Blogs

How to Choose the Right Beryllium Copper Distributors: A Step-by-Step Guide

Introduction

In the competitive landscape of industrial procurement, selecting the right distributor for beryllium copper is paramount to ensuring product quality and operational efficiency. With its unique blend of high strength, excellent electrical conductivity, and corrosion resistance, beryllium copper serves critical roles across various sectors, including aerospace and electronics. However, the decision-making process can be daunting, given the myriad of suppliers available.

This article delves into the essential criteria for evaluating potential distributors:

- Assessing their reputation

- Quality certifications

- Understanding their logistical capabilities

- After-sales support

By adopting a strategic approach to supplier selection, procurement managers can enhance their supply chain resilience and secure the high-performance materials necessary for their projects.

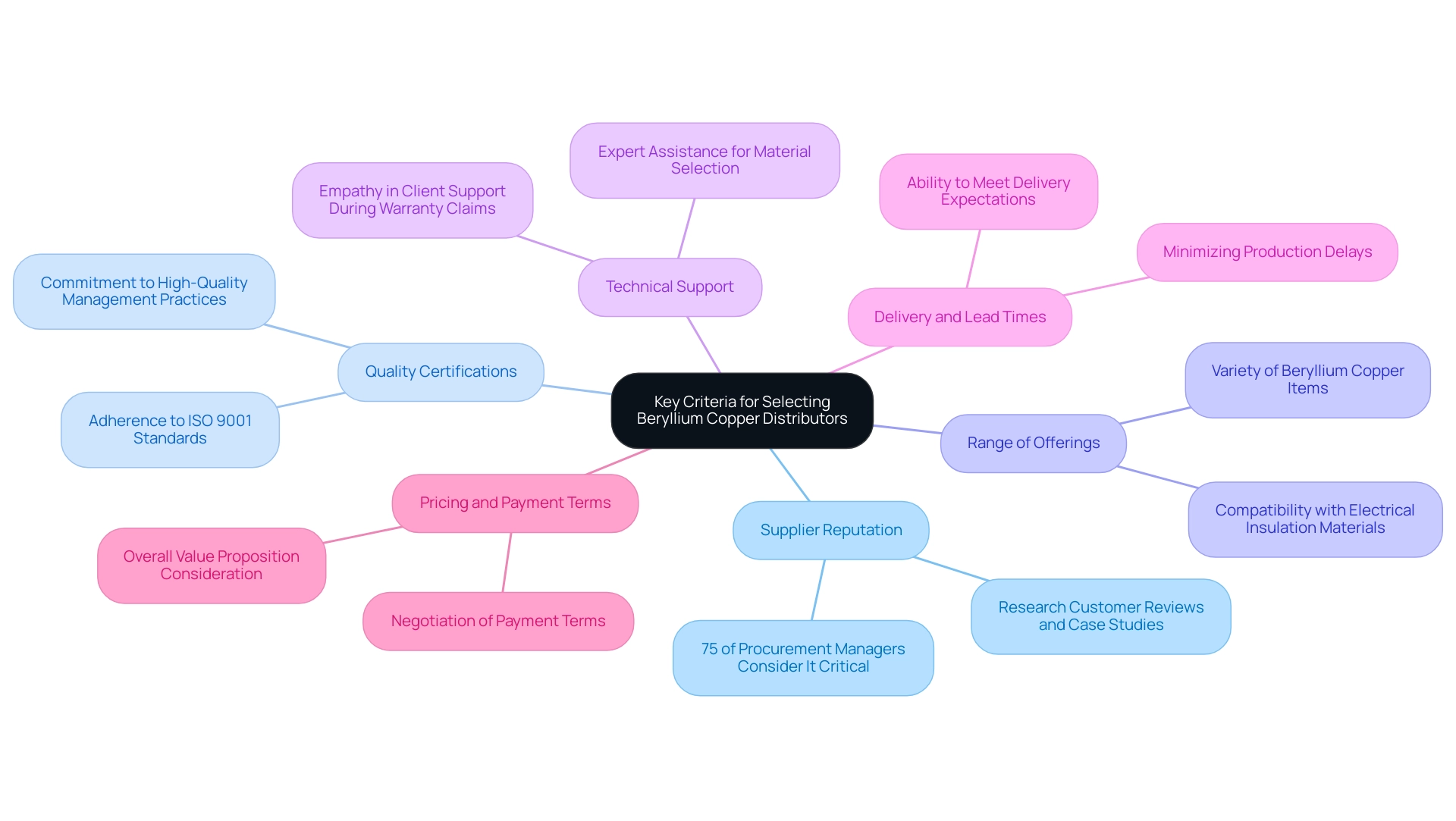

Key Criteria for Selecting Beryllium Copper Distributors

When evaluating potential distributors of beryllium copper, it is essential to focus on several key criteria that can significantly impact your procurement decisions:

Supplier Reputation: Conduct thorough research on the provider’s standing in the market. Statistics show that 75% of procurement managers consider supplier reputation as a critical factor in their decision-making process. Examine customer reviews, case studies, and their overall market presence. A strong reputation is often a reliable sign of excellence and dependability.

Quality Certifications: Confirm that the distributor adheres to internationally recognized quality standards, such as ISO 9001. These certifications demonstrate a commitment to upholding high-quality management practices, which is essential for consistent delivery.

Range of Offerings: Evaluate the variety of beryllium copper items accessible from beryllium copper distributors, including those that may be utilized alongside electrical insulation materials such as crepe paper and high-temperature fabrics. A supplier with a diverse product line is more likely to fulfill specific project requirements and adapt to changing needs.

Technical Support: Prioritize suppliers that provide expert technical assistance. Having access to knowledgeable support for material selection and application can prove invaluable, ensuring that you make informed choices tailored to your projects. As noted in industry insights, “Supporting clients through the stress of a denied warranty claim with empathy and clear explanations is crucial for maintaining strong supplier relationships.”

Delivery and Lead Times: Assess the supplier’s ability to meet your delivery expectations. Consistent and reliable lead times are vital for keeping your production schedules on track, minimizing the risk of delays.

Pricing and Payment Terms: While cost is a critical factor, it is important to consider the overall value proposition, which includes not just the price but also the quality of service provided. Negotiate payment terms that align with your financial planning and cash flow requirements.

Considering recent developments, like IBC Advanced Alloys expanding its alloy casting facility to enhance production capabilities, it is evident that selecting beryllium copper distributors who align with industry advancements can greatly influence your procurement success. Additionally, understanding the specific properties of beryllium, such as its high strength and excellent electrical conductivity, along with its applications in various industries, including aerospace and electronics, is crucial for informed decision-making. By concentrating on these criteria, procurement managers can make informed decisions that enhance supply chain efficiency and product quality in the procurement of beryllium.

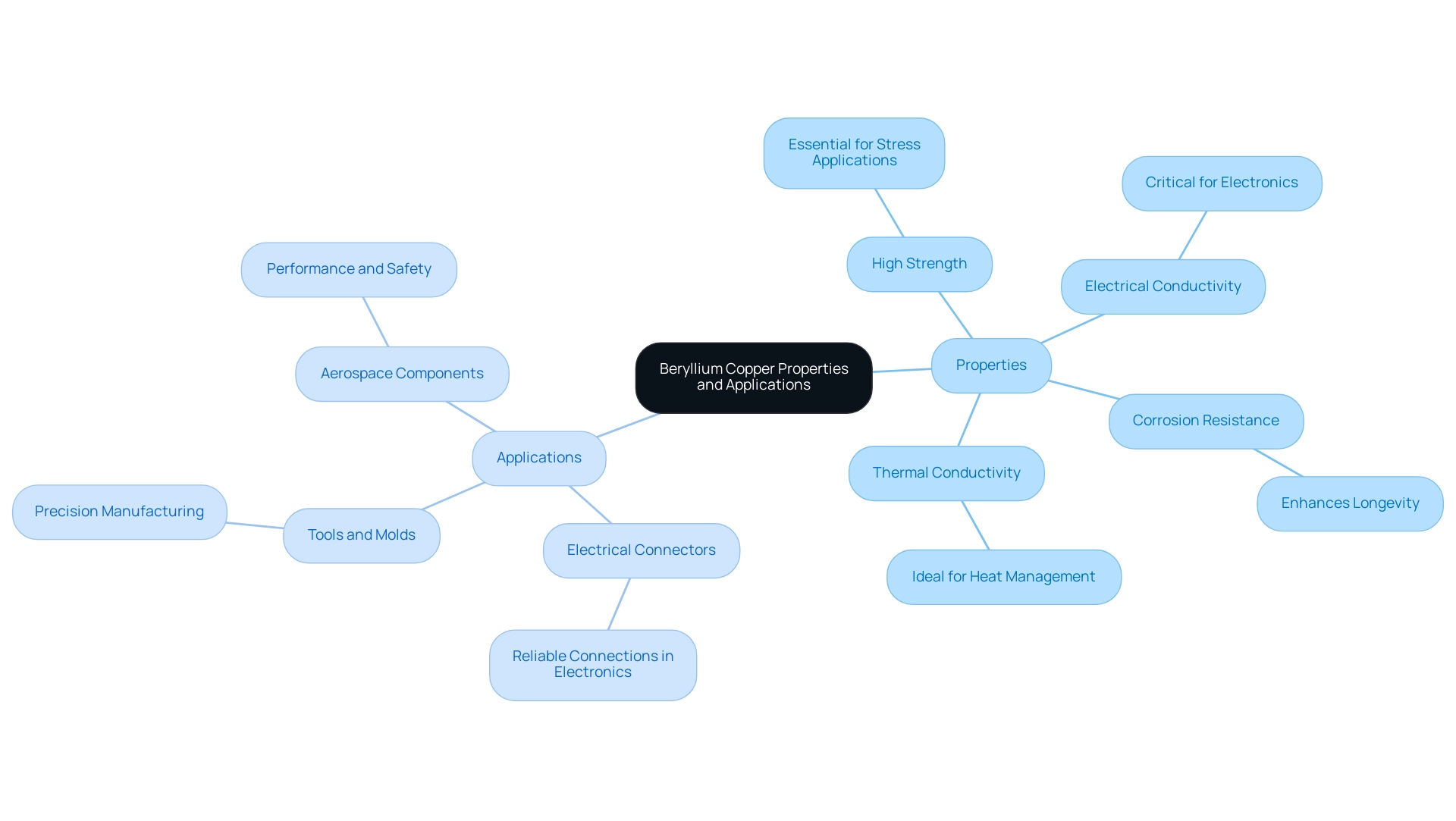

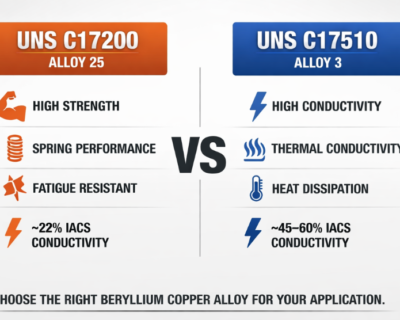

Understanding Beryllium Copper: Properties and Applications

Beryllium alloy, renowned for its high-performance characteristics, presents a unique combination of mechanical properties that make it a favored choice across various industries. Key attributes include:

- High Strength: This alloy outperforms many other copper alloys in strength, essential for applications subjected to significant stress and strain.

- Excellent Electrical Conductivity: Beryllium alloy maintains reliable electrical conductivity, a critical factor for components in electronics where performance is paramount.

- Corrosion Resistance: The alloy’s superior resistance to corrosion enhances its longevity, making it suitable for use in diverse environmental conditions.

- Thermal Conductivity: Its ability to dissipate heat effectively positions beryllium copper as an ideal material for applications in electronics and automotive sectors where temperature management is crucial.

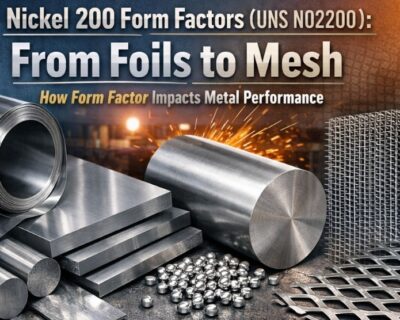

Domadia stands at the forefront of supplying high-performance Beryllium Copper Plates, offering an extensive product range that includes foils, sheets, rods, and wires. Our commitment to quality and innovation, backed by rigorous quality control and innovative manufacturing processes, ensures that we provide tailored solutions to meet the specific requirements of our clients.

Typical applications of beryllium copper encompass:

- Electrical Connectors: Leveraging its conductivity and strength, the alloy is integral in creating reliable electrical connections that ensure optimal performance in electronic devices.

- Tools and Molds: Thanks to its hardness and favorable thermal properties, beryllium alloy is widely utilized in the manufacturing of precision tools and molds, illustrating its versatility in production processes.

- Aerospace Components: The lightweight and robust nature of this alloy is particularly beneficial in aerospace applications, where performance, safety, and efficiency are non-negotiable. For instance, BrushCAST copper-beryllium casting alloys are utilized in defense components, demonstrating their capability to meet stringent technical specifications.

Tim Bradow from Rigaku emphasizes the significance of these materials, stating, “CT instruments can change battery analysis workflows,” highlighting the innovative applications of beryllium alloy in modern technology.

With nearly 100 years of expertise in material science, Materion stands as a leader in providing customized beryllium alloy solutions. Awareness of these properties and applications empowers procurement managers to make informed decisions when choosing potential suppliers. Identifying beryllium copper distributors like Domadia, who offer beryllium copper alloys tailored to specific needs, is crucial for achieving desired outcomes in demanding industrial applications.

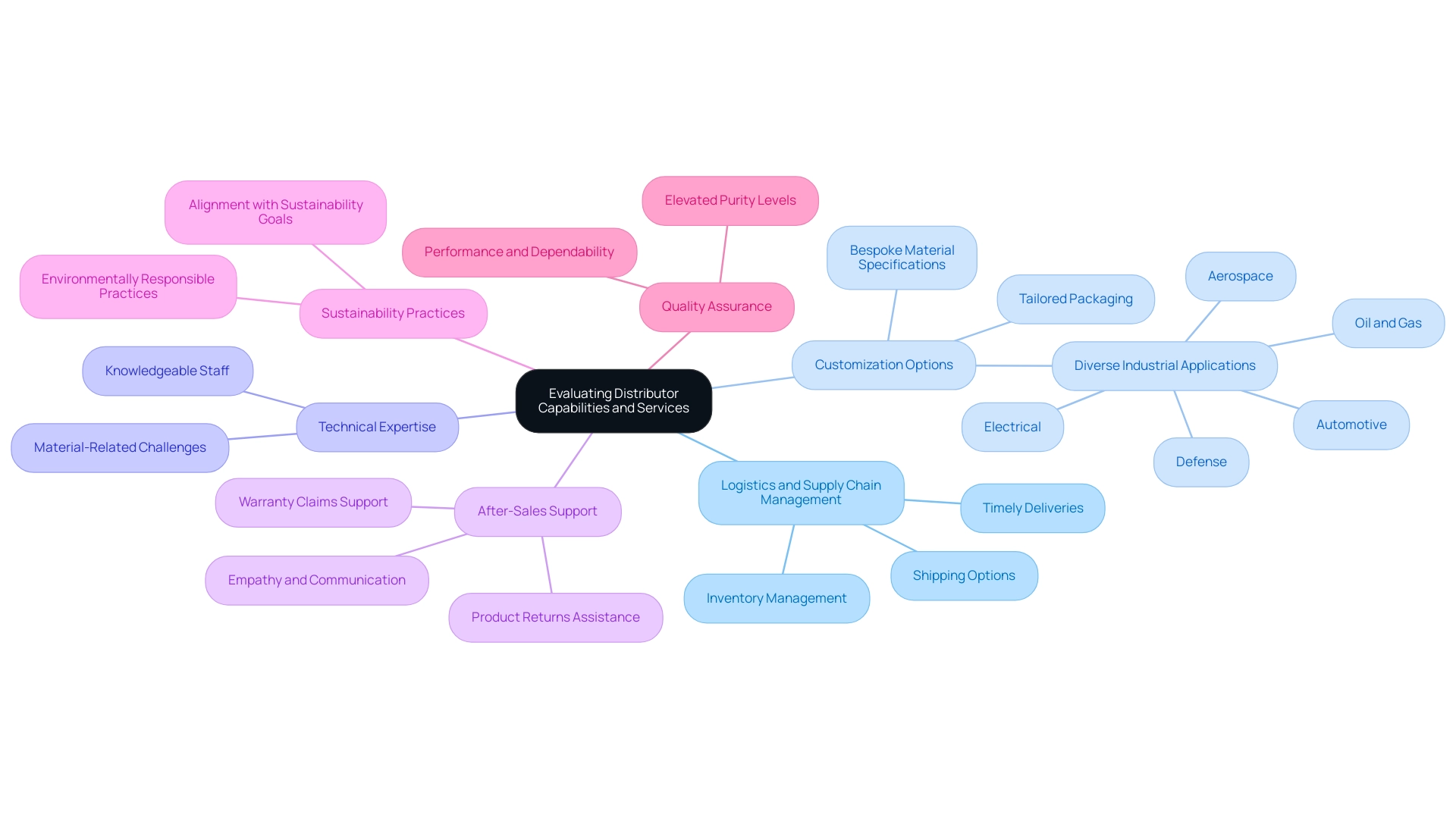

Evaluating Distributor Capabilities and Services

When evaluating potential Beryllium Copper suppliers, procurement managers should consider several key capabilities and services that can significantly impact their procurement process, especially regarding comprehensive solutions like those offered by Domadia:

Logistics and Supply Chain Management: Assess the supplier’s logistics capabilities, including inventory management and shipping options. Efficient logistics are vital for ensuring timely deliveries, which can affect production schedules and operational efficiency—critical factors for procurement managers.

Customization Options: Determine whether the supplier can provide customized solutions tailored to your specific needs, such as bespoke material specifications or tailored packaging. For example, Domadia excels in providing a variety of Beryllium Copper items sourced from beryllium copper distributors, including plates, rods, sheets, wires, and foil, all customizable to meet diverse industrial applications in sectors like aerospace, automotive, electrical, oil and gas, and defense.

Technical Expertise: Evaluate the level of technical expertise available from the supplier. Access to knowledgeable staff, like those at Domadia, can be invaluable for addressing material-related challenges and optimizing your selection effectively.

After-Sales Support: Inquire about the supplier’s after-sales support services, including assistance with product returns or warranty claims. Supporting clients through challenges, such as warranty issues, requires empathy and clear communication—qualities that Domadia prides itself on to enhance the overall procurement experience.

Sustainability Practices: Consider the supplier’s commitment to sustainability and environmentally responsible practices. Many organizations prioritize suppliers who align with their sustainability goals, making this a crucial factor in the selection process.

Quality Assurance: It is essential to consider the standard of the materials being procured. Domadia, a leading provider among beryllium copper distributors, offers Beryllium Copper Plates with elevated purity levels, ensuring the performance and dependability of your applications, which are essential for project success.

By carefully assessing these factors, procurement managers can make informed choices that align with their operational requirements and strategic goals while ensuring they collaborate with a supplier dedicated to quality and expert assistance. Contact Domadia today to learn more about our comprehensive Beryllium Copper solutions and how our beryllium copper distributors can support your next project!

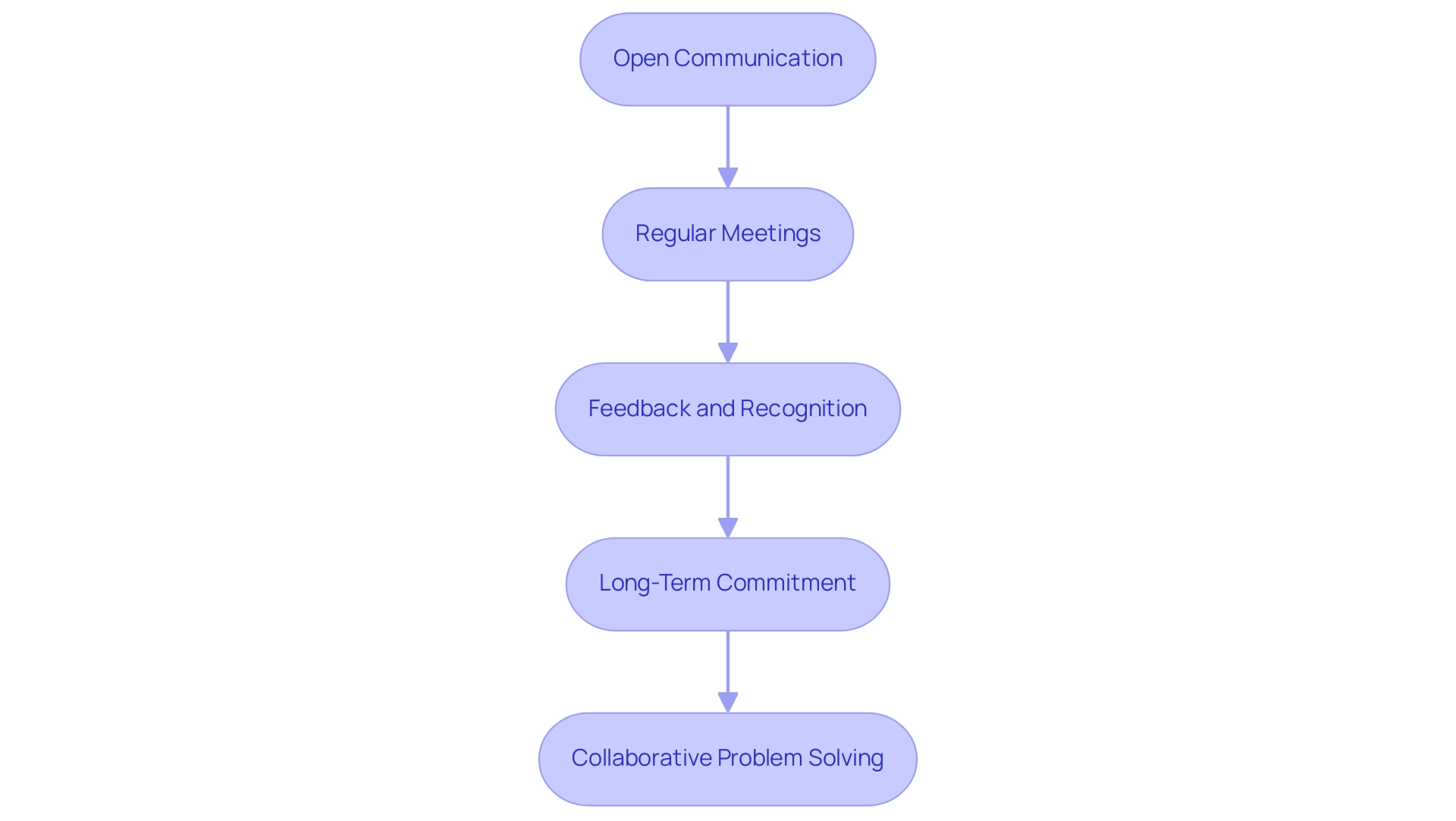

Building Relationships with Beryllium Copper Distributors

Building robust relationships with your beryllium copper distributors is crucial for optimizing supply chain management, particularly when managing specialized products such as the Beryllium Copper Non-Sparking Wrench, which is recognized for its safety features in hazardous environments. Consider the following strategies:

- Open Communication: Establishing clear and open lines of communication is fundamental.

Regular updates and constructive feedback foster transparency and cultivate trust between parties. Costas Xyloyiannis, CEO of HICX, underscores this notion, stating,

If staying resilient within an ever-changing world relies so heavily on supplier relationships, why aren’t we giving suppliers a more collaborative experience?

This highlights the need for a commitment to improved communication, which enhances resilience across the supply chain.

For instance, engaging in open dialogue can lead to better alignment on expectations and goals, particularly concerning the safety applications of products like the non-sparking wrench.

- Regular Meetings: Schedule consistent meetings to discuss performance metrics, upcoming requirements, and potential challenges.

These discussions not only strengthen collaboration but also ensure that both parties are aligned in their goals and expectations.

