Blogs

How to Choose the Right Monel Fasteners Suppliers: A Step-by-Step Guide

Overview

The article focuses on providing a step-by-step guide for selecting the right Monel fasteners suppliers, emphasizing the importance of quality assurance, supplier reputation, and capacity to meet project demands. It supports this by detailing essential criteria for evaluation, such as adherence to international standards and the supplier’s ability to deliver customized solutions, which ensures that procurement managers can make informed decisions aligned with their specific project requirements.

Introduction

In the realm of industrial applications, the choice of fasteners can significantly impact the performance and longevity of critical components. Monel fasteners, composed of a robust nickel-copper alloy, stand out for their exceptional corrosion resistance and high strength, making them ideal for demanding environments.

As industries increasingly seek materials that can withstand extreme conditions, understanding the specifications, properties, and applications of Monel fasteners becomes essential. This article delves into the key attributes of Monel fasteners, the criteria for selecting reliable suppliers, and the diverse applications across various sectors, providing valuable insights for procurement managers aiming to enhance operational efficiency and ensure compliance with industry standards.

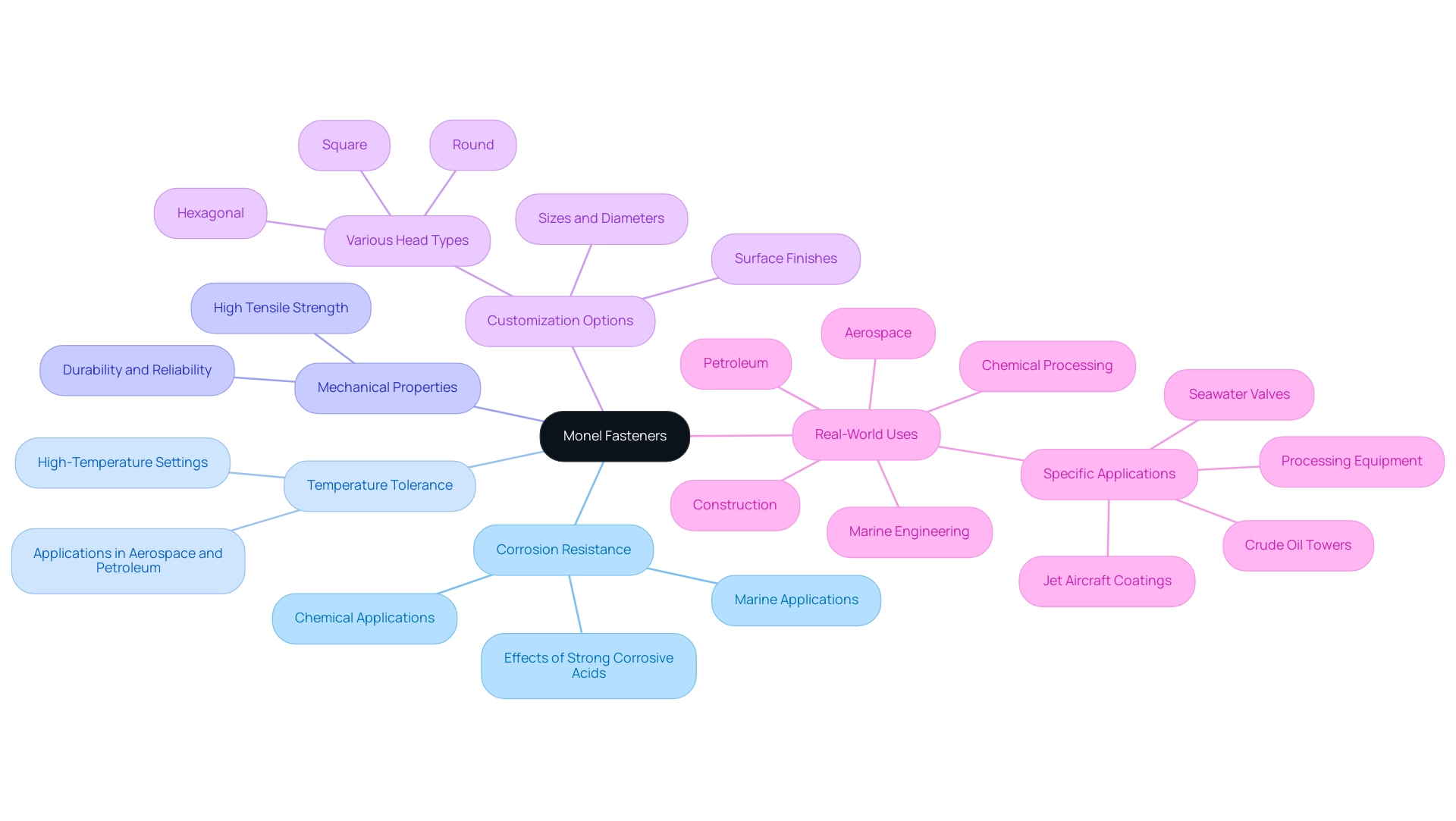

Understanding Monel Fasteners: Specifications and Properties

Nickel-copper alloy fixtures are celebrated for their outstanding resistance to corrosion, high strength, and ability to withstand extreme temperatures. When assessing these fasteners, consider the following key specifications:

Corrosion Resistance: These fasteners are highly resistant to a variety of corrosive environments, particularly in marine and chemical applications. As noted by industry expert Kathleen, in terms of water, saltwater, and sea air, this material is very corrosion resistant – so it won’t rust in atmospheric conditions. However, given a strong enough corrosive acid, this alloy, like any metal, can corrode when its limits have been exceeded. This emphasizes the significance of grasping the specific environmental conditions when choosing this type of hardware.

Temperature Tolerance: These components can function effectively in high-temperature settings, preserving their structural integrity even under demanding conditions. This renders them appropriate for uses in sectors like aerospace and petroleum, where temperature variations are frequent.

Mechanical Properties: The alloy exhibits high tensile strength and toughness, essential characteristics for uses demanding durability and reliability.

Customization Options: The bolts can be tailored with various head types, including hexagonal, square, and round, along with different sizes and diameters. These choices are essential for fulfilling particular project specifications, and Domadia provides a variety of customizable metal connectors to fit your project demands.

Real-World Uses: These connectors are employed in a variety of vital uses across different sectors, including marine engineering, automotive, and electrical fields. Notable uses include seawater valves, jet aircraft coatings, crude oil towers, and processing equipment. This versatility showcases the importance of monel fasteners suppliers in meeting the demands of marine, oil and gas, chemical processing, aerospace, and construction industries. With the latest specifications for 2024, understanding these key attributes and customization options will empower you to evaluate monel fasteners suppliers based on their product offerings and suitability for your specific needs. Browse Domadia’s extensive product catalog to discover the ideal metal connectors for your applications.

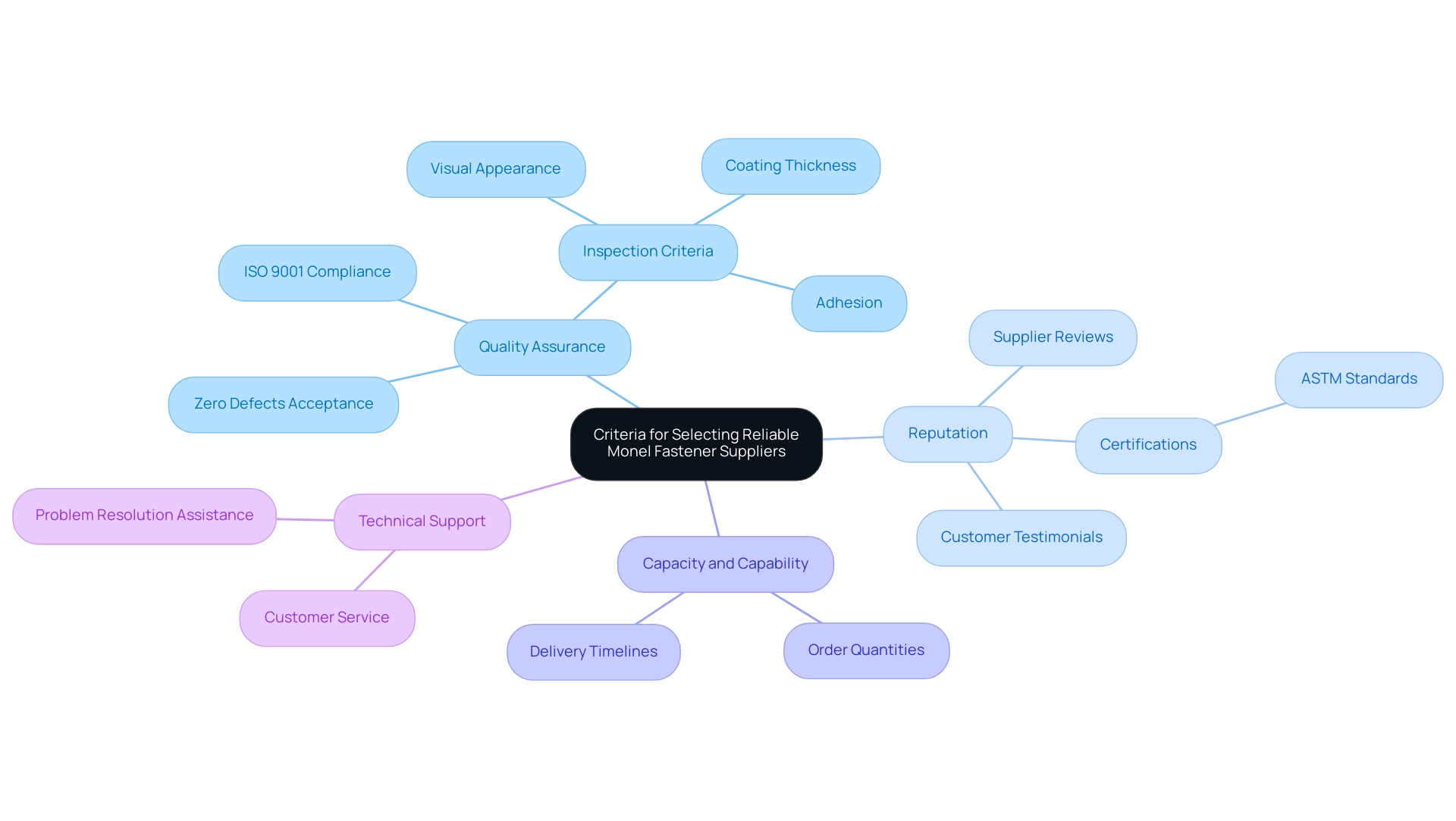

Criteria for Selecting Reliable Monel Fastener Suppliers

Choosing the appropriate suppliers for nickel-copper alloy components is essential for guaranteeing product quality and adherence to sector standards. When making your decision, consider the following essential criteria:

- Quality Assurance: It is vital to ensure that suppliers adhere to international quality standards, such as ISO 9001. Under F1470, the acceptance number in all cases is zero defects, emphasizing the importance of rigorous quality checks.

Additionally, specific inspection criteria such as coating thickness, visual appearance, and adhesion are detailed in F1470, ensuring that suppliers meet necessary safety and performance benchmarks. For instance, choosing Domadia for Mica Tape guarantees access to products that are rigorously tested to meet these international standards, enhancing reliability in your supply chain.

- Reputation: Conduct thorough research into supplier reviews and testimonials. This will provide insight into their reliability and overall service quality, helping you make an informed choice.

Domadia’s customer-centric approach and timely delivery further bolster its reputation as a dependable partner in supplying critical insulation materials. As one satisfied customer noted, ‘Domadia’s timely delivery and quality products have significantly improved our operations.’ Verify that the monel fasteners suppliers possess relevant certifications, including adherence to ASTM standards for Monel products.

This ensures that the materials meet necessary safety and performance benchmarks. Domadia’s commitment to quality assurance is reflected in its compliance with international standards, including ASTM certification, helping you mitigate risks associated with subpar materials.

Capacity and Capability: Evaluate the supplier’s ability to meet your order quantities and delivery timelines, as this will impact your project efficiency and success.

Technical Support: Assess the level of technical assistance and customer service offered by the supplier. Quality assistance, such as that offered by Domadia, can be a crucial element in resolving any problems that may occur during the procurement process.

The recent ISO Survey revealed a 44% rise in ISO 9001 certifications and a 72% increase in ISO 14001 certifications from 2018 to 2022, indicating a growing dedication to quality standards in the industry. By applying these criteria, you can identify suppliers that not only meet your quality expectations but also align with your project requirements.

Alana Fossa aptly notes,

This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability.

Therefore, making informed decisions based on thorough evaluations is paramount in securing reliable suppliers.

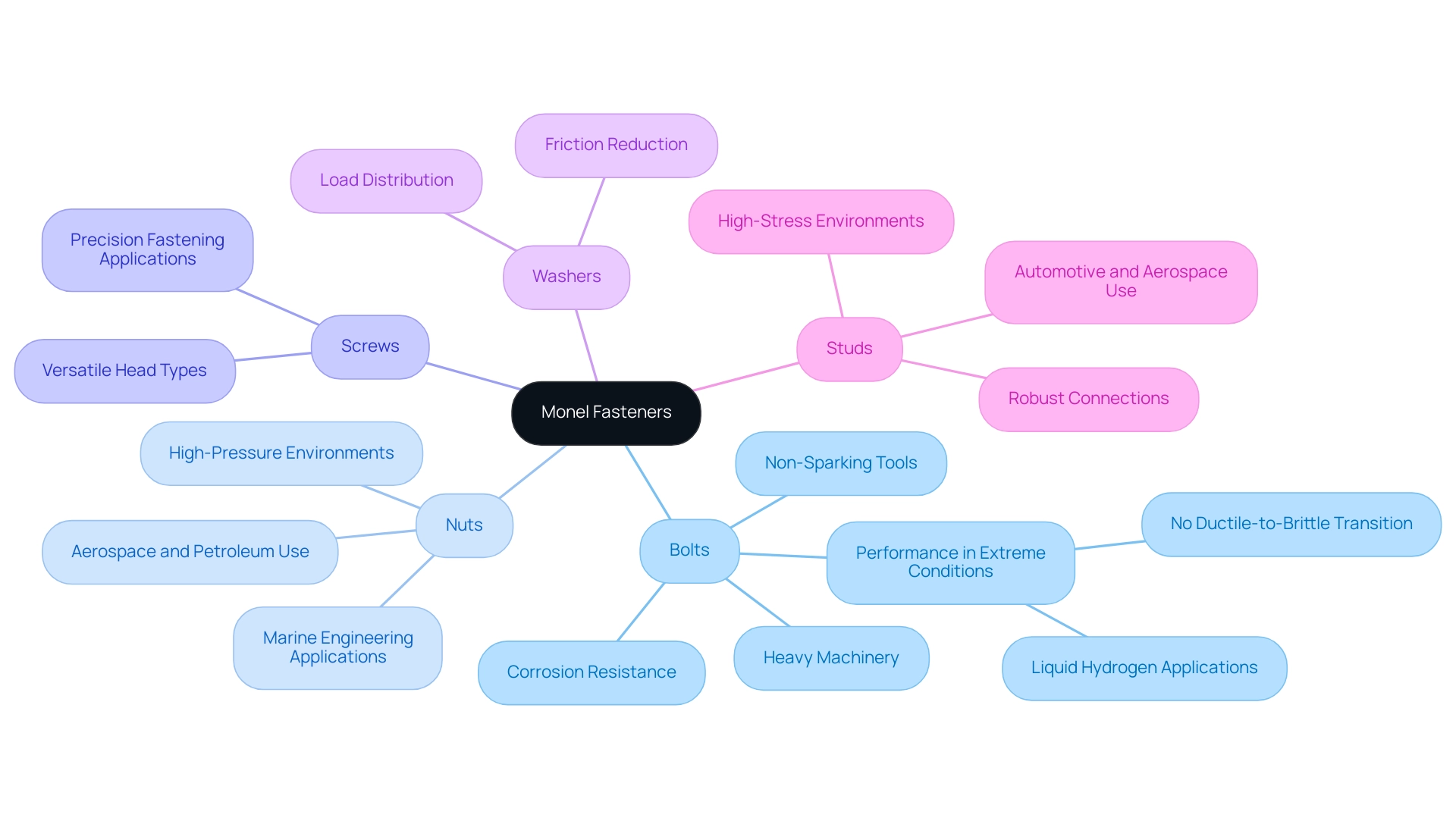

Exploring Different Types of Monel Fasteners

Fasteners include various types, each customized for specific applications, guaranteeing optimal performance in challenging environments:

- Bolts: Designed for heavy machinery and structural uses, these bolts demonstrate exceptional strength and corrosion resistance, making them perfect for marine engineering and chemical processing. Significantly, alloy 400 bolts exhibit no ductile-to-brittle transition even at the temperature of liquid hydrogen, demonstrating their performance in extreme conditions. In environments with explosive potential, pairing these with Non-Sparking Tools—crafted from materials like brass or aluminum—can significantly enhance safety by reducing the risk of sparks during operation.

- Nuts: These components are specifically designed to complement specialized bolts, providing secure fastening in harsh conditions, which is critical for maintaining integrity in high-pressure environments. These fasteners, offered by monel fasteners suppliers, are commonly utilized in marine engineering, aerospace, petroleum, and chemical sectors due to their remarkable characteristics, emphasizing the significance of choosing suitable fastening options in dangerous environments.

- Screws: Suitable for applications that require precise fastening, these screws are available in various head types, enabling versatility in design and functionality across multiple industries.

- Washers: Alloy washers play a vital role in load distribution and friction reduction, essential for maintaining the integrity of connections under stress, particularly in dynamic systems.

- Studs: Known for their robust connections in high-stress environments, these studs are commonly utilized in the automotive and aerospace sectors, where reliability is paramount. A case study from an oil refinery demonstrated the effectiveness of specific bolts in high-temperature, corrosive environments, resulting in reduced downtime and improved operational efficiency.

Additionally, when discussing specific components, it is crucial to consider suppliers and manufacturers of Non-Sparking Tools, such as those specializing in electrical insulation and high-temperature materials. By familiarizing yourself with these various types of metal connectors, along with their compatibility with Non-Sparking Tools, you will enhance your discussions with suppliers and facilitate the selection of the most suitable components for your specific projects, especially in environments where safety is a top priority.

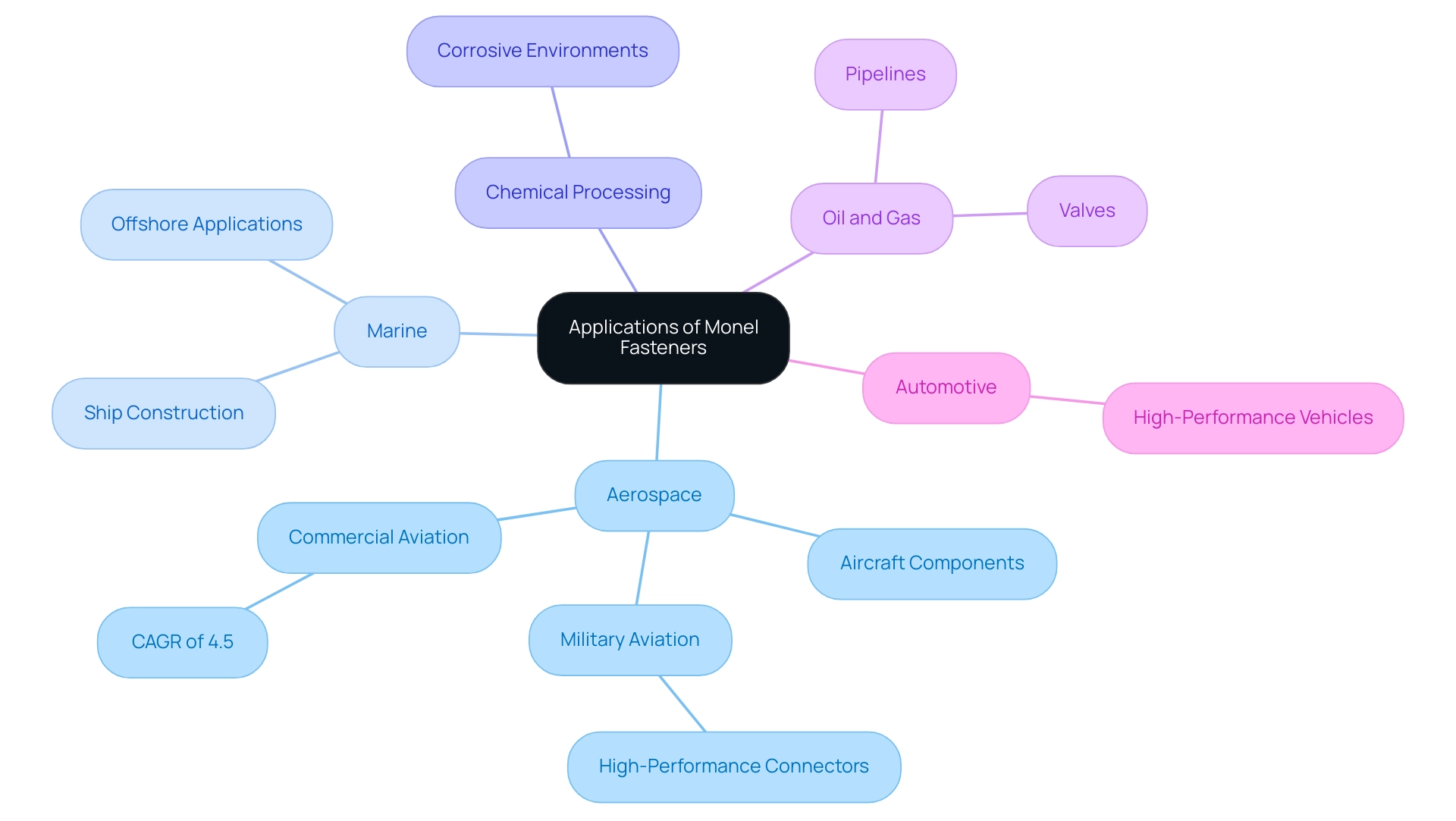

Applications of Monel Fasteners in Various Industries

Monel connectors are renowned for their exceptional properties and find extensive use across multiple industries. In the aerospace sector, these connectors are integral to aircraft components, offering high strength and remarkable corrosion resistance, which are critical for ensuring safety and performance in flight. Military aviation, especially, is the fastest-growing sector, requiring high-performance connectors to meet the rigorous standards of advanced aircraft design.

The commercial aviation industry, the largest segment in the aerospace hardware market, is projected to grow at a CAGR of 4.5%, fueled by the demand for new aircraft as global air traffic rises. This growth highlights the rising need for aerospace components, including the Monel alloy. Key participants in this market consist of:

1. Boeing Company

2. B&B Specialities Inc.

3. Bufab Group

4. Howmet Aerospace

5. LISI Aerospace

6. Precision Castparts Corp.

7. Stanley Black & Decker Inc.

This emphasizes the competitive environment and the significance of these alloys in fulfilling sector standards.

In the marine sector, these components are utilized in ship construction and offshore applications, where they endure the severe conditions of seawater exposure. This resilience is essential for maintaining the structural integrity of vessels and supporting infrastructure.

Moreover, in chemical processing, this alloy is favored for its ability to endure corrosive environments, ensuring longevity and reliability in systems handling aggressive substances. The oil and gas sector also utilizes specialized connectors in pipelines and valves, where durability under extreme conditions is paramount.

In the automotive field, high-performance vehicles benefit from the incorporation of these specialized connectors, which enhance safety and operational reliability under stress. Understanding these diverse applications is crucial for procurement managers, as it enables the identification of specialized suppliers, such as monel fasteners suppliers, that align with specific industry needs. As India’s internal air travel is projected to grow at a CAGR of 6.2% over the next twenty years, the need for aerospace connectors is anticipated to surge considerably.

The case study titled ‘Commercial Aviation’s Influence on Fasteners Demand‘ illustrates this impact, emphasizing the crucial role of aerospace components in aircraft assembly and maintenance.

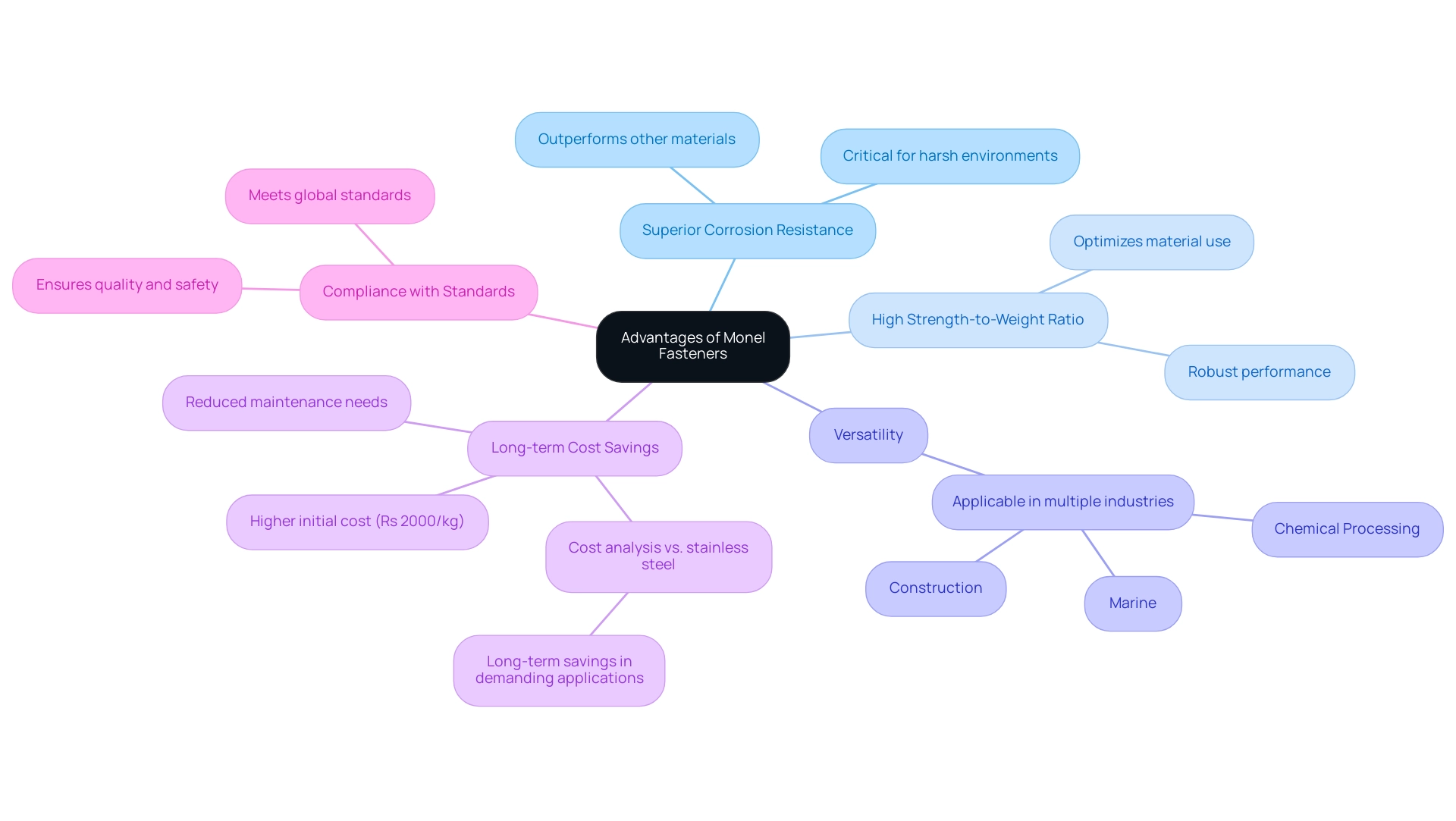

Advantages of Choosing Monel Fasteners

Opting for Monel fasteners provides several compelling advantages that make them particularly attractive for procurement managers:

- Superior Corrosion Resistance: Monel fasteners excel in harsh environments, outperforming many other materials and significantly prolonging the lifespan of components. This characteristic is critical in applications exposed to aggressive chemicals or extreme weather conditions.

- High Strength-to-Weight Ratio: These connectors provide robust performance without unnecessary weight, ensuring structural integrity while optimizing material use. This combination is especially advantageous in sectors where weight reductions can result in improved efficiency.

- Versatility: These fasteners are suitable for a diverse range of applications across multiple industries, including marine, chemical processing, and construction, making them a versatile choice for any project.

- Long-term Cost Savings: While this material may have a higher initial price point—averaging around Rs 2000 per kg—its durability leads to significant long-term savings. As noted, “the high nickel content and complex production process make this alloy significantly more expensive than stainless steel.” However, its reduced maintenance needs and the ability to withstand harsh conditions mean that this alloy often proves to be more cost-effective over time compared to alternatives like stainless steel, which may incur higher maintenance costs due to lower corrosion resistance in aggressive environments. A study titled ‘Long-Term Cost Implications of Monel and Stainless Steel‘ illustrates that the higher initial expense of this alloy is balanced by its superior corrosion resistance and reduced maintenance requirements in harsh environments.

- Compliance with Standards: These metal connectors satisfy multiple global standards, ensuring quality and safety. This compliance is essential for procurement managers aiming to uphold industry regulations and specifications.

These advantages collectively position Monel fasteners suppliers as an excellent choice for procurement managers focused on optimizing performance and reliability in their projects.

Conclusion

Monel fasteners represent a crucial component in the industrial landscape, offering exceptional properties such as corrosion resistance, high strength, and durability under extreme conditions. Their versatility spans across various applications, from aerospace to marine engineering, highlighting their importance in maintaining operational integrity in challenging environments. The specifications of Monel fasteners, including their customization options, further empower procurement managers to select the most suitable fasteners for specific projects, ensuring compliance with industry standards.

Selecting reliable suppliers is equally vital; the criteria outlined—ranging from quality assurance to technical support—provide a strategic framework for evaluating potential partners. By prioritizing suppliers who adhere to international standards and possess a strong reputation, procurement managers can mitigate risks and enhance their supply chain’s reliability. The growing commitment to quality standards in the fastener industry, as evidenced by increased ISO certifications, underscores the importance of making informed decisions when sourcing Monel fasteners.

Ultimately, choosing Monel fasteners not only addresses immediate project needs but also contributes to long-term operational efficiency and cost-effectiveness. Their superior properties and compliance with industry standards position them as a smart investment for industries that demand high performance under pressure. For procurement managers, understanding and leveraging the benefits of Monel fasteners is essential in driving success and maintaining a competitive edge in their respective fields.