Blogs

Understanding Invar Thermal Conductivity: A Complete Tutorial for Engineers

Introduction

Invar alloys stand out in the materials landscape for their unique thermal expansion properties, making them indispensable in applications that demand precision and stability. Composed primarily of iron and nickel, Invar exhibits minimal dimensional changes across varying temperatures, a characteristic that is crucial in sectors like aerospace and electronics.

As industries increasingly rely on advanced materials to enhance performance and efficiency, understanding the fundamental properties of Invar and its applications becomes paramount for procurement managers and engineers alike. This article delves into the exceptional qualities of Invar alloys, their comparative advantages over other metals, and the machining techniques that optimize their use in high-stakes environments.

By exploring these insights, professionals can better navigate the complexities of material selection and application in their respective fields.

Fundamental Properties of Invar Alloys

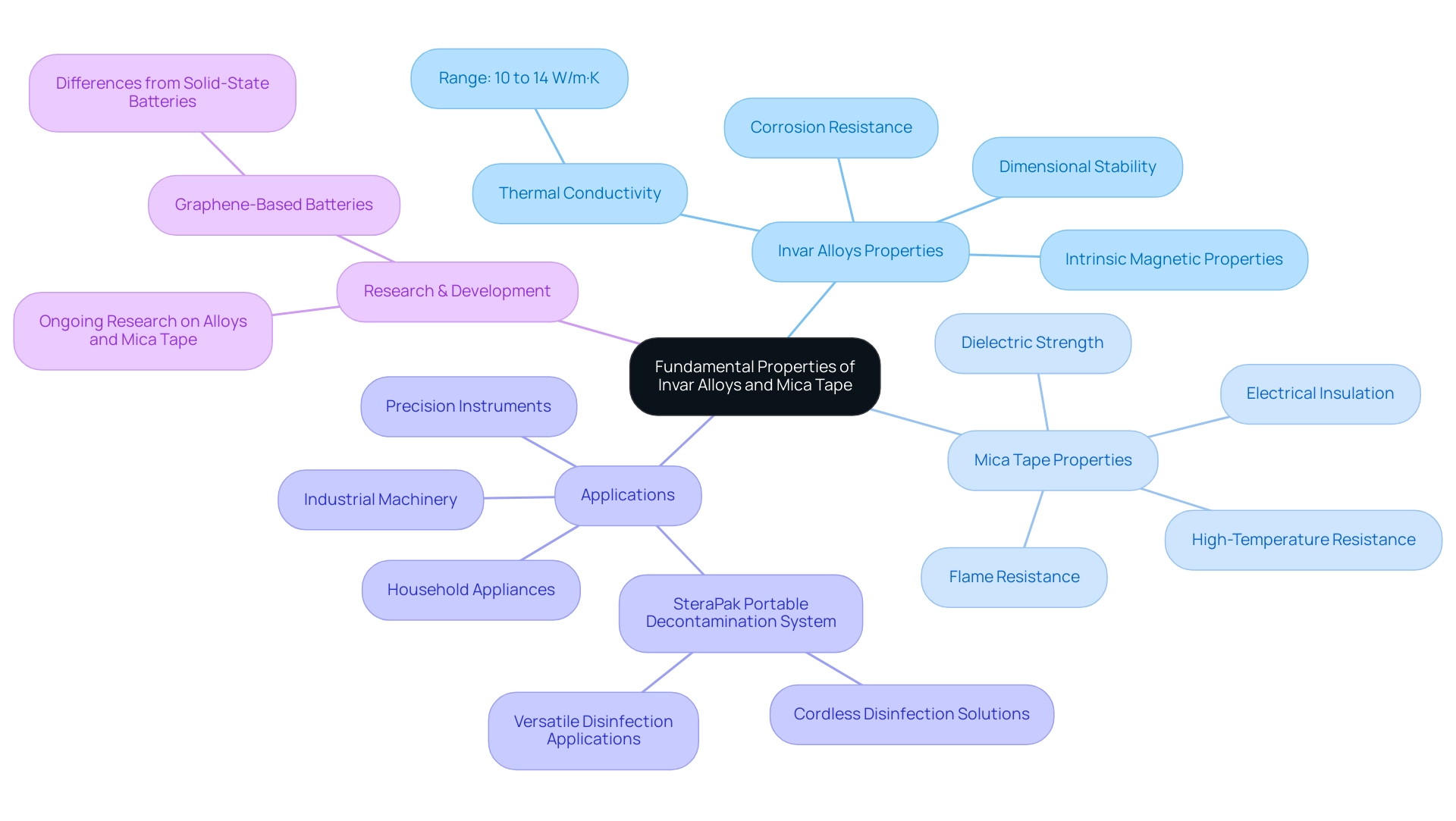

Certain alloys, mainly made up of iron and nickel, display extraordinary expansion characteristics defined by slight dimensional alterations over different temperature ranges. This exceptional stability is primarily due to the alloy’s invar thermal conductivity, which typically falls between 10 to 14 W/m·K. Such properties allow this material to maintain its shape and dimensions effectively, making it an ideal choice for precision instruments and scenarios where invar thermal conductivity is essential for closely regulating thermal expansion.

Along with Mica Tape products, they also offer outstanding high-temperature resistance and electrical insulation, making them appropriate for comparable uses. Mica Tape’s superior insulation properties ensure reliability in various uses, from household appliances to industrial machinery. Furthermore, the versatility of both alloys and Mica Tape products is emphasized in practical applications, such as in the SteraPak portable decontamination system, which advantages from the thermal stability and corrosion resistance of both substances.

Adjustments to speeds and feeds may be necessary based on the nature of the part being worked on, ensuring optimal performance in manufacturing processes. The intrinsic magnetic properties and high corrosion resistance of this material, alongside Mica Tape’s flame resistance and dielectric strength, further enhance their applicability across numerous engineering fields. As mentioned by James A. Monroe, founder and CEO, ‘The ALLVAR team has been working hard in 2023 and is prepared,’ emphasizing ongoing progress in the understanding and application of these resources.

Recent research continues to explore the unique characteristics of both certain alloys and Mica Tape, solidifying their reputation as essential components in high-precision environments. In light of current advancements in materials science, such as the development of graphene-based batteries, procurement managers should remain aware of evolving technologies that may impact their sourcing strategies.

Thermal Conductivity of Invar: Key Insights for Engineers

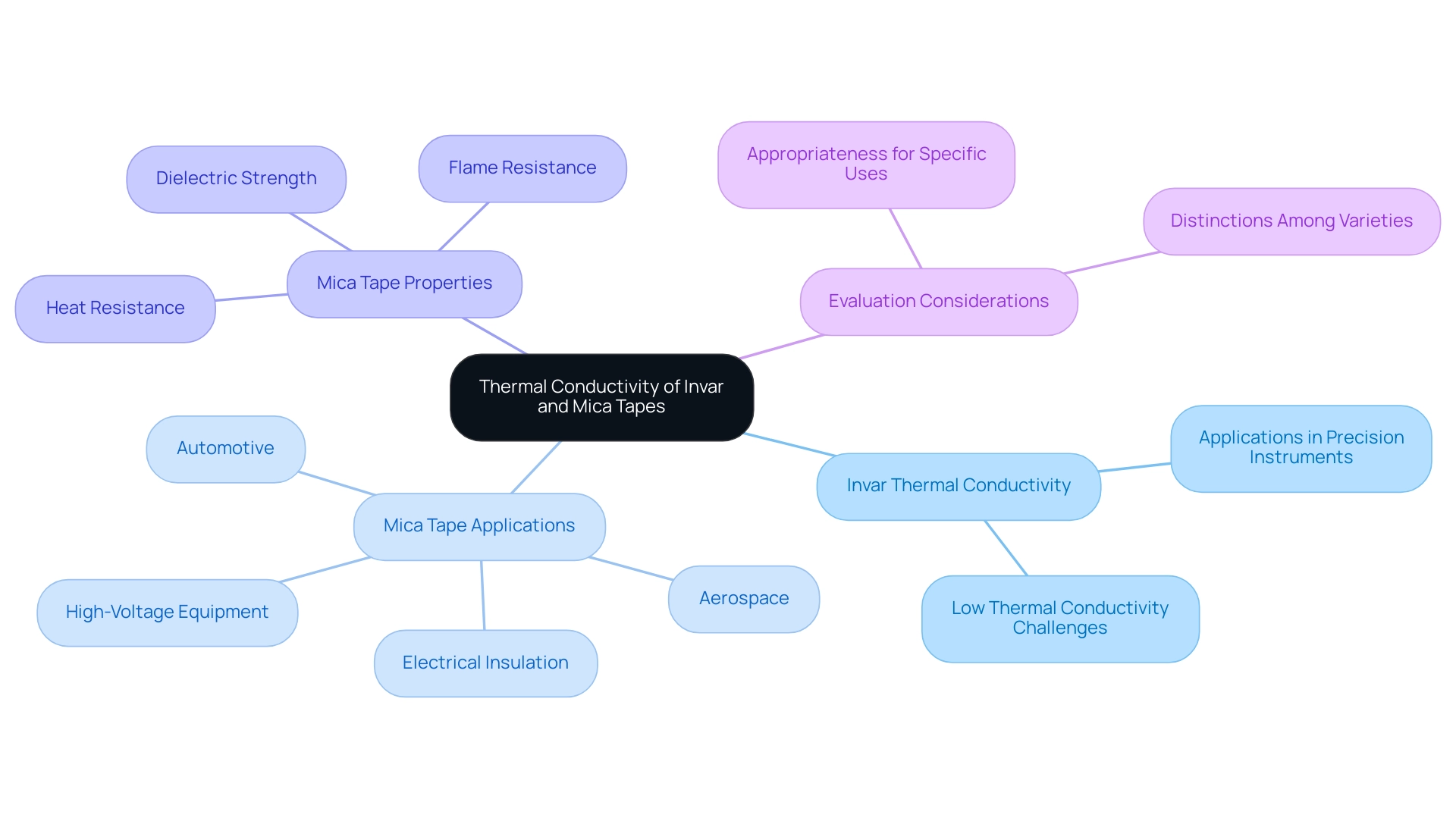

In engineering endeavors, especially in projects needing efficient thermal insulation, invar thermal conductivity, which is significantly lower than that of many traditional metals, acts as a double-edged sword. Domadia provides a range of Mica Tapes crafted specifically for high-temperature resistance and electrical insulation, rendering them perfect for use in aerospace and automotive industries, as well as in high-voltage equipment and fire-resistant cables.

The Mica Insulation Tape provides superior insulation properties, ensuring reliability in critical applications, while the Mica Tape for Electrical offers excellent flame resistance and dielectric strength, essential for safety in electrical systems.

Additionally, the Mica Sheet Tape is robust enough for insulating large flat surfaces, suitable for challenging environments. Their capacity to resist heat flow improves energy efficiency, particularly in settings where maintaining temperature stability is crucial. Engineers frequently utilize Invar in precision measuring instruments; however, the low invar thermal conductivity can pose a challenge in situations requiring rapid heat dissipation.

In contrast, Domadia’s Mica Tapes offer a strong solution for high-temperature electrical insulation requirements, defined by low heat conductivity and high heat resistance. This makes them indispensable in constructing components that require reliable insulation. Evaluating the thermal conductivity of different phase change substances (PCMs) ranging from 0.13 to 5 W/m.K further emphasizes the unique benefits of Mica Tapes in thermal management uses.

Frequent inquiries regarding Mica Tapes involve their appropriateness for particular uses and the distinctions among the varieties available, which procurement managers should evaluate when optimizing their benefits while minimizing possible disadvantages in inappropriate uses.

Applications of Invar in Engineering and Industry

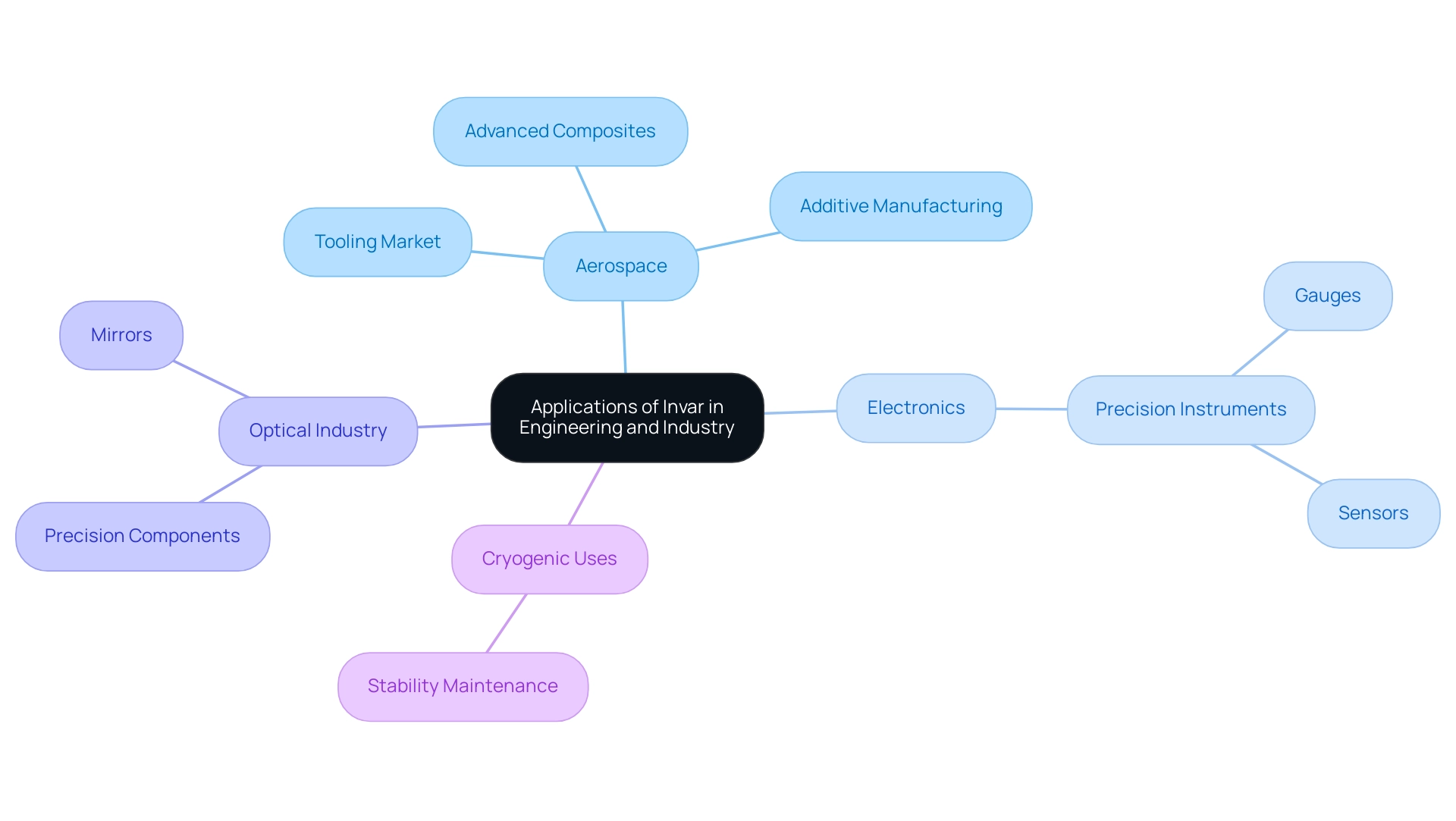

This alloy is a critical material in both the aerospace and electronics sectors, valued for its invar thermal conductivity and exceptional dimensional stability in response to temperature fluctuations. Its applications are particularly notable in precision instruments, including gauges and sensors, which demand high accuracy, reliability, and invar thermal conductivity. In the aerospace sector, the growing use of advanced composites in new aircraft initiatives has rejuvenated the tooling market, enabling precision manufacturing processes that enhance product quality.

This sector, along with others using this alloy, is expected to grow at a notable compound annual growth rate (CAGR), highlighting the substance’s increasing significance in contemporary manufacturing. Furthermore, the invar thermal conductivity of this material contributes to its unique properties, which extend into the optical industry, where it plays a vital role in constructing mirrors and components that require precision shape retention. Recent advancements also emphasize the substance’s effectiveness in cryogenic uses, where maintaining invar thermal conductivity is essential for stability.

As highlighted by Manoj Phagare, Senior Research Analyst at Cognitive Market Research, ‘The increasing acceptance of additive manufacturing technologies is expected to create new opportunities for market growth,’ underlining how these innovations are changing Invar’s uses in aerospace and electronics. Additionally, the ongoing regulatory changes and sustainability trends are influencing the market, prompting companies to seek materials that can reduce their environmental footprint while maintaining high performance. While Mica Tape products are designed for high-temperature resistance and electrical insulation, they do not directly connect to Invar’s distinctive qualities, which include dimensional stability and precision in various uses.

Comparative Analysis: Invar vs. Other Alloys

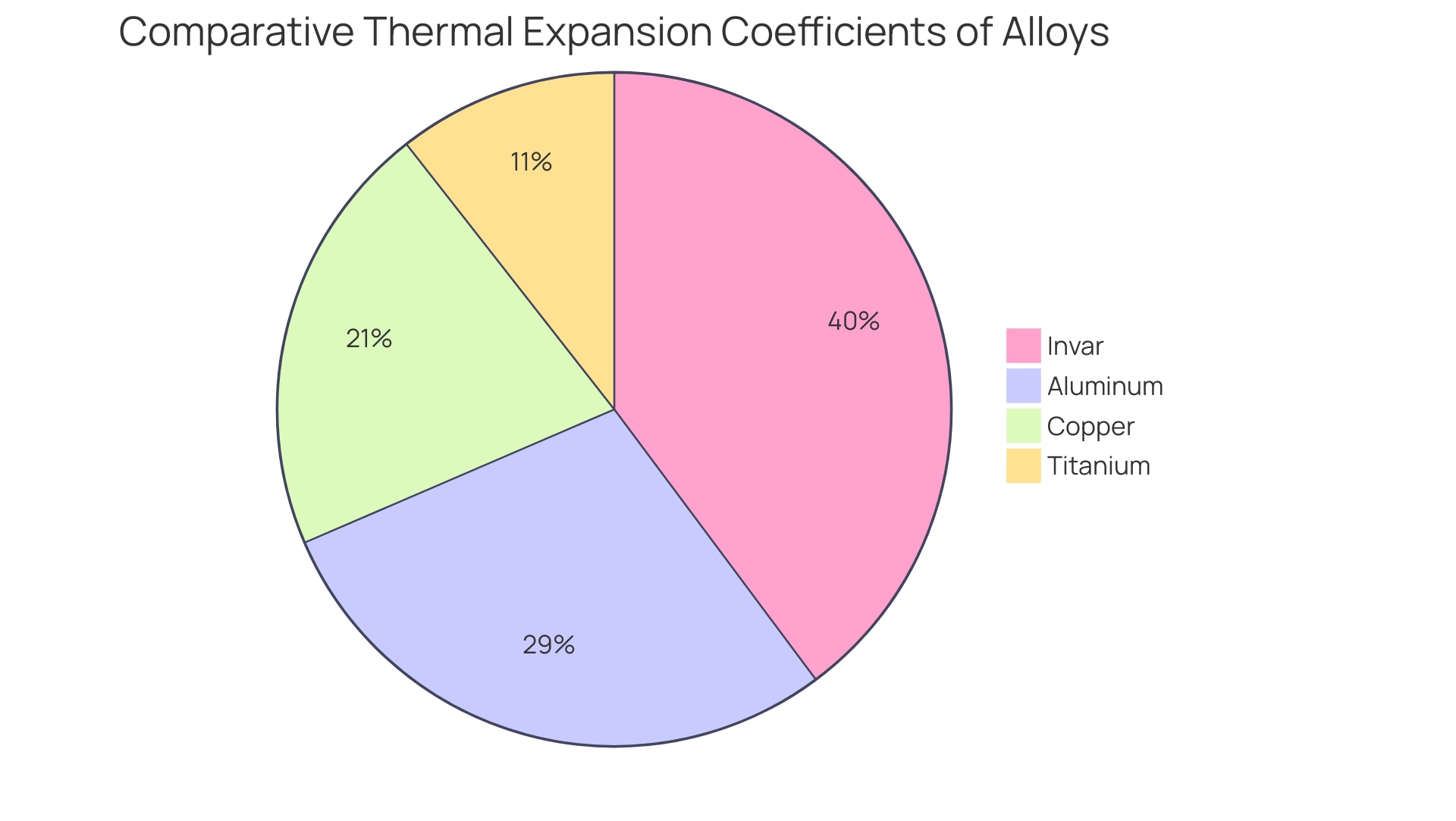

This material, recognized for its outstanding dimensional stability, provides unique benefits in the realm of Non-Sparking Tools, especially in explosive settings. Its low heat expansion coefficient—approximately 3.2 (10 in/(in F))—enables it to maintain precise dimensions, which is crucial for applications where safety and reliability are paramount. Unlike aluminum, which has a heat expansion coefficient of 0.0000231 per degree Celsius and is prized for its lightweight nature, this alloy offers the accuracy needed for critical environments.

Similarly, while copper is renowned for its excellent thermal and electrical conductivity, its higher thermal expansion coefficient of 0.0000168 can lead to dimensional changes that compromise safety. The significance of utilizing substances such as a specific alloy in Non-Sparking Tools cannot be overstated, as they help prevent ignition in environments with explosive potential. Providers and producers of Non-Sparking Tools should take into account the characteristics of a certain alloy when creating tools for these purposes, ensuring that safety standards are upheld without compromising performance.

Comprehending the coefficients of linear expansion in various materials, including those listed from aluminum to titanium, is essential for engineers and procurement managers in choosing suitable materials for particular uses. The case analysis of bimetallic strips further demonstrates how various expansion rates can be beneficial in uses such as thermometers or switches, emphasizing the significance of Ingvar’s characteristics in the field of Non-Sparking Tools.

