Blogs

Top 7 Benefits of Beryllium Bronze for Electrical Contacts in Switches & Connectors

Introduction

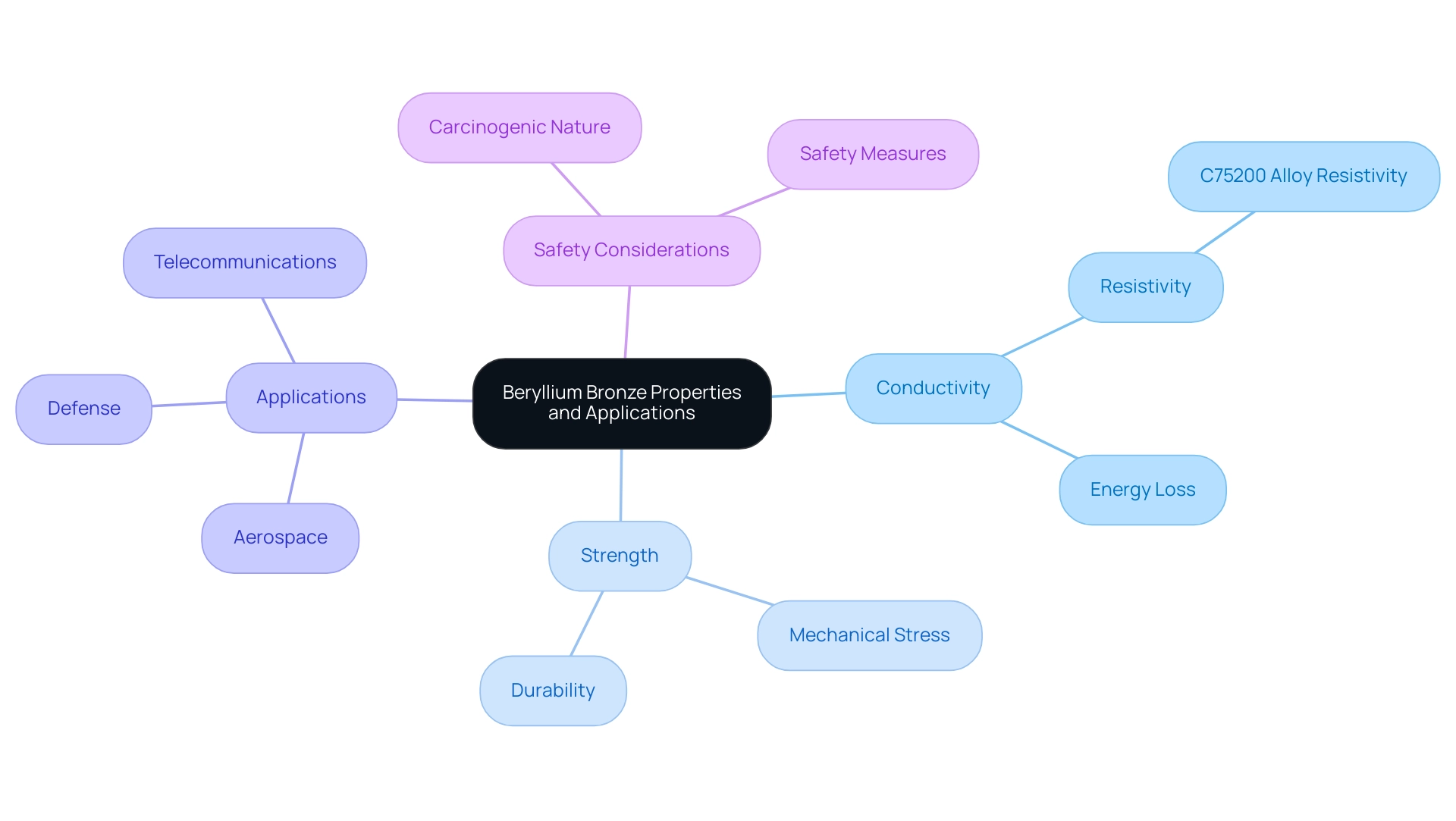

In the intricate landscape of electrical materials, beryllium bronze emerges as a formidable contender, combining exceptional conductivity with remarkable strength. This alloy, particularly the C75200 variant, not only meets stringent international standards but also showcases a resistivity that ensures minimal energy loss, making it indispensable in sectors where efficiency is paramount.

As industries like aerospace, defense, and telecommunications increasingly rely on robust electrical connections, understanding the unique properties of beryllium bronze becomes crucial. From its impressive resistance to corrosion and wear to its adaptability in high-performance applications, this material offers a wealth of benefits that can enhance operational reliability.

However, with these advantages come significant safety considerations, particularly regarding the handling of beryllium, a known carcinogen.

This article delves into the multifaceted applications of beryllium bronze, highlighting its mechanical properties, versatile uses in electronics, and the critical safety measures necessary to mitigate health risks, providing procurement managers with the insights needed to make informed decisions in their sourcing strategies.

Exceptional Conductivity and Strength of Beryllium Bronze

Beryllium bronze for electrical contacts in switches & connectors is notable in the realm of conductive materials, especially because of its impressive conductivity, which is essential for optimal performance in critical connections. This is exemplified by DOMADIA’s C75200 alloy, which complies with international standards such as UNS and ASTM and exhibits a resistivity of 2.870-07 ohm-m, underscoring its capacity to facilitate minimal energy loss during transmission. This attribute is especially vital in industries such as aerospace, defense, and telecommunications, where efficiency is paramount.

Moreover, the alloy’s exceptional strength enables it to endure substantial mechanical stress, making it an ideal selection for uses demanding durability and reliability. Recent advancements in understanding conductivity have been highlighted by the verification of a theoretical model of EMWM, which accurately predicts conductivity characteristics under varying temperatures. This model, backed by a case study that developed a simplified resistor network model, demonstrates the practical uses of Beryllium Copper in real-world situations.

Furthermore, the unique combination of high conductivity and robust strength not only enhances the dependability of connections but also significantly boosts the overall efficiency of electronic devices. However, it’s important to note that the National Toxicology Program (NTP) lists beryllium as a carcinogen, which necessitates careful consideration in its use. Therefore, appropriate safety measures and guidelines should be strictly followed when handling Beryllium Copper.

Expert opinions confirm that the benefits of beryllium bronze for electrical contacts in switches & connectors in power-related uses are significant, establishing it as a better choice compared to traditional copper alloys. At DOMADIA, we are committed to quality and customer satisfaction, ensuring that our Beryllium Copper products meet the highest standards for performance and reliability, including their corrosion resistance, which further enhances their appeal in various applications.

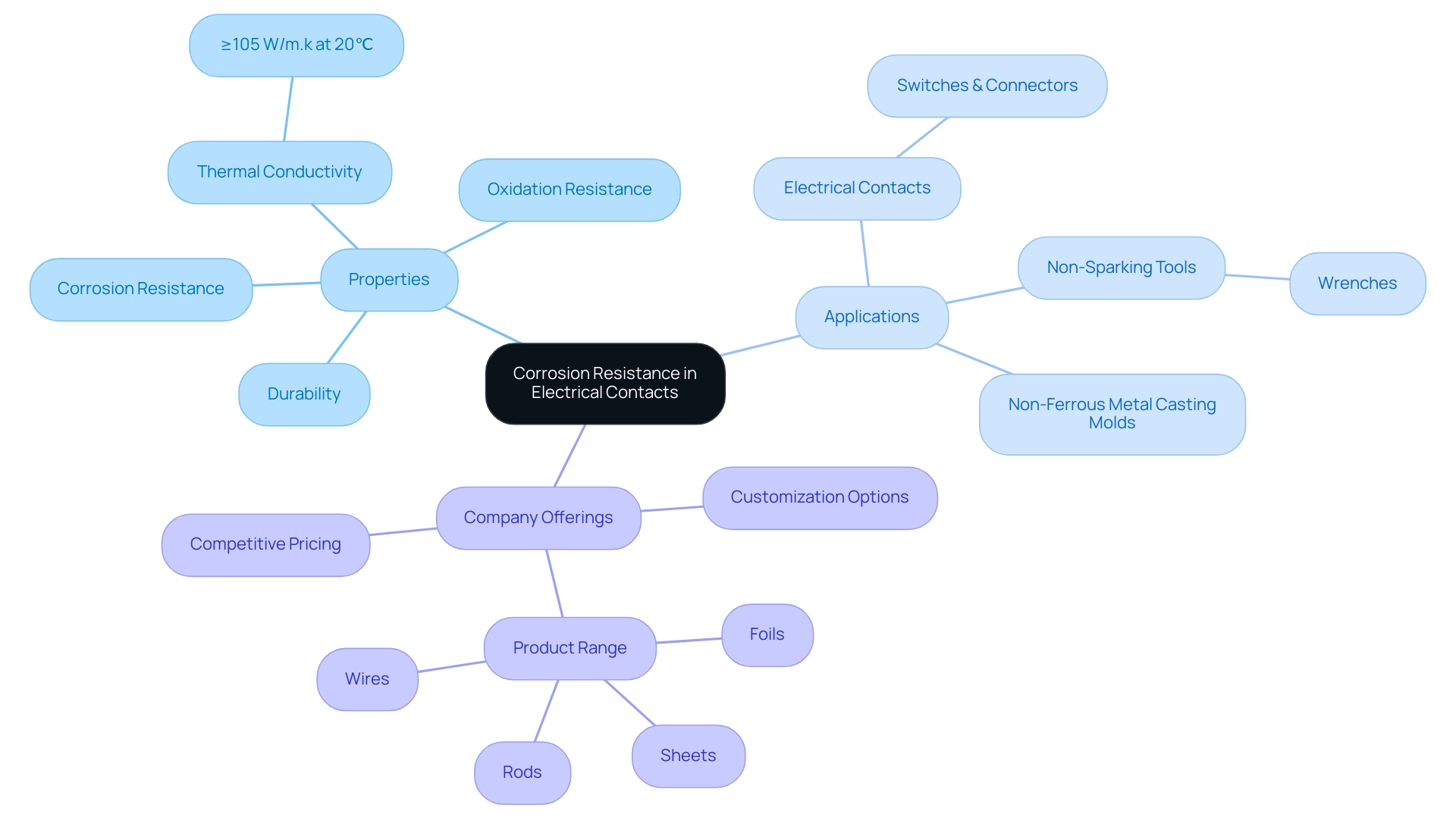

Corrosion Resistance: Ensuring Longevity in Electrical Contacts

Beryllium bronze for electrical contacts in switches & connectors is renowned for its outstanding corrosion resistance, a critical attribute that preserves the integrity of these contacts over time, particularly in demanding environments. This alloy, including the UNS C17200 variant, demonstrates remarkable resistance to oxidation and various forms of corrosive damage, ensuring functionality under extreme conditions. Notably, recent studies indicate that the corrosion resistance of beryllium-copper alloy (UNS C17200) is comparable to leading materials in the field, further supporting its reliability.

Furthermore, copper tools, such as non-sparking wrenches, are designed with safety in mind, making them ideal for use in explosive environments due to their non-sparking properties. With a thermal conductivity of ≥105 W/m.k at 20℃, copper alloy improves performance in scenarios requiring efficient heat dissipation, significantly decreasing the need for frequent replacements and maintenance. This durability is invaluable for components exposed to moisture, chemicals, or drastic temperature fluctuations, thus enhancing the longevity and performance of electrical contacts, particularly those made from beryllium bronze for electrical contacts in switches & connectors.

Furthermore, advancements in copper alloys enhance durability in high-performance applications such as non-ferrous metal casting molds, lowering production costs and enhancing casting quality. Domadia serves as your reliable partner for copper solutions, providing a wide product range, including foils, sheets, rods, and wires, along with custom fabrication options designed to meet your specific requirements. Our pricing for copper strips and non-sparking wrenches is competitive, with ready stock available for prompt delivery.

Our commitment to high-quality copper wire and exceptional customer service ensures project success and operational excellence. Monitoring the patina layer on beryllium alloys surfaces is essential, as it provides additional stability against corrosion; however, any cracks can accelerate degradation, highlighting the importance of careful maintenance to maximize operational lifespan. For further inquiries regarding customization options or inventory details, please contact us directly.

Mechanical Properties: Fatigue Strength and Hardness

Beryllium alloy stands out for its exceptional mechanical properties, particularly its impressive fatigue strength and hardness, making it ideal for high-performance applications in aerospace and telecommunications. These attributes are crucial for components subject to repeated stress and strain, particularly for those utilizing beryllium bronze for electrical contacts in switches & connectors. The fatigue strength of this alloy enables it to endure cyclic loading without succumbing to failure, ensuring reliable performance in demanding environments.

Coupled with its hardness, which enhances wear resistance, bronze components maintain their integrity and functionality over prolonged use, even under challenging operating conditions. Additionally, copper that contains beryllium, recognized for its distinctive blend of strength, excellent conductivity, and resistance to corrosion, is essential in battery contacts, providing stable connections over time. Domadia’s leadership in supplying and manufacturing high-performance Beryllium Copper Plates underscores their commitment to providing tailored solutions to meet industrial demands.

It is important to note that while copper alloy offers significant benefits, it contains a toxic element that poses health risks if not handled properly. Steven Bradley, Principal Consultant at Bradley Consulting Services, emphasizes,

The mechanical characteristics of this alloy make it an excellent choice for high-performance uses where durability is essential.

This reliability positions beryllium bronze for electrical contacts in switches & connectors as a preferred choice for manufacturers seeking materials that can meet rigorous operational demands while navigating the complexities of safety regulations associated with beryllium exposure.

Moreover, when evaluating alternatives, copper nickel alloys offer benefits over stainless steel, especially in marine settings for uses like ship hulls and offshore platforms. Their excellent corrosion resistance makes them suitable for automotive systems, electronics, heat exchangers, and coinage, highlighting their versatility and superiority in various sectors.

Versatile Applications of Beryllium Bronze in Electronics

Beryllium alloy demonstrates remarkable versatility in a range of electronic applications, making it a critical material in the industry. Notably, it is extensively employed in the production of electrical contacts in switches & connectors, relays, and circuit breakers, where its reliable electrical connections are indispensable. The inherent resilience of beryllium alloy allows it to endure significant mechanical and environmental stresses, positioning it as a favored choice among manufacturers seeking durability in their components.

Moreover, its high-performance applications in aerospace and military electronics underscore the material’s pivotal role in systems where reliability is non-negotiable. In environments with explosive potential, the use of Non-Sparking Tools is essential, as they provide a safe alternative that mitigates risks associated with sparks and ignition. Non-Sparking Tools are typically made from materials such as brass or aluminum, which are specifically designed to prevent sparks during use.

According to the article ‘Thermal Pulse Processing of Blanks of Small-Sized Parts Made of Alloy and 29 NK Alloy’, there has been a notable increase in the market share of the alloy in electronic components, reflecting its essential function in modern design and manufacturing processes. Industry leaders recognize this adaptability, with one expert stating, ‘The flexibility of this alloy in manufacturing is unmatched, as it fulfills strict standards across diverse uses.’ This viewpoint is additionally backed by data showing an increase in the use of a specific metal alloy in advanced electronics, reinforcing its significance in the field.

Furthermore, a case study named ‘Effect of Mechanical Surface Treatments’ showed that different mechanical surface treatments, like shot peening and roller burnishing, significantly improve the fatigue strength of specific alloys, thereby boosting its durability and reliability in challenging applications. The integration of Non-Sparking Tools complements this, ensuring a comprehensive approach to safety and performance in critical sectors, particularly where the characteristics of specific alloys are utilized alongside Non-Sparking Tools to enhance operational safety.

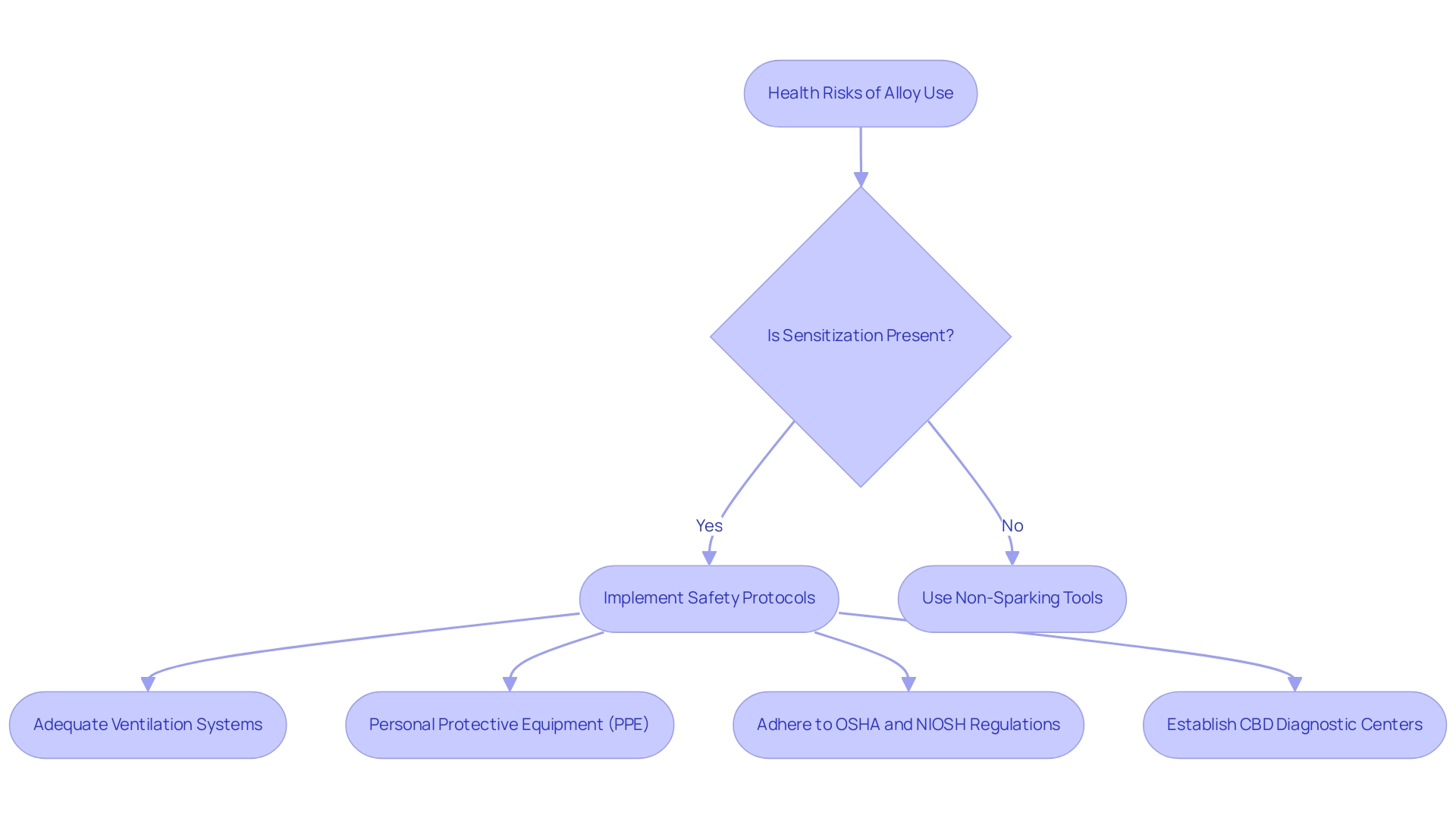

Safety Considerations: Health Risks and Precautions

While this alloy provides numerous benefits, it is crucial to recognize the health risks linked to its use, especially respiratory dangers from inhaling dust or fumes. A study at a former nuclear weapons facility indicated heightened sensitization rates among machinists and health physics technicians, with 11.4% and 11.9%, respectively. This highlights the critical need for stringent monitoring of exposure levels in environments where a type of bronze is handled.

As noted by Elaine R. Stearney, chronic exposure disease, or berylliosis, can develop in sensitized individuals, further emphasizing the importance of proactive safety measures. Moreover, a systematic review by Seidler et al. (2012) indicates that sensitization is a precursor to chronic disease, reinforcing the necessity for early intervention and continuous monitoring.

For procurement managers, this highlights the importance of implementing effective safety protocols, including:

- Adequate ventilation systems

- Personal protective equipment (PPE)

- Strict adherence to safety regulations such as those set by OSHA and NIOSH

Such measures not only protect workers but also promote responsible sourcing and handling of beryllium bronze in production processes. Additionally, the establishment of CBD Diagnostic Centers with on-site pulmonary specialists is crucial for early detection and intervention, aligning with the systematic review’s recommendations for timely medical evaluation.

Furthermore, utilizing Non-Sparking Tools, such as Beryllium Copper Non-Sparking Wrenches—which are considered the best alternative for non-sparking applications in explosive environments—is vital to ensure safety and compliance while performing critical operations. These wrenches feature safety designs that minimize the risk of sparking, making them ideal for use in hazardous settings.

Conclusion

Beryllium bronze, particularly the C75200 variant, is a powerhouse in the realm of electrical materials, known for its exceptional conductivity and strength. This alloy is integral to various industries, including aerospace, defense, and telecommunications, where efficiency and durability are paramount. The combination of high electrical conductivity and remarkable corrosion resistance not only enhances operational reliability but also significantly reduces energy loss, making it a superior alternative to traditional copper alloys. The mechanical properties of beryllium bronze further solidify its position as a preferred choice for high-performance applications, ensuring resilience under repeated stress and strain.

However, the advantages of beryllium bronze come with notable safety considerations. The potential health risks associated with beryllium exposure necessitate a proactive approach to safety protocols. Implementing stringent monitoring measures, utilizing personal protective equipment, and following regulatory guidelines are essential steps for procurement managers to ensure the safety of their workforce while leveraging the benefits of this remarkable material.

In conclusion, understanding the multifaceted applications and inherent risks of beryllium bronze is crucial for informed decision-making in procurement strategies. By balancing the material’s exceptional properties with comprehensive safety measures, organizations can confidently harness the advantages of beryllium bronze, enhancing both operational efficiency and employee safety in their processes.