Blogs

Thermostatic Bimetal vs Trimetal: What’s the Real Difference in Heat Response?

It’s Getting Hot in Here… But Who’s in Control?

Your coffee machine clicks off before it boils over. Your circuit breaker jumps to action just before a meltdown. These aren’t accidents—they’re miracles of materials engineering.

But here’s what’s really fascinating: the difference between safety and failure can boil down to two vs three layers of metal. Yep. The choice between thermostatic bimetal vs thermostatic trimetal could determine whether your design survives—or surrenders—to heat.

So… what’s really under the hood?

1. What Are They Made Of?

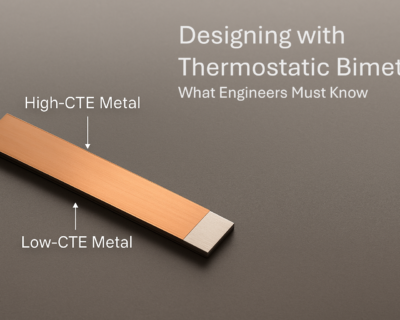

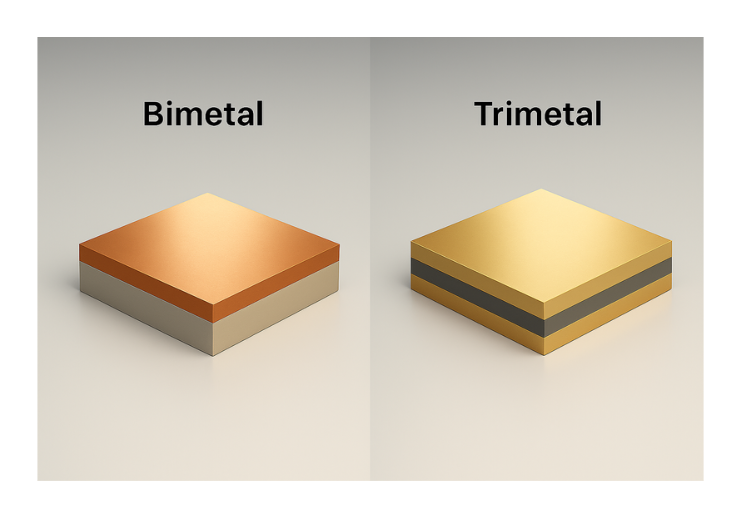

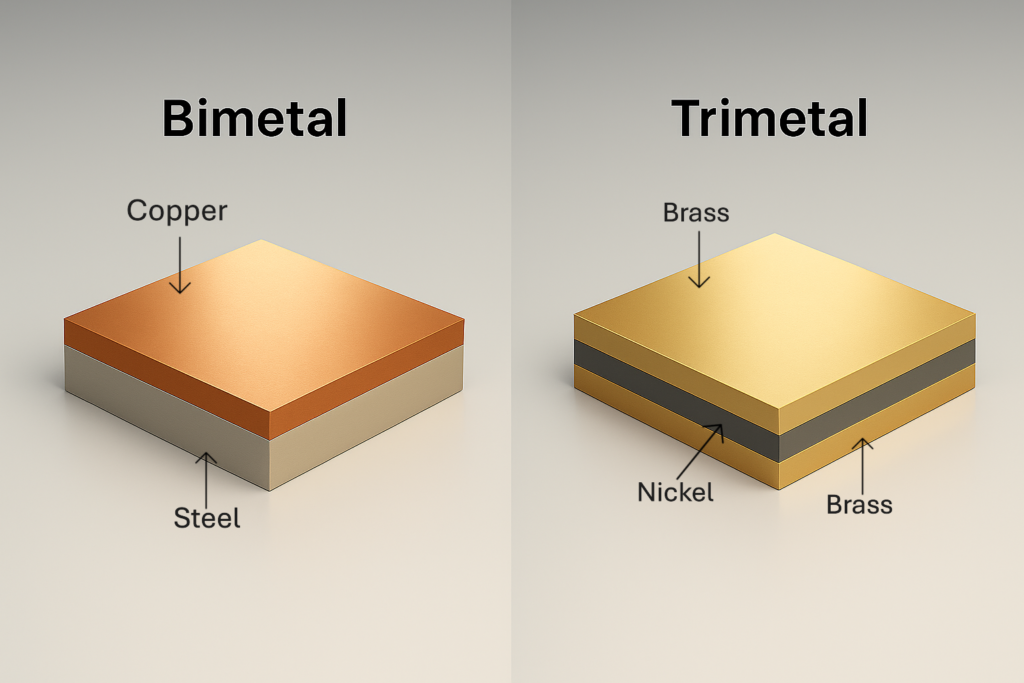

Thermostatic Bimetal

- Composed of two metals with contrasting thermal expansion rates.

- Bonded via cladding, welding, or brazing.

- When heated, the strip bends due to unequal expansion—acting as a switch.

- Common Combo: Steel + Brass

Thermostatic Trimetal

- Consists of three distinct metal layers.

