Blogs

What is Invar? A Comprehensive Definition and Overview

Introduction

Invar, a remarkable iron-nickel alloy, has carved out a critical niche within the realms of precision engineering and advanced technology. With its exceptionally low coefficient of thermal expansion, Invar stands out as a material that maintains dimensional stability under varying temperatures, making it indispensable in applications where accuracy is paramount.

From its discovery in the late 19th century by Charles Édouard Guillaume to its widespread use in aerospace, electronics, and metrology, Invar’s evolution reflects its adaptability and significance in modern engineering. As industries continue to seek materials that combine performance with reliability, the future of Invar appears promising, marked by innovations that expand its applications and enhance its properties.

This article delves into the unique characteristics of Invar, its historical journey, current applications, and the potential advancements that lie ahead, providing a comprehensive understanding of why this alloy remains a cornerstone in precision engineering.

Understanding Invar: Composition and Unique Properties

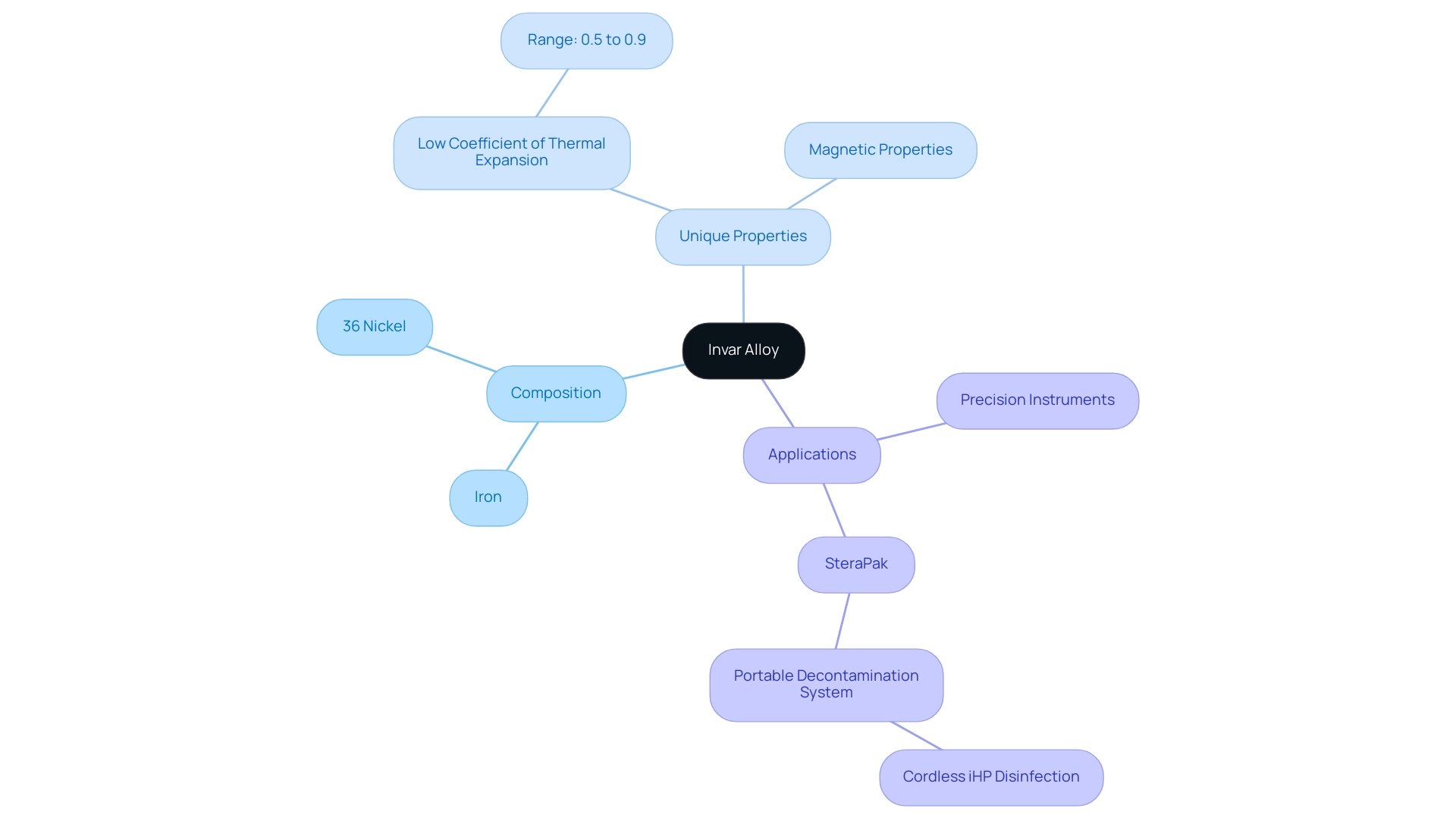

This alloy, a blend of iron and nickel, is characterized by its remarkably low coefficient of heat expansion (CTE), which usually varies from 0.5 to 0.9. The invar definition highlights why this property makes invar especially beneficial for applications requiring remarkable dimensional consistency. Composed of approximately 36% nickel, the alloy’s unique crystalline structure plays a crucial role in minimizing thermal expansion when exposed to temperature variations.

Such consistency is essential in the field of exact engineering, where even small changes in size can result in considerable operational difficulties. Furthermore, this material exhibits notable magnetic properties, which enhance its versatility across various applications, including precision instruments and electronic components. For example, the SteraPak, a mobile decontamination system, employs a specific alloy for its structural elements, gaining from its minimal expansion and reliability.

As emphasized by METTLER TOLEDO, progress in analysis techniques is crucial in improving the performance of renewable energy systems. This highlights the importance of substances similar to Invar in contemporary technological settings, where the invar definition of its blend of minimal heat expansion, dimensional stability, and magnetic characteristics makes it a top option for sectors where accuracy and dependability are crucial.

The History and Evolution of Invar: From Discovery to Modern Applications

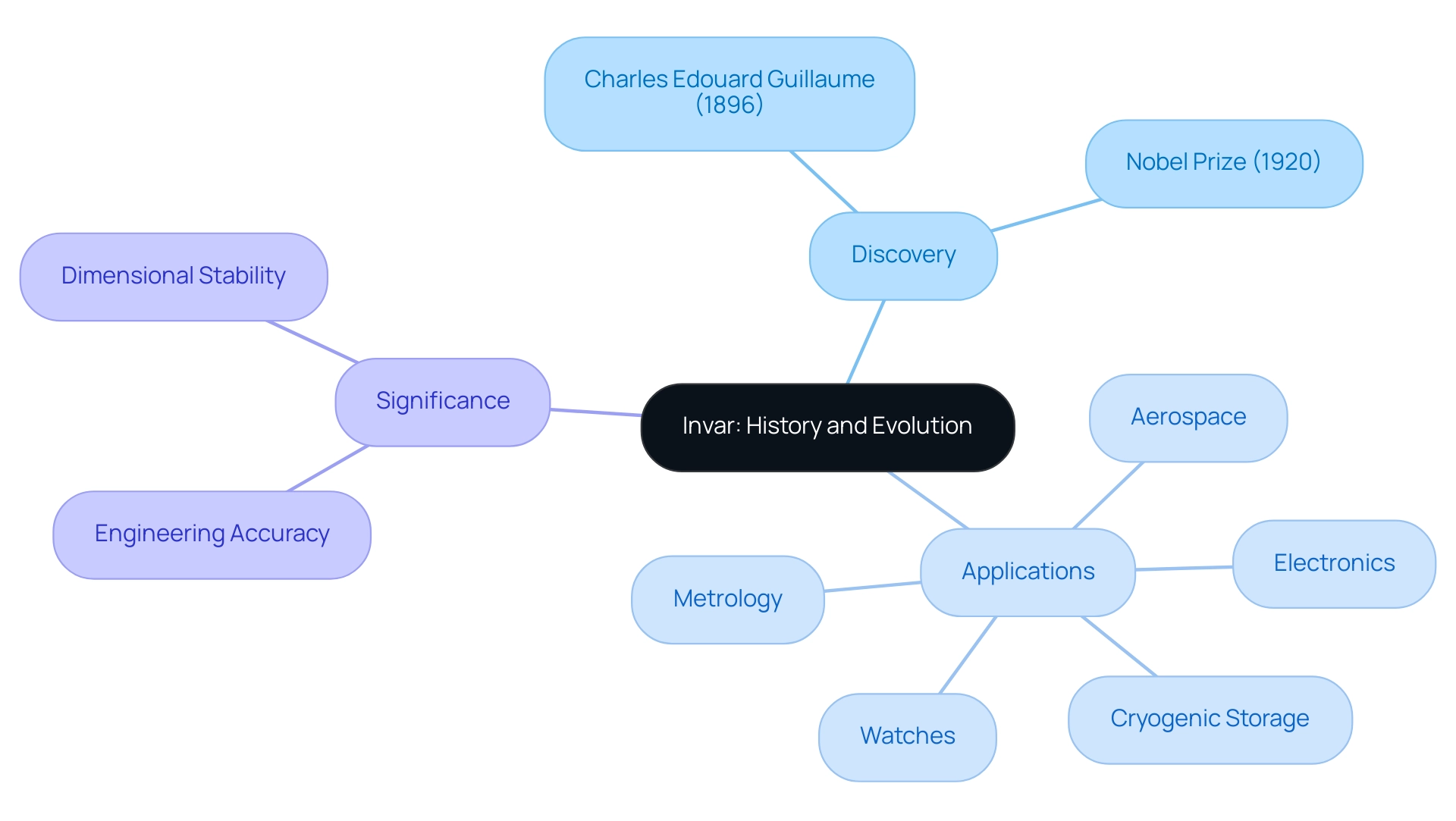

Discovered in 1896 by Swiss physicist Charles Edouard Guillaume, this alloy emerged from his meticulous studies on the thermal expansion properties of materials. This innovative alloy, which earned Guillaume the Nobel Prize in Physics in 1920, was initially used in accurate instruments due to its unique characteristics. Over the decades, this material has undergone substantial evolution, expanding its applications into diverse sectors, including:

- Aerospace

- Electronics

- Metrology

- Manufacturing of watches

- Cryogenic storage dewars

Its remarkable ability to maintain dimensional stability across varying temperatures renders it essential in the manufacturing of critical components such as:

- Clock pendulums

- Accurate measuring devices

- Sophisticated satellite parts

where accuracy is not just desired but imperative. Furthermore, theoretical calculations have indicated the presence of two magnetic phases in various ferromagnetic materials, extending the understanding of its properties. As Charles Edouard Guillaume stated, ‘The invar definition has been so important to scientific advancement that it earned the Nobel Prize in 1920 for its inventor.’

The legacy of this entity continues to expand as it adjusts to contemporary technological needs, further reinforcing its role as a foundation in engineering accuracy.

Applications of Invar: Where Precision Meets Performance

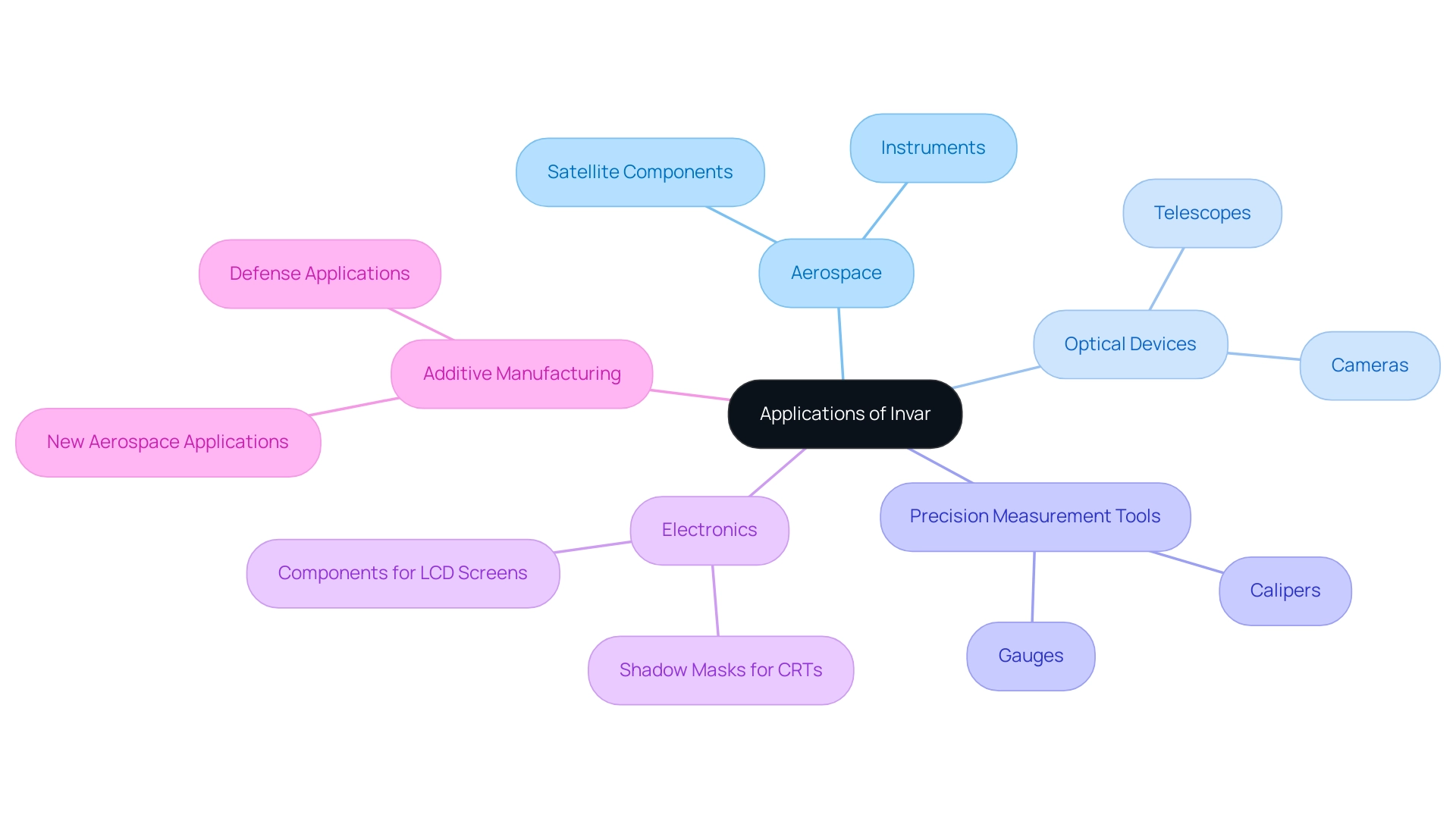

This alloy is celebrated for its remarkable stability and accuracy, rendering it essential in numerous high-accuracy applications. In the aerospace sector, this alloy is utilized in the construction of satellite components and instruments, where it effectively withstands temperature fluctuations. Its remarkable low thermal expansion coefficient is particularly beneficial in optical devices, such as telescopes and cameras, as it ensures that focus remains consistent under variable thermal conditions.

Furthermore, the alloy plays a crucial role in the manufacturing of precision measurement tools, including gauges and calipers, which demand minimal dimensional change to guarantee accurate readings. Additionally, this material is utilized in the electronics sector for producing shadow masks for cathode ray tubes and components for LCD screens, demonstrating its versatility across industries. Recent advancements in additive manufacturing are also creating new applications for the alloy, particularly in aerospace and defense, leading to further investment opportunities.