Machining and Processing Techniques for Invar Alloys

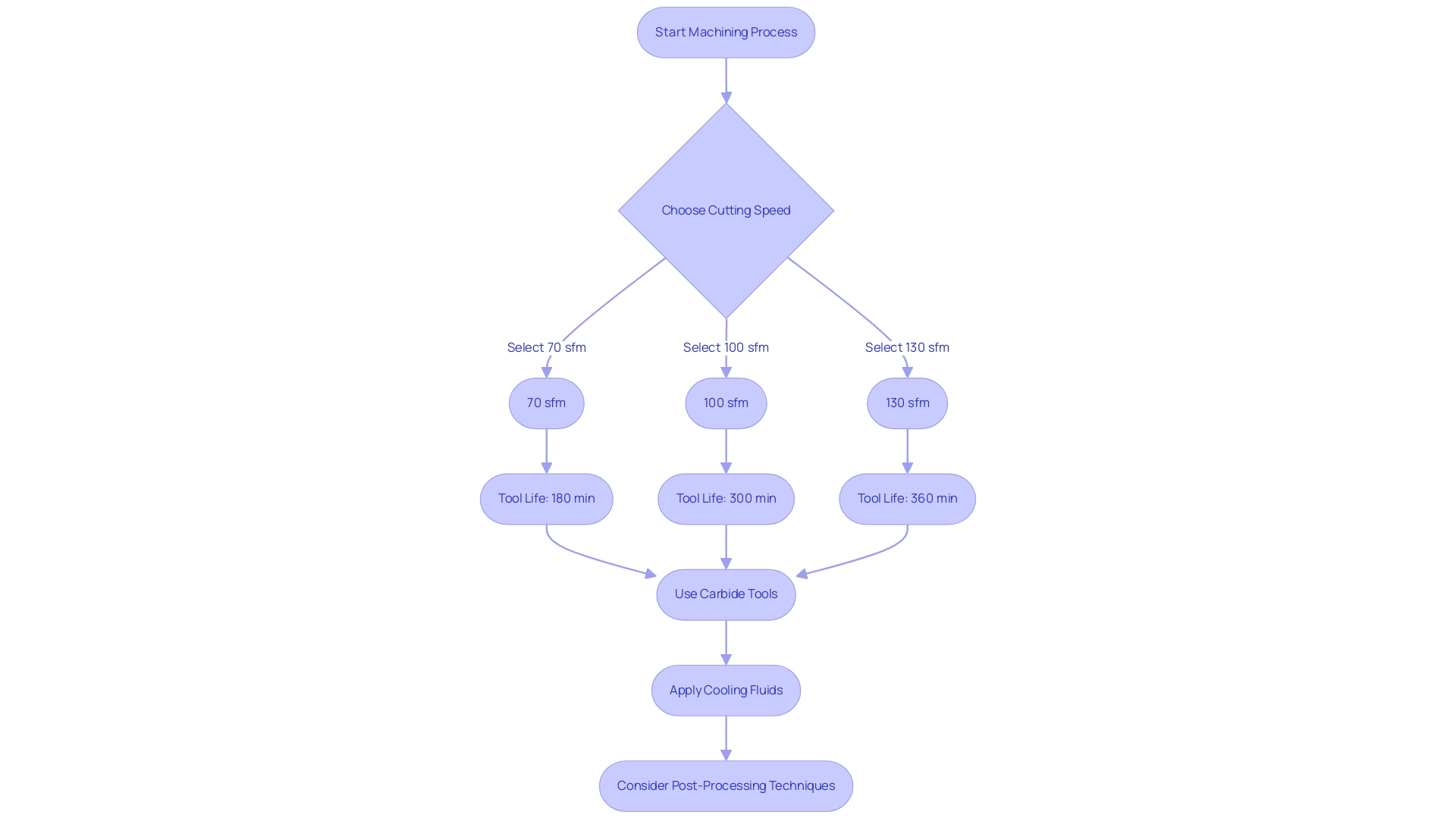

Machining Invar alloys requires a customized method due to their unique expansion characteristics and invar thermal conductivity properties. The utilization of carbide tools is highly recommended, as they offer superior sharpness retention and precision during cutting operations. Cooling fluids play a crucial role in this process, as they help mitigate overheating, which can adversely affect the material’s properties.

For instance, when operating at cutting speeds of 70 sfm, tool life averages around 180 minutes. In contrast, increasing the speed to 100 sfm can extend tool life to nearly 300 minutes, and at 130 sfm, it can reach up to 360 minutes. Therefore, slower cutting speeds are advisable to minimize tool wear while ensuring a smooth finish.

As Mark noted, ‘These laser systems can be really sensitive, alignment wise, with temperature variations,’ highlighting the importance of managing invar thermal conductivity during machining. Additionally, the case study on ‘Milling Alloys’ demonstrates that using carbide inserts and specific cutter types, such as helical or spiral cutters, can lead to improved surface quality and reduced chatter during machining. Furthermore, engineers should be aware of shear band instabilities in metal cutting, as these instabilities can be triggered by shear band nucleation at the tool tip, impacting machining outcomes.

In light of these considerations, exploring post-processing techniques such as annealing can relieve internal stresses and enhance the material’s overall performance. Mastery of these machining techniques will empower engineers to effectively integrate Invar into their designs, ensuring optimal outcomes in their applications.

Conclusion

Invar alloys are undeniably pivotal in numerous high-precision applications, primarily due to their unique thermal expansion properties. Their minimal dimensional changes across varying temperatures make them essential in industries such as aerospace and electronics, where accuracy is non-negotiable. The comparative analysis with other materials highlights Invar’s superiority in environments requiring precision and safety, particularly in the context of Non-Sparking Tools. This characteristic sets Invar apart from alternatives like aluminum and copper, which, while beneficial in other contexts, fall short when dimensional stability is critical.

The exploration of machining techniques further emphasizes the need for a specialized approach when working with Invar. Understanding the intricacies of cutting speeds, tool selection, and cooling methods is vital for optimizing performance and ensuring the longevity of tools. As industries evolve and incorporate advanced materials, the ongoing developments surrounding Invar alloys highlight their sustained relevance in modern manufacturing processes.

Ultimately, the strategic utilization of Invar and its complementary materials, such as Mica Tape, positions procurement managers and engineers to enhance operational efficiency and product quality. By remaining attuned to the properties and applications of Invar, professionals can make informed decisions that not only meet current demands but also anticipate future advancements in material science. Embracing these insights will undoubtedly facilitate the successful integration of Invar alloys into innovative engineering solutions.