Blogs

Best Practices for Utilizing Beryllium Copper Hardness in Plunger Tips: Expert Insights

Introduction

The increasing demand for high-performance materials in industrial applications has positioned beryllium copper as a material of choice for plunger tips, thanks to its unique mechanical properties and versatility. This alloy, celebrated for its exceptional strength, fatigue resistance, and electrical conductivity, offers a strategic advantage in environments where reliability is paramount.

As procurement managers navigate the complexities of sourcing, understanding the distinct characteristics of beryllium copper becomes crucial for ensuring optimal product performance and longevity. This article delves into the essential aspects of beryllium copper, from its intrinsic properties and the significance of heat treatment to best practices for procurement and sustainability considerations, equipping professionals with the insights needed to make informed decisions in their material selection process.

Understanding the Unique Properties of Beryllium Copper for Plunger Tips

The exceptional mechanical properties of beryllium alloy, along with its beryllium copper hardness for plunger tips, position it as an ideal material for a range of applications. This mixture, compliant with international standards UNS and ASTM, boasts a remarkable shear modulus of 50.0 GPA and high fatigue strength, contributing to its high strength-to-weight ratio and outstanding hardness. These characteristics ensure durability and performance even in extreme conditions, making it a reliable choice for various industrial applications.

Moreover, the outstanding electrical conductivity of this alloy is beneficial for uses that demand stable and dependable electrical contact. Coupled with its superior corrosion resistance, this material is less prone to wear and tear, which is critical for maintaining the integrity of plunger mechanisms over time. Specifically, age-hardened bronze mixtures, such as C17200 and C17300, achieve the highest strength among base metals, valued for their elasticity and corrosion resistance.

These alloys are particularly suitable for applications requiring high strength and durability, such as springs and intricate forms. Comprehending the distinctive characteristics of the alloy, including its shear modulus and fatigue strength, enables procurement managers to make informed choices when sourcing materials for plunger tip production, especially considering the beryllium copper hardness for plunger tips, ultimately driving improvements in product performance and durability. At DOMADIA, we are committed to providing high-quality Beryllium Copper solutions through innovative manufacturing and rigorous quality control, solidifying our leadership in supplying and manufacturing these indispensable materials.

We invite you to explore our product range and discover how our Beryllium Copper solutions can meet your industrial needs.

Best Practices for Implementing Beryllium Copper Hardness in Plunger Tip Production

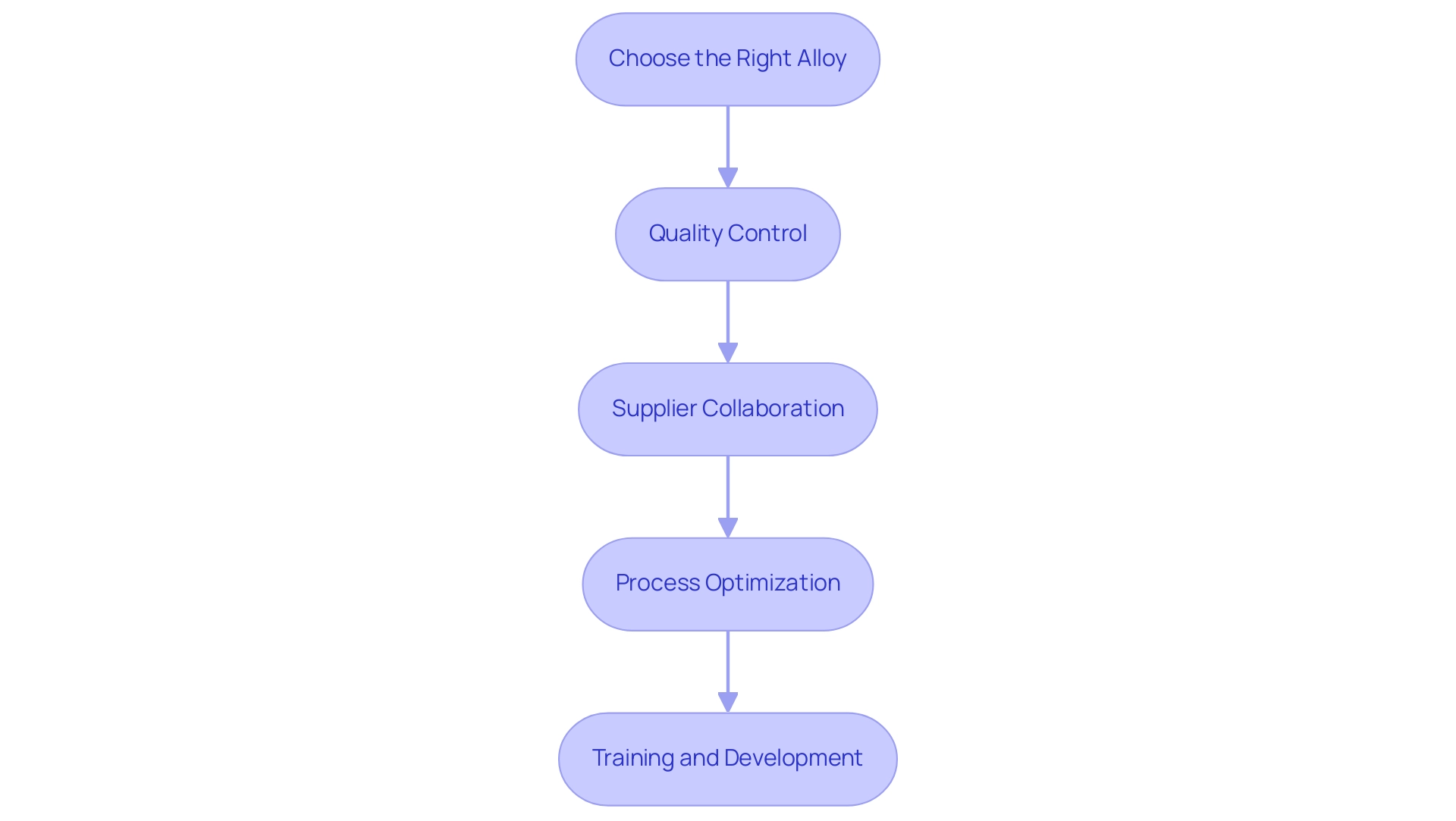

To effectively apply a specific alloy durability in plunger tip manufacturing, several best practices are essential:

It is essential to choose a beryllium-based metal that satisfies the beryllium copper hardness for plunger tips for the intended use. A thorough review of the mixture’s composition and mechanical properties is essential to ensure optimal performance. Domadia offers a diverse range of beryllium copper products, including foils, sheets, rods, and wires, ensuring you find the right alloy tailored to your needs.

Quality Control: Rigorous quality control measures should be established throughout both the procurement and production stages. Regular rigidity testing, along with evaluations of other mechanical properties, must be conducted to maintain consistency and adhere to industry standards. For instance, Verichek provides customized hardness testing services that can adapt to client needs, ensuring effective testing outcomes.

Supplier Collaboration: Strengthening robust alliances with suppliers, such as Domadia, who focus on specialized alloys can greatly improve material sourcing. Open dialogue regarding material specifications and quality expectations facilitates better procurement strategies and can lead to optimized costs through our custom fabrication options.

Process Optimization: Evaluate and improve production processes to utilize the distinct characteristics of a special alloy effectively. This includes making necessary adjustments to machining techniques and heat treatment processes, which can enhance the performance characteristics of the material, particularly in its age-hardened form. It’s important to note that a heat-up time of one hour per inch of thickness must be added to the soak time to ensure effective heat treatment. As noted by Mike Gedeon, Customer Technical Services Manager, in the mill hardened form, the material is age hardened at the mill, so no further heat treatment is required.

Training and Development: Investing in comprehensive training for production staff is vital. Grasping the particular criteria of working with this alloy will result in better handling and processing techniques, ultimately improving the quality of the final product. For questions concerning safe practices, product labels, and pricing information, it is recommended to consult the Materion Product Stewardship Group.

By following these best practices and utilizing Domadia’s wide product selection and expert knowledge, manufacturers can effectively leverage the natural benefits of this alloy’s strength, including the beryllium copper hardness for plunger tips, resulting in enhanced performance and durability.

The Role of Heat Treatment in Enhancing Beryllium Copper Hardness

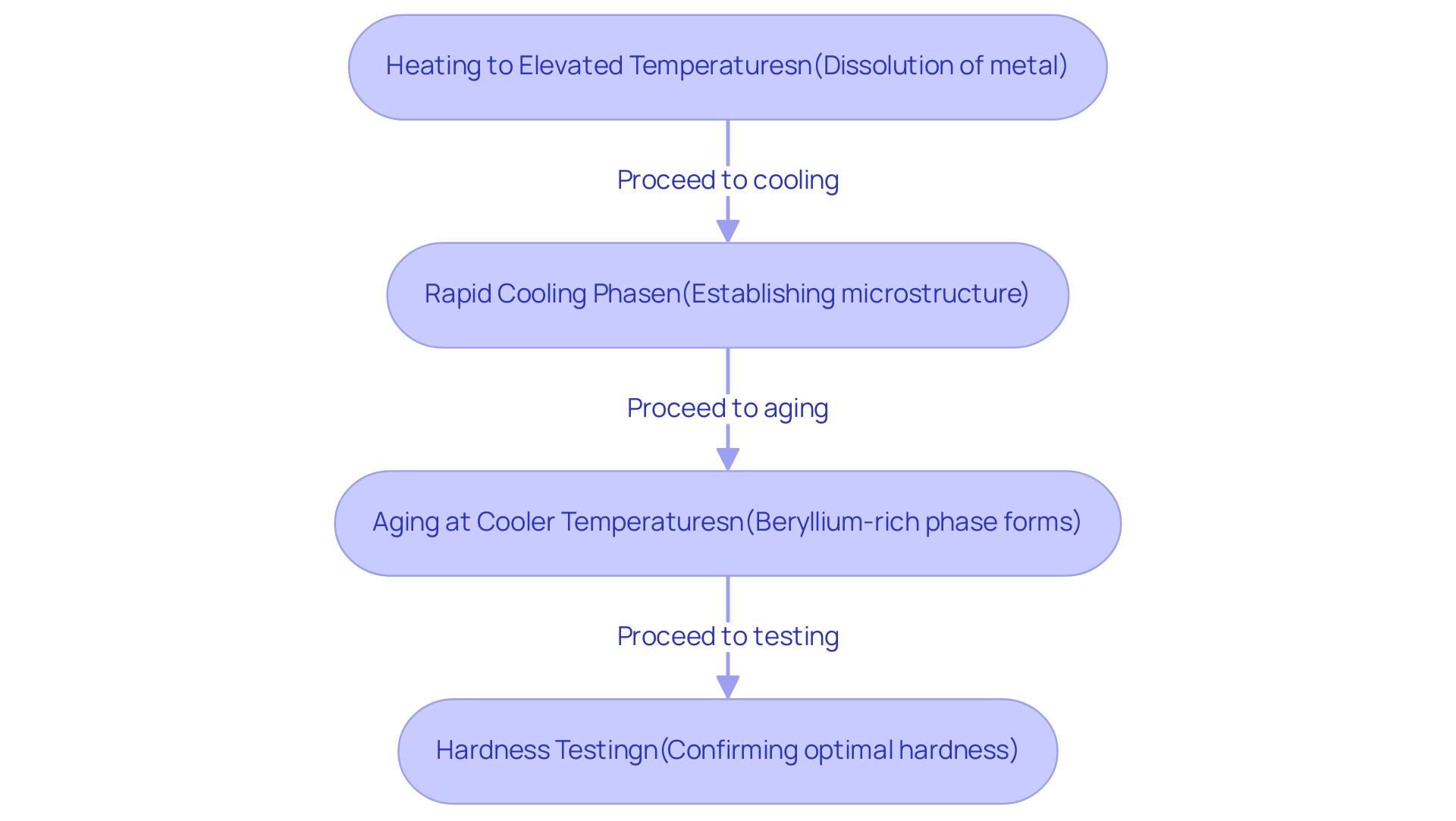

Heat treatment is essential for enhancing the toughness and overall functionality of beryllium-based metal mixtures, including uses such as the non-sparking wrench, which emphasizes safety in dangerous settings. The predominant methods utilized include solution heat treatment followed by aging, markedly enhancing the material’s hardness. This process starts with heating the copper alloy to elevated temperatures, facilitating the dissolution of the metal, followed by a rapid cooling phase that establishes the microstructure for subsequent aging.

Recent studies have compared the microstructure and mechanical properties of bronze under varying solution times and aging temperatures, providing valuable insights into optimizing these parameters for high-strength applications. During aging, carried out at cooler temperatures, a beryllium-rich phase forms, contributing to significant enhancements in toughness and strength. Notably, at an aging temperature of 320 °C, copper alloy exhibits an elongation of 5.16%, showcasing its mechanical resilience.

It is imperative to meticulously monitor both temperature and duration throughout the heat treatment to attain optimal beryllium copper hardness for plunger tips, which can be confirmed through rigorous hardness testing post-treatment. Furthermore, recent findings indicate that the heating rate during aging does not affect distortion, nor does the cooling rate following age hardening influence shape distortion—crucial for maintaining product integrity. By adhering to precise heat treatment protocols, manufacturers can ensure that their products, such as plunger tips that utilize beryllium copper hardness for plunger tips and non-sparking wrenches, consistently meet stringent performance standards.

Furthermore, it is crucial to evaluate the occupational health hazards linked to processing these metals, as improper management can result in severe respiratory illnesses. Therefore, procurement managers must consult safety guidelines and consider case studies on health and safety in processing metal mixtures to mitigate these risks. Current studies also show that the C17200 alloy retains outstanding wear resistance even at 300 °C, highlighting the efficiency of the heat treatment methods in improving the performance characteristics of this metal.

Domadia serves as your reliable ally in delivering high-quality alloy solutions, including tailored options and outstanding customer support to guarantee project success.

Evaluating Supplier Capabilities for Beryllium Copper Procurement

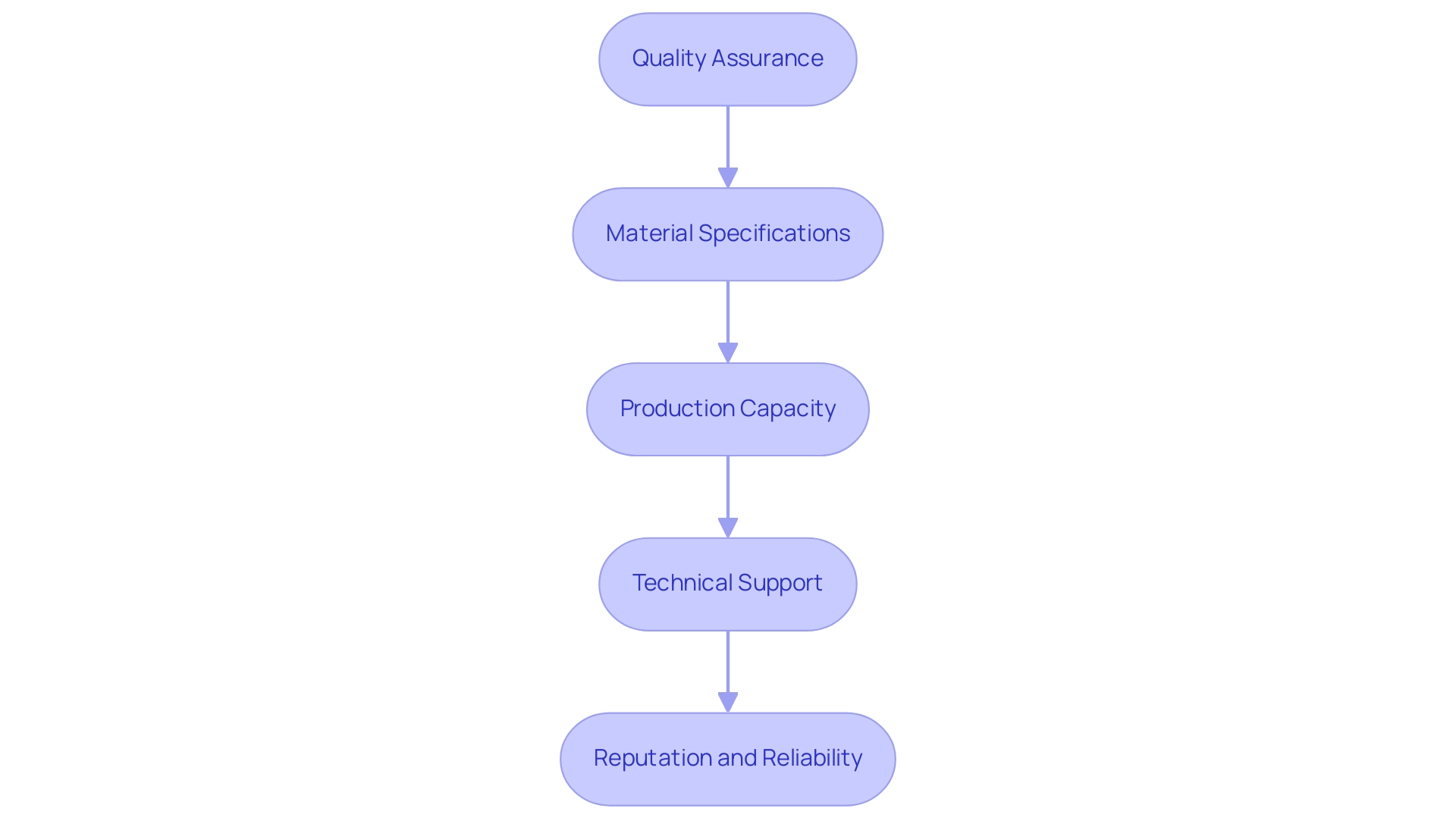

When choosing vendors for procurement of the alloy, it is essential to evaluate several important factors to guarantee the best results:

Quality Assurance: A thorough assessment of the supplier’s quality assurance processes is essential. Look for certifications such as ISO 9001, which denotes compliance with international quality standards. Recent statistics reveal that over 70% of metal suppliers have achieved ISO 9001 certification, emphasizing the importance of quality in procurement decisions. At Domadia, we are committed to providing high-quality Beryllium Copper Plates, customized to your specifications.

Material Specifications: Confirm that the vendor can provide an alloy that meets the specific beryllium copper hardness for plunger tips and composition requirements. Request detailed material test reports and certifications to confirm adherence to quality specifications. This is particularly relevant given this element’s unique properties, such as its electrical resistivity of 46.2 ohms-cmil/ft at 68°F, which are critical for various applications. Our expert support ensures that you receive the necessary documentation and guidance for successful project integration.

Production Capacity: Assess the supplier’s production capabilities to ensure they can meet your volume requirements and lead times. Understanding their capacity can prevent potential supply chain disruptions and ensure timely delivery of materials. Domadia’s established production lines are equipped to handle diverse and high-volume orders efficiently.

Technical Support: Engage with suppliers that provide technical support and expertise in material applications. This support can be essential during product development stages, allowing improved incorporation of the alloy into your projects. At Domadia, we pride ourselves on offering continuous technical support to help you achieve project success.

Reputation and Reliability: Conduct thorough research on the supplier’s reputation within the industry. Analyzing customer reviews and obtaining references can offer insights into their reliability and dedication to service. Our clients have consistently praised our commitment to quality and customer satisfaction, reinforcing our status as a trusted supplier in the market. For instance, one client stated, ‘Domadia’s Beryllium Copper Plates exceeded our expectations in both quality and service.’

By meticulously considering these criteria, procurement managers can establish effective partnerships with suppliers, ensuring a consistent supply of high-quality copper. As microelectronic designers, engineers, and manufacturers emphasize, they can be confident that beryllium-containing alloys will continue to be available to provide unique and reliable design solutions in EEE without legislative restrictions. Furthermore, the case study on Beryllium Registration under REACH highlights the importance of regulatory compliance and safety in its use, reinforcing the need for careful supplier evaluation. This strategic method not only improves production quality, including the beryllium copper hardness for plunger tips, but also enables organizations to take advantage of emerging opportunities in the alloy market. For detailed pricing and inventory information on Beryllium Copper Strips, please contact us directly.

Sustainability Considerations in Beryllium Copper Procurement

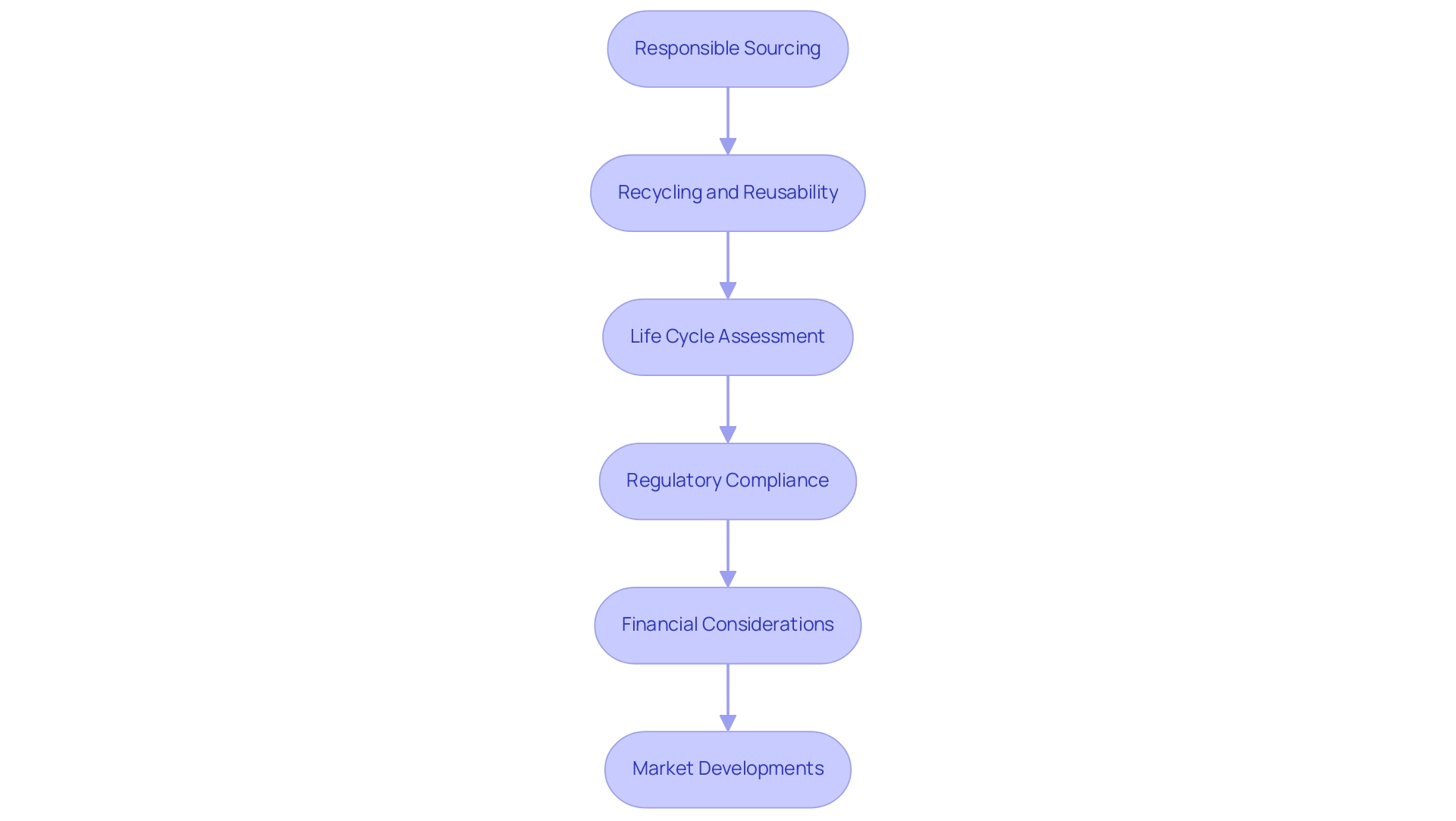

Integrating sustainability into procurement of the alloy necessitates a strategic approach that encompasses several essential practices:

Responsible Sourcing: It is vital to engage with suppliers who demonstrate a commitment to ethical mining practices. Verifying their environmental stewardship credentials ensures that the sourcing process aligns with sustainability goals, minimizing the ecological footprint of procurement activities.

Recycling and Reusability: Organizations should actively explore opportunities to recycle and reuse materials within their production processes. This practice not only reduces waste but also contributes to cost savings, making recycling an economically viable option that benefits both the environment and the bottom line.

Life Cycle Assessment: Conducting a thorough life cycle assessment (LCA) of this metal alloy is essential in comprehending its environmental effect from extraction to disposal. An LCA provides critical insights that inform sourcing decisions, enabling procurement managers to make informed choices that prioritize sustainability.

Regulatory Compliance: Keeping abreast of evolving regulations regarding the use of this element and its environmental implications is essential for compliance and risk mitigation. Continuous monitoring of legal frameworks helps organizations avoid potential liabilities while fostering a culture of responsibility.

Financial Considerations: As highlighted by recent contributions, overcoming resistance to budget analysis is crucial for integrating sustainability into procurement strategies. Clear communication and involvement in planning can facilitate this transition, ensuring that sustainability practices are financially supported.

