Blogs

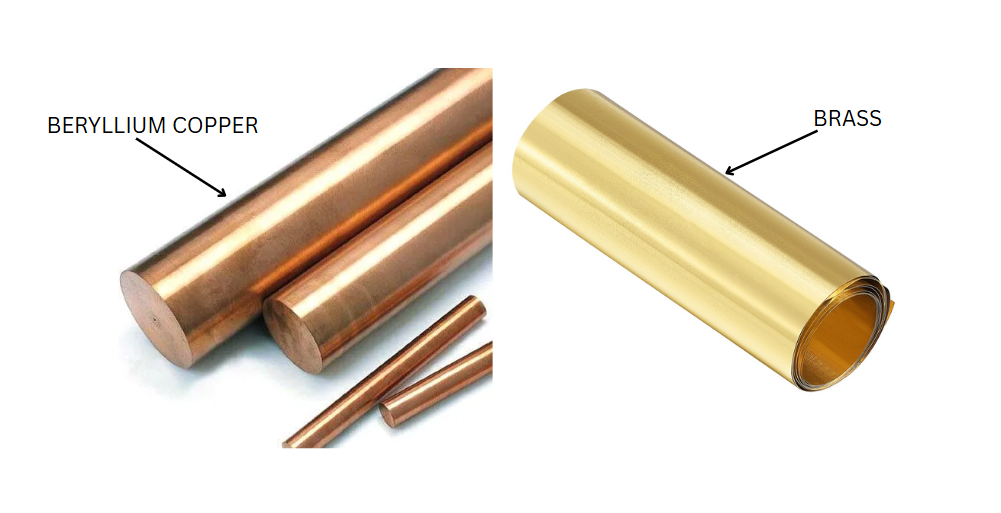

Is Beryllium Copper Worth It? A Complete Comparison with Brass

Introduction – “Not All That Glitters is Brass”

You wouldn’t wear flip-flops to climb Mt. Everest.

So why choose Brass for a high-load, high-fatigue, mission-critical component?

Just because brass is shiny, doesn’t mean it’s ready for battle. That’s where Beryllium Copper (UNS C17200) steps in. This metal may not be as cheap, but it punches well above its weight in strength, reliability, and long-term value.

Welcome to the Alloy Arena, where we pit the budget-friendly workhorse (Brass) against the elite performer (Beryllium Copper) in an ultimate material face-off.

Chemical Composition

| Element | Beryllium Copper (C17200) | Brass (C26000) |

| Copper (Cu) | 97.5 – 98.5% | ~68.5% |

| Beryllium (Be) | 1.8 – 2.0% | — |

| Zinc (Zn) | — | ~31.5% |

| Trace Additives | Cobalt, Nickel | Lead, Iron |

Translation: Brass is made for looks and basic conductivity. Beryllium Copper is engineered for high stakes.

Performance Comparison: Muscle vs Show

| Property | Beryllium Copper (C17200) | Brass (C26000) |

| Tensile Strength | 1100 – 1400 MPa | 300 – 550 MPa |

| Hardness (HV) | Up to 400 HV | 100 – 200 HV |

| Fatigue Resistance | Outstanding | Moderate |

| Corrosion Resistance | Excellent | Good |

| Conductivity | 22 – 25% IACS | 28 – 33% IACS |

| Elastic Modulus | ~131 GPa | ~100 GPa |

| Formability | Medium | Excellent |

Key Insight: While brass wins on ductility and price, beryllium copper dominates in mechanical strength and fatigue life.

Applications: Choose Your Fighter

🛠️ Beryllium Copper:

- High-load electrical contacts

- Military-grade connectors

- Springs and pressure diaphragms

- Oil and gas drilling components

- Non-sparking tools for explosive environments

🪞 Brass:

- Decorative fittings

- Plumbing and radiator parts

- Musical instruments

- Watch components and zippers

- Basic terminal lugs

If you’re building a saxophone—go brass.

If you’re building a fighter jet, or something that shouldn’t fail mid-air—you’ll want beryllium copper.

Industry Standards & Specs

| Specification | Beryllium Copper (C17200) | Brass (C26000) |

| ASTM | B196, B197 | B36, B134 |

| IS / JIS | IS 6748, JIS H3130 | IS 319, JIS H3250 |

| Forms Available | Rod, Strip, Wire, Sheet | Rod, Tube, Strip |

| Tempers | Aged, Annealed | Soft, Half-Hard, Hard |

Lifecycle & Sustainability

Imagine this:

A brass contact fails every 6 months. Beryllium copper lasts 5 years.

Now do the math:

🔄 10X fewer replacements

🛠️ Less downtime

♻️ Less scrap generated

🌱 Smaller carbon footprint

Yes, beryllium copper costs more upfront.

But the planet—and your bottom line—will thank you later.

Summary – Make The Right Match

| Feature | Winner | Why It Matters |

| Cost | Brass | Budget-friendly for low-stakes use |

| Strength & Fatigue | Beryllium Copper | Critical in high-load environments |

| Conductivity | Brass | Great for general electrical needs |

| Lifecycle Value | Beryllium Copper | Pays off in long-term applications |

| Environmental Impact | Beryllium Copper | Fewer replacements = less recycling |

| Appearance | Brass | Ideal for aesthetics |

Conclusion – When Performance is Non-Negotiable

At first glance, Brass (C26000) might seem like the obvious choice—lower cost, easier to machine, and widely available. But when you’re building for precision, endurance, and reputation, cutting corners on material can cost you far more in the long run.

Beryllium Copper (UNS C17200) isn’t just another alloy—it’s an investment in reliability, reduced downtime, fewer replacements, and a greener footprint.

🚫 Fewer failures

🔁 Longer service life

♻️ Less scrap

💰 Lower lifetime cost

So the next time you’re choosing between price and performance, ask yourself:

“Am I building to last—or just to get by?”

At Domadia, we partner with forward-thinking manufacturers who demand more from their materials. If you’re ready to build products that outlast, outperform, and outclass—Beryllium Copper is where your future begins.

Visit our website: Domadia.com

Email: sales@domadia.com

Call/WhatsApp: +91-9594066275

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia