Blogs

Understanding Moly Permalloy: A Comprehensive Tutorial on Properties and Uses

Overview

Moly permalloy is a nickel-molybdenum alloy known for its exceptional magnetic properties, corrosion resistance, and thermal stability, making it essential in various industrial applications, particularly in electronics and automotive sectors. The article details its composition, which includes 78% nickel and 16% iron, and emphasizes its effectiveness in magnetic shielding and high-performance components, underlining its critical role in advancing technology and meeting the demands of modern industries.

Introduction

In the realm of advanced materials, Moly Permalloy emerges as a pivotal player, particularly for industries that demand superior magnetic performance and reliability. This specialized nickel-molybdenum alloy, with its unique composition and exceptional properties, is not only critical for traditional applications like transformers and inductors but is also gaining traction in cutting-edge technologies such as electric vehicles and renewable energy systems.

As procurement managers navigate the complexities of sourcing high-performance materials, understanding the fundamental properties, compliance standards, and emerging trends associated with Moly Permalloy becomes essential.

This article delves into the multifaceted aspects of Moly Permalloy, offering insights that empower procurement professionals to make informed decisions in an ever-evolving market landscape.

Fundamental Properties and Composition of Moly Permalloy

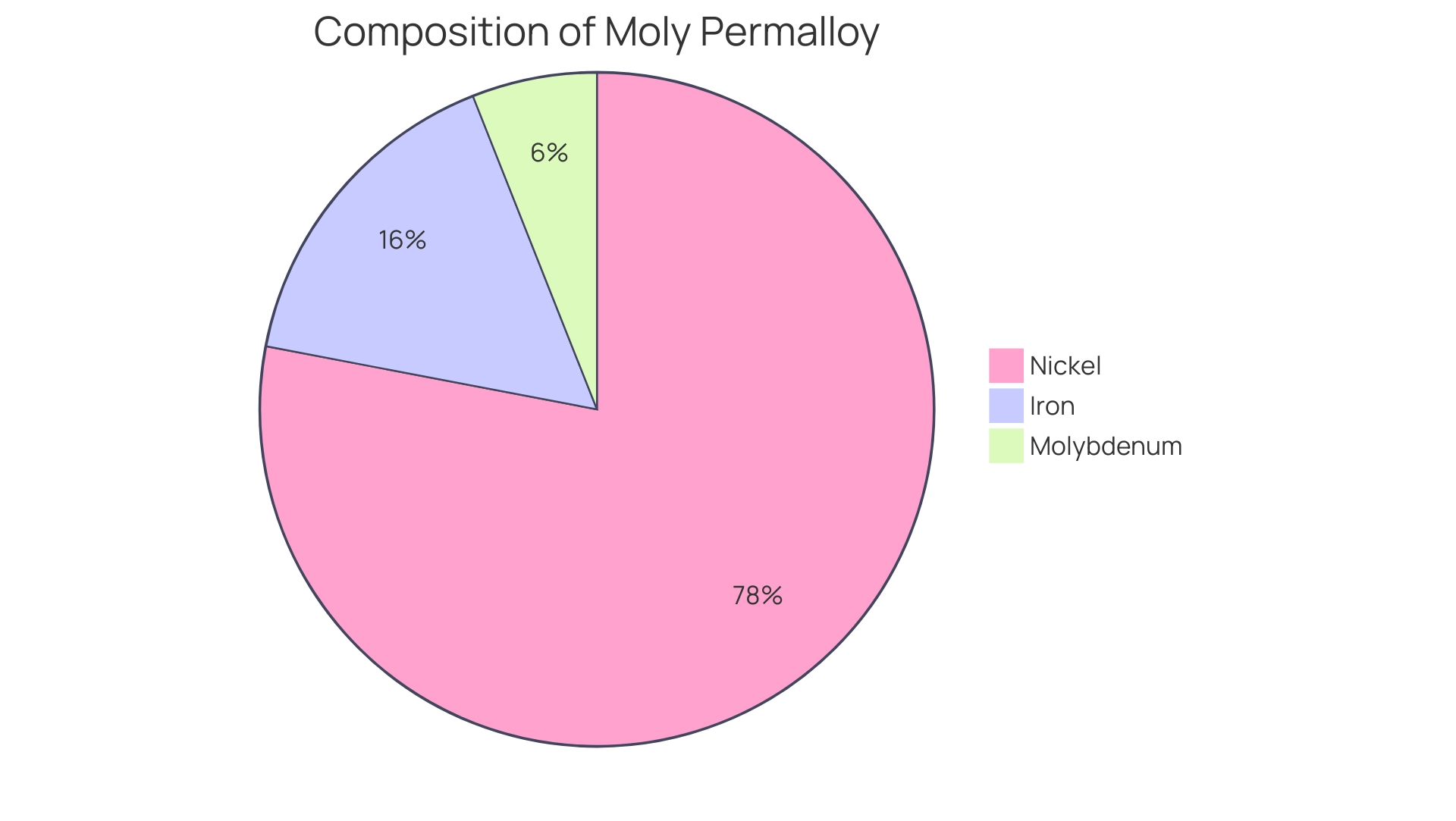

Moly permalloy, known for its outstanding magnetic properties and high permeability, is a specialized nickel-molybdenum mixture that is critical in various industrial applications. The typical composition includes approximately:

- 78% nickel

- 16% iron

- 6% molybdenum

Iron is the balance of the nominal composition, which creates a balance that maximizes performance. This mixture is defined by low coercivity and outstanding saturation magnetization, achieving a peak residual induction of 8,000 gauss, which is vital for uses necessitating effective magnetic performance.

Additionally, it exhibits superior corrosion resistance, further enhancing its suitability for demanding environments, such as those found in electronics and automotive industries. Its thermal stability and resistance to demagnetization at elevated temperatures underscore its utility in these applications. Recent research highlights the material moly permalloy’s ability to maintain performance under stress, which is vital for the reliability of sensitive electronic devices, as evidenced by case studies demonstrating its effective use in magnetic shielding materials.

The alloy is available in vacuum-sealed packaging options, including:

- 100g/bag

- 500g/bag

- 1kg/bag

- 25kg/drum

Customized packaging is available to meet specific procurement needs. With more than 70 years of expertise, DOMADIA Group has positioned itself as a reliable provider of nickel-molybdenum iron compositions and special metals, guaranteeing that procurement managers can rely on high-quality materials for their technology and manufacturing processes. Grasping these characteristics, such as corrosion resistance and packaging alternatives, is essential for procurement managers seeking to enhance material selection, ensuring that this alloy continues to be a favored option in the changing landscape of nickel-molybdenum alloys.

Applications of Moly Permalloy in Modern Technology

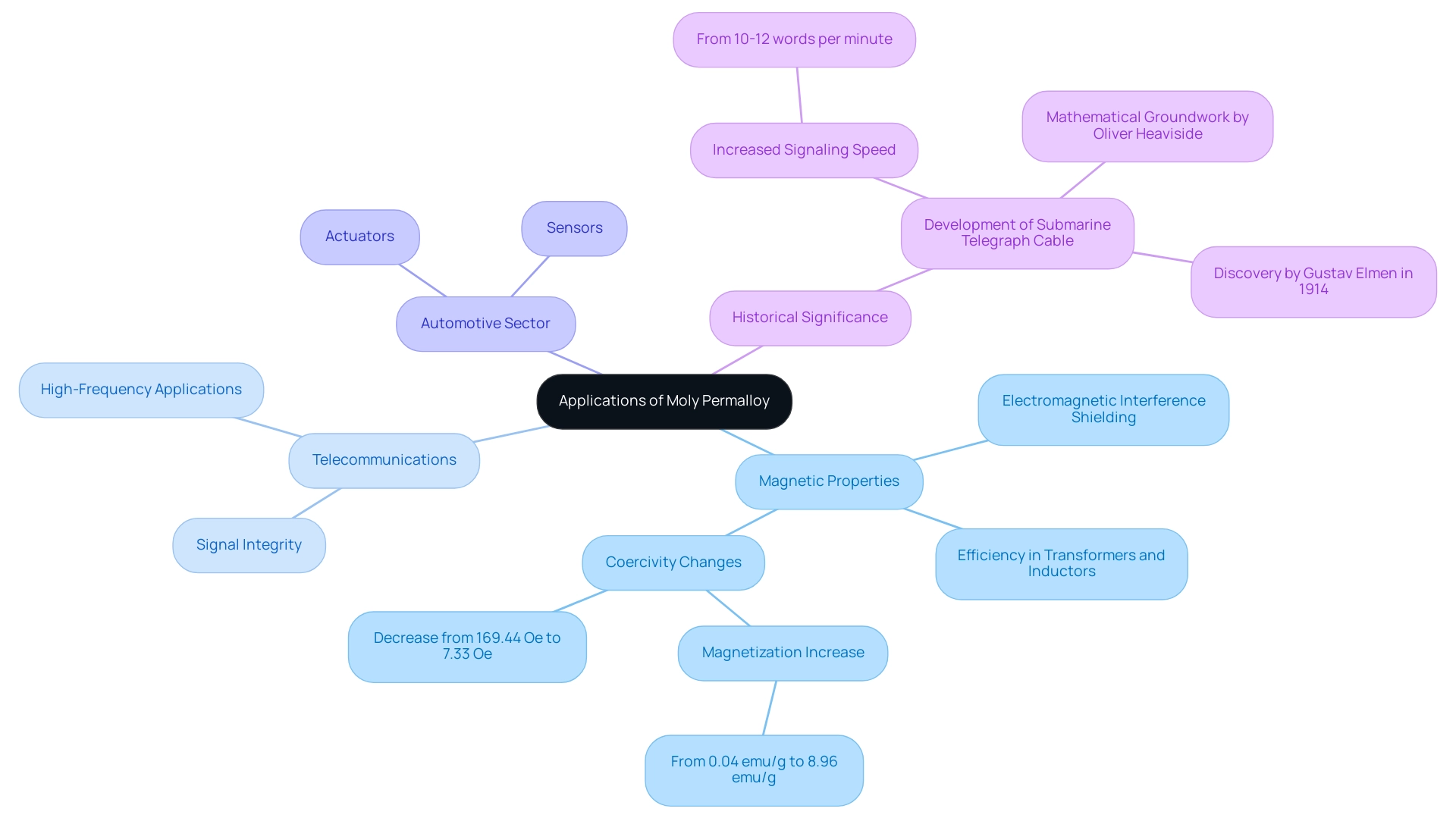

This alloy stands out for its remarkable magnetic properties, making it an essential material in the production of magnetic components like transformers and inductors. Its unique characteristics not only enhance the efficiency of these devices but also ensure optimal performance by shielding sensitive electronic equipment from electromagnetic interference. This capability is essential in preserving signal integrity, especially in high-frequency telecommunications contexts.

Moreover, in the automotive sector, moly permalloy is increasingly utilized in sensors and actuators, where precise magnetic properties are crucial for durability and reliability. Recent studies indicate that the diameter of the 1J85 permalloy wire utilized in these contexts is precisely 1 mm, showcasing its adaptability in modern technology. Ongoing research aims to address challenges and expand the functionalities of Permalloy-based magnetic sensors, indicating a promising future for this material.

Historically, the development of permalloy in submarine telegraph cables significantly improved signaling speeds due to its higher permeability compared to iron. As industry experts note, after the deposition of the moly permalloy layer, the magnetization of the molybdenum matrix increases from 0.04 emu/g to 8.96 emu/g, corresponding to a decrease in coercivity from 169.44 OE to 7.33 OE, illustrating its effectiveness in enhancing performance. Comprehending these varied uses enables procurement managers to strategically align their sourcing methodologies with the evolving demands of contemporary technology.

Quality Standards and Compliance for Moly Permalloy

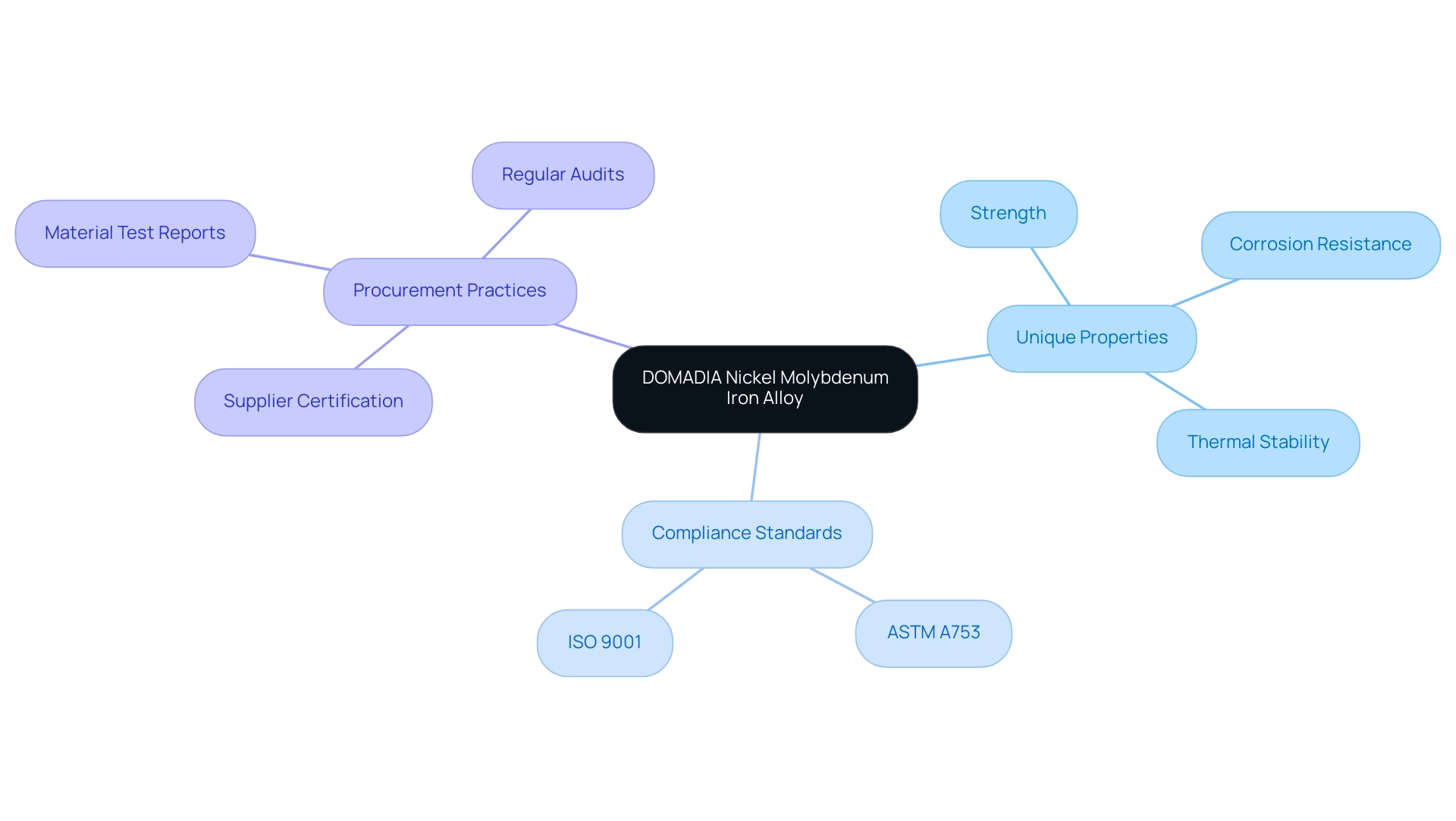

Q1. What makes DOMADIA Nickel Molybdenum Iron Alloy unique?

A1.

The DOMADIA Nickel Molybdenum Iron Alloy is distinguished by its remarkable strength, resistance to corrosion, and thermal stability, providing unparalleled performance across diverse sectors, establishing it as a favored option for essential uses. Moly is subject to rigorous compliance with international standards, notably ASTM A753 and ISO 9001, which define the quality and performance criteria essential for its use. With a maximum residual induction of 8,000 gauss, moly permalloy exhibits significant magnetic properties essential for transformer uses.

In contrast, the DOMADIA Nickel Molybdenum Iron Alloy stands out with exceptional strength, corrosion resistance, and thermal stability, making it a favored option for critical uses. As a procurement manager, it is essential to require that suppliers provide certification of compliance along with detailed material test reports that validate the properties of the metal. Insights from the EFINEA Alloy 79 case study reveal that this nickel-iron-molybdenum material is designed for applications requiring high initial and maximum permeability, with a maximum permeability of 250,000, showcasing its suitability for engineering applications.