Market Developments: Recent advancements in the alloy market, such as enhanced production capacities and strategic partnerships among key participants, highlight the significance of embracing sustainable practices. These trends not only respond to rising demand but also position organizations as leaders in sustainable industrial practices.

By embedding these sustainability considerations into procurement practices, companies can significantly enhance their corporate responsibility profile. This proactive approach not only ensures a reliable supply of beryllium copper hardness for plunger tips but also responds effectively to market demands and regulatory challenges.

Conclusion

The exploration of beryllium copper reveals its unparalleled advantages as a material for plunger tips, characterized by exceptional mechanical properties, fatigue resistance, and electrical conductivity. Understanding these intrinsic qualities is vital for procurement managers aiming to optimize product performance and ensure longevity in demanding industrial applications. By selecting the appropriate alloy and implementing rigorous quality control measures, manufacturers can harness the full potential of beryllium copper, enhancing the durability and reliability of their products.

Moreover, the significance of heat treatment cannot be overstated, as it plays a crucial role in achieving the desired hardness and strength. Adhering to precise protocols during the heat treatment process ensures that the final products meet stringent performance standards, while also addressing occupational health considerations associated with beryllium processing.

Evaluating supplier capabilities is essential for successful procurement, with a focus on:

– Quality assurance

– Material specifications

– Production capacity

Establishing strong partnerships with reputable suppliers like Domadia can facilitate access to high-quality beryllium copper and technical support, ultimately enhancing production quality.

Lastly, integrating sustainability considerations into the procurement process not only aligns with corporate responsibility goals but also addresses market demands for ethical sourcing and environmental stewardship. By embracing responsible practices, organizations can ensure a reliable supply of beryllium copper while positioning themselves as leaders in sustainable industrial practices.

In conclusion, the strategic approach to sourcing beryllium copper, encompassing its unique properties, heat treatment processes, supplier evaluation, and sustainability considerations, empowers procurement managers to make informed decisions. This comprehensive understanding not only drives product performance but also fosters innovation and sustainability in the ever-evolving industrial landscape.