Blogs

What Is Magnetic Shielding for Power Transformers? A Comprehensive Overview

Overview:

Magnetic shielding for power transformers is crucial for protecting sensitive electronic components from electromagnetic interference (EMI), thereby enhancing efficiency and reliability. The article emphasizes the use of high-permeability materials like mu-metal and silicon steel, alongside advanced technologies and design strategies, to effectively redirect magnetic fields, mitigate EMI, and improve overall transformer performance in various applications.

Introduction

In the intricate world of power transformers, magnetic shielding emerges as a vital component in safeguarding sensitive electronics from the pervasive threat of electromagnetic interference (EMI). As industries increasingly rely on precision and efficiency, understanding the nuances of magnetic shielding becomes paramount for procurement managers tasked with optimizing transformer performance.

This article delves into the definition and significance of magnetic shielding, explores the materials that enhance its effectiveness, and addresses the challenges faced in its implementation. Furthermore, it highlights future trends that promise to reshape the landscape of magnetic shielding, enabling organizations to navigate the complexities of modern transformer design with confidence.

By equipping themselves with this knowledge, procurement professionals can make informed decisions that drive operational excellence and ensure the longevity of electronic systems.

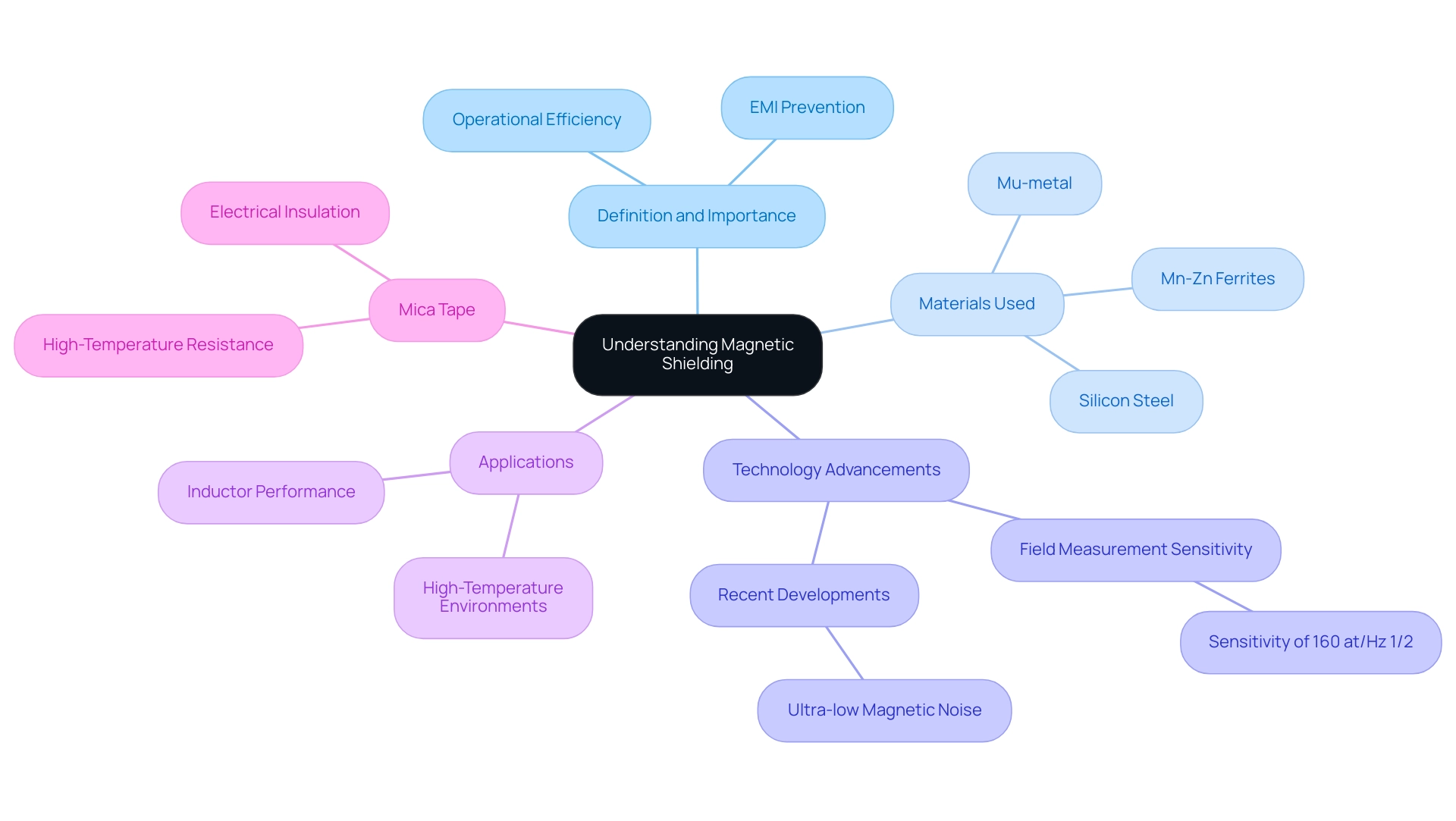

Understanding Magnetic Shielding: Definition and Importance

Field protection is an essential method that includes magnetic shielding for power transformers to safeguard delicate electronic parts from external influences. The presence of electromagnetic interference (EMI) can lead to significant inefficiencies and operational challenges, making magnetic shielding for power transformers essential. Materials such as mu-metal and silicon steel are commonly employed due to their high permeability, which allows them to redirect field lines away from sensitive areas.

This redirection prevents unwanted interference, thereby ensuring that transformers function with optimal efficiency and reliability. Recent advancements in field protection technology have demonstrated that sensitive measurements in field-protecting devices can achieve remarkable sensitivity, with a field measurement sensitivity of 160 at/Hz 1/2 noted in ferrite shields. This highlights the ongoing improvements in the field.

Additionally, soft ferromagnetic substances such as MN-Zn ferrites are acknowledged for their high permeability and low losses, rendering them suitable for utilization in electronics and protection applications. Comprehending the significance of magnetic shielding for power transformers is essential for enhancing device design, especially in scenarios where accuracy and dependability are vital. Additionally, incorporating Mica Tape products can further enhance these applications.

Mica Tape provides high-temperature resistance and outstanding electrical insulation characteristics, making it a perfect option for use alongside shielding materials. This combination not only enhances the overall performance of devices but also guarantees dependable operation in high-temperature environments. As highlighted by Zhang et al., “In order to improve the anti-disturbance ability of the MCG measurement, Zhang et al. adopted the extended state observer (ESO) to estimate the noise and established the disturbance feedforward control loop based on the compensation system composed of the radial and saddle coils.” This insight into practical strategies is vital for minimizing the effects of EMI. Ultimately, effective electromagnetic protection, complemented by Mica Tape, not only enhances the performance of inductors but also contributes to the overall efficiency and longevity of electronic systems.