- The middle layer often stabilizes motion or modifies the heat curve.

- Allows precise, gradual, or multi-stage movement.

- Common Combo: Brass + Nickel+ Brass

2. Heat Response: Behavior Under Pressure

| Feature | Bimetal | Trimetal |

|---|---|---|

| Response Type | One-directional bend | Multi-stage or progressive |

| Sensitivity | Moderate | Highly tuned |

| Thermal Stability | Good, but fatigues | Excellent, less hysteresis |

| Temperature Range | Everyday use | Extreme or precise needs |

Bimetals are like a light switch—on or off. Trimetals? Think of a dimmer. They don’t just respond—they adapt.

3. Application Showdown: Where Do They Work Best?

| Application | Bimetal | Trimetal |

|---|---|---|

| Home Appliances | ✔️Common | ⚠ Rare/Precision only |

| Automotive | ✔️Gauges, Fans | ✔️ Emissions, ECU tuning |

| Circuit Protection | ✔️Circuit Breakers | ✔️ High-precision relays |

| Industrial Sensors | ⚠ Basic only | ✔️ Harsh environments |

| Aerospace | ❌ Not used | ✔️ Preferred for stability |

🔍 Trimetals dominate in mission-critical applications. Bimetals? Perfect for cost-effective mass use.

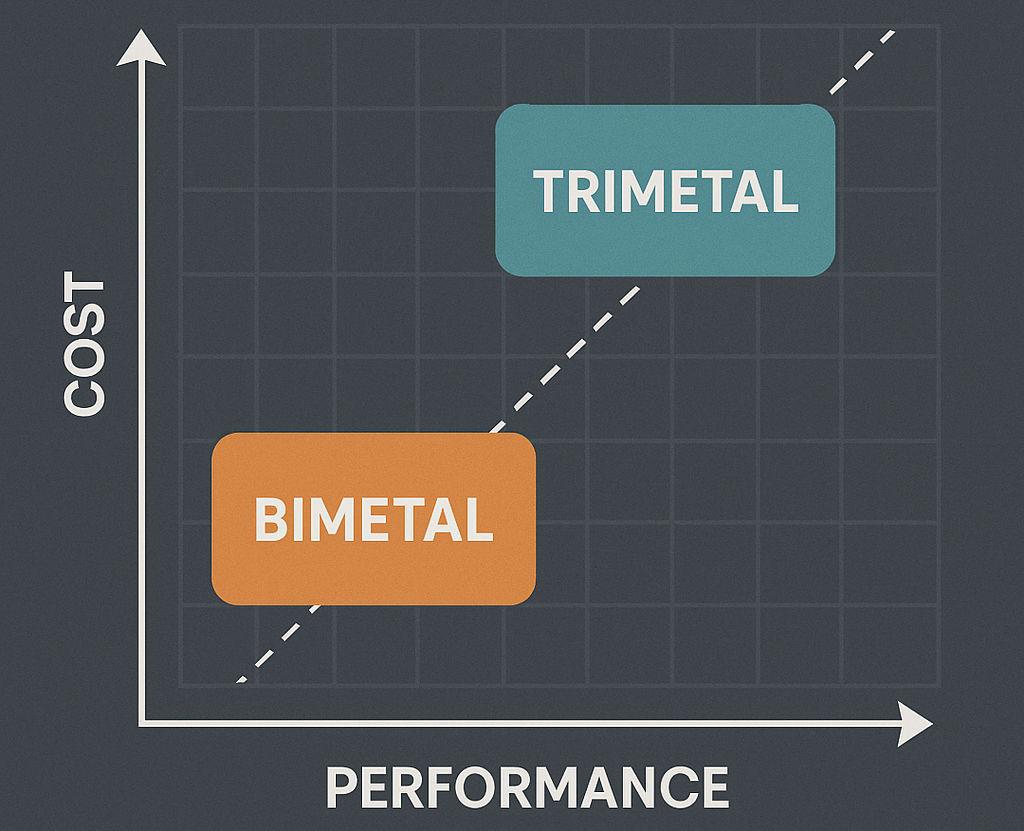

4. Cost vs Customization

- Bimetals:

- Low-cost

- Simple manufacturing

- Limited precision

- Trimetals:

- High-performance

- Tunable behavior

- More expensive

Your Thermal Hero Depends on Your Goal

In the thermostatic bimetal vs thermostatic trimetal debate, there’s no universal winner.

- Want reliability in a toaster? Go bimetal.

- Designing a sensor for a Mars rover? Only trimetal will do.

Whether it’s basic control or micro-level precision, choose your layers wisely.

And with that—this wraps our thermostatic bimetals blog series! 🎉

Confused between bimetal vs trimetal for your next thermal component?

📩 Reach out to Domadia’s expert team for custom recommendations.

Contact our experts today!

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia

Read our previous blog on https://domadia.net/thermostatic-bimetal/domadia-designing-with-thermostatic-bimetals/