Blogs

Why Are Some Materials Magnetic and Others Not? Exploring the Science Behind Magnetism

Introduction

In the intricate world of materials science, magnetism stands out as a fundamental property that shapes the functionality of countless industrial applications. Understanding the nuances of magnetic materials—ranging from ferromagnetic to diamagnetic—provides procurement specialists with valuable insights necessary for strategic sourcing and decision-making.

As industries evolve, the demand for advanced materials with specific magnetic characteristics is set to surge, particularly in sectors like automotive, electronics, and healthcare. This article delves into the essential principles of magnetism, the critical role of electron configuration, and the impact of temperature on magnetic properties, while also exploring the latest trends in magnetic materials research.

By equipping procurement managers with expert knowledge and practical applications, organizations can ensure they remain at the forefront of innovation and efficiency in their material selections.

Understanding the Basics of Magnetism: What Makes Materials Magnetic?

Magnetism is an intrinsic physical phenomenon resulting from the motion of electric charges, which creates fields of magnetism. The fundamental cause why certain substances display attractive features is explained by why are some materials magnetic and others not, which is based on their atomic composition. Materials can be classified into three main groups based on their attraction characteristics: ferromagnetic, paramagnetic, and diamagnetic.

- Ferromagnetic substances, like iron, cobalt, and nickel, exhibit prominent properties due to the alignment of their moments in a uniform direction. This alignment is facilitated by the presence of unpaired electrons within their atomic structure, which significantly enhances their attraction properties.

- Paramagnetic substances have unpaired electrons too but do not have the capacity to retain magnetization once the external field is taken away.

- Diamagnetic substances, such as copper and bismuth, contain fully paired electrons, leading to a slight repulsion from fields.

Grasping these classifications is crucial for procurement specialists, especially when evaluating the global market share of ferromagnetic substances and addressing the question of why are some materials magnetic and others not, which is anticipated to attain notable levels in 2024. For example, Metglas 2605S–3 has a maximum coercivity of 30,000 A/m and a resistivity of 1.58 μΩ·cm, demonstrating the advanced characteristics of specific substances.

Furthermore, when assessing substances for high-temperature resistance and electrical insulation, Domadia’s Mica Tape products stand out due to their superior durability and reliability, making them ideal for critical electrical engineering tasks that require robust insulation. These tapes excel in applications such as fire-resistant cables, where their flame resistance and dielectric strength are paramount. Additionally, the importance of Non-Sparking Tools in explosive environments cannot be overstated; these tools are designed with safety features to prevent spark-related incidents in potentially hazardous conditions, ensuring operational safety in critical applications.

The recent case study titled ‘Synthesis and Characterization of Magnetic Head’ emphasizes how the synthesis route significantly influences the phase structure and characteristics of high-entropy alloys. This understanding is essential for procuring resources in sectors like automotive and electronics, particularly in relation to why are some materials magnetic and others not, where both attraction characteristics and safe operational standards are paramount.

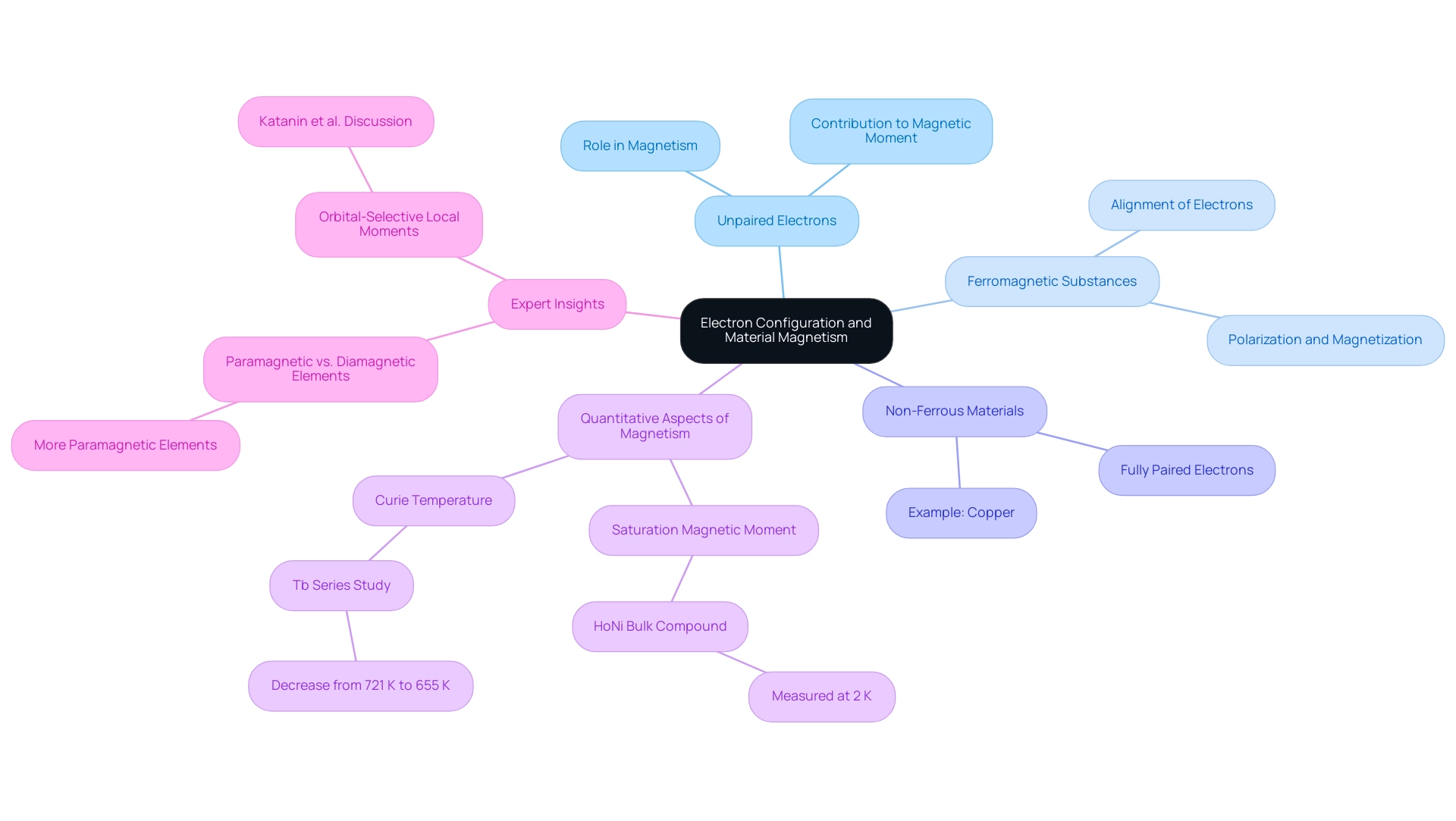

The Role of Electron Configuration in Material Magnetism

The electron arrangement of an atom is fundamental in determining why are some materials magnetic and others not, especially through the presence of unpaired electrons in outer shells. These unpaired electrons are crucial in explaining why are some materials magnetic and others not, as they contribute to the overall magnetic moment of substances that exhibit magnetism. For example, in ferromagnetic substances, when these unpaired electrons align in the same direction, it illustrates why are some materials magnetic and others not, as the substance exhibits polarization, enabling it to be magnetized.

In contrast, non-ferrous substances, such as copper, have fully paired electrons, resulting in a net magnetic moment of zero, which helps explain why are some materials magnetic and others not. This distinction is vital when evaluating uses in which particular electromagnetic features are essential, such as electric motors or sensors, and it helps explain why are some materials magnetic and others not. Significantly, the total saturation moment of the HoNi bulk compound is measured at 6.84 /f.u at 2 K, illustrating the quantitative aspects of magnetism.

Additionally, a study on the crystal and electronic structure of the Tb series revealed that Gd/Tb substitution leads to a decrease in lattice parameters and a reduction in the Curie temperature from 721 K to 655 K as the Tb content increases, which raises the question of why are some materials magnetic and others not in relation to electron configuration. Current studies also emphasize that more paramagnetic elements exist than diamagnetic ones, as noted by an expert in the field, who stated,

There are more paramagnetic elements than diamagnetic when considering the ground-state electron configurations.

Additionally, Katanin et al. discussed the orbital-selective formation of local moments in iron, adding complexity to the behavior of substances. For procurement specialists, understanding these nuances is crucial for making informed selections that align with operational requirements and technological advancements.

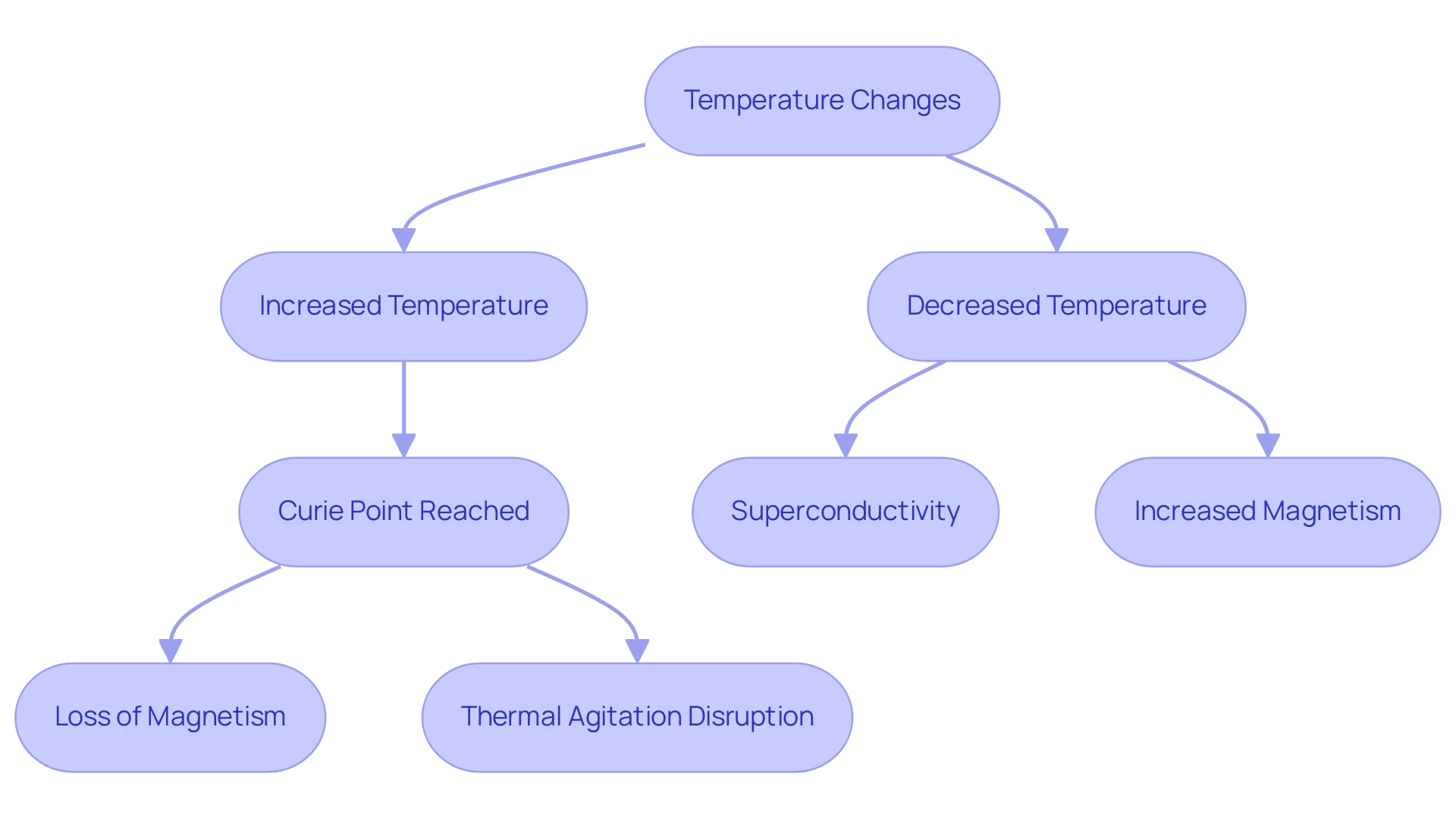

Temperature Effects on Magnetic Properties

Temperature plays a crucial role in defining the properties of substances, leading to the inquiry of why are some materials magnetic and others not, especially in ferromagnetic ones. When subjected to high temperatures, these substances can lose their magnetism, which leads to the question of why are some materials magnetic and others not, in a phenomenon known as the Curie point. Above this threshold, thermal agitation disrupts the orderly alignment of dipole moments, leading to a non-ferromagnetic state and prompting the inquiry of why are some materials magnetic and others not.

In contrast, certain substances demonstrate magnetic properties at lower temperatures, which leads to the question of why are some materials magnetic and others not, as exemplified by superconductivity. For procurement managers, grasping these temperature-dependent behaviors is crucial, particularly when choosing substances for applications exposed to significant thermal variations, such as in aerospace or automotive sectors. In this context, Domadia’s Mica Tape products, recognized for their flame resistance and dielectric strength, stand out as dependable solutions for high-temperature electrical insulation, ensuring optimal performance where conventional substances may fail.

Recent research indicates that ferromagnetic effects can produce magnetizations several orders of magnitude greater than the applied field, underscoring the substance’s potential before reaching its Curie point. Furthermore, it is crucial to acknowledge that not all temperatures are accessible in the Curie-point technique, as each temperature needs a specific alloy content for the wire or foil, which can complicate selection. In a recent study evaluating high-temperature structural stability, substances like CrIn, RhCl, and ZnNi successfully maintained their crystal structures at 400 K, while Mxene MN exhibited melting after just 3 ps, highlighting the importance of temperature resilience in practical applications.

As David E. Laughlin noted in ‘Physical Metallurgy (Fifth Edition)’, understanding the modified version of the Curie-Weiss law, which applies to the dielectric constant, is crucial for comprehending the interactions between temperature and magnetic properties. Understanding why are some materials magnetic and others not, alongside how temperature affects magnetism and the benefits of certain tapes—like Insulation Tape, Tape for Electrical, and Sheet Tape—for electrical insulation, is essential for informed selection. We encourage procurement managers to explore Domadia’s Mica Tape offerings to ensure optimal performance in challenging environments.

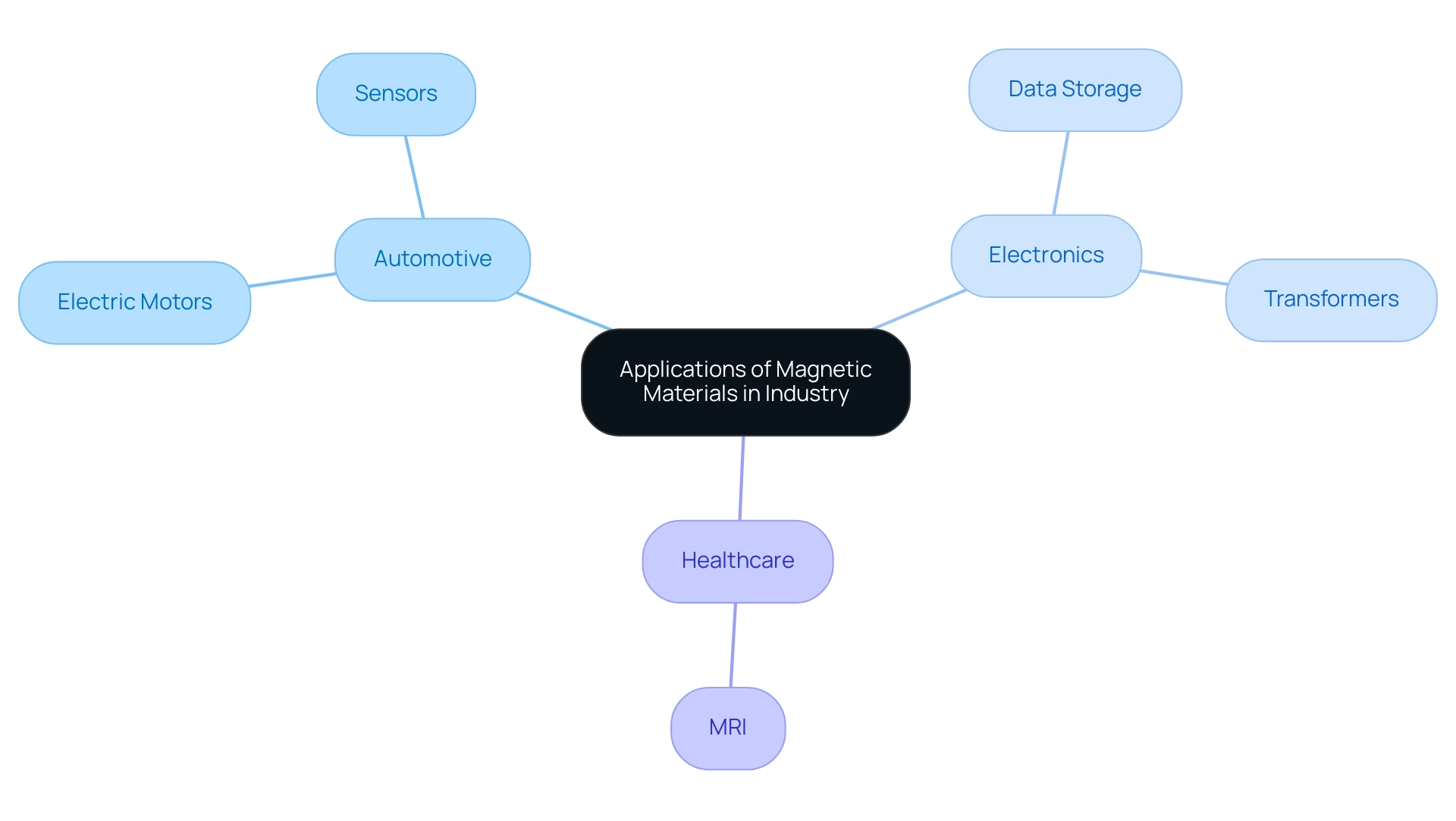

Applications of Magnetic Materials in Industry

Magnetic substances are integral to various industries, including automotive, electronics, and healthcare, prompting the question of why are some materials magnetic and others not, as each sector benefits from their unique properties. In the automotive sector, permanent magnets significantly enhance the efficiency and performance of electric motors and sensors. This trend is anticipated to propel market growth, with forecasts suggesting significant expansion in the automotive components sector by 2024, fueled by greater demand in the automotive and electrical industries, along with rising usage in the energy and power fields.

In the field of electronics, it is important to explore why are some materials magnetic and others not, as ferromagnetic substances play a crucial role in data storage solutions, including hard drives and tape storage, as well as in transformers and inductors, underscoring their significance in the digital era. Furthermore, in healthcare, magnetic resonance imaging (MRI) utilizes the characteristics of magnetic substances to explore why are some materials magnetic and others not, generating high-resolution images that are essential in medical diagnostics. Alongside these applications, products like Domadia’s high-quality Mica Tapes provide excellent electrical insulation at elevated temperatures, essential for various industrial processes.

Additionally, Domadia’s Oxygen Free Copper (OFE/OHFC) is crucial for critical medical components, ensuring reliability and performance. Join the ranks of satisfied customers who rely on Domadia for their high-temperature electrical insulation needs. Recognizing these applications allows procurement specialists to make informed choices about sourcing the most appropriate resources for their projects, ensuring compliance with performance standards.

As noted by the Critical Materials Institute, ‘This advancement is particularly noteworthy because it offers a pathway to creating compact and energy-efficient motors without relying on rare earth elements.’ Comprehending these advancements, along with the anticipated market size of ferrites in the automotive sector, is essential for procurement managers looking to enhance resource selection and promote innovation within their organizations. To explore our range of Mica Tapes and learn more about how they can benefit your business, visit our website or contact our expert team today.

Future Trends in Magnetic Materials Research

The field of ferromagnetic substances research is experiencing considerable change, propelled by the demand for improved performance along with sustainability. Advancements in nanostructures and composite substances are leading this evolution, providing encouraging paths for enhancing characteristics while reducing environmental effects. Recent advancements in the synthesis of nanostructures have demonstrated remarkable improvements in magnetic responsiveness and efficiency.

Simultaneously, the acquisition of high-temperature substances, like Tape Products, is becoming significant due to their outstanding insulation characteristics in numerous applications, including electrical engineering and industrial machinery. Mica Tape Products, known for their high-temperature resistance and electrical insulation, are indispensable in manufacturing fire-resistant cables and critical electrical insulation systems. Additionally, Non-Sparking Tools are becoming essential for operations in explosive environments; their flame-resistant characteristics and reliability significantly enhance safety during operations.

As procurement managers navigate these developments, it is imperative to remain informed about the suppliers and manufacturers of these critical materials. Furthermore, resolving conflicts and building a positive atmosphere in virtual team meetings is crucial; setting rules, encouraging dialogue, and addressing issues promptly can enhance collaboration during these transitions. By integrating these innovations and strategies into procurement practices, organizations can position themselves advantageously in a competitive landscape marked by rapid technological advancements.

Conclusion

Understanding the intricacies of magnetism is vital for procurement specialists aiming to make informed decisions in the fast-evolving materials landscape. This article has explored the foundational principles of magnetism, including:

- The classification of magnetic materials

- The significant role of electron configuration

- The effects of temperature on magnetic properties

It has also highlighted the practical applications of these materials across various industries, underscoring their importance in sectors such as automotive, electronics, and healthcare.

As the demand for advanced magnetic materials continues to grow, particularly in high-performance applications, procurement managers must stay abreast of emerging trends and innovations. The shift towards sustainable and efficient materials, such as nanostructured and composite options, presents both challenges and opportunities. By leveraging the latest research and understanding the unique characteristics of different materials, organizations can enhance their sourcing strategies and drive innovation.

Ultimately, the insights provided in this article serve as a strategic guide for procurement specialists. By making informed decisions grounded in the principles of magnetism and the specific requirements of their industries, organizations can ensure they remain competitive and responsive to market demands. Embracing these advancements will not only facilitate operational efficiency but also foster a culture of innovation that aligns with the future of materials science.