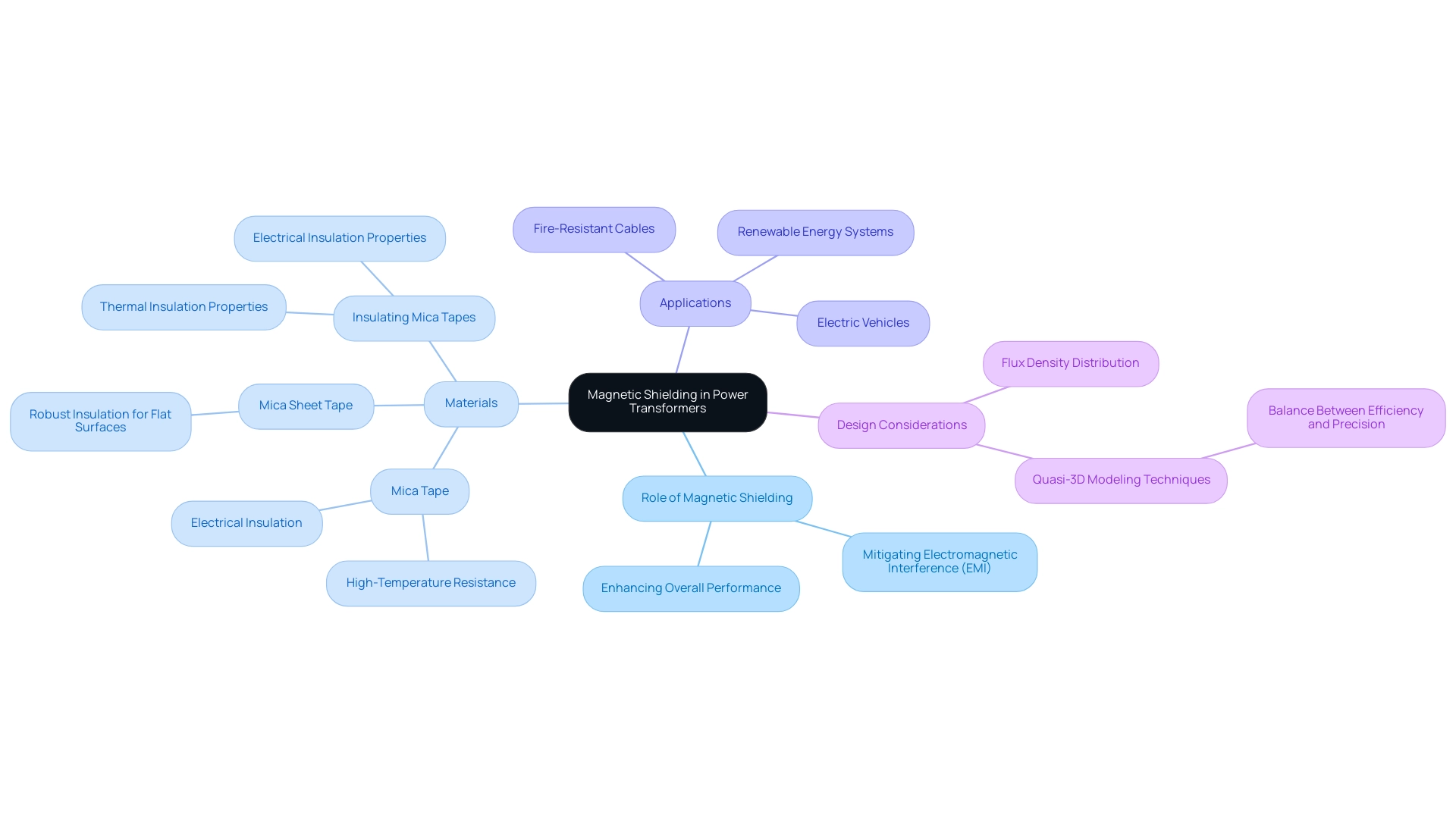

Applications of Magnetic Shielding in Power Transformers

Magnetic shielding for power transformers plays a pivotal role in mitigating electromagnetic interference (EMI) and enhancing overall performance. One common technique consists of encasing the transformer core with highly permeable substances, such as steel lamination stacks, which effectively safeguard internal components and reduce flux leakage. This is where high-performance materials like Mica Tape come into play, offering exceptional high-temperature resistance and electrical insulation crucial for demanding environments.

Specifically, Mica Sheet Tape provides robust insulation for large flat surfaces, while Insulating Mica Tapes deliver exceptional thermal and electrical insulation properties, making them indispensable in applications such as fire-resistant cables. The design of these tank shields must consider flux density distribution to optimize their effectiveness, particularly in high-frequency applications, such as renewable energy systems and electric vehicles, where operational efficiency is paramount. Furthermore, magnetic shielding can be strategically incorporated into enclosure systems to diminish interference from external sources.

Recent experimental analysis of lightning impulse voltage distribution along high-voltage windings have provided valuable insights for designers, enabling the production of dry-type devices with rated voltages exceeding 36 kV. Additionally, quasi-3D modeling techniques enable the calculation of 3D problems using multiple 2D models, providing a balance between computational efficiency and precision in design. By adopting robust magnetic shielding for power transformers, manufacturers can significantly enhance the reliability and efficiency of their devices, leading to improved operational performance in real-world applications.

Such insights are essential for procurement managers when assessing resources and suppliers capable of fulfilling these specialized requirements. As Zvonimir Jurkovic aptly states,

As such, the proposed approach has industrial value,

underscoring the practical significance of these advancements in power conversion technology.

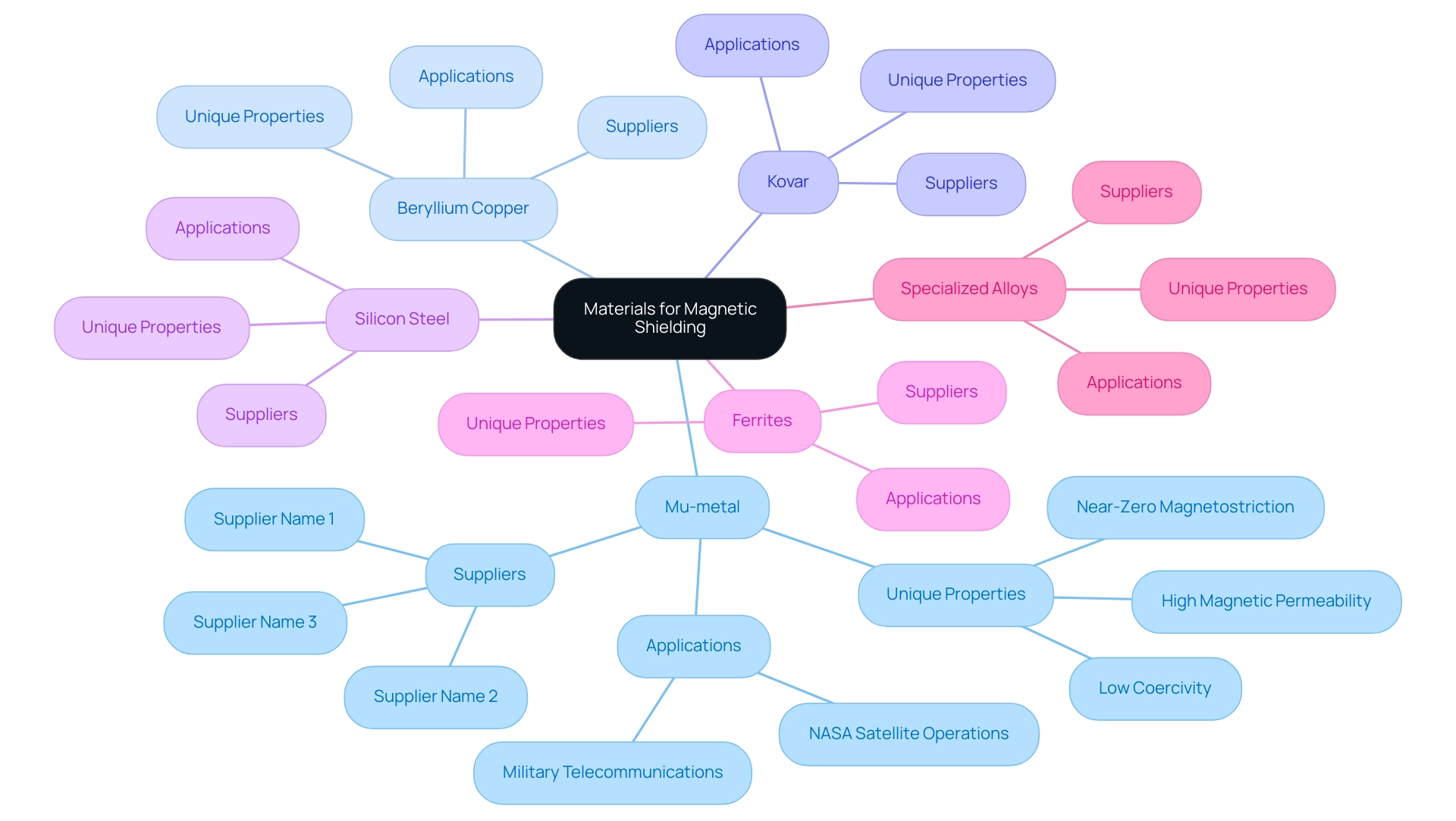

Materials Used for Magnetic Shielding

In the field of magnetic shielding for power transformers, several materials are notable for their effectiveness and application suitability. Mu-metal, known for its remarkably high magnetic permeability, is a favored option for magnetic shielding for power transformers that require strong protection against low-frequency magnetic fields. Notably, annealing can almost double the attenuation of Mu-metal, significantly enhancing its effectiveness in shielding applications.

Its unique properties, including low coercivity and near-zero magnetostriction, make it particularly advantageous in industrial scenarios where variable stresses are present in thin films. Suppliers such as [Supplier Name 1], [Supplier Name 2], and [Supplier Name 3] offer various options customized to specific design requirements, including Mu-metal, Beryllium Copper, and Kovar. Additionally, silicon steel serves as a popular alternative for magnetic shielding for power transformers, due to its favorable electromagnetic properties combined with cost-effectiveness.

Other substances, such as ferrites and specialized alloys, are also viable options. Recent research highlights the usefulness of these substances in the context of magnetic shielding for power transformers, allowing procurement managers to make informed sourcing choices that meet performance standards crucial for efficient electromagnetic protection. Furthermore, case studies highlight Mu-metal’s applications in critical environments, such as NASA satellite operations and military telecommunications, demonstrating its effectiveness in minimizing electromagnetic interference.

As Allen Green aptly noted, ‘150 Years Of Industry & Enterprise At Enderby’s Wharf,’ the ongoing evolution in substance science continues to shape best practices in the field, supported by a network of reputable suppliers and manufacturers of electrical insulation and high-temperature substances, including [Additional Supplier Name 1] and [Additional Supplier Name 2].

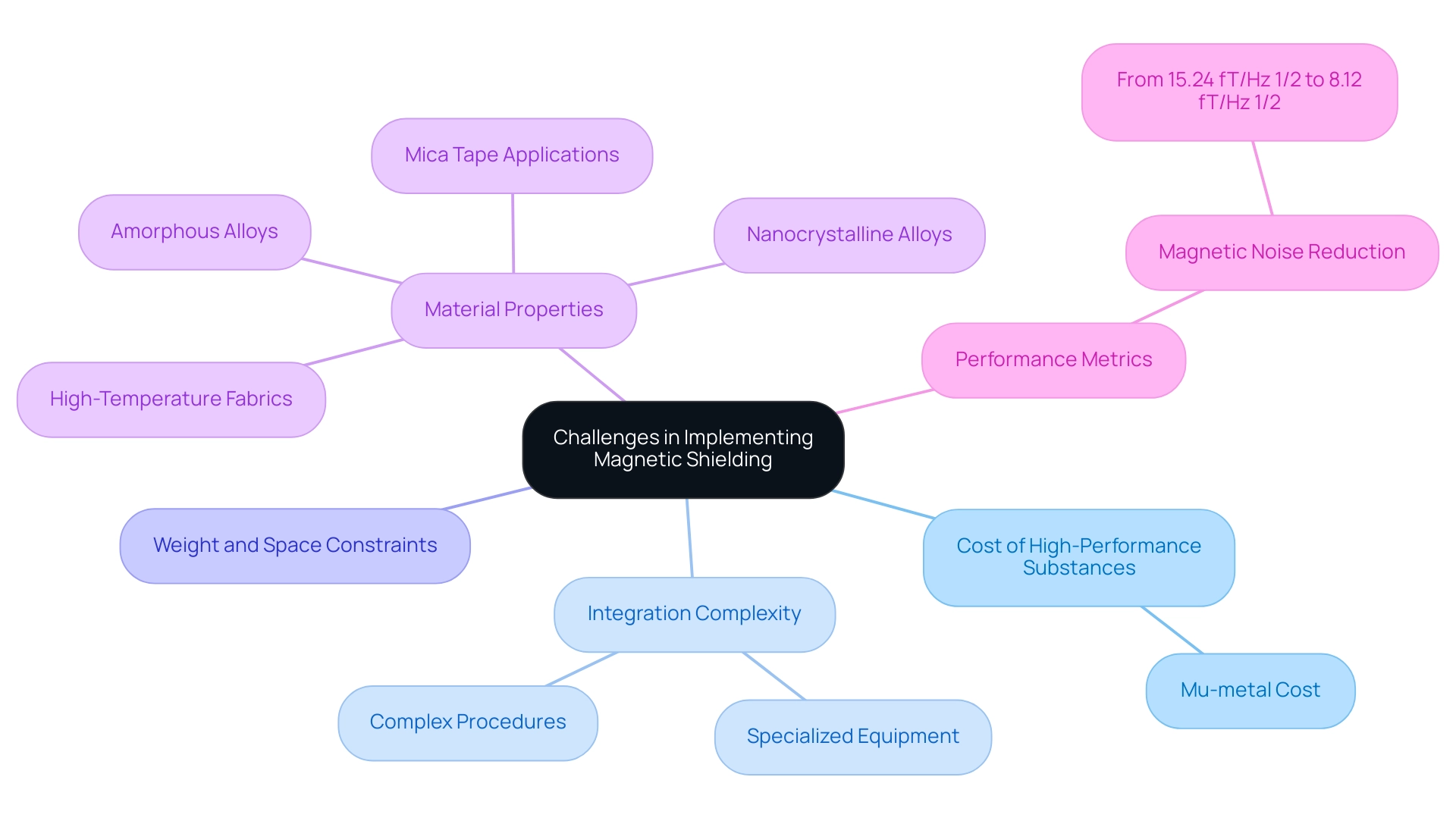

Challenges in Implementing Magnetic Shielding

Implementing magnetic shielding for power transformers poses several significant challenges that procurement managers must navigate. A primary concern lies in the cost associated with high-performance substances such as mu-metal. While these substances offer exceptional magnetic properties, their expense can make them impractical for various applications.

Additionally, the integration of these materials into manufacturing processes often requires specialized equipment and complex procedures, further complicating their use. Weight and space constraints in transformer design also limit the deployment of certain protective solutions, making the inclusion of magnetic shielding for power transformers crucial during the design phase. For instance, amorphous and nanocrystalline alloys have emerged as optimal choices for magnetic shielding for power transformers, due to their unique microstructural properties, which provide superior soft performance characterized by low coercivity and high permeability.

Furthermore, Mica Tape products, renowned for their high-temperature resistance and electrical insulation capabilities, serve as a critical component in environments requiring robust thermal management and safety. Recent studies have indicated that the electromagnetic noise at 1 Hz was effectively reduced from 15.24 Ft/Hz 1/2 to 8.12 Ft/Hz 1/2, emphasizing the efficiency of these substances. As Xu et al. modeled and calculated the noise of Fe-based nanocrystalline substances in the SERF magnetometer, considering temperature effects, this scholarly reference further supports the claims made about the performance of these substances.

Furthermore, other high-performance substances like electrical insulation papers, PTFE coated yarns, and high-temperature fabrics are important factors that procurement managers should assess when choosing components for protective applications. By identifying and tackling these challenges, procurement managers can successfully work with suppliers of electrical insulation and high-temperature products to create solutions that meet both performance and budgetary limitations, ultimately ensuring the effective execution of protective measures in devices.

As one expert noted, ‘You’re navigating agile marketing structures. How do you keep your creativity alive?’ This sentiment resonates in the procurement landscape as managers seek innovative ways to overcome these challenges.

