Blogs

Understanding Beryllium Copper Chemical Composition: An In-Depth Tutorial

Introduction

In the realm of advanced materials, beryllium copper alloys emerge as a cornerstone for industries demanding high performance and reliability. With a unique composition that blends copper’s excellent conductivity with beryllium’s remarkable strength, these alloys are tailored to meet stringent standards while ensuring safety in various applications.

As procurement managers navigate the complexities of material selection, understanding the intricate properties and behaviors of beryllium copper becomes essential. From automotive components to aerospace applications, the versatility of these alloys is evident, showcasing their critical role in enhancing operational efficiency.

This article delves into the fundamental aspects of beryllium copper, exploring its:

- Chemical composition

- Mechanical properties

- Applications

While also addressing the health and safety considerations that accompany its use. By equipping decision-makers with comprehensive insights, it aims to facilitate informed choices that drive success in industrial ventures.

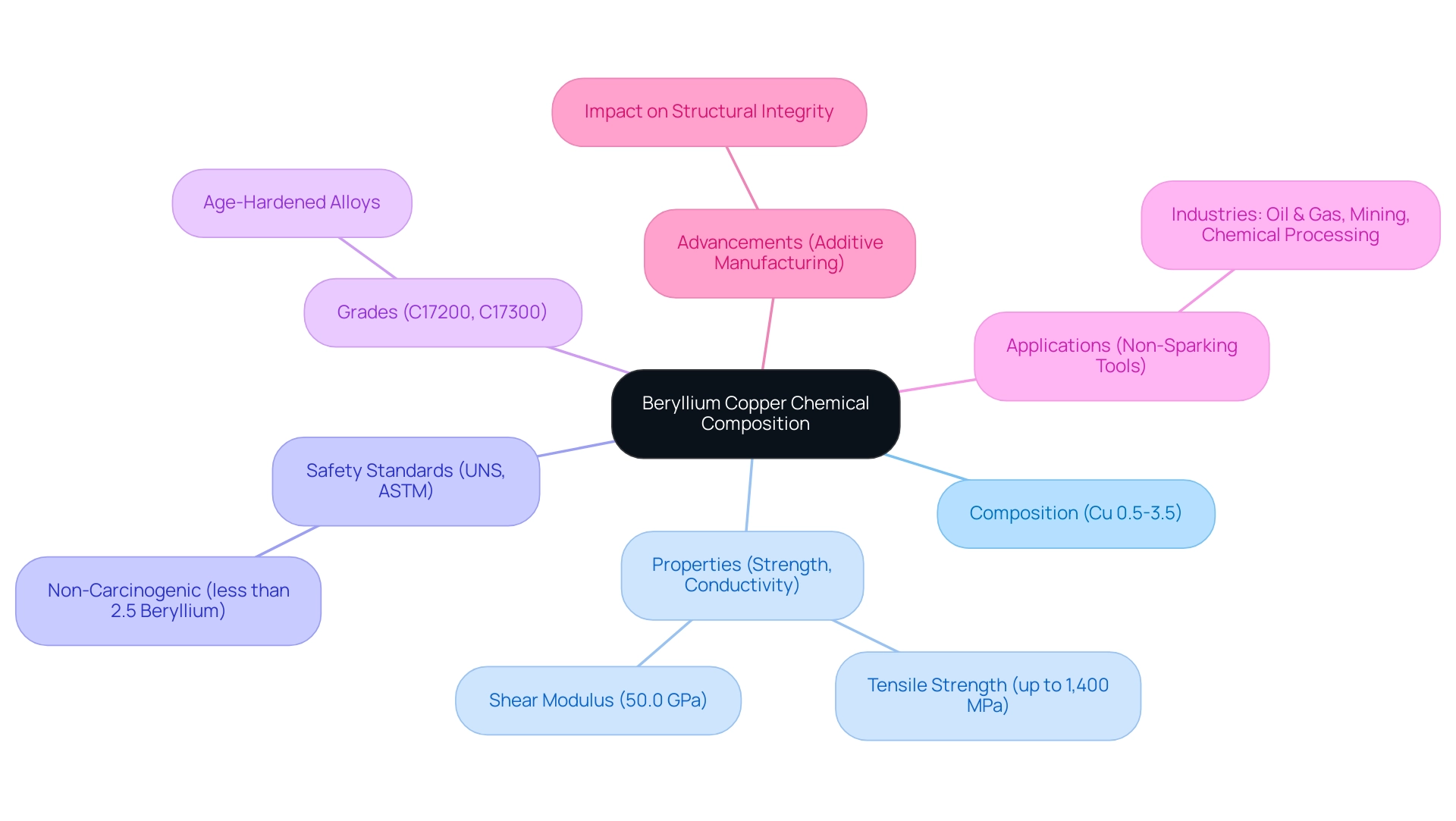

Fundamentals of Beryllium Copper Chemical Composition

Copper-beryllium mixtures, mainly made up of copper (Cu) with a content varying from 0.5% to 3.5%, are acknowledged for their improved strength and conductivity. Compliance with international standards, including UNS and ASTM, is a critical aspect of DOMADIA Beryllium Copper products, ensuring quality and safety in various applications. Significantly, mixtures with less than 2.5% of the element are not categorized as carcinogens, which is crucial for safety and adherence in industrial settings.

Additional elements such as nickel, cobalt, and iron may be incorporated to further optimize specific characteristics. Among the most prevalent grades are C17200 and C17300, each tailored to meet diverse industrial requirements without necessitating further heat treatment. A case study demonstrates that these age-hardened materials are esteemed for their remarkable strength and durability, attaining a tensile strength of up to 1,400 MPa.

With a shear modulus of 50.0 GPA, they exhibit remarkable stiffness and resilience. Grasping the essential beryllium copper chemical composition of alloys is vital for choosing the suitable material for particular uses while ensuring compliance with the latest industry standards, as specified for 2024. Moreover, the safety features of the Beryllium Copper Non-Sparking Wrench render it a crucial tool for industries where spark risk is a concern, including oil and gas, mining, and chemical processing.

Recent advancements in additive manufacturing are set to transform the beryllium alloy industry, with insights from experts like Prof. Bo Chen highlighting the significance of evolving compositions and uses. For pricing and inventory details, DOMADIA offers competitive rates and a robust supply chain for Beryllium Copper Strips, ensuring availability for various industrial needs.

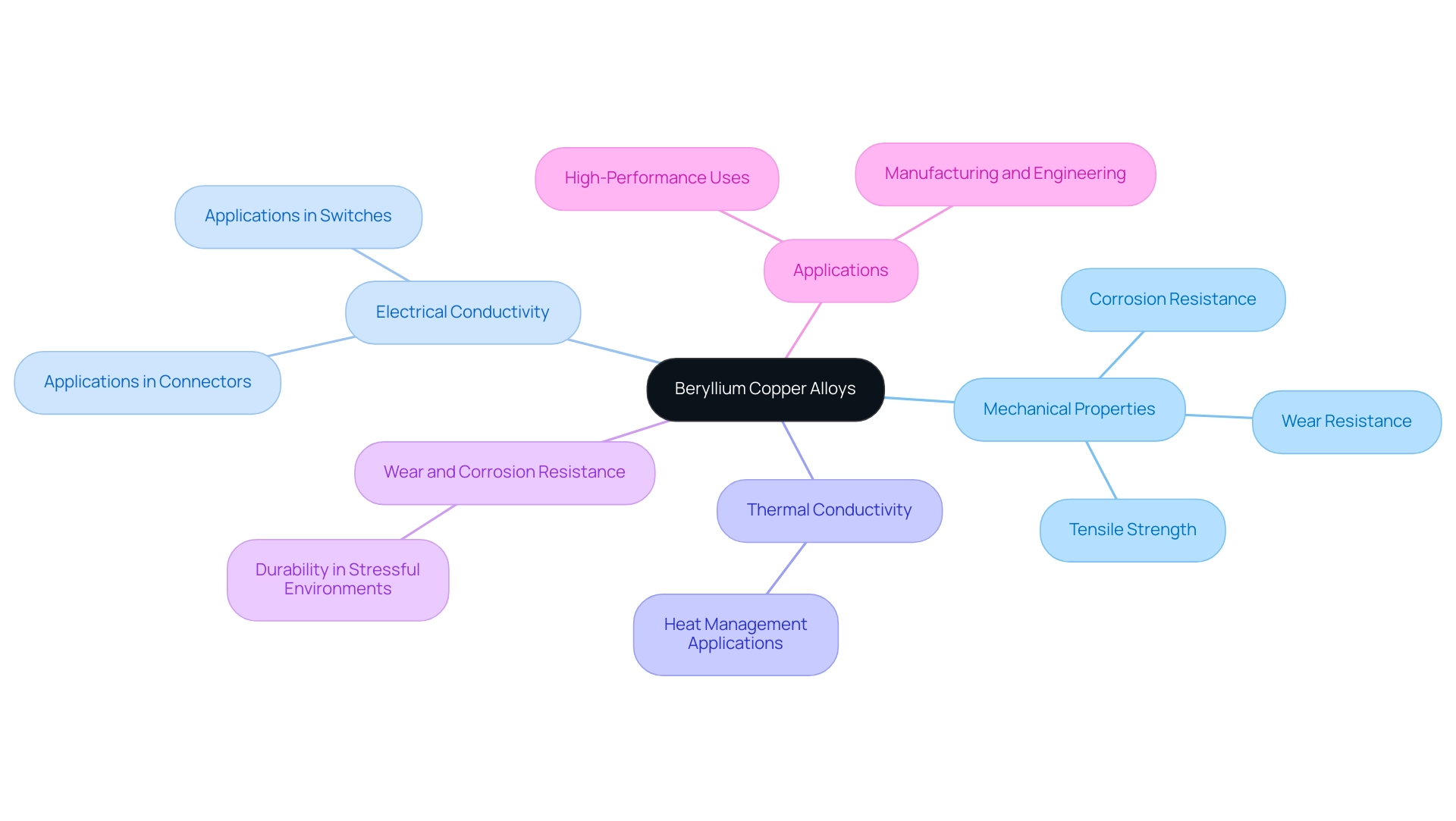

Properties and Characteristics of Beryllium Copper Alloys

The beryllium copper chemical composition of mixtures, especially C17200, is famous for its outstanding mechanical characteristics and is a mainstay in high-performance uses. These mixtures demonstrate tensile strengths that not only meet but often surpass those of many steel grades, showcasing superior performance in demanding environments. At Domadia, we take pride in supplying high-quality Beryllium Copper Plates that leverage this strength, along with excellent wear resistance and corrosion resistance—making them essential in scenarios subjected to constant stress and fatigue.

Furthermore, our Beryllium Copper compositions boast commendable electrical and thermal conductivity, positioning them as a preferred choice for critical electrical uses such as connectors and switches.

Recent advancements in understanding the mechanical properties of these materials have been documented, revealing a robust correlation between processing parameters and the resulting material characteristics. For procurement managers, this insight is crucial for optimizing material selection based on performance criteria. Notably, studies have illustrated strong relationships between specific alloying elements and mechanical performance, reinforcing the strategic importance of the beryllium copper chemical composition in modern manufacturing and engineering.

At Domadia, we are committed to providing customized solutions based on beryllium copper chemical composition that meet the highest standards of quality.

Our expert support ensures that you have the right materials for your project, ultimately contributing to its success. As emphasized by industry specialists, the combination of strength, conductivity, and durability in our Beryllium Copper Plates not only improves product reliability but also prolongs the lifespan of components in electrical use. Don’t just take our word for it—our satisfied customers have praised our products for their performance and reliability.

Experience the difference quality and expertise can make in your next project. Contact us today to learn more about our Beryllium Copper Plates and how we can help take your project to the next level.

Applications of Beryllium Copper in Industry

Beryllium alloy C17200 stands out for its extensive use in the automotive, aerospace, and electronics sectors, where its unique properties deliver significant advantages. In the automotive sector, this metal is especially appreciated for uses such as:

- Electrical contacts

- Connectors

- Springs

This is due to its outstanding electrical conductivity, which reaches up to:

- 23.19% IACS in Cluster 0

- 19.33% IACS in Cluster 1

- 20.80% IACS in Cluster 2

In aerospace, the material is integral to components that demand high durability and thermal stability—examples include landing gear and hydraulic systems.

The non-sparking nature of beryllium copper tools is crucial in explosive environments, ensuring safety during operations. The alloy’s hardness and wear resistance also make it ideal for tooling purposes, ensuring longevity and performance under stress. As K.W. Mlynarski notes in the U.S. Geological Survey Minerals Yearbook, understanding the properties and applications of nonfuel minerals is crucial for effective material evaluation.

Moreover, procurement managers must consider factors influencing the pricing of scrap metal, including:

- Market demand

- Purity

- Current metal prices

These elements are essential for informed decision-making. At Domadia, we are committed to fair and transparent pricing, maintaining strong relationships with suppliers to ensure competitive rates.

Additionally, referencing the case study ‘Market Position Analysis Parameters’ can provide deeper insights into market attractiveness and external factors affecting the industry, aiding procurement managers in their evaluations.

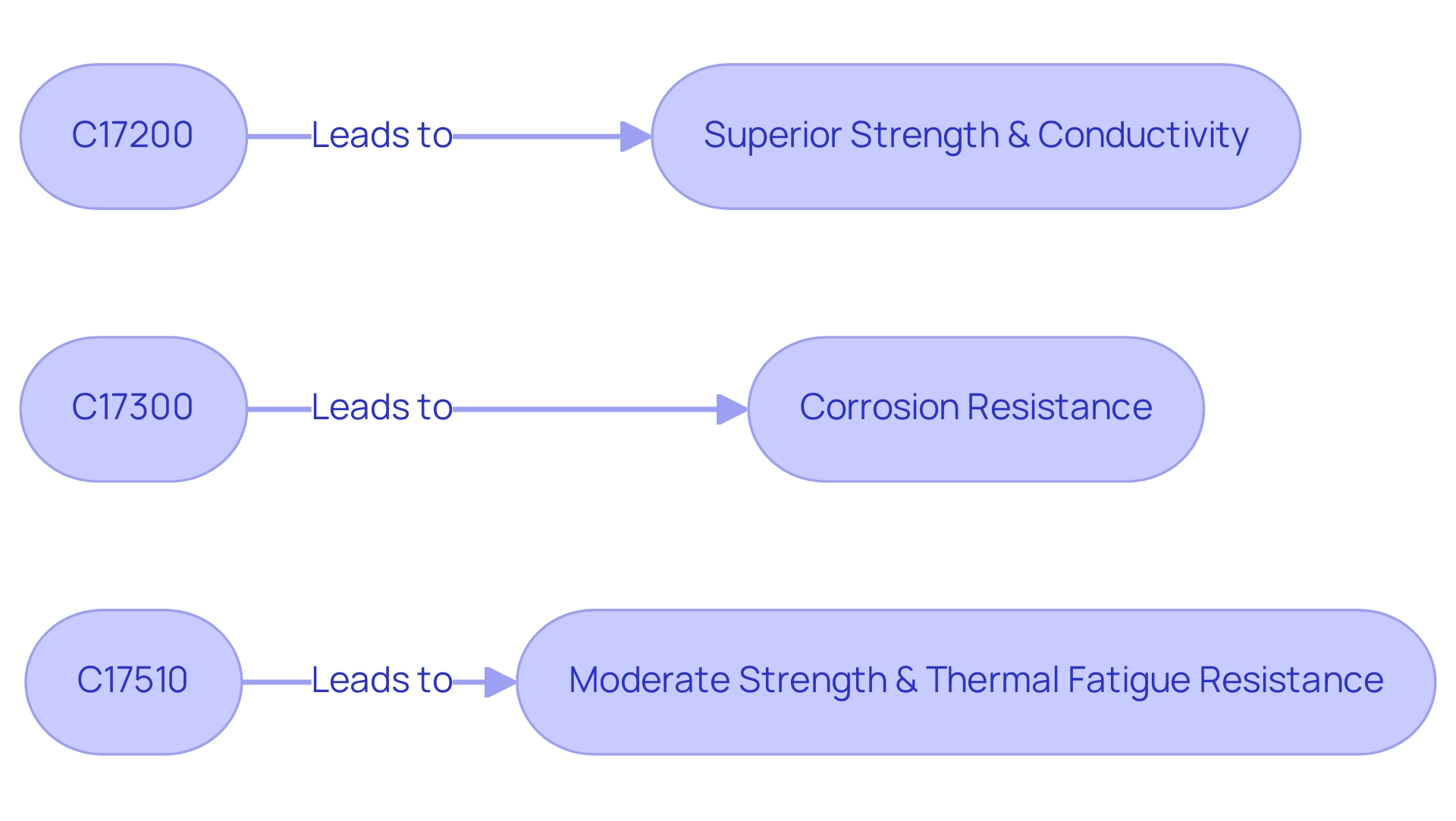

Comparative Analysis of Beryllium Copper Alloys

When evaluating beryllium copper alloys, the beryllium copper chemical composition is pivotal, along with factors such as tensile strength, electrical conductivity, and corrosion resistance. For example, C17200 is often preferred in situations requiring superior strength and conductivity, making it ideal for components like switches and contacts, where performance is critical. Conversely, C17300 is better suited for environments that prioritize corrosion resistance, offering a robust choice for uses exposed to harsh conditions.

The inclusion of other alloying elements can profoundly influence these properties; notably, nickel serves to enhance both the strength and oxidation resistance of the mixture. Moreover, nickel alloys provide considerable benefits in marine settings, including remarkable corrosion resistance and outstanding thermal and electrical conductivity, rendering them more favorable than stainless steel in certain uses. They also possess antimicrobial properties, which are particularly valuable in hygiene-sensitive applications.

Recent studies have indicated that over 60% of this alloy is utilized in elastic components, showcasing the material’s versatility. However, safety measures are essential when working with copper alloy due to the toxic dust and fumes it can produce. As Geof aptly stated, ‘Looks like nasty stuff to me,’ emphasizing the importance of handling this material with care.

Moreover, the C17510 composition, which includes 0.2% to 0.6% of a specific element and 1.4% to 2.2% nickel, is intended for moderate strength and thermal fatigue resistance, rendering it a beneficial option in offshore oil and gas sectors for power and signal cables as well as in welding uses. Comprehending the differences between these materials, including the beryllium copper chemical composition, is crucial for making informed choices in material selection, ensuring the selected substance aligns with the specific needs of the application at hand. The strategic selection of the appropriate alloy can result in considerable enhancements in performance and durability.

For procurement managers, it is also crucial to consider pricing and inventory details when selecting copper strips and non-sparking wrenches to ensure cost-effectiveness and availability for projects.

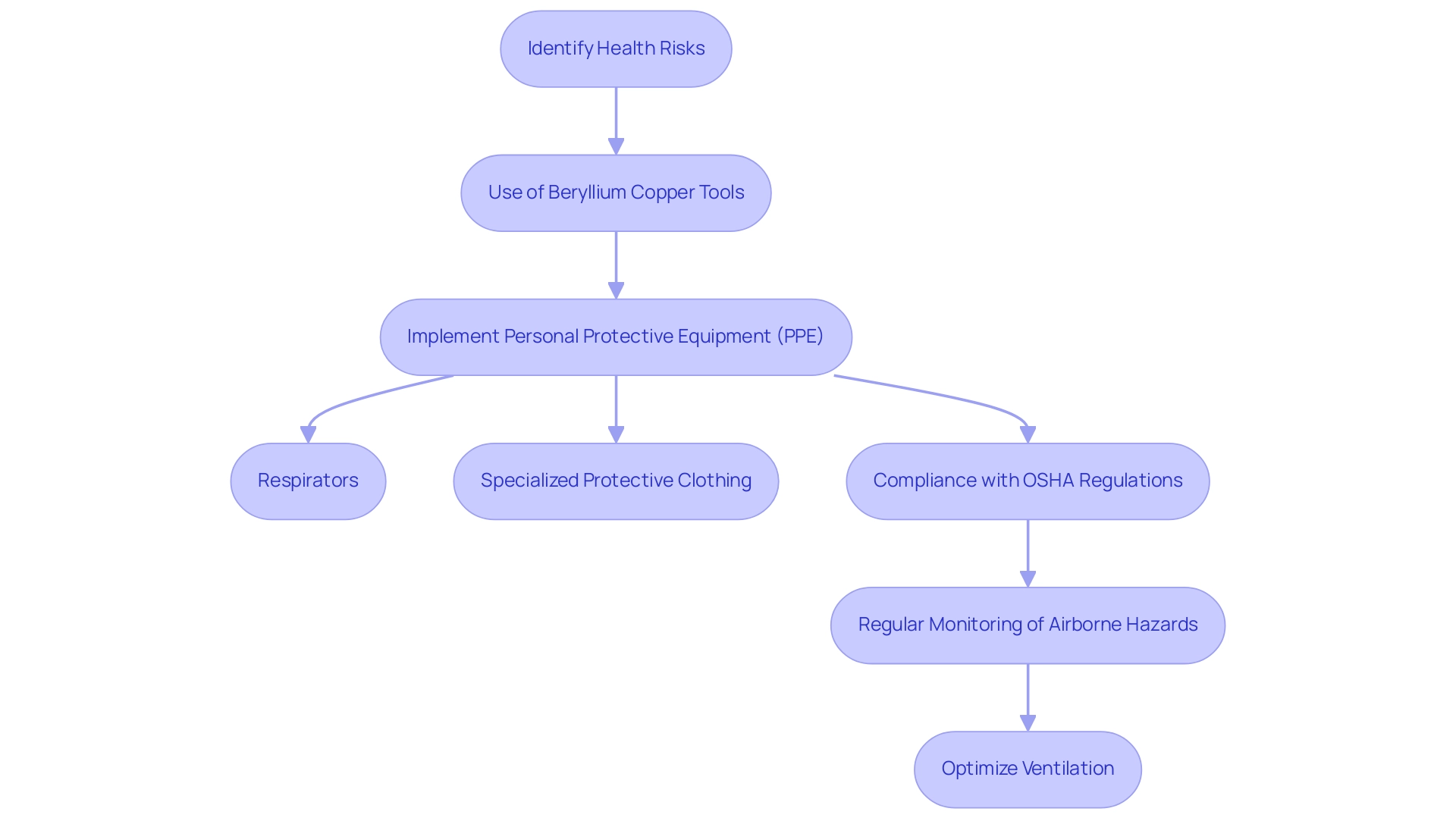

Health and Safety Considerations in Beryllium Copper Use

While Beryllium poses significant health risks, particularly when inhaled as dust or fumes, leading to chronic beryllium disease, the use of tools designed with beryllium copper chemical composition, such as non-sparking wrenches, can mitigate safety concerns in explosive environments. Domadia stands as your trusted partner for Beryllium Copper solutions, offering an extensive product range, including:

- Foils

- Sheets

- Rods

- Wires

All designed according to the beryllium copper chemical composition to meet your specific requirements. Our products are available in ready stock and can be tailored to meet specific needs.

Our non-sparking Beryllium Copper tools are designed with an optimal beryllium copper chemical composition, ensuring they are not only durable and corrosion-resistant but also provide excellent thermal and electrical conductivity, making them ideal for industrial applications where safety is paramount. As emphasized by the National Research Council, managing exposure to this substance necessitates rigorous adherence to personal protective equipment (PPE) protocols, including:

- Respirators

- Specialized protective clothing

Employers must establish safety protocols that include regular monitoring of airborne hazardous material levels and optimizing ventilation in workspaces.

Compliance with OSHA regulations is crucial in mitigating health hazards associated with this material. Furthermore, proactive strategies are essential for preventing exposure and ensuring workplace safety, as the management of chronic beryllium disease often requires long-term treatment. By choosing Domadia, organizations can confidently leverage our expertise and product offerings to foster a safer work environment, ensuring that all safety protocols are followed diligently.

Conclusion

Beryllium copper alloys stand out as a vital resource in modern industrial applications, driven by their unique chemical composition and exceptional mechanical properties. The combination of copper and beryllium not only enhances strength and conductivity but also ensures compliance with stringent safety standards, making these alloys indispensable across sectors such as:

- Automotive

- Aerospace

- Electronics

Understanding the various grades, such as C17200 and C17300, allows procurement managers to make informed decisions tailored to specific application needs, ensuring optimal performance and reliability.

The versatility of beryllium copper alloys extends beyond mechanical properties; they also address critical safety concerns in environments prone to ignition and explosive risks. The integration of advanced manufacturing techniques promises to further enhance their applications, providing innovative solutions that meet evolving industry demands. As the landscape of material selection continues to shift, staying abreast of the latest developments in beryllium copper technology becomes essential for maintaining a competitive edge.

In conclusion, the strategic selection of beryllium copper alloys can significantly impact operational efficiency and product longevity. By prioritizing quality and safety in material procurement, organizations can not only enhance performance but also foster a safer working environment. Leveraging expert insights and comprehensive knowledge of beryllium copper’s properties and applications will empower decision-makers to navigate the complexities of material selection with confidence, ultimately driving success in their industrial ventures.