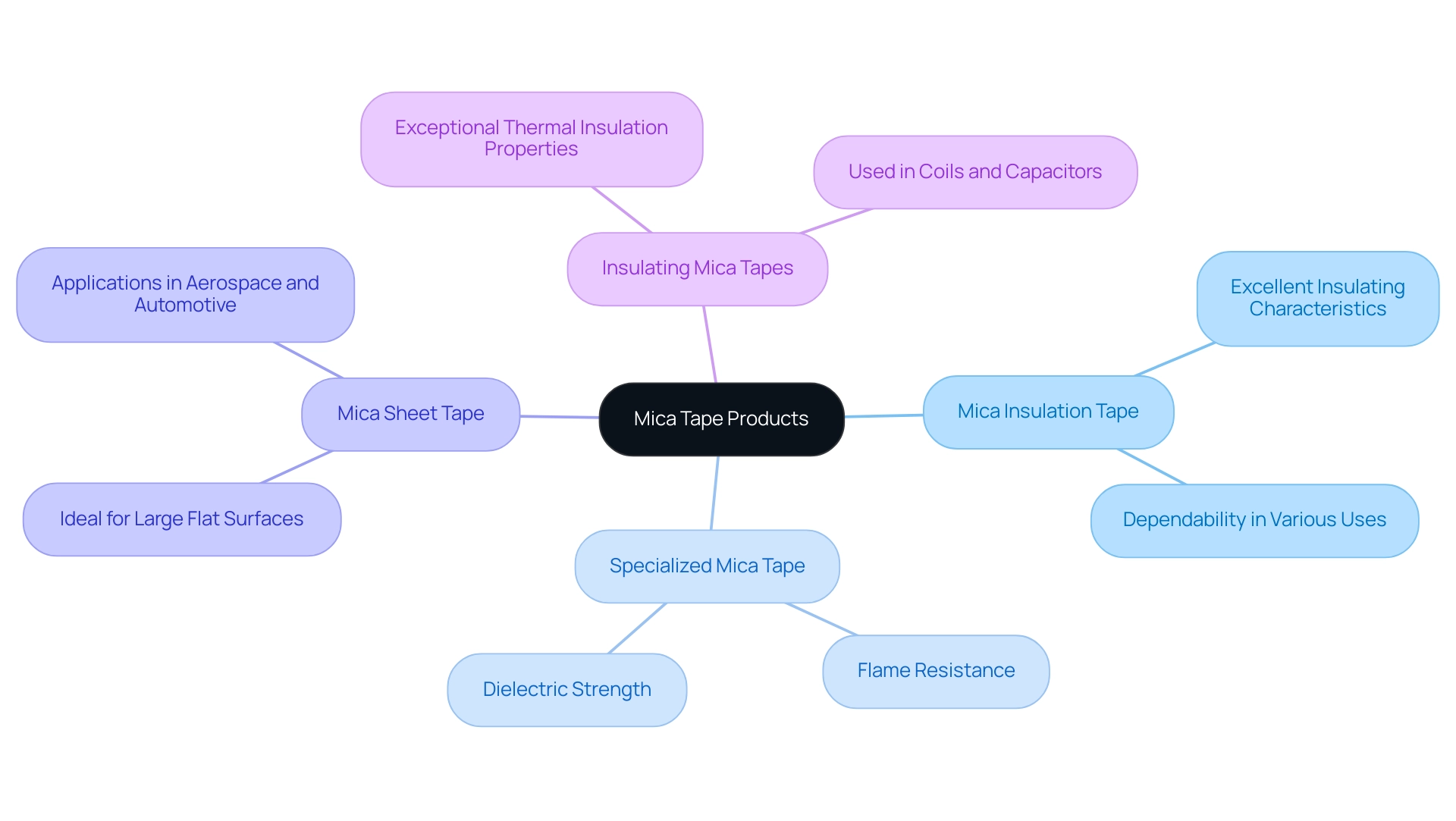

In addition to the advanced Invar alloys, procurement managers should consider the exceptional range of Mica Tape products available in the market, designed to meet high-temperature resistance and electrical insulation requirements. Our Mica Insulation Tape provides excellent insulating characteristics, guaranteeing dependability in uses spanning from home devices to industrial equipment. The specialized Mica Tape for electrical uses provides excellent flame resistance and dielectric strength, crucial for fire-resistant cables and other critical electrical insulation systems.

Furthermore, our Mica Sheet Tape is ideal for insulating large flat surfaces in challenging environments, particularly within aerospace and automotive sectors. Additionally, our range of Insulating Mica Tapes is tailored to provide exceptional thermal and electrical insulation properties, making them indispensable in the construction of coils, capacitors, and other components that require high-grade insulation to maintain safety and performance. Understanding the benefits and applications of these various Mica Tape solutions is essential for navigating material selection complexities and ensuring that performance requirements are met across diverse applications.

Conclusion

Invar stands out as a pivotal material in precision engineering, primarily due to its remarkable low thermal expansion properties. This nickel-iron alloy has established itself as indispensable across various sectors, including aerospace and precision instruments, where even the slightest dimensional changes can lead to significant operational challenges. The article highlights how Invar’s chemical composition, primarily consisting of 36% nickel and 64% iron, plays a crucial role in its performance, offering both strength and stability under temperature fluctuations.

Furthermore, the diverse applications of Invar—from precision measuring devices to critical aerospace components—underscore its versatility and growing market demand. With projections indicating a robust annual growth rate for Invar tooling, procurement managers are urged to recognize the strategic advantages this material offers. Understanding the unique properties of Invar, including its excellent mechanical performance and resistance to extreme conditions, is essential for informed decision-making in selecting the right materials for specific applications.

In conclusion, the significance of Invar in achieving operational excellence cannot be overstated. As industries increasingly prioritize precision and performance, leveraging the advantages of Invar will be crucial for maintaining competitive edge and meeting the rigorous demands of today’s technological landscape. Emphasizing strategic material selection and fostering effective communication within procurement processes will further enhance the ability to capitalize on the exceptional properties of Invar and its variants.