Such diligence ensures product quality and significantly mitigates the risk of supply chain disruptions arising from regulatory inconsistencies. Additionally, implementing regular audits and assessments of suppliers not only bolsters compliance but also reinforces quality assurance practices, ensuring that the rigorous testing and inspection standards of the DOMADIA alloy are met. Ultimately, this enhances the reliability of your procurement processes.

It is also essential to remember that agreements are governed by Pennsylvania law, which should be considered in all procurement practices.

Sourcing Strategies for Moly Permalloy

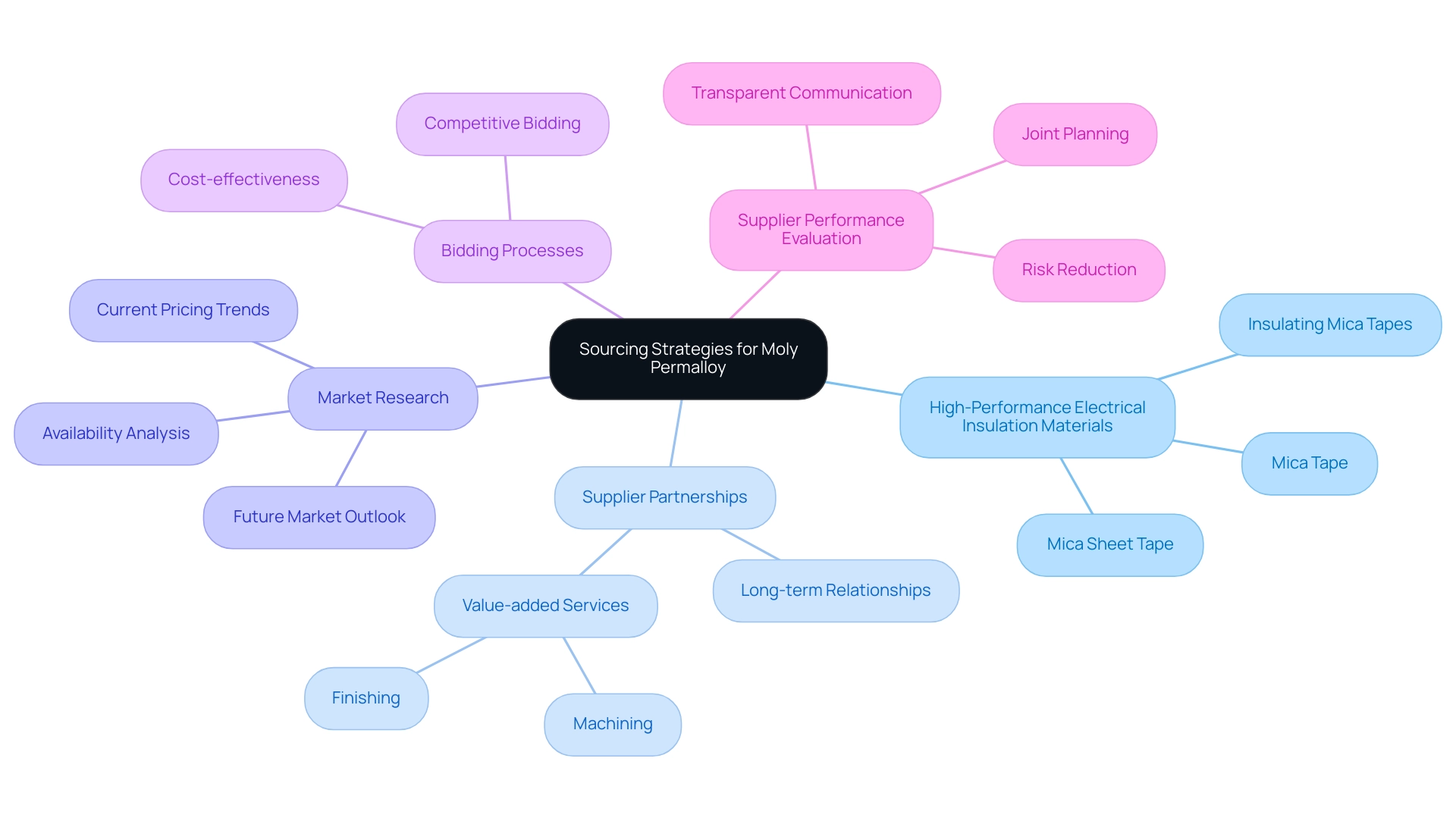

To effectively source moly permalloy, procurement managers must implement a strategic, multi-faceted approach that includes high-performance electrical insulation materials such as:

