Blogs

Top 7 Benefits of Monel 400 Pipe Fittings You Should Know

Overview

The top benefits of Monel 400 pipe fittings include exceptional corrosion resistance, high strength and durability, versatility across various environments, excellent weldability, and low maintenance costs. The article supports this by detailing how these properties make Monel 400 fittings ideal for demanding applications in industries such as marine engineering, chemical processing, and aerospace, ultimately leading to enhanced reliability and reduced lifecycle costs.

Introduction

In the realm of industrial materials, Monel 400 stands out as a premier choice for procurement managers seeking reliability and performance in challenging environments. This nickel-copper alloy, celebrated for its exceptional corrosion resistance and mechanical strength, is engineered to thrive in applications ranging from marine engineering to aerospace.

Its unique composition not only ensures durability but also enhances operational efficiency, making it a strategic asset in various sectors. As industries increasingly demand materials that can withstand extreme conditions, the advantages of Monel 400 become even more pronounced.

This article delves into the composition, properties, and diverse applications of Monel 400 pipe fittings, offering valuable insights for those tasked with making informed procurement decisions.

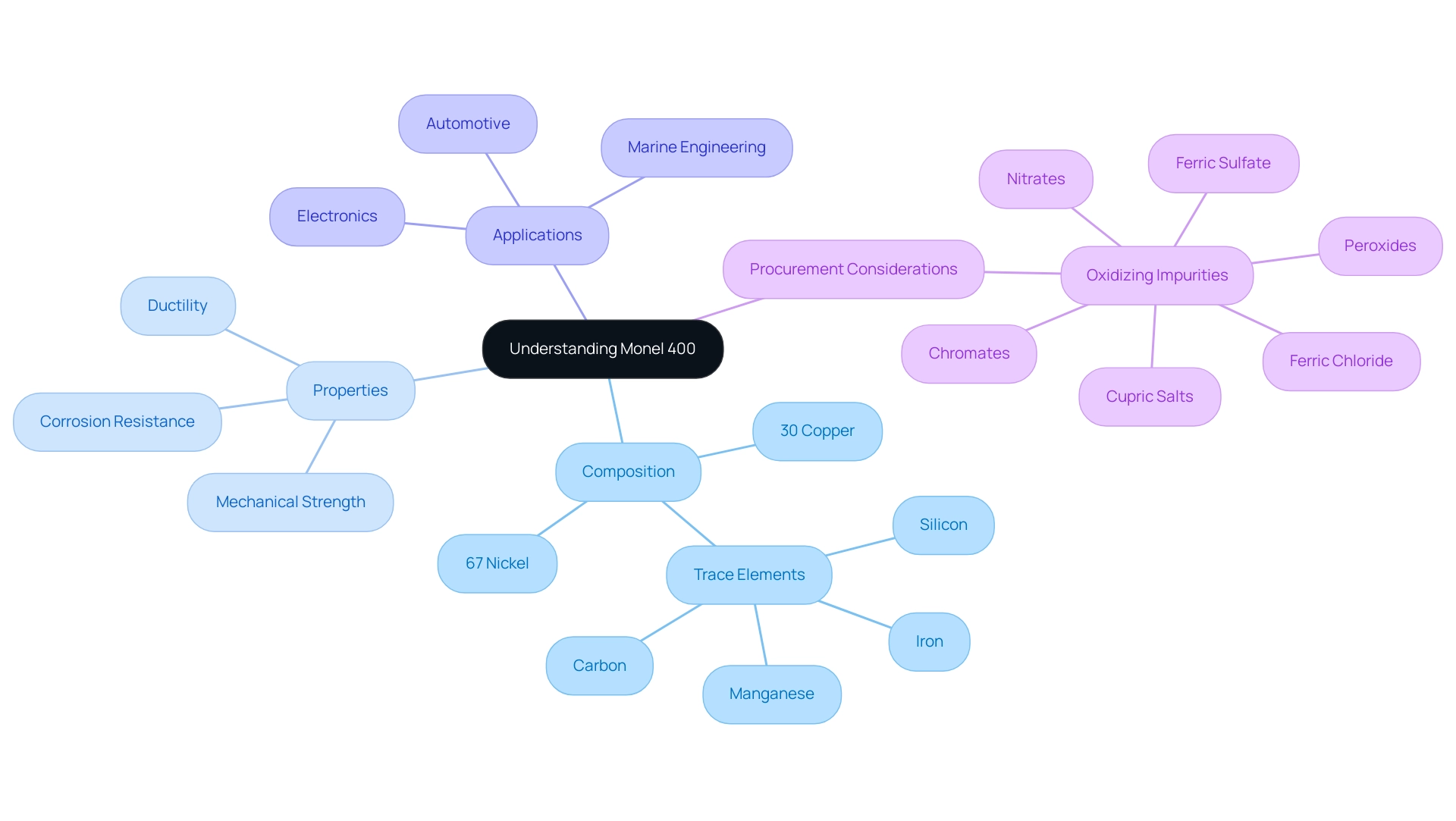

Understanding Monel 400: Composition and Properties

Alloy 400 is a nickel-copper mixture characterized by its remarkable corrosion resistance and impressive strength. Comprising approximately 67% nickel and 30% copper, along with trace elements of iron, manganese, carbon, and silicon, this alloy is uniquely formulated to endure extreme environments, such as seawater and acidic conditions. This alloy is characterized by its remarkable ability to resist oxidation and boasts superior mechanical properties, including high tensile strength and ductility.

Consequently, the use of monel 400 pipe fittings is increasingly preferred in vital applications across different industries, especially in automotive and electronics, where dependability and longevity are crucial. At Domadia, we provide a diverse selection of copper nickel alloys, including grade 400, and we also offer monel 400 pipe fittings, designed for various applications from marine engineering to electronics. These alloys not only provide excellent corrosion resistance but also high conductivity, making them ideal for demanding environments.

Recent advancements in materials like monel 400 pipe fittings, which are nickel-copper alloys, reinforce their position as the materials of choice for engineers and procurement specialists alike. For instance, machining alloy 400 can be optimized with parameters such as:

- A depth of cut at 0.009″ per tooth

- A feed rate of 140 SFM

This ensures efficiency and precision. Furthermore, the case study on ‘Ultrasound-Assisted Decopperization’ illustrates innovative methods for enhancing metal recovery processes, demonstrating the significance of alloy 400 in improving efficiency and reducing environmental impact.

It is also important for procurement managers to consider recent findings that oxidizing impurities like ferric chloride and nitrates can affect the performance of alloy 400 when evaluating material options.

Key Advantages of Monel 400 Pipe Fittings

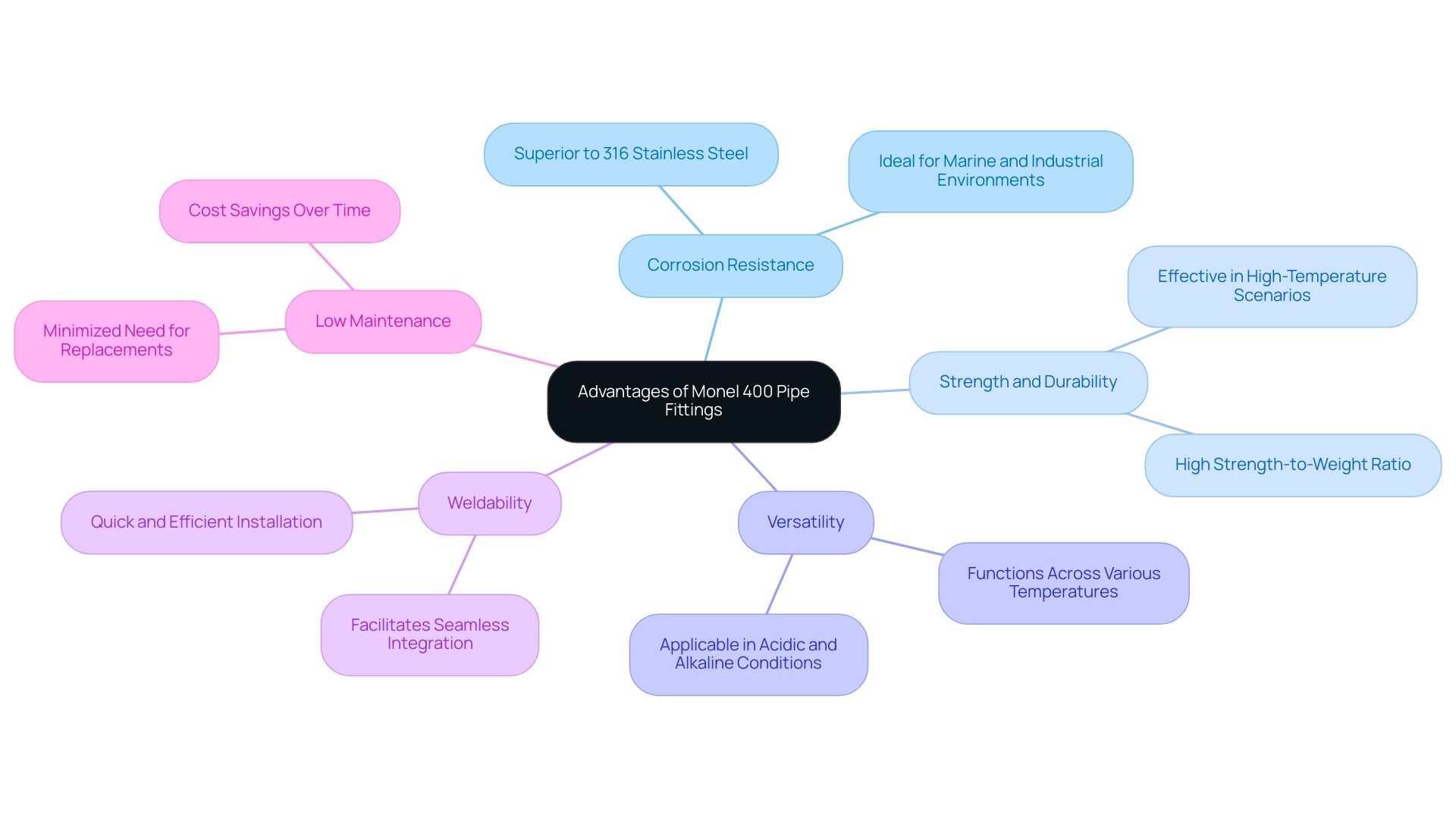

Monel 400 pipe fittings present a range of significant advantages that make them a top choice for procurement managers:

Corrosion Resistance: Alloy 400 is renowned for its exceptional resistance to corrosion, particularly in marine and industrial environments. This characteristic not only improves the durability of the components but also guarantees dependability in challenging environments, exceeding the corrosion resistance of 316 stainless steel.

Strength and Durability: With a high strength-to-weight ratio, alloy 400 fittings can endure high-pressure conditions without compromising structural integrity, making them perfect for essential uses. Unlike 316 stainless steel, which has a maximum temperature limit of 590 degrees Celsius, this alloy can perform effectively in higher temperature scenarios.

Versatility: Alloy 400’s capability to function efficiently across a wide range of temperatures and settings—spanning from acidic to alkaline conditions—enhances its attractiveness, permitting various uses in multiple industries.

Weldability: The alloy’s excellent weldability facilitates seamless integration into piping systems, ensuring quick and efficient installation. This feature is particularly beneficial in complex setups where adaptability is essential.

Low Maintenance: The inherent durability of this alloy 400 minimizes the need for frequent replacements or repairs, resulting in significant cost savings over time. This benefit is additionally reinforced by practical uses in marine operations, where the characteristics of monel 400 pipe fittings have proven essential for valves, pumps, and tanks subjected to severe conditions. Significantly, alloy 400 is resistant to amalgamation by mercury, which improves its usability in water treatment uses.

As demonstrated by the case study named ‘Alloy 400 in Marine Operations,’ monel 400 pipe fittings are used in numerous marine applications due to their resistance to corrosive substances and their dependability in critical settings. As recent developments continue to emphasize the performance of alloy 400 in high-pressure settings, its benefits make it a strategic option for procurement managers seeking dependable and efficient solutions.

Applications of Monel 400 Pipe Fittings in Industry

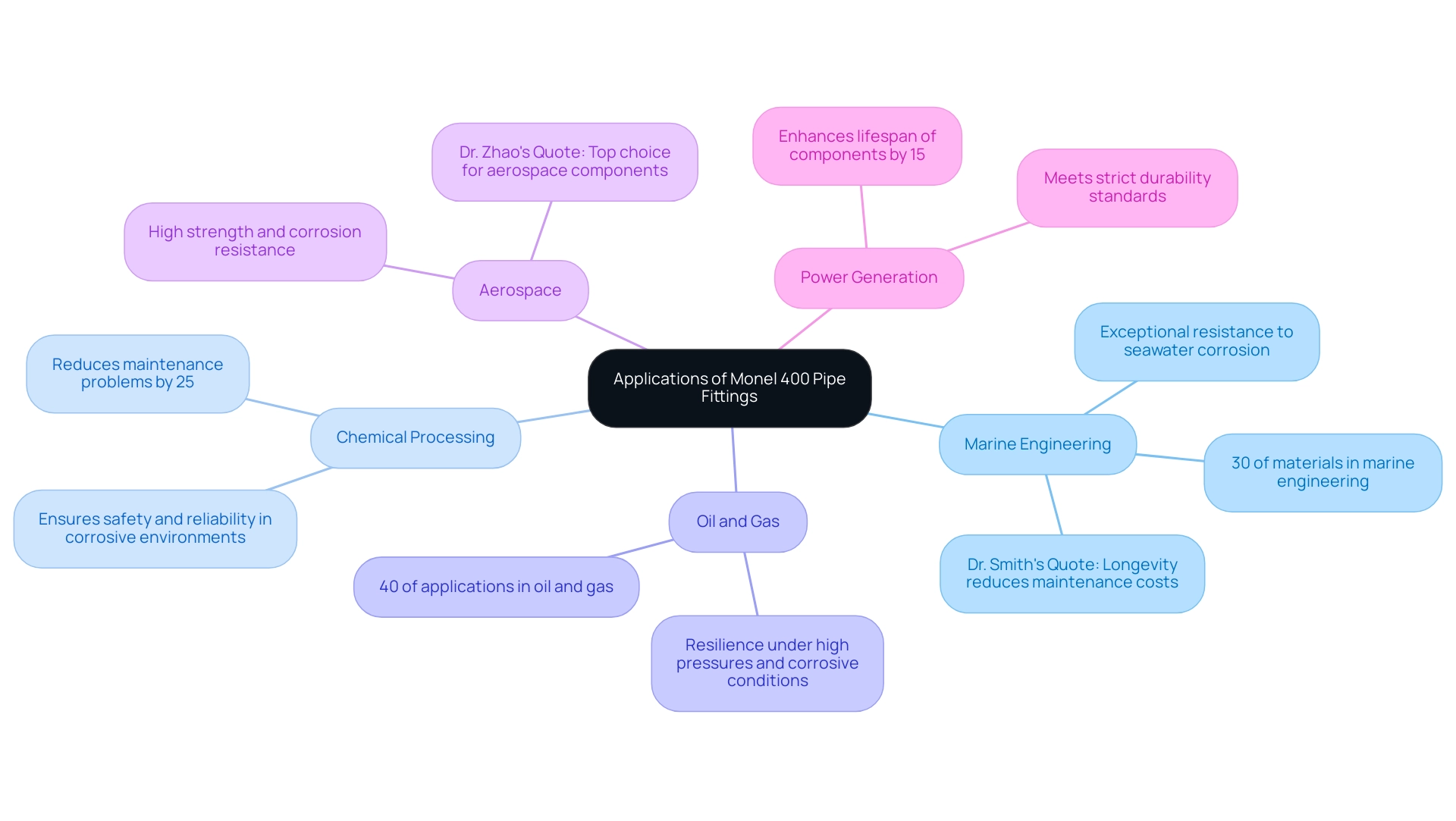

Monel 400 pipe fittings are crucial elements in various sectors, renowned for their outstanding characteristics that aid in their extensive application. Here are some prominent applications:

Marine Engineering: In shipbuilding and offshore structures, alloy 400 fittings exhibit exceptional resistance to seawater corrosion, making them a favored option for marine uses. According to industry statistics, monel 400 pipe fittings account for approximately 30% of the materials used in marine engineering because of their durability in harsh environments. Industry expert Dr. Smith emphasizes, “The longevity of alloy 400 in marine applications is unmatched, significantly reducing maintenance costs over time.”

Chemical Processing: Monel 400 pipe fittings are particularly well-suited for piping systems that transport corrosive chemicals, ensuring both safety and reliability. Recent evaluations suggest that alloy 400’s capacity to endure harsh materials greatly diminishes the likelihood of leaks and failures in chemical management. A case study from XYZ Chemical Company emphasized a 25% decrease in maintenance problems after transitioning to alloy 400 components in their systems.

Oil and Gas: Monel 400 pipe fittings are extensively used in oil rigs and refineries, where they endure high pressures and corrosive environments. Their resilience under such conditions makes them invaluable in maintaining operational integrity. As highlighted in a recent industry report, monel 400 pipe fittings are utilized in over 40% of oil and gas applications because of their exceptional performance.

Aerospace: Components produced from alloy 400 are employed in aircraft engines and other essential systems, where performance and reliability are paramount. The alloy’s properties ensure that it can withstand the demanding conditions of aerospace applications. Dr. Zhao states, “Alloy 400’s unique characteristics make it a top choice for aerospace components that require high strength and corrosion resistance.”

Power Generation: In both nuclear and thermal power facilities, monel 400 pipe fittings are used to meet the strict standards for durability and resistance to extreme conditions. Their performance in these settings is crucial for the safe and efficient generation of power. A recent case study revealed that alloy 400 connectors enhanced the lifespan of essential components by 15% in a thermal power station setting.

With these applications, alloy 400 continues to demonstrate its versatility and effectiveness across multiple sectors, reinforcing its status as a preferred material for procurement managers focused on quality and reliability.

Maintenance and Care for Monel 400 Pipe Fittings

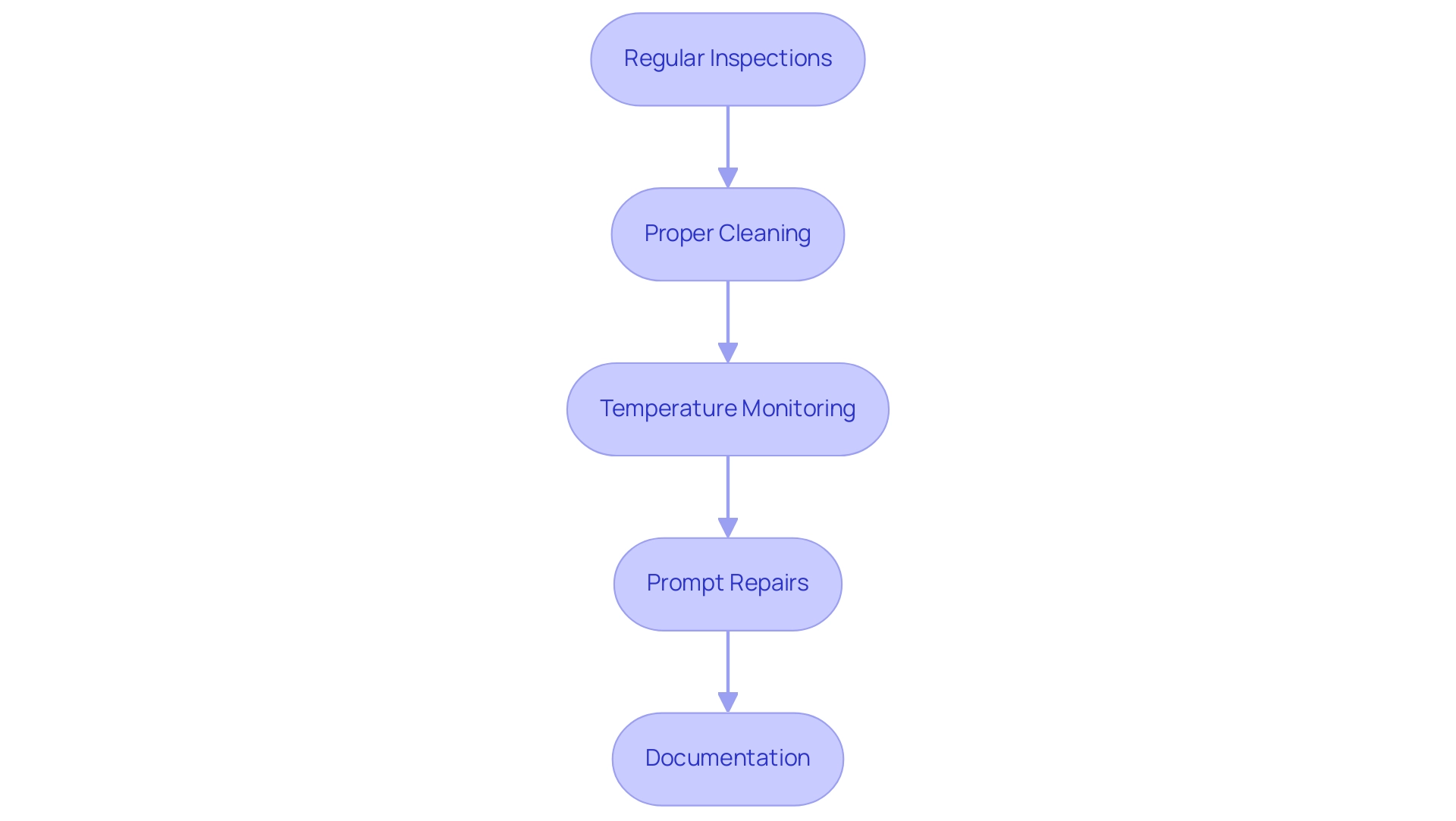

To ensure the longevity and optimal performance of Monel 400 pipe components, it is essential to implement the following maintenance strategies:

- Regular Inspections: Conduct routine inspections to identify signs of wear or corrosion, especially in high-stress environments. This proactive measure can significantly extend the lifespan of components, which have been shown to last over 20 years under ideal conditions.

- Proper Cleaning: Utilize non-abrasive cleaners that won’t damage the surface of the fixtures. It is crucial to avoid harsh chemicals that can compromise the integrity of the alloy, ensuring continued performance.

- Temperature Monitoring: Regularly check that connections remain within their specified temperature limits to prevent deformation or failure. Alloys 400 are designed to withstand a range of conditions, but exceeding these limits can lead to significant issues.

- Prompt Repairs: Address any leaks or damage immediately. Delaying repairs can lead to more extensive deterioration, potentially affecting system integrity and safety.

- Documentation: Maintain detailed records of inspections and maintenance activities. This documentation aids in monitoring the performance and lifespan of fittings, offering essential insights for future maintenance and procurement choices.

Integrating these best practices not only improves the reliability of Monel 400 pipe fittings but also ensures conformance to industry standards for quality and performance. The manufacturing process of alloy 400 flanges involves rigorous testing and inspection to ensure compliance with required standards, which supports the maintenance strategies outlined. Additionally, it is important to note that alloy 400 is not suitable for use with nitric acid or ammonia systems, making it crucial for procurement managers to consider these factors when implementing maintenance practices.

Conclusion: The Comprehensive Benefits of Monel 400 Pipe Fittings

Monel 400 pipe fittings are an excellent option for various industrial uses, primarily due to their remarkable corrosion resistance, strength, and versatility. These components are designed to withstand harsh environments, making them particularly appropriate for marine, chemical, and aerospace industries. For instance, Nickel 400 is highly versatile, used in applications such as:

- Heat exchangers

- Pumps

- Valves

- Pressure vessels

- Oil and gas pipes

This demonstrates its reliability under extreme conditions.

By choosing alloy 400 fittings, procurement managers can not only ensure long-term performance and reliability but also achieve significant cost savings through decreased maintenance requirements and improved operational efficiency. Additionally, the durability of this alloy contributes to lower lifecycle costs, making it a strategic investment for any industrial project. As Robert Crooks Stanley, the chemist who discovered the alloy in 1905, noted, ‘The alloy was discovered in 1905 by the American chemist Robert Crooks Stanley at the International Nickel Company (INCO),’ illustrating the material’s unique properties that have stood the test of time.

Moreover, alloy 500 is distinguished by its increased resistance to abrasion and erosion, providing a comparative advantage for applications requiring enhanced durability. Overall, the decision to incorporate Monel 400 pipe fittings aligns with a forward-thinking approach to procurement, ensuring sustainability and performance for years to come.

Conclusion

Monel 400 pipe fittings represent a superior choice for procurement managers across various industries due to their remarkable properties. This nickel-copper alloy excels in corrosion resistance, strength, and versatility, making it an ideal material for demanding applications in:

- Marine engineering

- Chemical processing

- Aerospace

- Oil and gas sectors

Its unique composition allows it to withstand extreme environments, ensuring longevity and reliability while minimizing maintenance needs.

Investing in Monel 400 fittings not only enhances operational efficiency but also leads to significant cost savings over time. The reduced frequency of replacements and repairs translates into lower lifecycle costs, reinforcing the strategic value of this alloy in industrial projects. Furthermore, the various applications of Monel 400, from heat exchangers to pressure vessels, highlight its adaptability and effectiveness in critical conditions.

In conclusion, the decision to utilize Monel 400 fittings is a proactive step towards ensuring sustainable and reliable performance for the future. By choosing this alloy, procurement managers can secure a material that not only meets the rigorous demands of today’s industries but also stands the test of time, ultimately contributing to the success of their operations.