Blogs

Testing Thermostatic Bimetals: Standards That Shape Performance

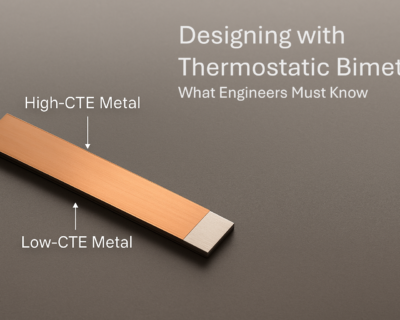

Thermostatic bimetals are often unseen but critical components—controlling heat, power, and safety without fail. But behind every reliable bimetal strip is rigorous testing and quality control, ensuring it performs consistently in real-world environments.

In this blog, we unpack how thermostatic bimetals are tested, what global standards guide their evaluation, and why reliability starts long before the product is used.

Why Testing Matters

Thermostatic bimetals must:

- Bend predictably at specific temperatures

- Survive millions of heating/cooling cycles

- Maintain structural and electrical integrity under stress

This is crucial for:

- Fire alarms that must activate at the right moment

- Thermostats that control appliances without drift

- Circuit breakers that protect against overcurrent faults

Every piece is put through thermal, mechanical, and visual tests before it earns its place in a device.

Standards That Govern Testing

🔹 ASTM B106 – Standard Specification for Thermostatic Bimetal

This widely adopted standard defines:

- Material composition

- Thermal deflection behaviour

- Tolerance levels

- Bond strength requirements

- Testing procedures for strip consistency

🔸 ISO 10318 – International Testing Guidance

Covers international recommendations for:

- Mechanical durability

- Dimensional conformity

- Heat cycling behaviour

- Deflection repeatability and response speed

These standards ensure interchangeability, reliability, and certification compliance across global markets.

Fatigue Testing: Simulating Real-Life Use

Fatigue is the enemy of performance. Repeated bending can weaken even the best materials.

In fatigue testing:

- The bimetal is subjected to hundreds of thousands to millions of cycles

- Heated and cooled through its working range

- Monitored for loss of deflection, bond separation, or failure

Bimetals that pass demonstrate long-term resilience, critical for 10+ year life cycles in industrial and consumer environments.

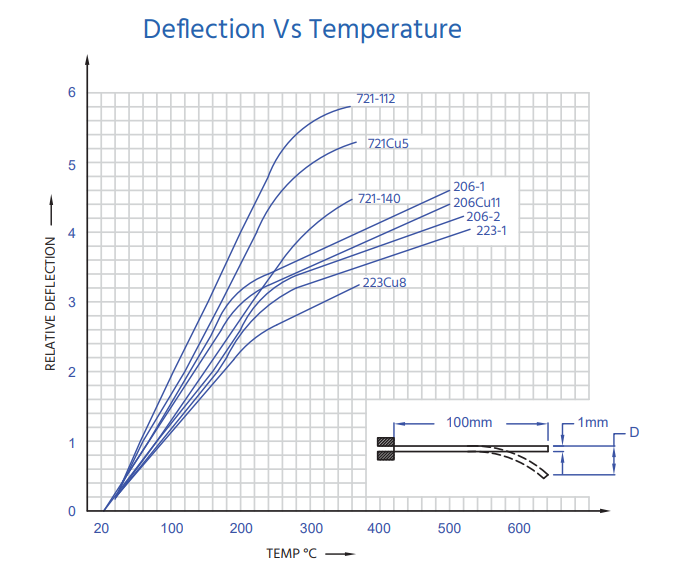

Curvature and Response Time Measurements

These tests validate how quickly and how much the strip bends under thermal stimulus.

Key metrics include:

- Curvature per °C: The degree of bending per unit of temperature

- Response delay: Time taken to reach actuation position

- Recovery rate: Time to return to original position when cooled

These are plotted as deflection vs. temperature graphs to ensure consistency.

Consistent curves = predictable behaviour in every product.

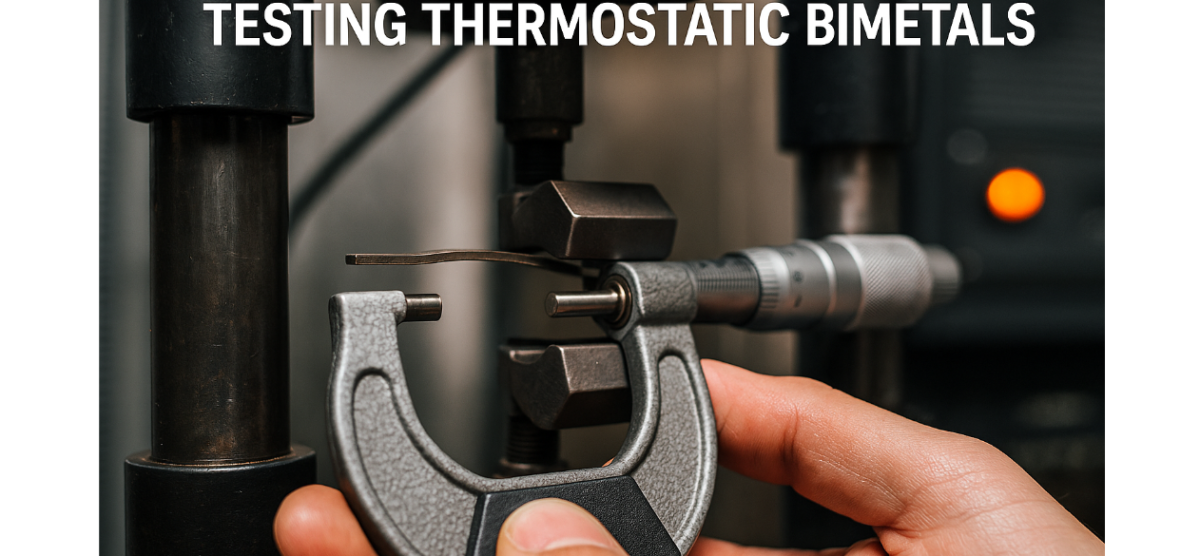

Visual & Mechanical Inspection

Visual Inspection

- Look for surface defects: cracks, delamination, uneven surfaces

- Confirm proper marking and orientation

- Ensure no oxidation or contamination from the bonding process

Mechanical Inspection

- Check thickness and width tolerances

- Confirm edge smoothness

- Verify mounting hole positions and clearances

Precision tools such as:

- Digital micrometers

- Optical comparators

- Microscopy imaging

are used for sub-millimeter accuracy.

Final Quality Control Checklist

| Test | Purpose |

| Fatigue Testing | Simulate long-term use |

| Curvature Testing | Measure bend per °C and return accuracy |

| Thermal Cycling | Assess behavior over operating temperature |

| Visual Inspection | Identify surface or bonding defects |

| Mechanical Inspection | Verify dimensions and tolerances |

Only bimetals that pass all tests proceed to packaging and shipment.

Conclusion: Performance Starts with Precision

Thermostatic bimetals may look simple—but what makes them dependable is an uncompromising testing regimen guided by ASTM and ISO standards.

From thermal sensitivity to long-term durability, every strip is validated to ensure it bends at the right moment, in the right direction, every time.

🔗 Coming Up in Blog 5: Properties of Thermostatic Bimetals

What gives thermostatic bimetals their unmatched durability, precision, and energy-free response?

In our next post, we’ll break down the key physical and mechanical properties—from thermal sensitivity and stress-strain behavior to corrosion resistance and fatigue life.

📘 Blog 5: What Makes It Tick – Properties of Thermostatic Bimetals

Got questions? or got an ideas—we’re always ready to dive deeper!

Contact our experts today!

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia

Read our previous blog on https://domadia.net/thermostatic-bimetal/how-thermostatic-bimetals-are-made/