A recent case study highlights the evolving landscape of the alloy market, showcasing a significant focus on precision engineering and sustainability, which is driving investment opportunities. As Pavel Uncuta, Founder of AIBoost Marketing, aptly noted,

Looks like the alloy market is set for some serious growth from 2024 to 2031! 📈 Exciting times ahead for innovation and technology!

This reinforces the idea that the versatility of this alloy in these critical applications not only underscores its importance in contemporary engineering but also signals a promising future for its use across various industries. For those interested in exploring the material further, options to request a free sample report are available.

Why Choose Invar? Advantages Over Other Alloys

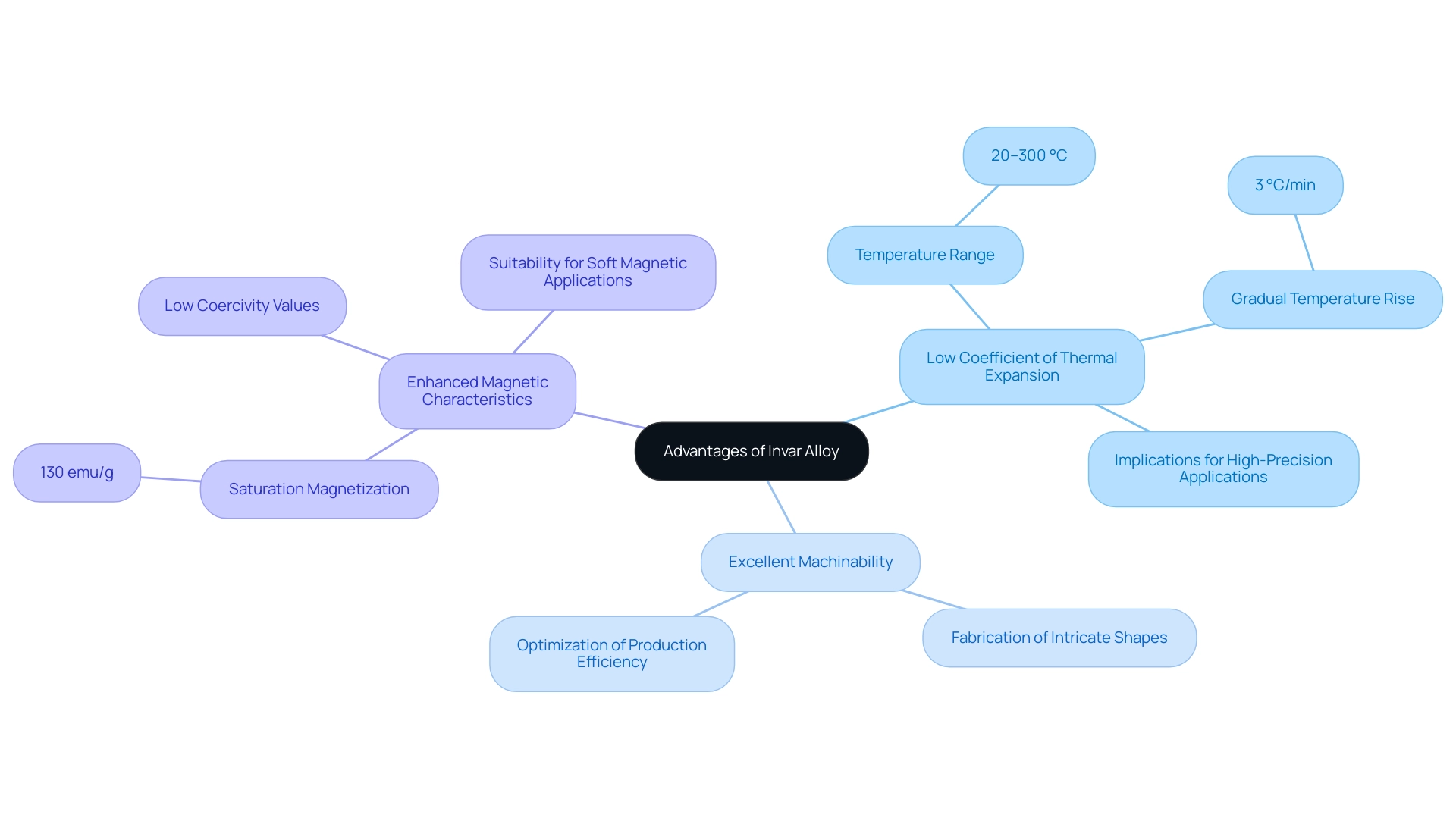

Choosing this alloy over other options offers numerous significant benefits, particularly its remarkably low coefficient of expansion with temperature. This unique property ensures that components retain their dimensions even across a broad temperature spectrum, significantly minimizing the risk of failure in high-precision applications. Research suggests that the thermal expansion testing for the alloy takes place within a regulated range of 20–300 °C, with a gradual temperature rise of 3 °C per minute, reinforcing its resilience under changing thermal conditions.

Markus Merkel emphasizes this stability, stating, ‘Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Alloy 36.’ Furthermore, this material demonstrates excellent machinability, allowing for the fabrication of intricate shapes with relative ease, making it particularly advantageous for manufacturers aiming to optimize production efficiency. In high-temperature environments, the use of Non-Sparking Tools is essential to prevent ignition risks, emphasizing the importance of choosing materials that can endure such conditions.

Recent analyses of the alloy’s magnetic characteristics, conducted using Quantum Design DynaCool-9 vibrating sample magnetometry, revealed an increase in saturation magnetization to 130 emu/g and low coercivity values, indicating enhanced suitability for soft magnetic applications. Overall, this exceptional combination of dimensional stability, fabrication versatility, and performance reliability positions it as a premier choice for industries that demand precision and resilience.