Utilizing tools like Silo can provide insights into inventory management, making these meetings more productive.

- Feedback and Recognition: Providing constructive feedback is essential for growth.

Acknowledge your suppliers’ efforts when they meet or exceed expectations; positive reinforcement encourages a culture of excellence and continuous improvement.

This ties into effective conflict resolution, where understanding perspectives and recognizing achievements can lead to stronger relationships. Emphasizing the importance of employee engagement can further enhance this process, as a committed workforce is essential for maintaining high standards in supplier interactions.

- Long-Term Commitment: Consider forming long-term contracts with reliable suppliers.

Such commitments can yield favorable pricing and priority service, further solidifying the partnership while ensuring reliability in supply.

- Collaborative Problem Solving: Involving suppliers in discussions when challenges occur encourages a collaborative problem-solving approach.

This not only leads to innovative solutions but also reinforces the partnership, ensuring that both parties work together to navigate obstacles effectively.

For instance, adhering to the steps presented in the effective conflict resolution case study—remaining composed, comprehending viewpoints, and pursuing shared interests—can improve this process.

By utilizing these tactics and utilizing resources like Silo, procurement managers can strengthen their connections with beryllium copper distributors, resulting in a more robust and efficient supply chain while ensuring the safety and dependability of items like the Beryllium Copper Non-Sparking Wrench.

Conducting Supplier Audits and Evaluations

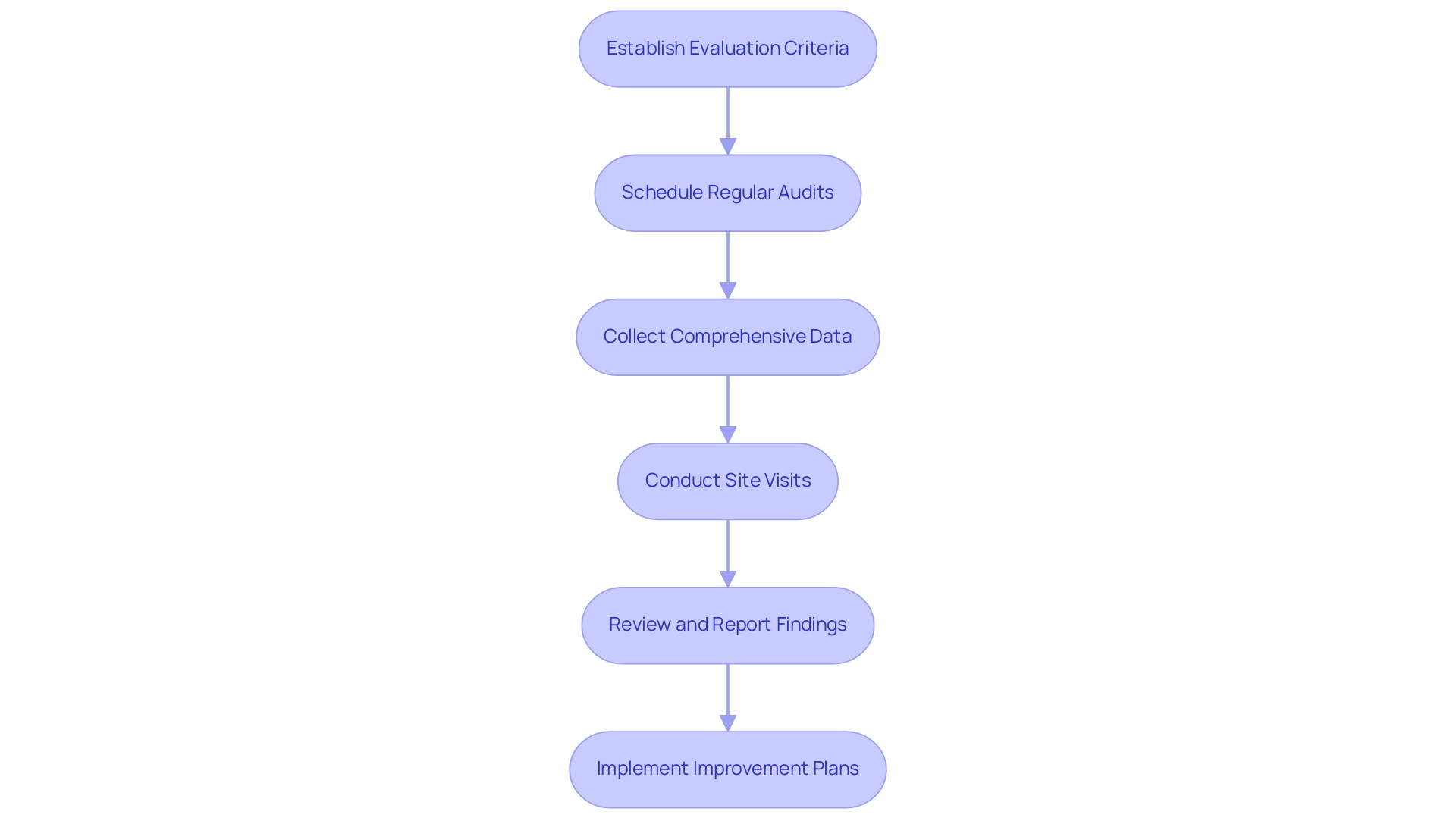

To execute effective supplier audits and evaluations, adhere to the following strategic steps:

- Establish Evaluation Criteria: Clearly define the assessment criteria for your distributors, focusing on essential factors such as excellence, delivery performance, and adherence to industry standards.

- Schedule Regular Audits: Implement a structured audit schedule, ideally on an annual or bi-annual basis, to ensure sustained compliance and performance evaluation. Consider that a product launch involving 100 suppliers may need to budget for an auditing cost that is twice the amount of a product launch involving 50 suppliers, highlighting the financial implications of thorough audits.

- Collect Comprehensive Data: Accumulate detailed data on supplier performance, which should include metrics such as delivery timelines, performance reports, and insights from customer feedback.

- Conduct Site Visits: Where feasible, arrange site visits to observe the supplier’s operations and their quality control processes in action, providing invaluable firsthand information.

- Review and Report Findings: Document your findings in a structured report that highlights both the strengths and areas needing improvement. This report should be shared with the supplier to foster constructive dialogue.

- Implement Improvement Plans: Collaborate closely with the distributor to create actionable improvement plans based on the audit results, ensuring a commitment to continuous enhancement of their services. This proactive strategy not only tackles critical issues but also enhances the overall control and compliance systems within the supply chain. As illustrated in the case study titled “Monitoring Supplier Progress,” establishing regular communication channels post-audit is essential to track status and resolve challenges effectively. Furthermore, as Regina Ssebaggala-Kisitu, a former quality controller at Harrods, insightfully noted,

Prioritizing corrective actions ensures that the supplier addresses the most critical issues first, emphasizing the importance of focusing on key areas for improvement.

Conclusion

In the realm of industrial procurement, selecting the right distributor for beryllium copper is a critical decision that directly impacts product quality and operational efficiency. The evaluation process involves several vital criteria, including:

- The distributor’s reputation

- Adherence to quality certifications

- Logistical capabilities

- The level of after-sales support they provide

By prioritizing these factors, procurement managers can ensure they partner with suppliers who align with their operational needs and strategic goals.

Understanding the unique properties and applications of beryllium copper is equally essential. Its high strength, excellent electrical conductivity, and corrosion resistance make it a preferred choice across various industries, particularly aerospace and electronics. Recognizing these attributes empowers procurement managers to make informed decisions that not only enhance supply chain resilience but also secure the high-performance materials necessary for their projects.

Moreover, fostering strong relationships with distributors through open communication, regular meetings, and collaborative problem-solving can lead to improved outcomes. Establishing long-term commitments and conducting regular audits further solidify these partnerships, ensuring that both parties remain aligned in their objectives and consistently meet quality standards.

Ultimately, a strategic approach to selecting and managing beryllium copper distributors is paramount. By focusing on the outlined criteria and nurturing supplier relationships, procurement managers can enhance their supply chain efficiency and ensure the success of their projects. The right distributor not only provides high-quality materials but also becomes a valuable partner in navigating the complexities of industrial procurement.