- Mica Tape

- Mica Sheet Tape

- Insulating Mica Tapes

Establishing long-term partnerships with trusted suppliers who specialize in these materials is essential for ensuring reliability and consistency. Mica Insulation Tape, known for its high-temperature resistance and superior electrical insulation properties, plays a critical role in various applications, from household appliances to industrial machinery.

Notably, Anglo American’s planned investment of over USD 80 million in Peru for better copper and molybdenum recovery underscores the evolving market dynamics and potential impacts on sourcing strategies. Conducting comprehensive market research is crucial to understanding current pricing trends and availability, particularly as the moly permalloy market is projected to evolve significantly by 2028. This evolution presents new opportunities based on regional dynamics and competitor strategies, especially in the Asia-Pacific region, which dominates the Global Moly Permalloy Market.

Utilizing competitive bidding processes not only enhances cost-effectiveness but also upholds stringent quality standards. Furthermore, engaging suppliers who provide value-added services, such as machining or finishing, can streamline the supply chain and significantly reduce lead times. A satisfied client noted, ‘The report is excellent and has a good amount of data,’ reflecting the importance of having reliable information in sourcing strategies for high-performance alloys and insulation materials.

Consistently evaluating supplier performance is crucial; through joint planning and transparent communication, procurement managers can foresee future requirements and efficiently reduce risks, securing a robust sourcing strategy for the company. Additionally, the unique features of Mica Tape products, such as their flame resistance and dielectric strength, make them indispensable in the manufacture of fire-resistant cables and other critical electrical insulation systems, further emphasizing the need for informed sourcing decisions.

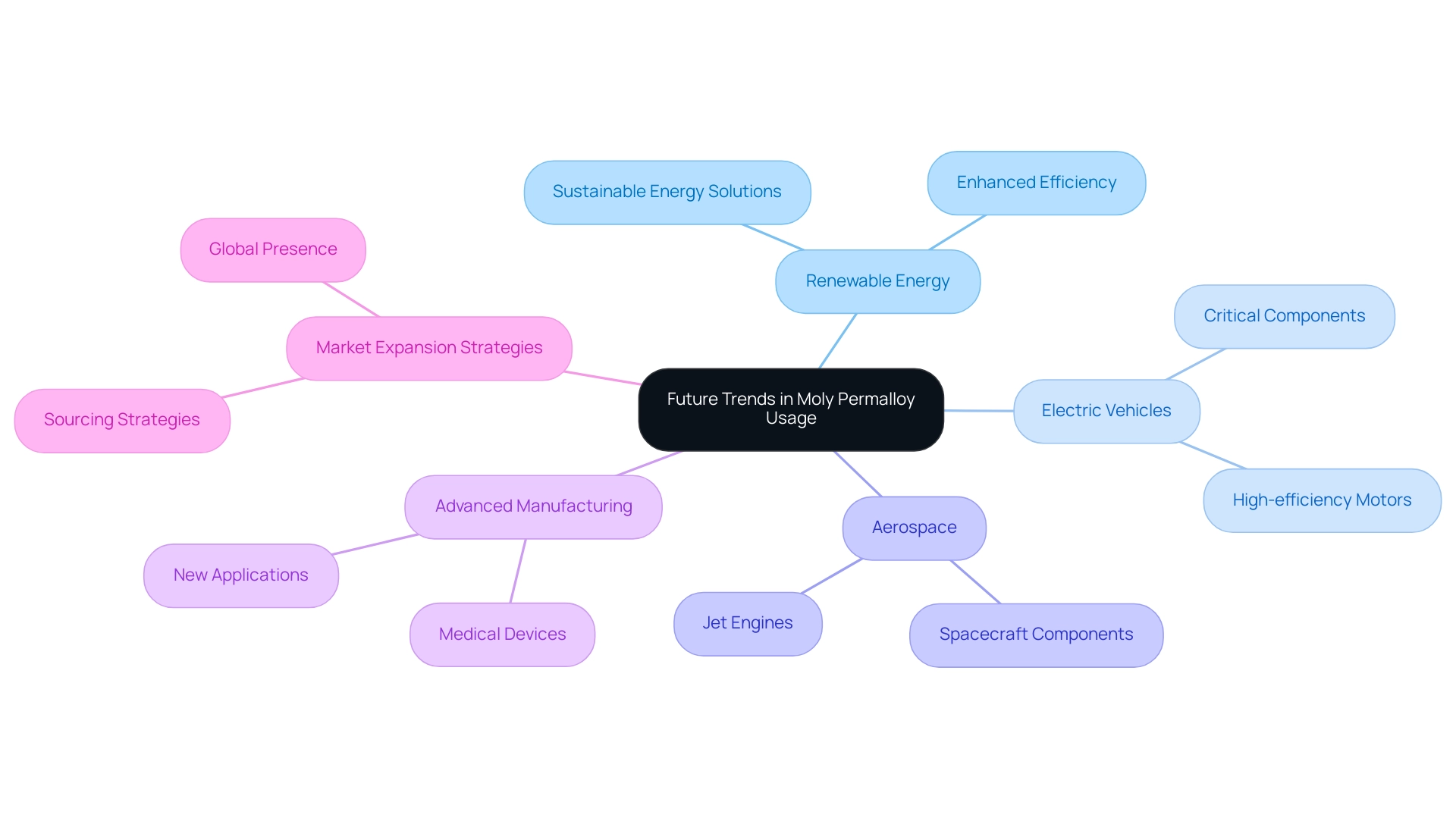

Future Trends in Moly Permalloy Usage

The continuous advancement of technology is expected to greatly boost the demand for Molybdenum Nickel Alloy, particularly in the renewable energy industry and electric cars. Its excellent magnetic properties make it particularly well-suited for high-efficiency motors and other critical components that require superior performance. As the global push towards sustainable energy solutions accelerates, the role of moly permalloy in enhancing the efficiency of electric vehicles becomes increasingly vital.

According to Boeing, molybdenum alloys are used in jet engines and spacecraft components, highlighting its importance in advanced technologies. Furthermore, with identified molybdenum resources standing at 20 million tons, the potential for sustainable sourcing practices becomes even more crucial. Advanced manufacturing processes are paving the way for new uses in sectors such as medical devices and aerospace technology.

Leading manufacturers are focusing on expanding their global presence and market share, as illustrated by the case study on market expansion strategies of molybdenum manufacturers. This highlights the necessity for procurement managers to proactively adjust their sourcing strategies in response to the expected increase in Molybdenum alloy applications. Staying ahead of these developments will ensure they remain competitive in a rapidly evolving market, capitalizing on the growth trajectory of moly permalloy.

Conclusion

Moly Permalloy stands as a cornerstone in advanced materials, demonstrating exceptional magnetic properties that are essential across various industries. Its unique composition, primarily consisting of nickel, iron, and molybdenum, provides outstanding performance in applications ranging from transformers and inductors to the burgeoning fields of electric vehicles and renewable energy. The rigorous compliance with international standards further reinforces its reliability, making it a critical choice for procurement managers who prioritize quality and performance in their sourcing decisions.

Understanding the diverse applications of Moly Permalloy reveals its integral role in modern technology, particularly in shielding sensitive electronic devices and enhancing the functionality of automotive sensors. As industries evolve, the demand for this specialized alloy is expected to grow, driven by advancements in technology and the increasing need for efficient, high-performance components. Strategic sourcing practices, including establishing long-term partnerships with trusted suppliers and embracing competitive bidding, are vital for navigating this dynamic market landscape.

Looking ahead, the future of Moly Permalloy is bright, with increasing demand anticipated in sectors focused on sustainability and innovation. As procurement managers adapt to these trends, staying informed about market developments and emerging applications will be crucial. By leveraging the unique properties of Moly Permalloy, organizations can ensure they are well-equipped to meet the challenges of tomorrow’s technology landscape, securing a competitive edge in an increasingly complex environment.