Blogs

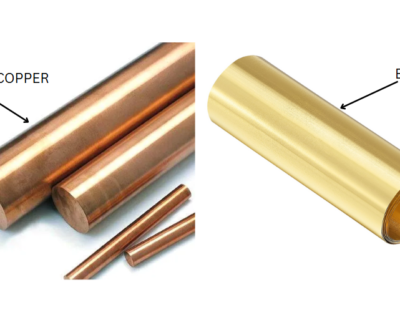

Beryllium Copper vs Chromium Copper: The High-Performance Alloy Face-Off (UNS C17200 vs UNS C18200)

When most engineers compare Beryllium Copper vs Chromium Copper, they ask:

“Which one costs less?”

But here’s the truth: It’s the wrong question.

Because when your product fails early, causes downtime, or risks safety, the cheaper metal suddenly becomes very expensive.

Instead, ask:

- Which alloy can handle high stress without wearing out?

- Which one prevents tool failure, sparks, or conductivity loss over time?

This mindset shift helped a major OEM reduce replacements by 70% simply by switching from Chromium Copper to Beryllium Copper.

In this blog, we break down everything you need to know—from composition to real-world ROI—so you can stop guessing and start engineering smart.

Chemical Composition

| Property | Beryllium Copper (C17200) | Chromium Copper (C18200) |

| Copper (Cu) | ~98% | ~98.6% |

| Beryllium (Be) | 1.80 – 2.00% | — |

| Chromium (Cr) | — | 0.6 – 1.2% |

| Other | Cobalt, Nickel (trace) | Trace impurities |

Key Properties Comparison

| Feature | Beryllium Copper (C17200) | Chromium Copper (C18200) |

| Hardness (after aging) | Up to 40 HRC | ~18–30 HRC |

| Electrical Conductivity | 22% IACS | 80–90% IACS |

| Thermal Conductivity | 105 W/m·K | 320 W/m·K |

| Tensile Strength | Up to 1400 MPa | ~400 MPa |

| Fatigue Resistance | Excellent | Moderate |

| Workability | Moderate | Excellent |

| Corrosion Resistance | Very good | Good |

| Non-Sparking | Yes | No |

Applications (Explained Briefly)

✅ Beryllium Copper (C17200)

- Aerospace: Ideal for springs, bushings, and fasteners due to its high strength, fatigue resistance, and ability to perform under vibration and pressure changes.

- Oil & Gas: Used for non-sparking tools in hazardous environments where safety from ignition is critical.

- Electronics: Preferred in high-reliability connectors and switches thanks to its conductivity and mechanical strength.

- Defense: Powers precision components in sensors and targeting systems, offering corrosion resistance and long lifecycle.

- Medical: Safe for MRI and imaging equipment due to its non-magnetic nature and excellent machinability.

✅ Chromium Copper (C18200)

- Resistance Welding: Commonly used in welding electrodes for its heat resistance and durability under repeated cycles.

- Electrical Systems: Serves in contacts, switchgear, and breakers where high conductivity and erosion resistance are essential.

- Heat Sinks: Efficient in thermal management applications in electronics and laser systems.

- Industrial Dies: Used in die casting and mold tools for its balance of hardness and heat conductivity.

- Power Conductors: Performs well in heavy-duty electrical systems, including busbars and grounding rods.

Technical Specifications & Standards

Beryllium Copper (C17200)

- ASTM B194, AMS 4533, RWMA Class 4

- Shapes: rods, plates, sheets, strips, wires, bars

Chromium Copper (C18200)

- ASTM B170, RWMA Class 2

- Shapes: bars, rods, tubes, electrodes

Life Cycle & Cost Analysis

- Initial Cost: Beryllium Copper is 3–4x more expensive.

- Lifecycle: Beryllium Copper lasts up to 5x longer.

- Downtime: Chromium Copper often leads to higher tool wear & replacements.

- ROI: Beryllium Copper = longer-term gains.

Environmental Impact: Greener Through Durability

Every extra replacement = more carbon footprint. More scrapped parts. More waste.

Beryllium Copper’s superior lifespan means fewer replacements, less energy used in recycling, and fewer disruptions—making it an eco-conscious engineering choice.

Why Beryllium Copper Is More Effective Than Chromium Copper

- Stronger: Beryllium Copper has up to 3x the strength of Chromium Copper, making it ideal for high-stress, fatigue-prone parts.

- Longer-lasting: It lasts up to 5 times longer, reducing replacement costs and machine downtime.

- Safer: It’s non-sparking and non-magnetic, perfect for hazardous and sensitive environments.

- More Sustainable: Fewer replacements mean less scrap, lower carbon footprint, and greener operations.

- Better ROI: Though more expensive upfront, Beryllium Copper saves money long-term by reducing maintenance and failure risk.

Conclusion: Beryllium Copper vs Chromium Copper – What’s Your Pick?

In the debate of Beryllium Copper vs Chromium Copper, it’s not just about price—it’s about performance, longevity, and impact.

- Choose Beryllium Copper (C17200) when strength, safety, and durability matter most.

- Choose Chromium Copper (C18200) for high conductivity and cost-effective electrical use.

While Chromium Copper suits many standard applications, Beryllium Copper often proves more valuable over time, reducing downtime, replacements, and environmental waste.

Smart materials = smarter decisions.

At Domadia, we partner with forward-thinking manufacturers who demand more from their materials. If you’re ready to build products that outlast, outperform, and outclass—Beryllium Copper is where your future begins.

Visit our website: Domadia.com

Email: sales@domadia.com

Call/WhatsApp: +91-9594066275

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia