Blogs

Beryllium Copper vs. Phosphor Bronze: Is the 5X Price Tag Worth It?

Introduction: The Costly Mistake of Going Cheap

Beryllium Copper vs. Phosphor Bronze — on paper, it feels like a simple pricing decision. But in the real world, it can mean the difference between smooth operations and catastrophic failure.

Case in point:

An electronics plant runs into a sudden shutdown. The culprit? A tiny spring contact made of phosphor bronze failed due to metal fatigue. Production halts for 3 full days.

Lost orders.

Stressed clients.

Total cost? Over ₹15 lakhs.

All because they chose the cheaper material in the Beryllium Copper vs. Phosphor Bronze debate — and paid the price.

This blog breaks down the real story behind the numbers — why Beryllium Copper may cost 5X more, but often saves 10X over time through lifecycle performance, reliability, and even environmental impact.

Chemical Composition

| Property | Beryllium Copper (UNS C17200) | Phosphor Bronze (UNS C51000 / C54400) |

| Copper (Cu) | ~97.5% | ~94–95% |

| Beryllium (Be) | 1.8–2.0% | — |

| Cobalt/Nickel (Co/Ni) | Up to 0.6% | — |

| Tin (Sn) | — | 4.0–5.5% |

| Phosphorus (P) | — | 0.03–0.35% |

Mechanical Properties Comparison

| Property | Beryllium Copper | Phosphor Bronze |

| Tensile Strength (MPa) | 900–1400 MPa | 350–800 MPa |

| Hardness (HV) | 200–450 HV | 100–200 HV |

| Fatigue Resistance | ★★★★★ | ★★★☆☆ |

| Conductivity (% IACS) | 22–60% | 15–20% |

| Operating Temp Range | -200°C to +350°C | -200°C to +200°C |

| Elastic Limit | Very High | Moderate |

Applications: Where They Shine

Beryllium Copper

- High-performance spring contacts

- Aerospace and avionics connectors

- Downhole oil & gas tools

- Defense-grade sensors and actuators

- MEMS & precision instrumentation

Phosphor Bronze

- Electrical connectors (budget grade)

- Musical instruments (strings, reeds)

- Bearings and bushings

- Springs (medium duty)

- Marine hardware

Environmental Impact: Domadia’s Green Advantage

Most engineers calculate cost in rupees per kilogram.

At Domadia, we calculate cost per lifecycle.

And that includes our planet.

💡 Here’s the truth:

The more often you have to replace, scrap, and recycle metal — the greater the carbon footprint, energy consumption, and waste generated.

| Factor | Beryllium Copper | Phosphor Bronze |

| Recyclability | High | High |

| Replacement Cycle | 1 per 5–10 years | 4–6 per 5 years |

| Scrap Generation (per line) | Minimal | Frequent |

| Energy Spent on Reprocessing | Lower (longer life) | Higher (frequent recycling) |

| Carbon Emissions (overall) | Lower | Higher |

At Domadia, every time we help our client choose Beryllium Copper, we reduce:

- Raw material extraction

- Furnace re-melting cycles

- Manufacturing energy use

- Carbon emissions by tons over years

🛡️ That’s not just good engineering. It’s responsible engineering.

Lifecycle & Reliability Analysis

| Factor | Beryllium Copper | Phosphor Bronze |

| Lifecycle (cycles) | > 1 million | 200,000–300,000 |

| Downtime due to failure | Rare | Frequent |

| Replacement frequency | Once in years | Often annually |

| Total Cost of Ownership | Low | High |

The Real Cost: Breaking Down the Price Myth

| Item | BeCu | PB |

| Initial Material Cost | ₹5,000/kg | ₹1,000/kg |

| Replacement every 2 years | 1x | 4–6x |

| Downtime cost/year | Negligible | ₹1–2 lakhs/year |

| Total 5-Year Cost (per item) | ₹5,000–6,000 | ₹8,000–12,000 |

So while Beryllium Copper may be pricier at the start, it wins big on durability, downtime prevention, eco-footprint, and total cost.

Standards & Specifications

| Standard Type | Beryllium Copper | Phosphor Bronze |

| ASTM | B196, B197, B194 | B103, B139, B160 |

| UNS Designation | C17200, C17300 | C51000, C54400 |

| RoHS Compliance | Requires verification | Generally compliant |

| Heat Treatable | Yes (for peak strength) | No |

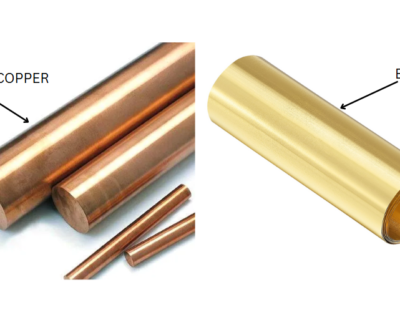

Shapes Available

| Shape | Beryllium Copper | Phosphor Bronze |

| Strips | ✅ | ✅ |

| Rods | ✅ | ✅ |

| Sheets & Plates | ✅ | ✅ |

| Wire | ✅ | ✅ |

| Tubes | ✅ (limited) | ✅ |

| Custom Profiles | ✅ | ✅ |

Conclusion: Pay Now or Pay Forever

Choosing Phosphor Bronze may seem like a cost-saving move — until your system fails, your line halts, or your carbon footprint spikes.

With Beryllium Copper, you’re not just buying performance.

You’re investing in:

- Longer lifespans

- Fewer replacements

- Less waste

- More uptime

- A greener tomorrow

At Domadia, we believe in building better parts — and a better planet.

🌿 Beryllium Copper: Because sustainability and performance can go hand in hand.

Ready to upgrade your material strategy?

📩 Message us to explore how Beryllium Copper can cut costs and carbon in your operations.

Email: sales@domadia.com

Call/WhatsApp: +91-9594066275

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia