Blogs

Understanding ASTM A753 PDF: A Complete Tutorial on Standards and Applications

Introduction

In the realm of advanced materials, ASTM A753 alloys have emerged as a cornerstone for industries that demand exceptional magnetic performance and reliability. These wrought nickel-iron soft magnetic alloys are meticulously designed to meet stringent specifications, making them indispensable in applications ranging from automotive to renewable energy.

As the demand for energy-efficient solutions escalates, procurement managers must navigate the complexities of sourcing these specialized materials while ensuring compliance with international standards.

This article delves into the key properties, applications, and future trends surrounding ASTM A753 alloys, providing valuable insights for professionals looking to enhance their sourcing strategies and stay competitive in an evolving market landscape.

Overview of ASTM A753: Specifications and Standards

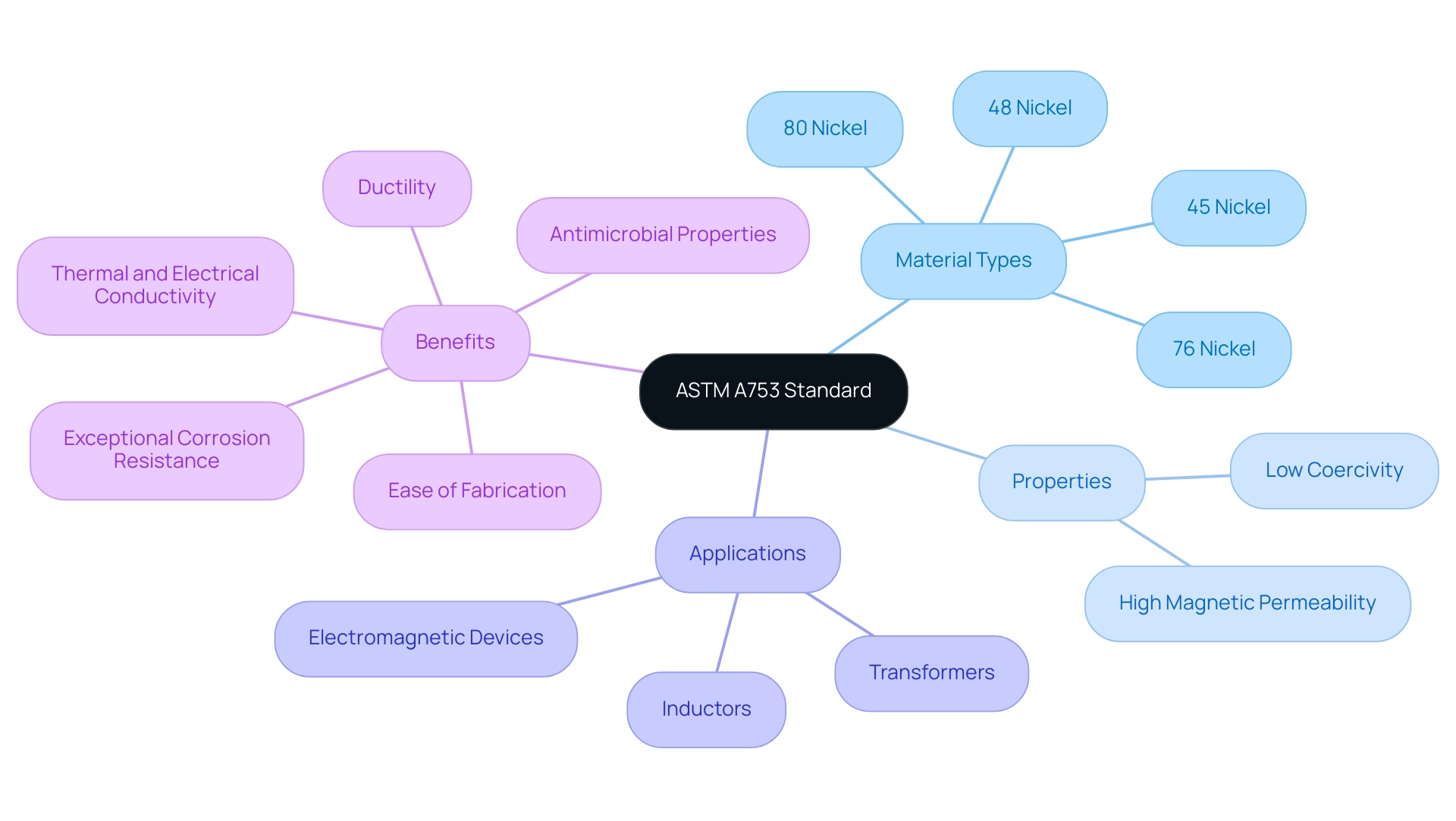

ASTM A753 serves as a pivotal standard for wrought nickel-iron soft magnetic materials, crucial for applications demanding superior magnetic characteristics. This specification meticulously details the required chemical composition, physical properties, and mechanical criteria necessary for ensuring both performance and reliability. It specifically addresses metal types containing nominally 45, 48, 76, and 80 nickel.

Notably, these materials exhibit low coercivity and high magnetic permeability, making them particularly suitable for use in transformers, inductors, and various electromagnetic devices. Furthermore, DOMADIA Beryllium Copper products are compliant with international standards such as UNS and ASTM, reinforcing the quality assurance for procurement managers. The benefits of copper nickel mixtures, including:

- Exceptional corrosion resistance

- Thermal and electrical conductivity

- Ductility

- Ease of fabrication

- Antimicrobial properties

make them a preferred choice in marine engineering, automotive systems, electronics, heat exchangers, and coinage.

The ICS Number Code for this specification is 77.120.40, reinforcing its classification within nickel and chromium combinations. For procurement managers, a comprehensive understanding of the ASTM A753 PDF, published on October 10, 1997, is imperative to guarantee that sourced materials not only comply with industry regulations but also meet the stringent performance benchmarks essential for their intended applications.

Applications of ASTM A753 Alloys in Industry

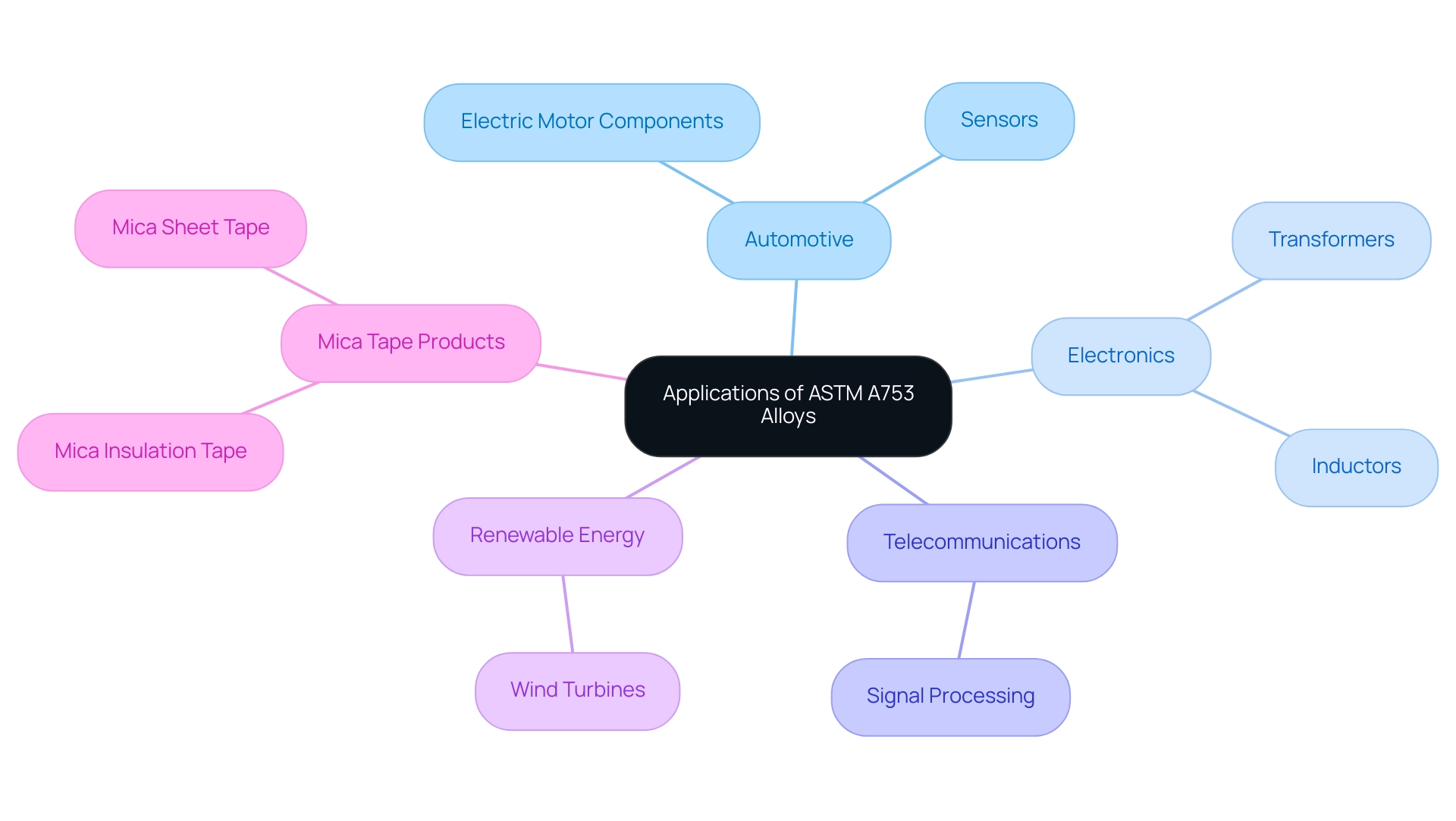

The exceptional magnetic properties of ASTM A753 materials, as detailed in the ASTM A753 PDF, are increasingly acknowledged, making them invaluable across various industries. In the automotive sector, these materials are crucial for electric motor components and sensors, where high performance and efficiency are paramount. As the market for nickel-iron compositions expands in 2024, automotive manufacturers are prioritizing these materials to meet growing demands for electric vehicles.

In the electronics realm, the ASTM A753 PDF highlights how ASTM A753 alloys play a significant role in the production of transformers and inductors, which are essential for the effective management of electrical energy. They are also crucial in telecommunications for signal processing and renewable energy uses, such as in wind turbines, where efficient magnetic performance is vital. Additionally, our Mica Tape products, including Mica Insulation Tape and Mica Sheet Tape, are designed for high-temperature resistance and electrical insulation, featuring excellent flame resistance and dielectric strength.

These attributes make them perfect for essential roles in electrical engineering. The superior insulation properties of Mica Tape ensure reliability across various uses, from household appliances to industrial machinery. As emphasized by industry leaders such as Carpenter Electrification, compliance with strict specifications is essential in manufacturing processes.

Furthermore, the case study of Hipernom™, used in magnetic shielding and transformer core laminations, illustrates the practical uses of A753 grades and Mica Tapes in electrical settings, as supported by the ASTM A753 PDF, showing these to be beneficial substances in electrical contexts. This understanding equips procurement professionals with the knowledge needed to make informed sourcing decisions, ensuring alignment with market trends and operational needs. Notably, Alloys International, Inc. is accredited with AS9100D & ISO 9001:2015, reinforcing the quality and reliability of materials sourced in this sector.

Key Properties of ASTM A753 Alloys

ASTM A753 materials are characterized by their low coercivity, high saturation magnetization, and exceptional permeability, which significantly improve energy conversion efficiency while reducing energy loss in electromagnetic uses. Notably, the minimum AC impedance permeability for EFINEA Alloy 79 at 60 Hz includes:

- 35,000 at 4 mT

- 40,000 at 20 mT

- 50,000 at 200 mT

This underscores its performance in high-frequency applications. These materials not only excel in magnetic performance but also demonstrate commendable mechanical strength and ductility, facilitating diverse processing and fabrication methods.

For procurement managers, understanding these key properties, including the fact that iron serves as the balance of the composition by difference, is crucial for selecting resources that align with specific project performance requirements. In combination with these materials, Mica Tape Products provide high-temperature resistance and outstanding electrical insulation, rendering them essential in scenarios where safety and performance are crucial. The aerospace sector, recognized for its energy consumption, can gain from incorporating advanced materials such as A753 composites alongside Mica Tape to improve energy efficiency, as detailed in the astm a753 pdf.

Furthermore, Hipernom™ is employed in magnetic shielding and transformer core laminations, demonstrating its significance in electrical uses and emphasizing the essential role of both A753 materials and Mica Tape Products in contemporary applications. Ongoing research and performance testing continue to reveal the magnetic benefits of these materials over others, further enhancing their relevance.

Comparison with Other Magnetic Alloys

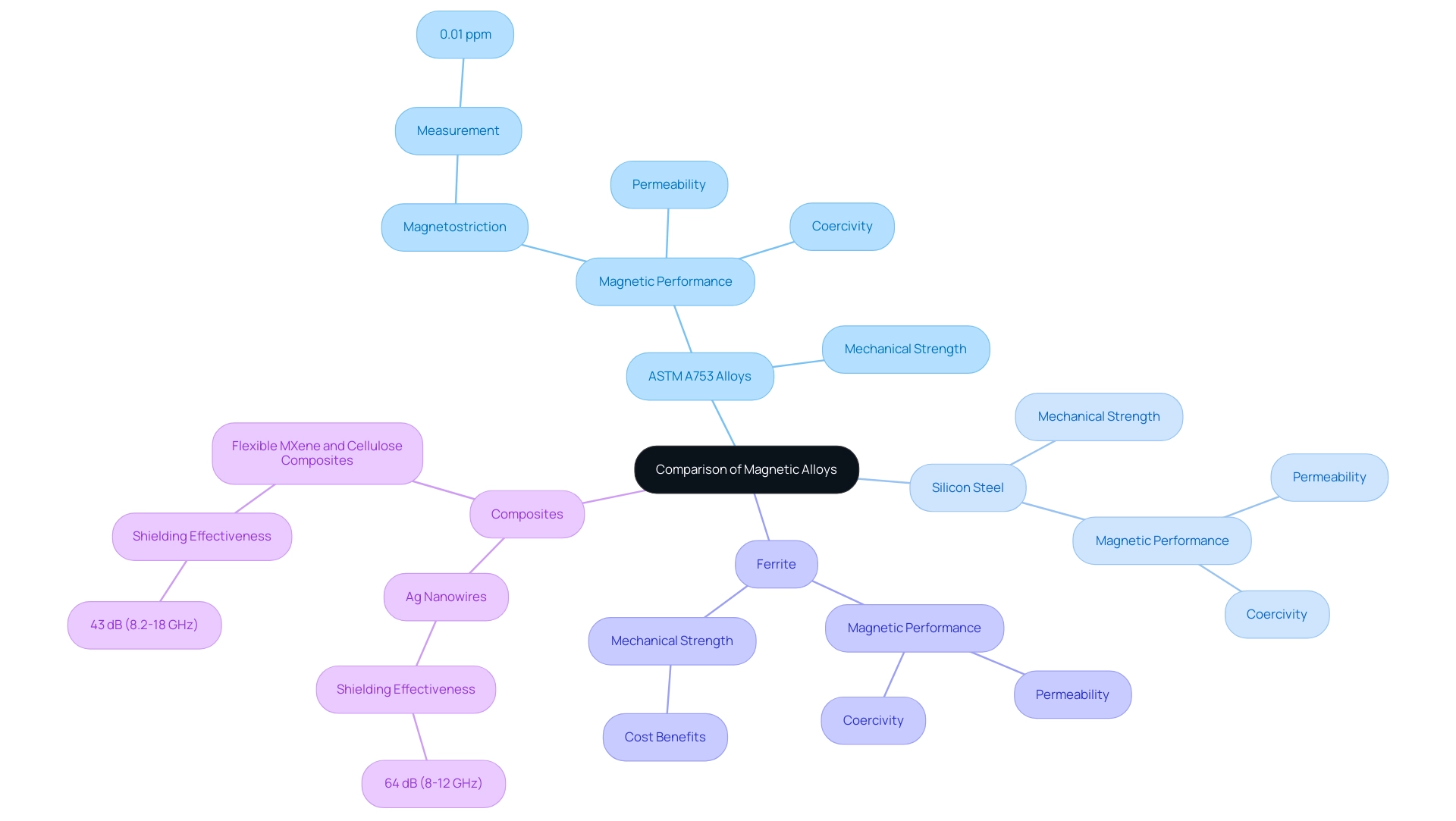

When assessing magnetic blends, A753 materials clearly surpass substitutes such as silicon steel and ferrite in magnetic performance. Although silicon steel is a common choice in transformer usage, it often lacks the permeability and low coercivity necessary for high-efficiency operations. In contrast, ASTM A753 alloys, as detailed in the ASTM A753 PDF, are engineered specifically to maximize these attributes, making them ideal for demanding applications.

Ferrite substances provide cost benefits but typically lack mechanical strength, rendering them less appropriate for demanding environments. For procurement managers, understanding these distinctions is essential for selecting the most effective resources. Recent studies highlight that the ASTM A753 PDF shows how ASTM A753 alloys exhibit superior magnetostriction, with 6.5 wt% Si steel demonstrating a remarkably low measurement of just 0.01 ppm.

Furthermore, advancements in composite substances are noteworthy. For instance, composites with Ag nanowires have achieved a maximum shielding effectiveness (SE) of 64 dB within the 8 to 12 GHz frequency range, showcasing significant improvements in magnetic performance. Additionally, a case study on ‘Flexible MXene and Cellulose Composites’ demonstrated an SE of 43 dB in the 8.2 to 18 GHz range, further illustrating the real-world uses of these components.

As mentioned by N.S., ‘All authors have read and agreed to the published version of the manuscript,’ highlighting the collaborative effort in advancing the understanding of magnetic materials. These developments underline the evolving landscape of magnetic performance metrics and the importance of informed material selection.

Challenges in Sourcing ASTM A753 Alloys

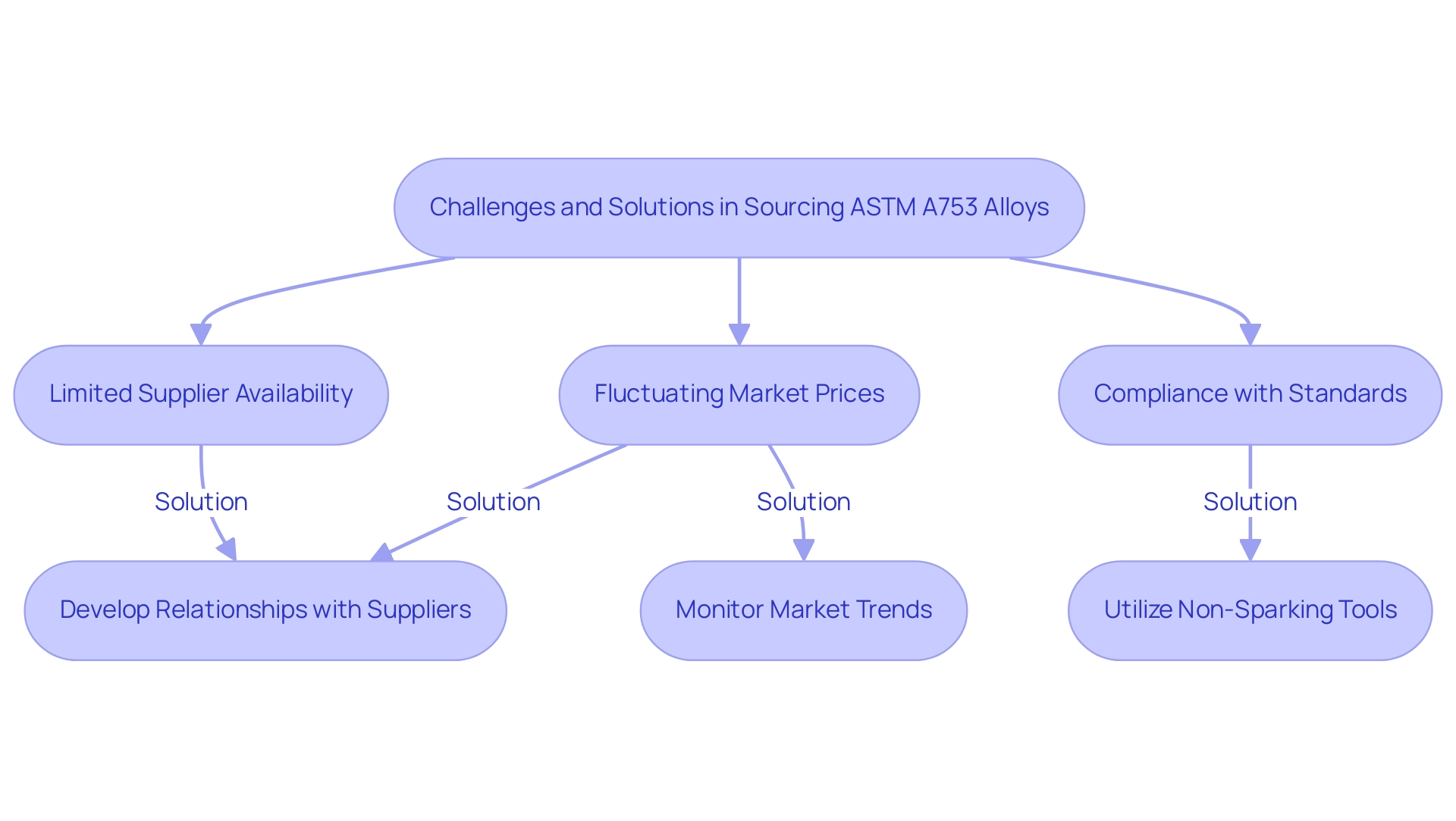

Sourcing materials as outlined in the ASTM A753 PDF poses a range of challenges that procurement managers must navigate effectively. Fluctuating market prices, especially for nickel-iron mixtures, have become a significant concern in 2024, impacting procurement budgets and decision-making. Limited supplier availability further complicates the landscape, as the specialized nature of these alloys often results in longer lead times due to tailored manufacturing processes.

According to Rear Admiral W.R. Arguin of the U.S. Coast Guard, the intricacies of sourcing such specialized resources require a strategic approach to ensure compliance with international standards while maintaining operational readiness.

To address these challenges, procurement managers should focus on developing robust relationships with trusted suppliers, enabling better communication and reliability. Staying abreast of market trends is crucial for adapting sourcing strategies to mitigate risks associated with price volatility.

Adopting strategic sourcing methods can improve supply chain resilience, ensuring consistent quality and availability of A753 products according to the ASTM A753 PDF.

Moreover, in explosive environments, the use of Non-Sparking Tools is paramount to ensure safety and compliance with operational standards. These tools reduce the risk of ignition in potentially dangerous situations, making them essential when working with A753 alloys.

For instance, the minimum emergency venting capacity for 1,000 square feet is 685,000 cubic feet free air per hour, a statistic that highlights the importance of sourcing resources that meet stringent safety and operational standards. Moreover, each power bilge pump must create a suction velocity of no less than 400 feet per minute, as specified in the ASTM A753 PDF, emphasizing particular technical specifications pertinent to the acquisition of A753 alloys.

Additionally, SAE International’s issued standards, especially those updated in 2014 and 2018, illustrate how the industry is advancing to meet the mechanical and material criteria essential for flame control in marine contexts. The incorporation of SAE J429 and SAE J1928 into relevant regulatory frameworks illustrates how adherence to established standards can inform procurement strategies. By utilizing such frameworks and case studies, procurement managers can enhance their strategies and navigate the complexities of sourcing A753 materials more effectively, while ensuring the use of Non-Sparking Tools to maintain safety in explosive environments, as outlined in the ASTM A753 PDF.

Future Trends in ASTM A753 Alloy Applications

The trajectory of the uses of ASTM A753 PDF alloy is being profoundly influenced by technological advancements and an escalating demand for energy-efficient solutions. According to recent reports, the global market for energy-efficient products is projected to grow by 15% annually, with significant contributions from the automotive and renewable energy sectors. Industry leaders, including specialists from [Industry Leader’s Name], stress that ‘the shift towards electrification is not merely a trend; it’s a fundamental change in how we approach material selection and usage.’

Innovations in alloy compositions and manufacturing processes are on the horizon, promising enhanced performance characteristics such as improved temperature stability and reduced weight. In this context, Mica tape products from Domadia, including Mica Sheet Tape and Insulating Mica Tapes, emerge as essential solutions for high-temperature resistance and electrical insulation in various uses, such as fire-resistant cables and critical electrical insulation systems. These products boast superior insulation properties and mechanical strength, making them indispensable in various industries.

Moreover, the use of Non-Sparking Tools, such as wrenches and hammers specifically designed for explosive environments, is crucial for maintaining safety and reliability where traditional tools may pose risks. For procurement managers, staying informed about these trends, including the integration of advanced substances like Mica tapes and the use of non-sparking tools, is essential for aligning sourcing strategies with the evolving market landscape and the latest technological breakthroughs. Additionally, case studies on effective strategies for handling conflicts in sourcing decisions, such as utilizing open communication and thorough documentation, can provide valuable insights for navigating challenges in procurement.

This proactive approach will ensure that organizations remain competitive in a rapidly changing environment, characterized by the integration of advanced materials in high-demand applications.

Conclusion

ASTM A753 alloys stand out as essential materials in the modern industrial landscape, particularly due to their superior magnetic properties and reliability. The detailed specifications outlined in ASTM A753 ensure that these nickel-iron soft magnetic alloys meet rigorous standards, making them suitable for critical applications across various sectors, including:

- Automotive

- Electronics

- Renewable energy

Understanding the key properties, such as low coercivity and high magnetic permeability, empowers procurement managers to make informed decisions that align with their operational needs and industry regulations.

As industries increasingly prioritize energy efficiency, the demand for ASTM A753 alloys is expected to grow, especially in the context of electric vehicles and advanced electromagnetic devices. The strategic sourcing of these materials is not without challenges, including:

- Fluctuating market prices

- Supplier availability

However, building robust supplier relationships and staying abreast of market trends can mitigate these risks, ensuring consistent quality and performance.

Looking ahead, the evolution of ASTM A753 alloys will be driven by technological advancements and a commitment to sustainability. Innovations in alloy compositions and manufacturing processes are poised to enhance performance characteristics, reinforcing the relevance of these materials in future applications. By staying informed and adapting sourcing strategies accordingly, procurement managers can leverage the strengths of ASTM A753 alloys, positioning their organizations for success in an increasingly competitive market.