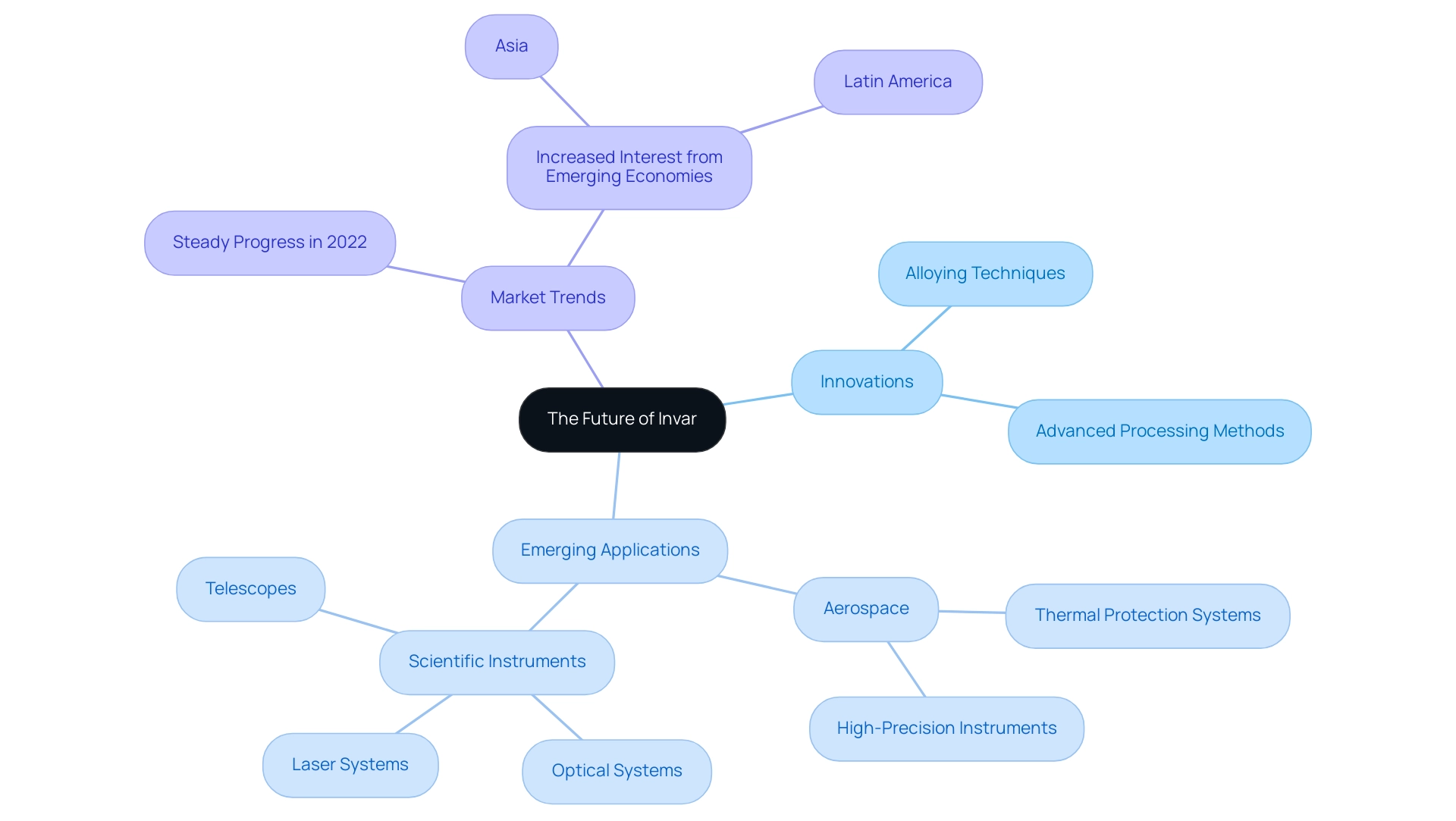

The Future of Invar: Innovations and Emerging Applications

The future landscape of this material is set to be expansive, driven by rigorous research focused on enhancing its properties and broadening its applications. Innovations in alloying techniques and advanced processing methods are currently being explored to create specialized variants of this material that cater to the specific needs of various industries. For instance, the aerospace industry is experiencing advancements that enable the application of a specific material in thermal protection systems and high-precision instruments, where its unique thermal stability is essential.

Additionally, scientific instruments in high-precision settings, such as laboratories, often utilize a specific alloy for constructing optical and laser systems, as well as telescopes. The material’s ability to maintain precision alignment over temperature shifts is crucial for the functionality of these instruments. Furthermore, the emergence of advanced technologies, such as quantum computing and sophisticated sensor systems, highlights its potential to contribute significantly to future innovations.

The alloy market demonstrated steady progress in 2022, laying a strong foundation for accelerated growth in the coming years. As industries increasingly prioritize materials that deliver both exceptional performance and reliability, its distinctive characteristics will continue to position it as a cornerstone in material science advancements. As Dr. Yong He from the Nuclear Power Institute of China notes, his research interests are in the preparation and post-processing of nuclear materials, which underscores the relevance of the invar definition in future technologies.

Conclusion

The journey of Invar from its discovery to its current applications illustrates the alloy’s unparalleled significance in precision engineering. With its low coefficient of thermal expansion and remarkable dimensional stability, Invar is indispensable in fields ranging from aerospace to electronics. Its unique properties not only enhance performance but also ensure reliability, making it the material of choice for high-precision instruments and components.

As industries continue to evolve, the versatility of Invar opens doors to new applications and innovations. Ongoing research into advanced processing methods and alloying techniques promises to further enhance its properties, ensuring that Invar remains at the forefront of technological advancements. The potential for growth in sectors such as quantum computing and sophisticated sensor systems highlights the alloy’s relevance in shaping future innovations.

In summary, Invar stands as a cornerstone in the realm of precision engineering, embodying the perfect blend of stability, performance, and adaptability. As industries increasingly seek materials that meet the demands of modern technology, the enduring legacy and promising future of Invar will undoubtedly continue to influence advancements across various fields.