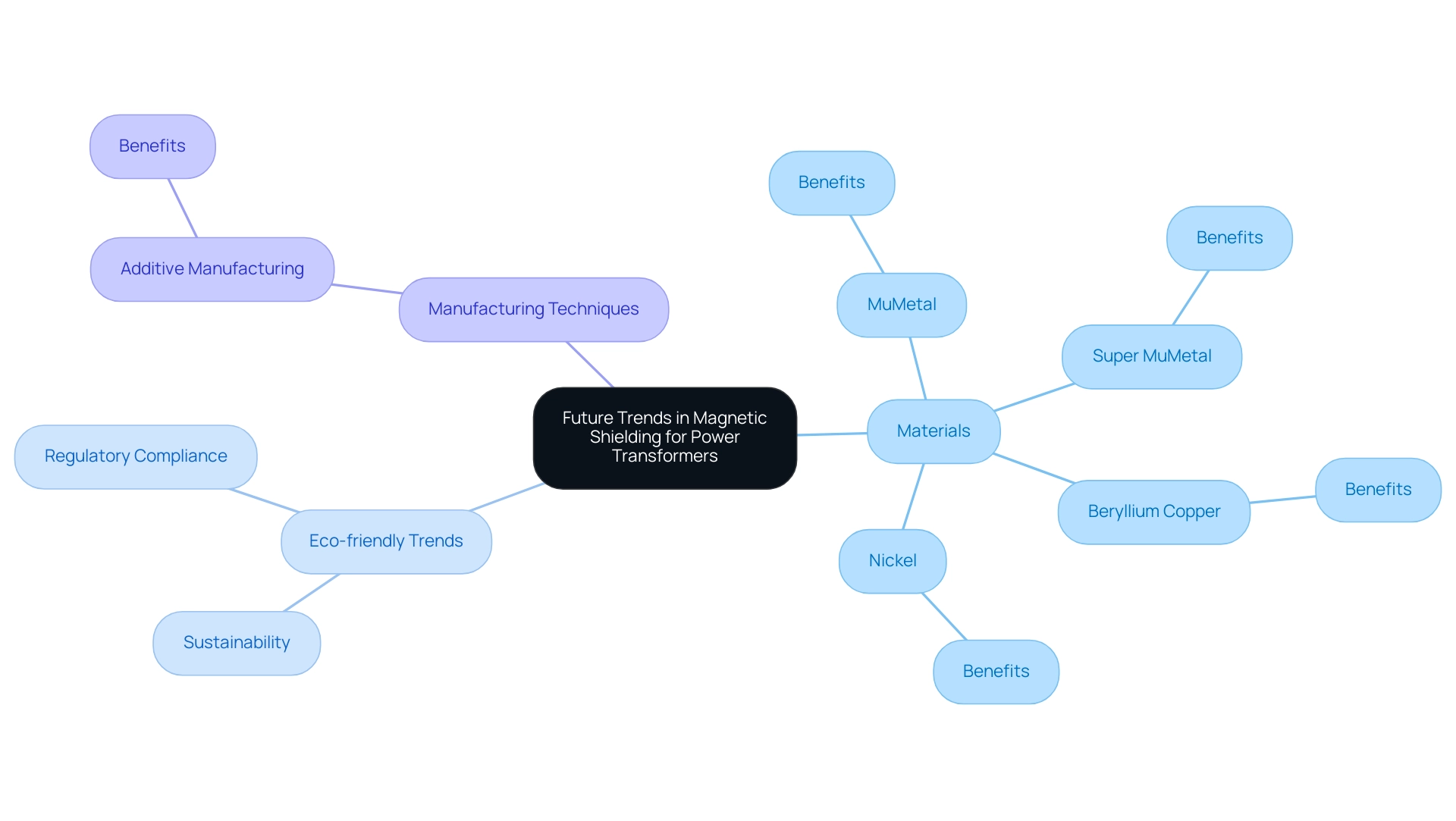

Future Trends in Magnetic Shielding for Power Transformers

The electromagnetic protection environment for power converters is on the verge of revolutionary progress, propelled by breakthroughs in substance science. Research indicates that substances such as:

- MuMetal

- Super MuMetal

- Beryllium Copper

- Nickel

are evolving, paving the way for lighter and more effective shielding solutions that integrate seamlessly into transformer designs. Notably, the optimal thickness of the vertical magnetic shunt is 10 mm, providing a critical technical insight for procurement managers.

As the industry increasingly prioritizes energy efficiency and sustainability, there is a growing trend towards adopting eco-friendly substances that not only meet performance requirements but also adhere to environmental regulations. Furthermore, advancements in manufacturing techniques, particularly additive manufacturing, allow for the creation of intricate and optimized geometries that were previously unattainable. Tao Wang from Tsinghua University highlights that ‘the impact of the protective barrier is confirmed by finite-element analysis,’ suggesting a strong validation process for these new substances.

Additionally, the case study titled ‘Magnetic Shaking for Shielding Performance‘ illustrates how magnetic shaking has been utilized to improve the shielding factors of magnetic substances, demonstrating significant enhancements in shielding performance despite the complexities introduced in maintaining a nearly zero-field environment. Procurement managers must stay alert in tracking these trends, as adjusting sourcing strategies to incorporate the latest innovations and technologies—including product categories like Beryllium Copper, Kovar, Metal, and Nickel from reputable suppliers—will be crucial for improving transformer performance and adhering to evolving regulatory standards. Notably, suppliers such as [insert specific suppliers here] offer these materials, providing valuable support for customer inquiries and sourcing needs.

Conclusion

Effective magnetic shielding is integral to the performance and reliability of power transformers, safeguarding sensitive electronics from the detrimental effects of electromagnetic interference (EMI). The exploration of magnetic shielding has revealed its critical role in optimizing transformer design, particularly through the use of high-permeability materials such as mu-metal and silicon steel, which redirect magnetic field lines to enhance operational efficiency. Additionally, the incorporation of Mica Tape products not only improves thermal management but also fortifies electrical insulation, ensuring robust performance in demanding environments.

As the industry evolves, procurement managers face various challenges in implementing magnetic shielding, including cost considerations and material integration complexities. However, advancements in materials science, such as the development of amorphous and nanocrystalline alloys, present viable alternatives that offer superior magnetic performance while addressing budgetary constraints. Future trends suggest a shift towards eco-friendly materials and innovative manufacturing techniques, such as additive manufacturing, which promise to revolutionize shielding applications and enhance compliance with environmental regulations.

In navigating these complexities, procurement professionals are equipped with the insights necessary to make informed sourcing decisions that align with both performance and economic goals. Embracing these advancements not only fosters operational excellence but also ensures the longevity and reliability of electronic systems in an increasingly demanding technological landscape. The strategic integration of magnetic shielding will undoubtedly play a pivotal role in the future of power transformers, enabling organizations to maintain a competitive edge in the market.